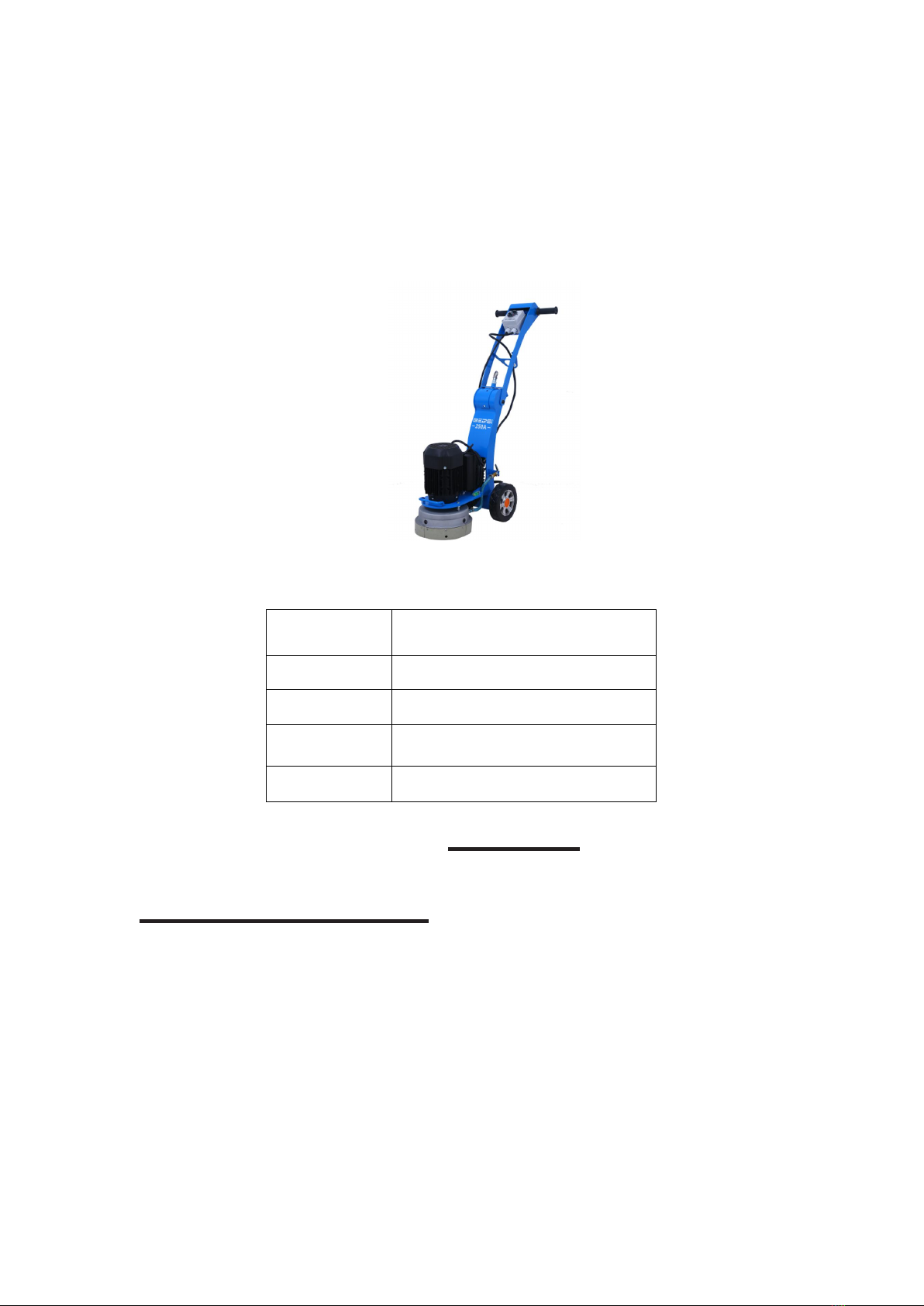

Bersi 250A User manual

www.bersivac.com

Concrete Grinding Machine

250A Operator’s Manual

Electric Model

www.bersivac.com

SAFETY INSTRUCTION

General safety precautions

• Do not use the machine without first reading and

understanding the contents of this Operator’s Manual.

Work area safety

Do not use the machine in bad weather, such as dense fog,

rain, strong wind, intense cold, etc.

Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

The machine should not be used in areas where potential for

fire or explosions exist.

Electrical safety

• Never drag the machine by means of the cord and never

pull out the plug by pulling the cord.

• Keep all cables away of water, oil and sharp edges. Make

sure the cable is not pinched in doors, fences or the like.

It can cause the object to become live.

• Check that the cables are intact and in good condition.Use

cable intended for outdoor use.

• Never use the machine if any cable is damaged, but hand it in

to an authorized service workshop for repair.

• The machine should be connected to an earthed outlet

socket.

• Check that the mains voltage corresponds with that stated on

the rating plate on the machine.

• Be on your guard for electrical shocks. Avoid having body

contact with lightning-conductors/metal in the ground.

• To avoid overheating do not use the extension cord while it is

rolled up.

• Ensure the cord is behind you when you start to use the

machine so that the cord will not be damaged.

Personal safety

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• People and animals can distract you causing you to lose

control of the machine. For this reason, always remain

concentrated and focused on the task.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Never leave the machine unsupervised with the motor

running.

• Make sure that there is always another person close

at hand when you use the machines, so that you can

call for help if an accident should occur.

• Always ensure you have a safe and stable working

position.

www.bersivac.com

Operating Dimension

250A Electric Model

Model

250A

Length

740mm

Width

420mm

Height

850mm

Weight

68kg

Note :All dimensions and weight are all for reference only and subject to change at any

time

HOW TO ORDER REPAIR PARTS

To insure product safety and reliability, always use

replacement parts when making repairs to the equipment.

When ordering parts, please specify the MODEL and SERIAL

NUMBER of the machine as given on the NAMEPLATE. In

addition, give part number, description and quantity as listed

on the parts list.

Please note: Due to improvements and changes in the equipment

the illustrations shown may be different from the actual

Machine.

www.bersivac.com

Operating Instruction

Cup wheels layout

1. 1pc 10inch grinding cup wheel

2. 3pcs 4inch grinding cup wheel

3. 3pcs trapezoid grinding cup wheel

Connect the vacuum cleaner

2’’ vacuum port is reserved to connect the vacuum cleaner. Pay attention to dust during

operation.

www.bersivac.com

Level and water cooling

Adjustable

Removable shroud for edge grinding

Transport

The machine can be folded to minimize space needed for transport.

Carefully fold the machine forward. Put padding between

the motor and the electric box to prevent damage to the machine

www.bersivac.com

Start and Stopping

Perform Pre-Start Check

Visually inspect the equipment for wear or damage

Be sure all guards are in place and functional properly,Do not operate unless all guards are in

place and secure

Perform all daily maintenance

Inspect accessories -Be sure the correct accessory is install properly on the machine,mounting

arrangement and its intended use

Inspect work area to determine the presence and location of deck inserts,pipes,columns and

objects producing from the slab surface so that they may be avoided during the grinding

operation.

Plug power supply to the grinder

MAINTENANCE

Faults and trouble shooting

The machine will not run

• Check the power supply and the power cables and

make sure that they are not damaged.

• Check that the emergency stop button is not pressed

by turning it clockwise.

Machine is hard to hold onto

• Not enough diamonds under the machine (if grinding

thick glue or soft floors, too few diamonds under the

Machine will greatly increase the load on grinder and

operator).Usually also accompanied by high current draw by

motor.increase number of diamonds under machine to

reduce load on grinder and operator.

Machine is jumping around

• Rubber shock absorber pads in grinding unit may be

worn out or damaged. Check and change if necessary.

• Diamonds may not be fitted correctly or have different

heights. Check to ensure all diamonds are fitted

Correctly and are the same height.

The machine stops after just a while

• The machine is overloaded and the overload

protection has been released. Reduce load. The

machine will reboot after about a minute when the

motor has cooled off.

The machine stops during start-up

• The electric motor has been overloaded or a phase is

missing. Allow the machine one or two minus to reset

and try again. When this does not help, contact an

authorized service workshop.

Cleaning

A Always pull out the plug from the outlet socket before

cleaning, maintenance or assembly.

Always clean all the equipment at the end of the working

da day

Do not use a high pressure washer to clean the machine.

In order for the machine to always be cooled sufficiently

the cooling air openings must be kept clear and clean.

Rubber shock absorber pads

Check the rubber shock absorbing pads every month.

Replace if necessary.

www.bersivac.com

Electrical Feed

Check that the cord and extension cord are intact and in

good condition.Never use the machine if the cord is

damaged, hand it in to an authorized service workshop for

repair.

Service

Table of contents

Popular Floor Machine manuals by other brands

MasterCraft

MasterCraft MTHC16EHR-3450 Safety, operation & maintenance manual

Bartell Global

Bartell Global CONTEC ALPHA Owner's manual and parts book

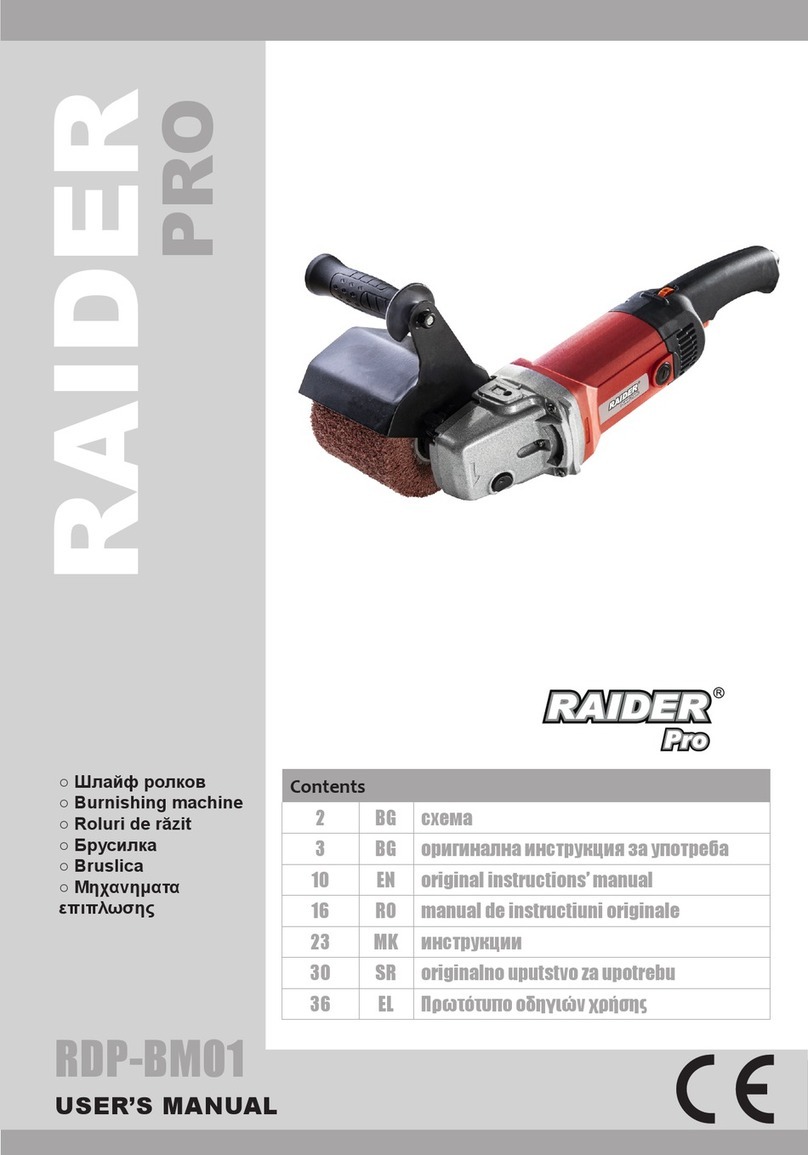

Raider

Raider RDP-BM01 user manual

Nilfisk-Advance

Nilfisk-Advance BR 755 Instructions for use

GÜDE

GÜDE GKM 100 Translation of the original instructions

COMAC

COMAC CM1500 S Use and maintenance manual