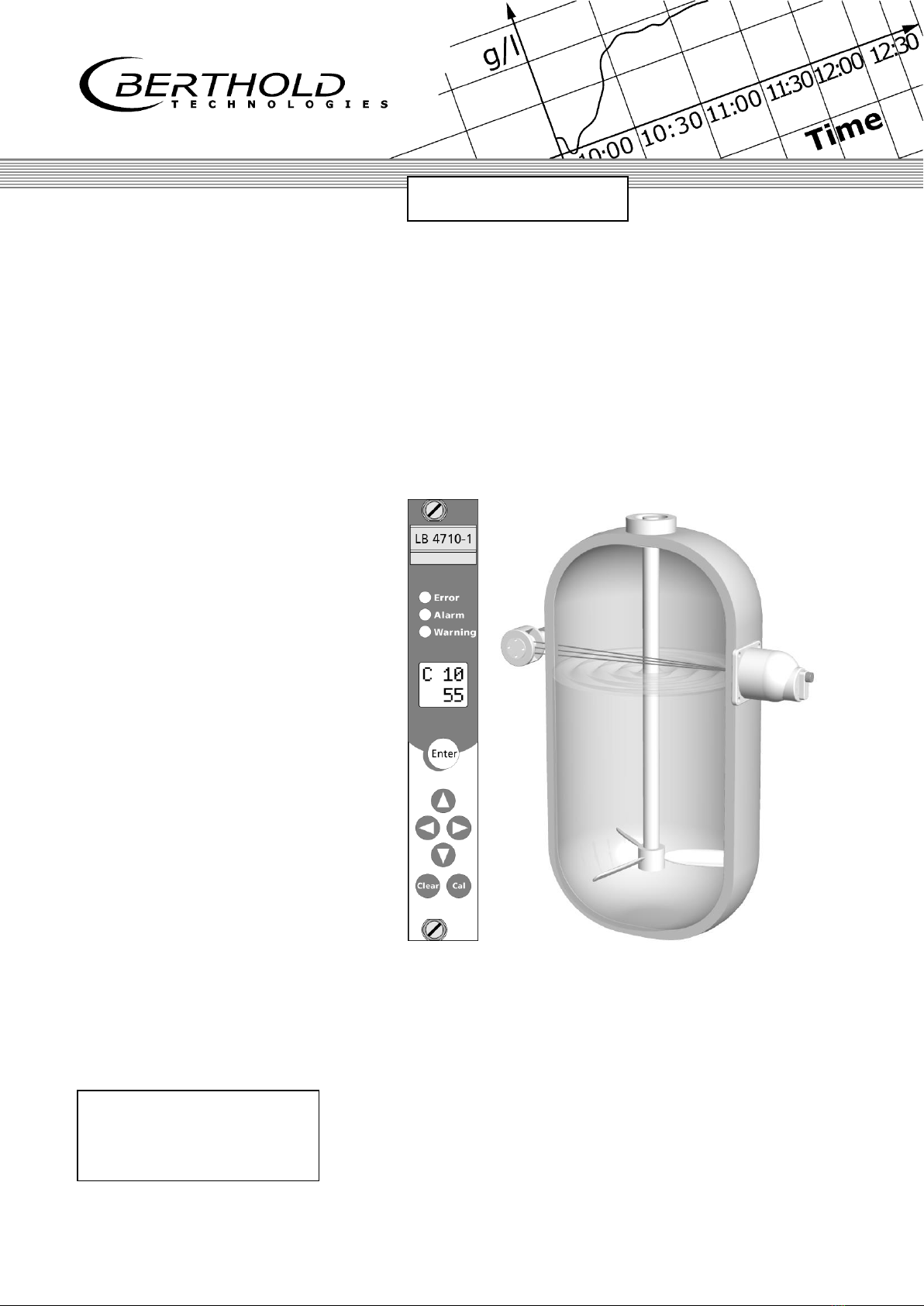

BERTHOLD TECHNOLOGIES LB4710-050 User manual

Process Control

Limit Switch

Mini-Switch LB 471

Hardware Manual

ID No. 39505 BA2

Rev. No.: 03 17. Nov. 2015

Soft. Version: 1.12 or higher

detect and identify

User’s Guide

The units supplied should not be repaired by anyone other than Berthold Service en-

gineers or technicians by Berthold.

In case of operation trouble, please address to our central service department.

The complete user’s guide consists of two manuals, the hardware de-

scription and the software description.

The hardware manual comprises:

mechanical components

assembly

electrical installation

radiation protection guidelines

technical data

electrical and mechanical drawings

The software manual comprises:

operation of the evaluation unit

parameter description

basic setting

calibration

error messages

The present manual is the hardware description.

Subject to change in the course of further technical development.

Table of Contents

Mini-Switch LB 471

5

Table of Contents

Page

Chapter 1. General Information 9

1.1 Use and Function 9

1.2 Target Group 9

1.3 Radiation Protection Courses 10

1.4 Definitions 10

1.5 Safekeeping of the User’s Guide 12

Chapter 2. Safety 13

2.1 Safety Concept 13

2.2 Symbols and Pictograms 13

2.3 Radiological Safety Officer 14

2.4 Duty of Notification 14

2.5 Radiation Protection Areas 15

2.5.1 Exclusion Areas 15

2.5.2 Controlled Areas 15

2.5.3 Monitoring Areas 16

2.6 Safety Installations 17

2.6.1 Source Shieldings 17

2.7 General Safety Instructions 19

2.8 Emergency Instructions 19

2.8.1 Theft Protection 20

Chapter 3. Functional Safety 21

3.1 Use and Function 21

3.2 Safety Function 22

3.3 Safety Requirement 22

3.4 Project Planning 22

3.5 Getting Started 24

3.6 Behavior during Operation and Malfunctions 28

3.7 Recurrent Performance Test 29

3.8 Safety-Technical Data 29

Chapter 4. Instrument Description 36

4.1 Function 36

4.2 Mini Switch LB 471 Versions 37

4.2.1 Type Code 39

4.3 Detectors 40

4.3.1 GM Detector 40

4.3.2 NaI Detector 41

4.3.3 Super-Sens Detector 43

Chapter 5. Installation 45

5.1 Transport to the Installation Site 45

5.1.1 Transporting Detector and Evaluation Unit 45

5.1.2 Transport Shielding with Source 45

Table of Contents

Mini-Switch LB 471

6

5.1.3 Temporary Storage of Sources 46

5.1.4 Installation Site 46

5.1.5 Unpacking and Cleaning System Parts 46

5.2 Installing the Detector 47

5.2.1 Fastening Clamps for GM Detectors and NaI Counters 48

5.2.2 Stainless Steel Detector Holder (Alternative) 48

5.2.3 Installation of the GM Detector 49

5.2.4 Installation of the GM Detector 51

5.2.5 Installation of Super-Sens with Axial Irradiation 54

5.2.6 Installation of Super-Sens with Radial Irradiation 56

Chapter 6. Water Cooling 59

6.1 Subsequent Installation of Water Cooling (Option) 61

6.1.1 Water Cooling for NaI Detector with Collimator 62

6.1.2 Water Cooling for NaI Detector with Collimator 64

6.1.3 Water Cooling for GM Detector 65

6.2 Amount of Cooling Water Required 66

Chapter 7. Shielding Installation 67

7.1 General Installation Instructions 67

7.2 Installation Proposal for Shielding 68

7.3 Pneumatic Shielding Shutter (Option) 70

Chapter 8. Electrical Installation 71

8.1 Connecting Evaluation Unit and Detector 72

8.1.1 Pin Assignment of Terminal Block 73

8.1.2 Installing NaI Detector or Super-Sens 74

8.1.3 Installing the GM Detector 75

8.2 Digital In-/Outputs 77

8.2.1 Relays 77

8.2.2 Digital Input 77

8.3 Connecting the Evaluation Unit to Power 78

Chapter 9. Maintenance 79

9.1 Malfunctions 79

9.2 Replacing Fuses 79

9.3 Replacing the Evaluation Unit 80

9.4 Repairing the Detector 80

9.4.1 Dismantling the NaI Detector 81

9.4.2 Checking the Crystal-Multiplier Combination 84

9.4.3 Assembly of Crystal-Multiplier Combination 85

9.4.4 Plateau Measurement 86

9.4.5 Dismantling the GM Detector 87

9.5 Replacing the Source 88

9.5.1 Replacing the Source 90

9.6 Customer’s Service 92

9.6.1 Sending in the Electronics 93

9.6.2 Sending in Source and Shielding 94

Table of Contents

Mini-Switch LB 471

7

Chapter 10. Servicing the Shielding 95

10.1Checking Shielding and Source 95

10.1.1 Testing the Locking Mechanism 95

10.2Leak Test 96

10.2.1 Leak Test Documentation 96

10.2.2 Performing a Wipe Test 97

Chapter 11. Radiation Protection 99

11.1Basics and Directives 99

11.2Radiation Dose Calculations 101

11.3Calculation with a given Dose Rate 101

11.4Activity-based Calculation 102

Chapter 12. Disposal 103

Chapter 13. Technical Data 105

13.1Evaluation Unit 105

13.2Detectors 106

13.3Shieldings 108

13.4Pneumatic Locking Drive 108

Chapter 14. Certificates 109

14.1ATEX Certificate for Evaluation Unit LB 4710-XXX 109

14.2ATEX Certificate NaI Detector 113

14.3ATEX Certificate GM Detector 117

14.4EC Declaration of Conformity 119

Chapter 15. Technical Drawings 121

15.1NaI Detector 121

15.2GM Detector 122

15.2.1 Fastening Clamps 123

15.2.2 Detector Holder for GM Detector and NaI Counter 124

15.3Super-Sens Detectors 125

15.4Point Source Shielding LB 744X 131

15.5Dimensions of the Evaluation Unit 134

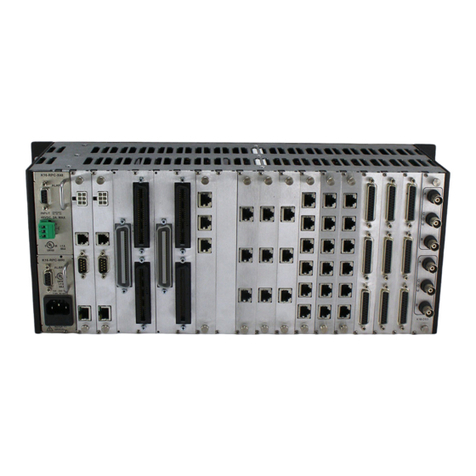

15.5.1 19" Rack 134

15.5.2 Wall Housing 135

15.5.3 Cassette 136

15.6Connection Diagrams 137

15.6.1 19" Rack 137

15.6.2 Wall Housing 138

15.6.3 Cassette 139

15.6.4 Connection Diagram for Power Supply Unit in 19" Rack 140

Chapter 1 General Information

Mini-Switch LB 471

9

Chapter 1. General Information

1.1 Use and Function

The limit switch system LB 471 Mini Switch has been designed for

monitoring and detection of levels in containers and pipelines.

Licensed as an “overflow protection device for containers storing

liquids that are hazardous to waters”in accordance with the Water

Resources Act, the system may also be used as overflow protec-

tion device.

Beyond this scope, each application is considered as not being in

compliance with the law and may result in severe personal injury

or property damage.

BERTHOLD TECHNOLOGIES does not assume any liability for this kind

of injuries or damage.

1.2 Target Group

This user’s guide has been written for operating, assembly and

service personnel.

The system may only be assembled, serviced and maintained by

authorized and trained persons. Any modification of the settings

may only be carried out by persons who are familiar with the func-

tion of the system. Persons working with ionizing radiation must be

familiar with the rules of radiation protection and adequate work

techniques.

Personnel have to be specially trained and informed about possible

hazards. Detailed knowledge of this user’s guide and careful ob-

servation of the instructions contained therein is an essential pre-

requisite.

Each staff member has to know the major rule of the “ALARA prin-

ciple”(as low as reasonably achievable).

BERTHOLD TECHNOLOGIES is offering appropriate training courses.

Depending on the participant’s professional qualifications, two

kinds of training can be chosen:

Qualification

Training

Chapter 1 General Information

Mini-Switch LB 471

10

1.3 Radiation Protection Courses

Special course in radiation protection

(Duration: 2 days)

This course is needed if the participant has not yet received any

radiation protection training. A successfully completed course

has a validity of 5 years.

Refreshing course in radiation protection

(Duration: 1 day)

All persons who have already successfully completed the spe-

cial course may refresh their special knowledge with this course

(Radiation Protection Ordinance of August 1, 2001).

A successfully refreshing course has a validity of 5 years.

1.4 Definitions

Automatic

Some parameters can either be set to the automatic or manual

mode. In the automatic mode the value is calculated using a

formula. Enter -1 to enable the automatic mode. The inverted C

in the top row indicates whether a parameter has been set to

automatic.

EVU

Evaluation Unit

Edit

Change value

Edit mode

In this mode, a value can be changed. Not every parameter can

be changed since some parameters are only used as display

values. Editable Parameters can be set to the edit mode with

the “Enter”button. In the edit mode the cursor positioned over

a digit is flashing.

GM detector

Detector with Geiger-Müller counter tube

NaI detector

NaI = sodium iodine crystal = scintillator

Scintillation detectors are very sensitive to Gamma radiation.

See pages 40 and 121.

Super-Sens detector

Detector which is highly sensitive to Gamma radiation with

large-volume plastic scintillator 150x150mm

See pages 43 and 125.

Limit value

Count rate or percentage value upon reaching the measure-

ment level

Chapter 1 General Information

Mini-Switch LB 471

11

HV

Detector high voltage

Cassette

Case (7 TE) into which the evaluation unit LB 4710 is installed,

so it can be used in any 19" rack

Empty

Level below limit value.

Empty count rate

Count rate with empty container

Manual

Some parameters can either be set to the automatic or manual

mode. For the manual mode you have to enter a fixed value in

the respective parameters.

Nuclide / Isotope

Type of radiation source: Cobalt-60 (Co-60) or Cesium-137

(Cs-137) for level measurements.

Zero count rate

Count rate caused by natural environmental radiation.

Parameters

A value stored under a certain code.

Timeout

Time after which an automatic reset is performed.

Full

Level below limit value.

Full count rate

Count rate with full container.

Count rate

Value of counts relative to one second.

cps

Count rate unit: Counts per second.

Read in count rate

A process that is started by the user in order to determine the

average value of the count rate at the respective level. This

count rate is needed to calibrate the measurement. The count

rate is averaged over a certain time (standard 60 s) to exclude

statistical and process-immanent fluctuations.

Factory setting

All parameters have been preset by the manufacturer using

standard values. In most cases this simplifies calibration of the

instrument significantly. Despite factory setting, calibration al-

ways has to be performed.

mSv

Dose rate unit

Millisievert

Chapter 1 General Information

Mini-Switch LB 471

12

MBq

Mega-Becquerel

This unit indicates the source activity. Each Bq corresponds to

one decay per second..

1 MBq = one million decays

mCi

Milli-Curie

This unit is also used for the activity of a source. However, this

unit has been replaced by the unit MBq (1mCi = 37 MBq)

1.5 Safekeeping of the User’s Guide

Note!

This user’s guide always has to be available at a fixed place. The

personnel have to be informed about this place. Any time the de-

vice is used by another operator and whenever there is a change

in ownership of the device, the user’s guide has to be given to the

new operator or owner.

Chapter 2 Safety

Mini-Switch LB 471

13

Chapter 2. Safety

2.1 Safety Concept

The state-of-the-art system is designed in accordance with accept-

ed safety rules to ensure the greatest possible on-the-job safety.

To rule out health hazards when handling radioactive substances,

limit values stating the highest acceptable radiation exposure of

the operating personnel have been defined on an international lev-

el. These limits have to be observed when designing shieldings and

planning the configuration of the measuring system at the meas-

urement point.

2.2 Symbols and Pictograms

The following symbols identify safety instructions in this user’s

guide:

Danger!

Possible danger for life and health hazard

Caution!

Possible hazard

Minor personal injuries

Warning!

Possible hazard

Property damages

Note!

Tips for application and useful information

The safety instructions are supplemented by explanatory picto-

grams, for example:

Chapter 2 Safety

Mini-Switch LB 471

14

2.3 Radiological Safety Officer

To ensure proper handling and the observance of the statutory

requirements the operating company has to appoint a radiological

safety officer who is in charge of all radiation protection issues in

connection with the measuring system.

The radiological safety officer has to:

monitor working with the radiometric measuring system

draw up a plan for the organization of radiation protection

monitor compliance with the regulations of the Radiation Pro-

tection Ordinance

issue directives and carry out training and instruction of the

employees

get on-site information on the situation and takes appropriate

actions immediately if operation problems have occurred

cooperates with the work’s council or the personnel office and

qualified personnel for on-the-job safety, advises and informs

them on important radiation protection issues.

2.4 Duty of Notification

Caution!

Radioactivity!

In case of suspected damage to the shielding, the radiological

safety officer has to be informed immediately. Further steps can

be taken in consultation with BERTHOLD TECHNOLOGIES.

Chapter 2 Safety

Mini-Switch LB 471

15

2.5 Radiation Protection Areas

Radiation protection areas define the boundaries around a radia-

tion source. The maximum dose rate defines the limit. We distin-

guish three radiation protection areas:

2.5.1 Exclusion Areas

Exclusion areas are areas in which the local dose rate may be ex-

ceed 3 Millisievert (mSv) per hour. These areas have to be pro-

tected such that nobody has unchecked access to these areas –

not even with single body parts. Actually, these areas can occur

only in the active beam in the direct vicinity of the shielding.

Caution!

Radioactivity!

The radiation protection directives have to be observed.

Exclusion areas have to be protected such that nobody has un-

checked access to these areas –not even with single body parts.

This has to be ensured through constructive measures, for exam-

ple by protective covers.

2.5.2 Controlled Areas

Controlled areas are areas in which persons in one calendar year

may receive an effective dose of more than 6 mSv if they stay in

this area 40 hours a week and 50 weeks per calendar year. Based

on this, the calculated maximum dose rate is 3 µSv/h. These areas

should be planned such that accessibility is virtually not possible or

that the required safety fences can be installed easily. If con-

trolled areas are accessible they have to be secured. Moreo-

ver, they have to be identified clearly and permanently by a radia-

tion danger sign and the comment “Controlled Area”. Persons may

access controlled areas only to carry out maintenance work for the

operations going on inside this area (§ 37). Body doses have to be

calculated or personal doses have to be measured. The authorities

may permit exceptions from the demarcation and identification

duty, provided individuals or the general population are not en-

dangered. Higher limit values are admissible if reliable in-

formation is provided that the person affected stays within

the controlled area for a shorter period of time.

Chapter 2 Safety

Mini-Switch LB 471

16

Caution!

Radioactivity!

The radiation protection directives have to be observed.

Controlled areas outside the shielding have to be identified and

secured if they are accessible.

2.5.3 Monitoring Areas

Monitoring areas are operation areas which do not belong to the

controlled area. In these areas, a person may receive an effective

dose of more than 1 mSv in one calendar year.

The monitoring area starts at the controlled area. It is an area in

which persons staying permanently in this area may be exposed to

a radiation level of more than 1 mSv in one calendar year. For a

stay of 40 hours per week and 50 weeks per year the area is be-

tween the dose rate limit values of 3 µSv/h and 0.5 µSv/h. It has

to be ensured that persons are not exposed to a dose exceeding

1 mSv per year, taking into account the actual time they stay in

this area. This means that no permanent work place may be set up

in this area.

Chapter 2 Safety

Mini-Switch LB 471

17

2.6 Safety Installations

2.6.1 Source Shieldings

Caution!

Radioactivity!

The shielding with the source installed may be taken into opera-

tion by specially licensed persons who have been trained on han-

dling radioactive materials only after consultation and coordination

with the radiological safety officer.

The radiation exit channel must only be opened by authorized per-

sons after consultation with the radiological safety officer.

Modification of or tampering with the shielding construction are

prohibited.

Co-60 or Cs-137 point sources are used for the system. They

are tightly welded into a sturdy stainless steel capsule, so that the

radioactive substance cannot escape and contamination is pre-

vented. The capsule with the source is fixed on a holder and

installed into the shielding.

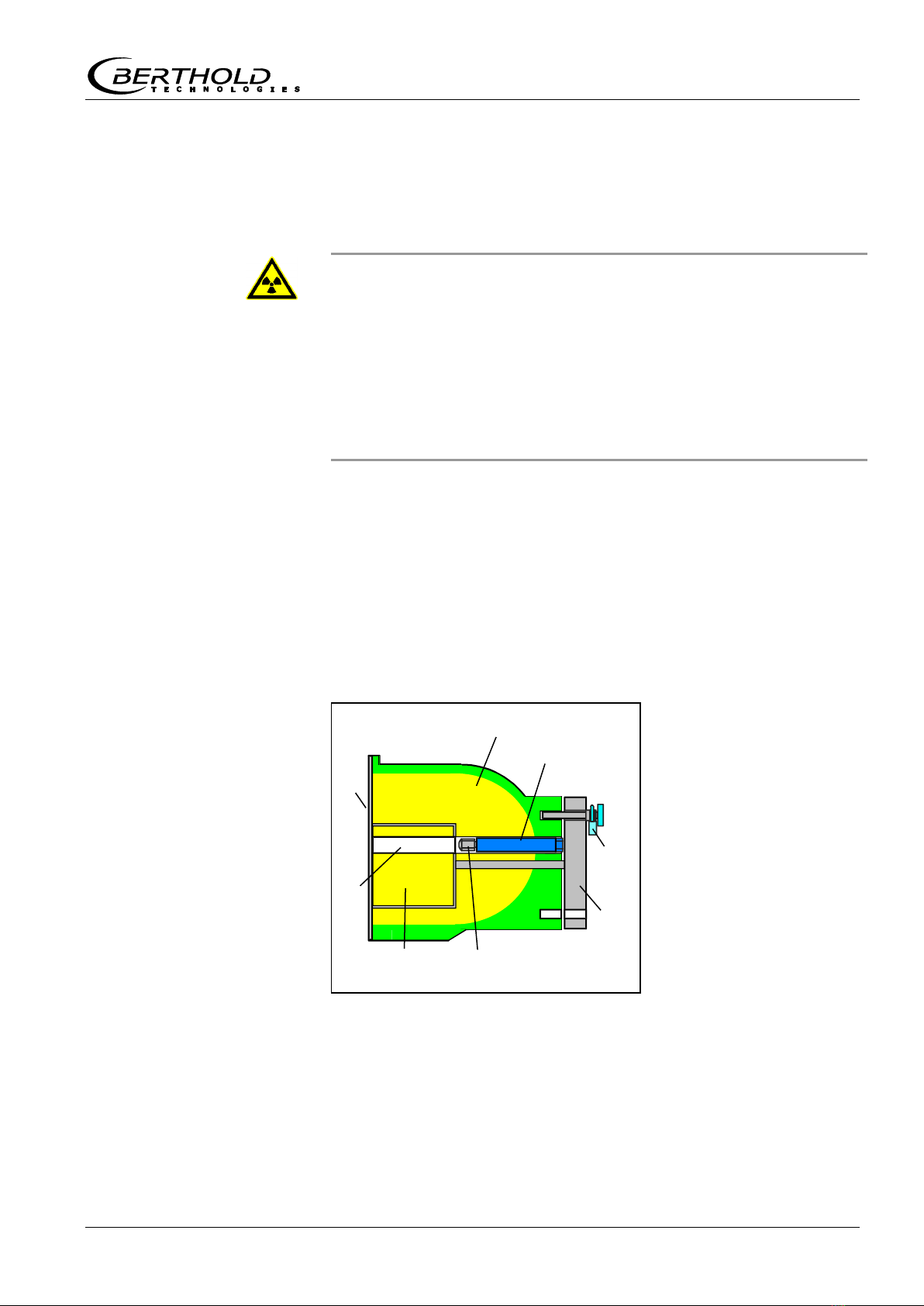

The shielding consists of a lead cylinder with radiation exit channel

, surrounded by a steel jacket. The locking core is fixed to a

lever . The padlock secures the open / closed position and

protects the source against unauthorized removal.

Shielding

Locking core

Radiation channel

Point sources

Source holder

Lever

Padlock

Cover plate front

When turning the lever , the locking core is rotated as well and

the radiation exit channel is opened towards the detector. The ar-

row on the lever is pointing towards “OPEN”.

Source

Shielding

Figure 1:

Point source shielding

radiation channel open

Sectional drawing

Chapter 2 Safety

Mini-Switch LB 471

18

Lever with arrow

Padlock

Cover plate rear

The radiation exit channel has to be closed during transport, as-

sembly and while carrying out work on the container.

The arrow on the lever is then pointing to “CLOSED”.

The lever or the locking core is secured by a padlock in the

“OPEN”and in the “CLOSED”position.

Shielding, radiation type, isotope and activity have to be selected

for each measuring configuration such that the internationally

permissible dose rate limits will not be exceeded.

The source and shielding version is documented in the supplied

technical source documentation and on the type label on the

shielding.

Source number

Activity

Isotope

Source manufacturing

date

Dose rate in

1m distance

Effective shielding

thickness

Shielding material

Type of shielding

Shielding manufacturer

Figure 2:

Shielding

- view of lock

Type label

Figure 3:

Type label

on shielding

Strahler-Nr.: 1234 - 11- 94

MBq Co-60

400

Abschirmung

mm

Datum 12.11.94

Pb

98

Dosisleistung in 1m Abstand

5Sv/h MODEL LB7440

Bad WildbadD-75323

Chapter 2 Safety

Mini-Switch LB 471

19

2.7 General Safety Instructions

Caution!

The safety instructions in this user’s guide have to be observed

without fail.

All laws, directives, accident prevention regulations and generally

accepted safety regulations have to be complied with!

The system may be used only in technically good order and only

for contractual use!

Only persons may work with the system who have been author-

ized to do this and who have the proper qualification and have

received the necessary instructions!

Installations and modifications on the system which may affect the

operational safety are prohibited!

2.8 Emergency Instructions

The following basic principles are indispensable for health and

safety: Time, distance and shielding. In an emergency, the follow-

ing provisions have to be taken:

Danger!

Hazard due to radiation damages.

Never touch the source with your hands!

Restrict access to this area, identify radiation protection areas.

Check the function of the shielding and measure the dose rate.

Localize the source.

Document the event and, if possible, estimate the potential

radiation exposure of the persons involved.

Report event to BERTHOLD TECHNOLOGIES.

In case of loss of radiation sources, the regulatory agency has

to be notified immediately.

In case of suspected damage to the source capsule the follow-

ing issues have to be taken into consideration:

Grasp source with a tool (e.g. a pair of pliers or tweezers) and

put both (source and tool) into a plastic bag.

Place plastic bag behind an auxiliary shielding (concrete wall,

steel or lead plate).

Check if environment is free of contamination.

If a source has any leaks or if you suspect that the permissible

dose has been exceeded, the regulatory agency has to be noti-

fied immediately.

Chapter 2 Safety

Mini-Switch LB 471

20

2.8.1 Theft Protection

Radioactive substances or facilities containing radioactive sub-

stances have to be secured such that they are protected against

access by unauthorized persons. If you discover that radioactive

substances are missing, you have to notify the radiological safety

officer and the regulatory agency. In case of theft, the police have

to be informed.

Please see Chapter 11 for more information on radiation protection.

This manual suits for next models

7

Table of contents

Popular Switch manuals by other brands

Enterasys

Enterasys Matrix 2G4072-52 Configuration guide

pro bel

pro bel Freeway Series user guide

SICK

SICK i16S operating instructions

Signature Hardware

Signature Hardware AIR SWITCH 948127 quick start guide

Intel

Intel EXPRESS 330T quick start guide

Eterna

Eterna WS120PIR Safety and installation instructions