BERNHARDT design a.k.a. Casegoods User manual

a.k.a. casegoods

instructions

∞≤√

September 2012

a

a.k.a. workwall installation

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

Tools required for assembly of workwalls:

Tape measure

48” to 60” Level

Cordless drill w/ driver & drill bits

Rubber mallet

Wood leveling shims

Laser level

Suggested Fasteners for Workwall Structure connection to the wall:

Toggler® Snaptoggle® or similar high performance anchors — we suggest you use the ¼”– 20 bolt version for added flexibility.

Workwall Installation

Step 1

Identify the highest point of the floor along the intended

mounting wall. The highest point can be found by

projecting a laser level on the wall and measuring the

distance from the floor to the line. The smaller dimension is

the highest point of the floor.

Step 2

Mark stud locations on the intended mounting wall.

Additional anchoring to the studs is required

during installation.

September 2012

Step 3

The Workwall Structure must be installed starting at the

highest point of the floor. Once the side to side location

of the Workwall is determined, place the provided height

spacer block in the corner at the predetermined

highest point of the floor.

Standard Workwall configuration – 7 7/8” / 200mm above the high spot.

Electrical Workwall Configuration – 21 7/8” / 556mm above the high spot.

Step 4

Place the first Workwall Structure piece on the

height spacer block.

Step 5

Using the vertical and horizontal laser guides, align the first

Workwall Structure section. It is very critical that this

first section is mounted level.

Step 6

Once the first section is leveled, temporarily attached

the Workwall Structure section to the wall using drywall

screws. This will temporarily keep the panel in position

for marking the location of the wall anchors.

September 2012

Step 7

Using a ¼” drill bit - drill through the pre-machined holes

on the Workwall Structure into the drywall. This will locate

the locations of the Snaptoggles®.

Note: you will also need to drill new holes through the

Workwall Structure along the line where you have

previously located the wall studs so that you can

connect the panel to the studs with a #8 or #10 screw.

Step 8

Once all the holes have been drilled, remove the temporary

drywall screws and set the first Workwall Structure section

aside. Using a ½” drill bit, open up all the ¼” holes just

drilled into the drywall to ½”.

Step 9

Install 1 Toggler® Snaptoggle® wall anchor into each of

the ½” holes.

Step 10

The first Workwall Structure section can now be attached

to the wall using the ¼”-20 bolts into each of the Toggler®

wall anchors. Be sure to re-level before securing

the panel.

September 2012

Step 11

To install the next Workwall Structure section, simply lift

into place and slip the yellow alignment pins into

corresponding rail of the previous mounted section. Make

sure that the seam between the two sections is tight

without gaps.

Repeat Steps 7-11 for the remaining Workwall Structure

sections.

Step 12

After all Workwall Structure sections have been mounted,

they then must be shimmed to be made flat and true

across all of the mounted panels.

Step 13

Place a level or long straight edge along the front surface

of each of the Workwall rails to show the dips or

protruding areas.

Warning: If the panel assembly is not flat and free of any

dips or bulges there may be issues in securing panels or

hanging components properly.

Step 14

The ¼”– 20 bolts use to attached the Workwall sections

can be loosened and a shim can be added between the

wall and the Workwall section to bring out any low spots.

September 2012

Step 15

It is very important that the Workwall sections are very

straight from side to side. Any contour along the length of

the Workwall rails will make the remaining installation more

difficult.

Step 16

With the Workwall Structure level, flat and mounted

secure, it is time to install the Workwall Panels. The

number of panels will vary depending on the setup. The

bottom edge of the Workwall Panel is marked with a letter

and a number. Always work from left to right, top to

bottom. The letter on the bottom of the panel indicates its

position left to right. The number on the bottom of the

panel indicates its position top to bottom. Letter A will be

the leftmost panel. Number A1 will be the top left panel.

To install the Workwall Panels, simply align between the

proper aluminum rails on the Workwall Structure, and push

in place. There will be a positive engagement between the

Workwall Panels and the Workwall Structure. Continue

the process working left to right, bottom to top until all

panels are installed.

Step 17

Once all of the Workwall Panels are installed we

recommend that any overhead unit is installed next. This

will allow for any lighting wires to be run prior to the

installation of the end caps.

September 2012

Step 18

Workwall mounted items attach to the Workwall by locking

the Workwall rails into a mating extrusion on the mounted

component. Simply lift the mounting item to the desired

attachment rail and rotate upward to a 45° angle. The

mating extrusion should slide into the Workwall rail. Slowly

rotate the mounting item back to level while keeping

pressure toward the Workwall.

Make sure to check that the full length of the mounting

item is engaged into the Workwall Rail.

Step 19

Once the component is hung make sure that the two

extrusions are fully engaged. If there are any dips in the

Workwall Structure it may cause the extrusions to not fully

engage.

This is a critical step – please verify.

Step 20

This step can be done before or after an overhead is

installed.

To install the LED Light Rail, scribe a line 6” back from the

front edge of the shelf or overhead. Space the Light Rail

Mounting Brackets evenly over the entire length of the

Light Rail. Attach the Light Rail Mounts following the

instructions printed on each one.

September 2012

Step 21

Slide the LED Light Rail into place, keeping the front edge

close to the underside of the shelf or overhead. The front

edge of the Light Rail Mount Brackets will catch the LED

Light Rail. Rotate the back edge up toward the underside

of the shelf or overhead and push upward until the

Mounting Brackets click. Pressure is best applied directly

underneath the Mounting Brackets.

Step 22

After the LED Light Rail is mounted, run the low voltage

power line behind the overhead unit and to the closest end

where it can be run down to the floor before the end caps

are installed.

To secure the power line behind the overhead, swing the

overhead out a little so you can loop the line over the

spacers on the back of the overhead.

Step 23

Identify the top Workwall Trim Cap. Place the Trim Cap on

the top of the Workwall Structure and line up the two ends

to the proper positions.

Using a rubber mallet, gently knock the extrusion in place.

The T-slot barb on the Trim Cap will fit into a groove along

the Workwall Structure.

September 2012

Step 24

After the top Trim Cap is installed, the side Trim piece can

be attached next. It is recommended to wait until after all

lighting and wiring is completed to do this. The low voltage

wire from task lights is able to run down the sides of the

Workwall and should be taped in place before attaching

the Trim Caps.

Step 25

Once the top and end caps are installed the remaining

components can be moved into place and the office

completed.

September 2012

a.k.a. glass run-off desk

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

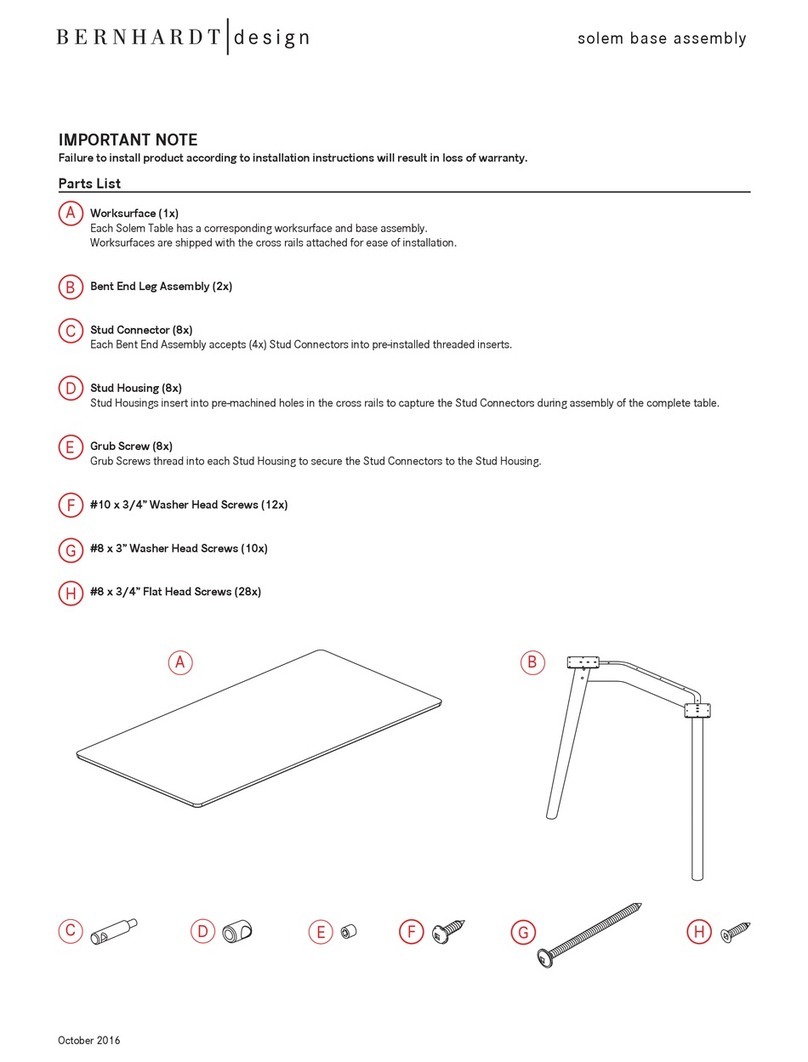

Cartons contain all hardware required for assembly. Machine screws

Glass Run-Off Desk Installation

These illustrations show the assembly

process for installing a glass run-off desk.

Please note that the glass run-off desks

can only be mounted to a workwall

structural rail.

Insert the included aluminum mount

bracket into workwall rail and let it

hang flat.

Press the back edge of the runoff against

the aluminum mount bracket and let it rest

on the horizontal leg.

Align the countersunk holes in the mount

bracket with the tapped holes in the

mount plate.

Thread the provided machine screws into

each hole and tighten.

Be sure runoff is completely secure to

mounting bracket.

Level runoff as needed.

Mount Bracket

And Mount Plate

Leveler

Workwall structure

Wood Deck Panel

Wood Deck Panel

Loop or Panel

End Support

Loop or Panel

End Support

a.k.a. overhead loop support

and tower deck assembly

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

Cartons contain all hardware required for assembly. Drill Fixture Mod-eez® Post Sex Bolts

Deck Assembly Instructions Using a Loop/Panel Support and a Tower

The illustrations here show the assembly

process for connecting a loop or panel

support end and a tower to a wood

deck panel.

Mod-eez® clip installed into the end of the

wood deck panel.

2 Mod-eez® post installed in wood loop

(this could also be a veneer panel end).

Attach loop support to deck panel by

aligning posts in loop with clips in panel

and then sliding loop upwards until the

posts fully engage.

Mod-eez® clip installed into the end of the

wood deck panel.

When posts are fully engaged the top of

the deck panel will align with the top of

the loop support.

Support panel should fit tight and square

to the wood deck panel.

a.k.a. overhead loop support

and tower deck assembly

The illustration here show the machining

necessary for connecting a wood deck

panel to a worksurface tower unit.

Measure from the top back edge of the

tower to locate where the holes are to be

drilled for the Mod-eez® posts.

Using a 5mm drill bit drill two 13mm

( ½” ) deep holes for the Mod-eez® posts

in the specified locations.

Screw the Mod-eez® posts into the

machined holes.

Step 1

Step 2

1

2

Wood Deck Panel

Wood Deck Panel

a.k.a. overhead loop support

and tower deck assembly

\

These illustrations show the final assembly

process of the wood deck panel to a

tower.

If another support end is specified in the

place of the tower shown, just repeat the

procedure from page 1.

In step 1 take the wood deck panel / loop

panel end assembly and lift it up so that it

will engage into the Mod-eez® clips.

Once the assembly is engaged in the clips

then step 2 is to push this assembly down

carfully until the posts and clips are fully

engaged and locked into place.

Mod-eez® clip installed into the end of the

wood deck panel.

Completed bottom assembly

Next step is the installation of the

overhead cabinet.

Front

Back

Bottom view of overhead

cabinet shown here

Back

Front

a.k.a. overhead loop support

and tower deck assembly

These illustrations show the machining of

an overhead cabinet for connection to a

support tower.

To assemble a loop support to the

underside of the overhead you must first

pre-drill and install the Mod-®eez posts.

Use the plastic drill-jig provided.

Using a 5mm drill bit drill two 13mm

( ½” ) deep holes into the underside of the

overhead for the Mod-eez® posts.

Screw the Mod-eez® posts into the

machined holes.

1

2

Front

a.k.a. overhead loop support

and tower deck assembly

This illustration shows the assembly of the

deck structure to the loop or panel end

support.

Stand the bottom assembly with the wood

deck panel and its end upright either on

the floor or on the worksurface where you

can get easy access to the connectors.

Step 1 is to lift the overhead above the

bottom deck assembly and push it slightly

behind the assembly. Rest the overhead

on the loop support with the Mod-eez®

posts aligned in Mod-eez® clips.

Step 2 is to push the loop support back

until the posts lock into the clips and the

front of the overhead aligns with the front

of the support.

If assembling one side of the overhead to

a tower be sure to support that end while

assembling the support to the overhead.

Worksurface tower cabinet shown in the

background. See the next page for your

final step in completing this assembly.

Back of overhead

Overhead cabinet

a.k.a. overhead loop support

and tower deck assembly

The illustrations shown on this page show

the final process of the deck assembly

Align the top and front of the overhead to

the tower. Use clamps to keep the units

together to ensure proper alignment.

Use a 3/8” drill bit to drill through the top

shelf pin hole and through the side panel

on the overhead. Use caution not to blow

out the inside face of the overhead.

Once holes are drilled, insert sex bolts and

tighten while making sure the front and

top edges are aligned and flush.

Remove clamps and assembly is

complete. Lift and move assembly into

place.

Note: It is better to install any lighting

and run the wires through the provided

wireway holes on the wood deck panel

before the assembly is moved back to

the wall.

Completed assembly

September 2012

a.k.a. loop base

upholstered modesty panel

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

Cartons contain all hardware required for assembly. #8 Wood Screws

Loop Run-off Base and Upholstered Modesty Panel Installation

Illustrations are shown with both the wood

loop run-off base as well as the optional

upholstered modesty panel.

Location of upholstered modesty panel

(Optional).

Mount wood loop base to underside of

top with attached brackets. Flush leg to

the outside of the table top.

To install the upholstered modesty panel

locate as per the dimensions shown and

attach to the underside of the top with

included #8 wood screws making sure to

keep the face of the modesty panel

parallel with the edge of the top.

Location of upholstered modesty panel.

Mount wood loop base to underside of

top with attached brackets. Flush leg to

the outside of the table top.

To install the upholstered modesty panel

locate as per the dimensions shown and

attach to the underside of the top with

included #8 wood screws making sure to

keep the face of the modesty panel

parallel with the edge of the top.

Upholstered

Modesty Panel

36” Wood Loop Base

30” Wood Loop Base

Upholstered

Modesty Panel

September 2012

a.k.a. c-base

wood veneer modesty panel

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

Cartons contain all hardware required for assembly.#8 Wood Screws

C-Base and Wood Veneer Modesty Panel Installation

Illustrations are shown with both the

c-base as well as the optional wood

veneer modesty panel.

Location of wood veneer modesty panel

(Optional).

Mount c-base to underside of top through

the top plate of the base. Locate the base

by the dimensions shown.

To install the wood modesty panel align

the face of the wood veneer panel to the

back or user side of the c-base. Locate

the panel so that it runs parallel to the

edge of the top and attach it to the

underside of the top with the attached

angle brackets.

Location of wood veneer modesty panel

(Optional).

Mount c-base to underside of top through

the top plate of the base. Locate the base

by the dimensions shown.

To install the wood modesty panel align

the face of the wood veneer panel to the

back or user side of the c-base. Locate

the panel so that it runs parallel to the

edge of the top and attach it to the

underside of the top with the attached

angle brackets.

Wood Veneered

Modesty Panel

36” C-Base

30” C- Base

User side of base

User side of base

Wood Veneer

Modesty Panel

September 2012

a.k.a. t-base

upholstered modesty panel

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

Cartons contain all hardware required for assembly. #8 Wood Screws

T- Base and Upholstered Modesty Panel Installation

Illustrations are shown with both the t-

base as well as the optional upholstered

modesty panel.

Location of upholstered modesty panel

(Optional).

Mount t-base to underside of top through

the top plate of the base. Locate the base

by the dimensions shown.

To install the upholstered modesty panel

locate as per the dimensions shown and

attach to the underside of the top with

included #8 wood screws making sure to

keep the face of the modesty panel

parallel with the edge of the top.

Level the base as needed.

Location of upholstered modesty panel

(Optional).

Mount wood loop base to underside of

top with attached brackets. Flush leg to

the outside of the table top.

To install the upholstered modesty panel

locate as per the dimensions shown and

attach to the underside of the top with

included #8 wood screws making sure to

keep the face of the modesty panel

parallel with the edge of the top.

Level the base as needed.

Upholstered

Modesty Panel

36” T- Base

30” T- Base

Upholstered

Modesty Panel

September 2012

a.k.a. easel base

upholstered modesty panel

IMPORTANT NOTES

Failure to install product according to installation instruction will result in loss of warranty.

Cartons contain all hardware required for assembly. #8 Wood Screws

Easel Base and Upholstered Modesty Panel Installation

Illustrations are shown with both the easel

run-off base as well as the optional

upholstered modesty panel.

Location of upholstered modesty panel

(Optional).

Mount easel base to underside of top with

attached brackets. Locate by dimensions

shown.

To install the upholstered modesty panel

locate as per the dimensions shown and

attach to the underside of the top with

included #8 wood screws making sure to

keep the face of the modesty panel

parallel with the edge of the top.

Location of upholstered modesty panel.

Mount wood loop base to underside of

top with attached brackets. Flush leg to

the outside of the table top.

To install the upholstered modesty panel

locate as per the dimensions shown and

attach to the underside of the top with

included #8 wood screws making sure to

keep the face of the modesty panel

parallel with the edge of the top.

Upholstered

Modesty Panel

36” Wood Loop Base

30” Wood Loop Base

Upholstered

Modesty Panel

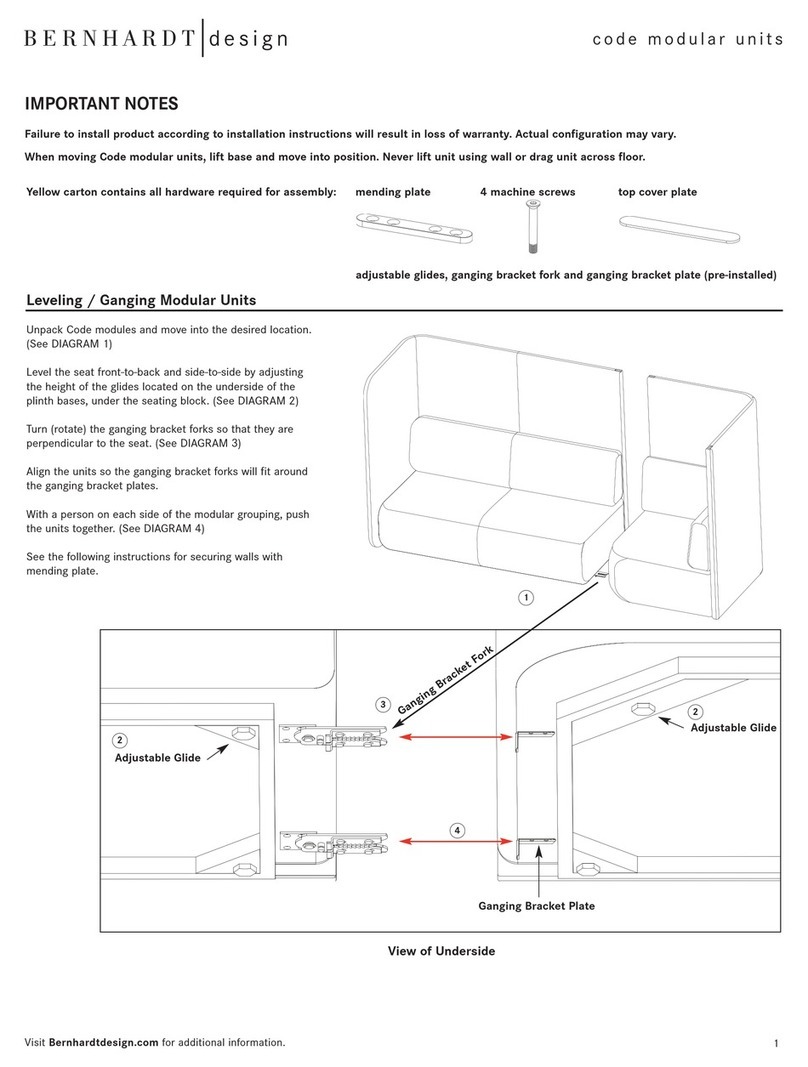

This manual suits for next models

7

Table of contents

Other BERNHARDT design Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Balkene Home

Balkene Home Coconino 61469 instructions

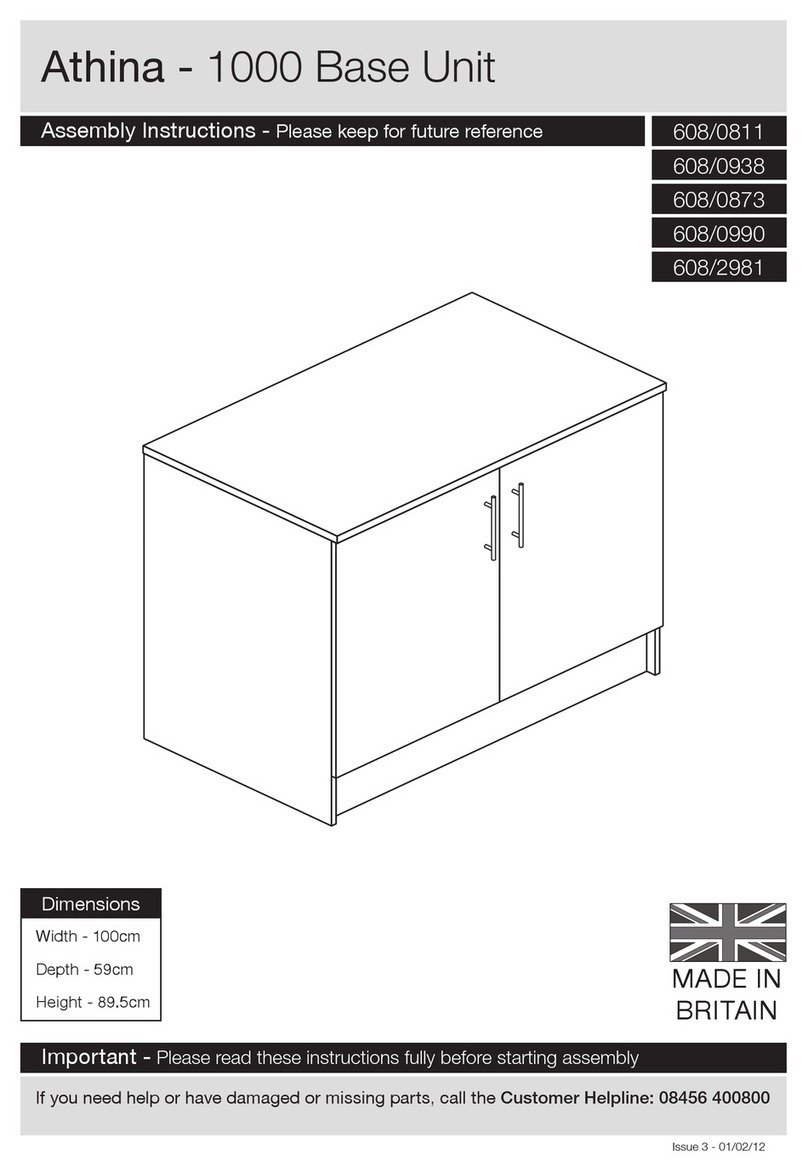

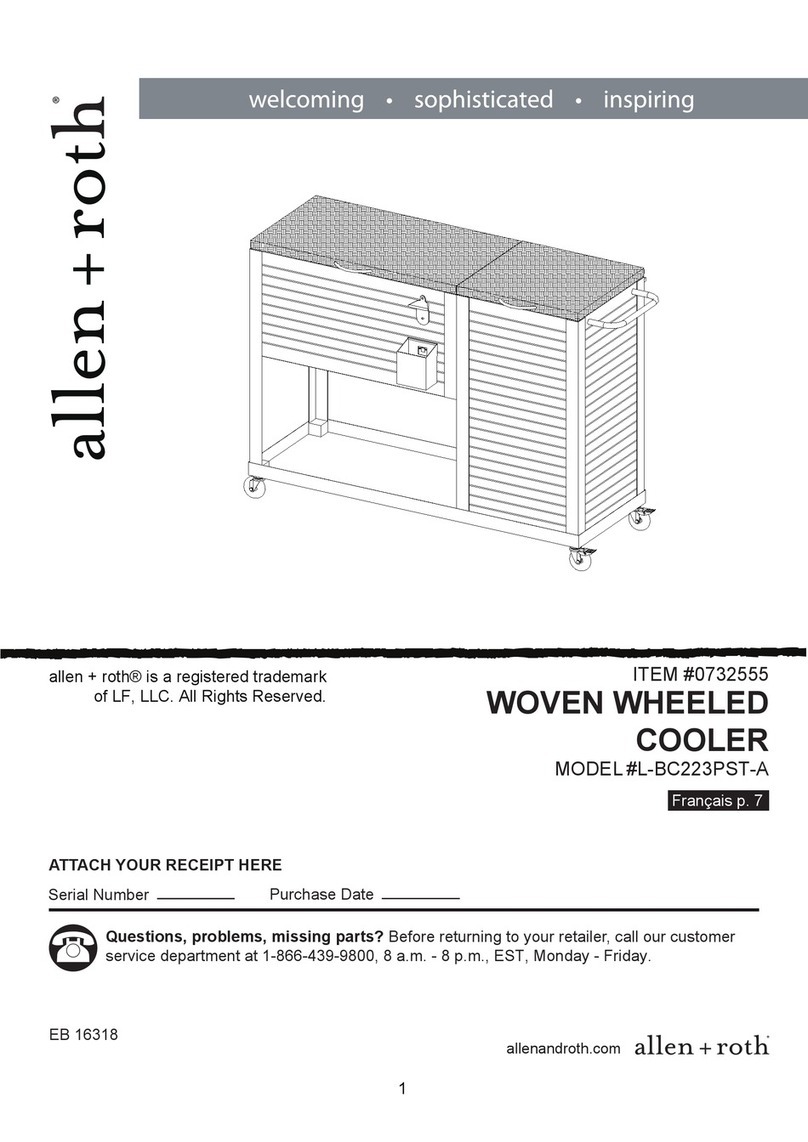

Allen + Roth

Allen + Roth L-BC223PST-A manual

Onespace

Onespace 50-612ES Assembly instructions

Unfinished Furniture of Wilmington

Unfinished Furniture of Wilmington WC-19A Assembly instructions

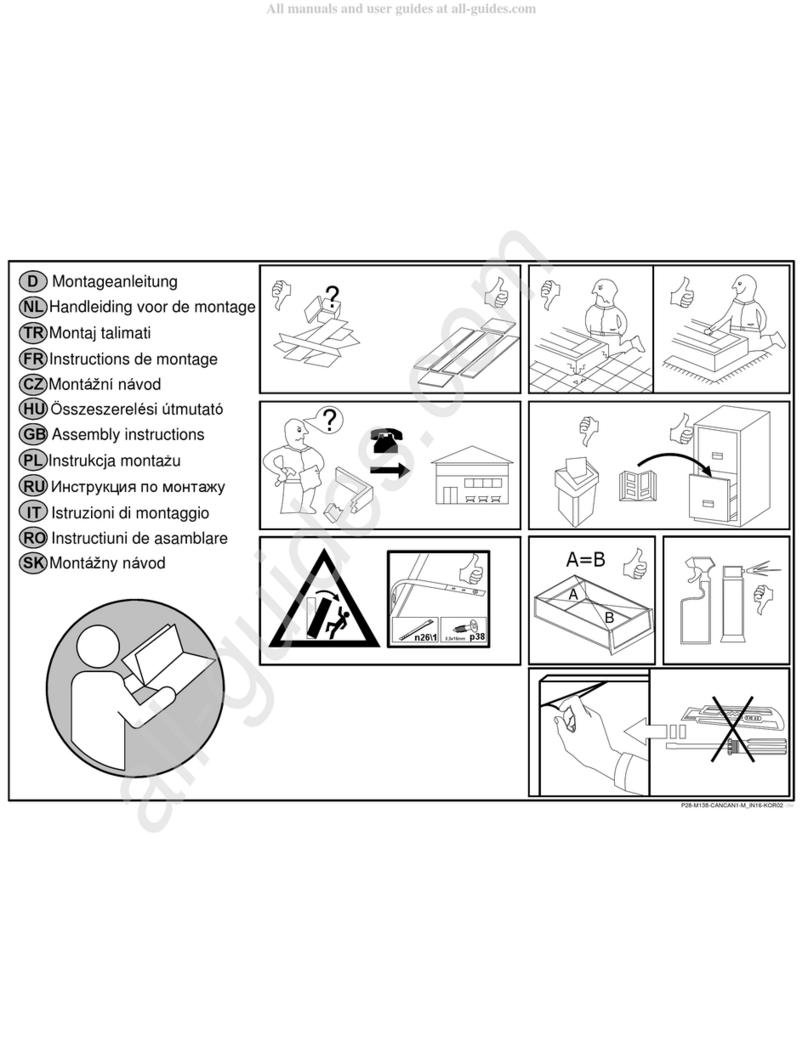

BLACK RED WHITE

BLACK RED WHITE M138-CANCAN 1 Assembly instructions

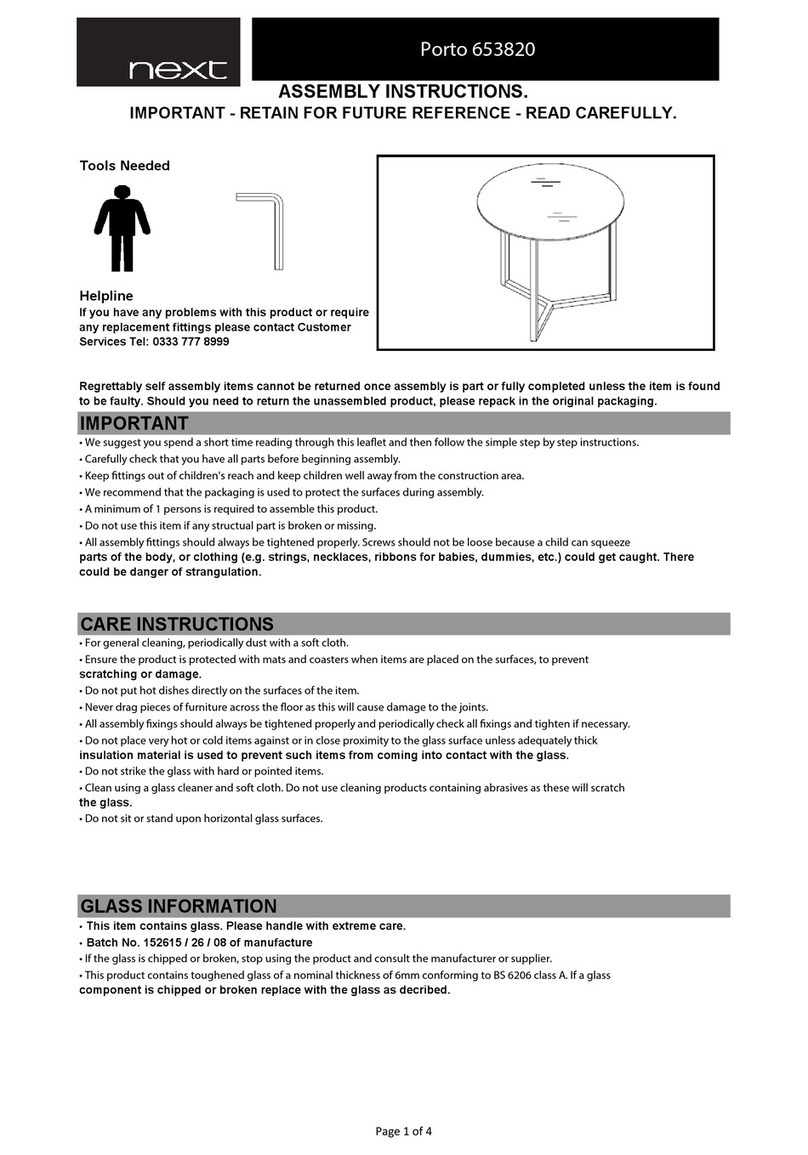

Next

Next 122388 Assembly instructions