Berthoud TRACKER User manual

TRACKER / TRACKER-S

D.P.A Regulation

(Proportional Flow Rate to Advance)

With or without TELEVOLUX, with or without BERJUST

To be read attentively

and kept for further reference

82.503-B ENGLISH

Tables of Nozal nozzles: see manual No. 82.467

Tracking drawbar: see manual No. 82.444

TELEVOLUX function: see manual No. 82.470

BERJUST 2000: see manual No. 82.441

AXIALE boom: see manual No. 82.438

AXIALE II boom: see manual No. 82.486 (30/32 m)

RLD boom: see manual No. 82.450

R

Sprayer safety, checks and maintenance: see manual 82.471

Wiring diagrams: Refer to Dealer manual No. 589.494

© BERTHOUDAgricole 09/2011

2 82.503 TRACKER / TRACKER-S D.P.A

82.503 TRACKER / TRACKER-S D.P.A 3

- General and safety

(See manual No. 82.471)

•Technicalspecications ................................................................................. 5

•Dimensions.................................................................................................... 6

•Sound measurements.................................................................................... 6

•Position of the safety stickers........................................................................ 7

•Descriptive plate............................................................................................ 8

•Table of weights............................................................................................. 8

- Starting-up the sprayer

(See manual No. 82.471)

•Adapting the PTO shaft.................................................................................. 10

•Adjustment of the track width......................................................................... 10

•Rinsingthesprayerbeforerstuse ............................................................... 11

•"ACTIFLEX" suspension (TRACKER-S)........................................................ 11

•Opening the fairing ........................................................................................ 12

-Choiceofnozzlesandtablesofowrates

(See manual No. 82.467)

- Using the sprayer

•Hitching the sprayer to the tractor.................................................................. 14

•Adjustable height drawbar (Option)............................................................... 14

•Parking brake................................................................................................. 14

•Unhitching the sprayer................................................................................... 15

•Checks to be carried out every time before the sprayer is used.................... 15

•Recommendations for use............................................................................. 15

•Presentation of the D.P.Acontrol box with TELEVOLUX (Option)................. 16

•Presentation of the D.P.Acontrol box with BERJUST (Option)...................... 17

•Adjustmentofowrates/hectare ................................................................... 18

•Adjustment of the compensated return (V.M.m) (Motorised valves).............. 20

•Adjustmentofthecompensatedreturn(V.E.C)(Electricapvalves) ............ 22

-Mainsprayerfunctionswithcentrifugalpump

•Adjustment of the valves................................................................................ 25

•Filling / Incorporation hopper......................................................................... 26

•Spraying / Mixing / Transferring..................................................................... 28

•Rinsing operations......................................................................................... 30

- Other sprayer functions

•Draining the tank............................................................................................ 34

•Float gauge.................................................................................................... 34

•Tape gauge (Option)...................................................................................... 34

•Electric gauge (Option).................................................................................. 34

•Handwash tank.............................................................................................. 34

•Rinsing tank................................................................................................... 34

•Rinsing the main tank.................................................................................... 36

•Stirring ........................................................................................................... 36

•Pressure gauge ............................................................................................. 36

•Safety valve................................................................................................... 36

•Running board............................................................................................... 36

contents

See pages

4 82.503 TRACKER / TRACKER-S D.P.A

See pages

•Height of the boom ........................................................................................ 36

•External washing device (Option).................................................................. 38

•External washing procedure.......................................................................... 38

- Maintenance of the sprayer

(See manual No. 82.471)

•Practical recommendations for the servicing of your sprayer........................ 40

•Checks before spray season......................................................................... 40

•Foaming in the tank....................................................................................... 40

•Lastllingoperation....................................................................................... 41

•Protection against oxidising agents............................................................... 41

•Maintenance after operation.......................................................................... 41

•Winter storage ............................................................................................... 41

•Nozzlesorltersdirty .................................................................................... 42

•Suctionlter ................................................................................................... 42

•Deliverylter .................................................................................................. 42

•Maintenance of plastic valves........................................................................ 43

•Servicing the boom........................................................................................ 43

•Checking nut tightness .................................................................................. 43

•Lubrication and greasing ............................................................................... 44

•Safety when changing a wheel...................................................................... 46

- Maintenance diagram

•Spraying circuit.............................................................................................. 48/49

- Remember your parameters............................................................................. 50

- Notes on the treatments carried out during the season................................ 51

82.503 TRACKER / TRACKER-S D.P.A 5

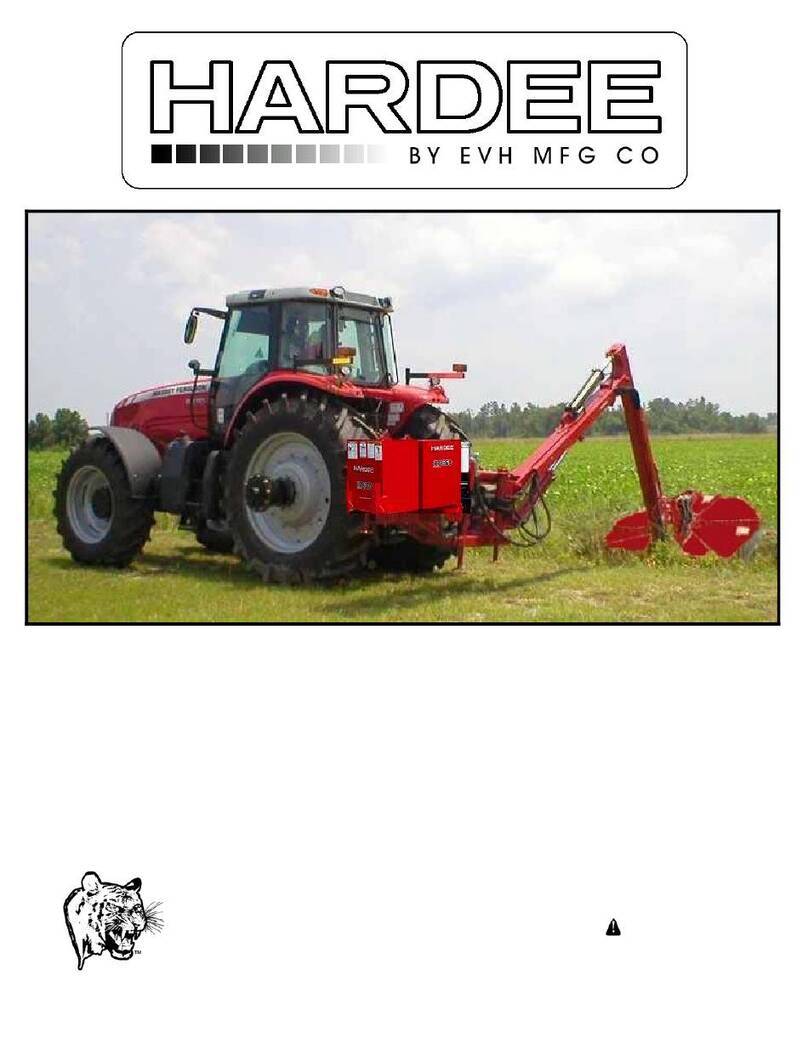

TRACKER / TRACKER-S 3200 D.P.A regulation

Trailedsprayerwithproportionalowratetoadvance(D.P.A.).

- Steel CHASSIS protected by U.H.R. polyester

paint.

- Stainless steel NUTS and BOLTS.

- High-density polyethylene TANK:

- Nominal capacity 3,200 litres.

- Widellingorice.

- RINSE TANK in polyethylene with 330 litres capacity.

- HANDWASH TANK in polyethylene with 20 litres

capacity.

- GraduatedoatGAUGE.

- AXLE adjustable from 1.55 to 2.10 m.

- "ACTIFLEX" SUSPENSION (TRACKER-S):

spring inclined with shock absorbers, ensuring an

independent operation of the load.

- WHEELS:

(*) 420/85 R38 (min. track 1.71 m; max. track 2.09 m).

- MECHANICAL parking BRAKE.

- HYDRAULIC service BRAKE.

- Coupling DRAWBAR with eye.

- Crank-operated JACKSTAND.

- CENTRIFUGAL PUMP for:

- Filling, agitation with mixing boom, xed rinsing,

transferring, incorporation of trace elements.

- FILLING AND FILTRATION:

- Fillingvia themanholeordirectllingwithcame

lock (diameter 50 mm).

- Incorporationhopper(25litres)withcans rinse and

circuit rinsing.

- Filtration:

▪Fillinglter(sieve,8/10mesh).

▪Suctionlter(vannolter,6/10mesh).

▪Deliverylter(1/4turnlter,4/10mesh).

TECHNICAL SPECIFICATIONS

- "VOLUX 240" METERING PUMP with 2 double-

acting pistons and 2 drive speeds (including one for

low volume/ha) for the spraying.

- REMOTE CONTROL of the VOLUX pump via

solenoid valve block

- Manualvolume/haADJUSTMENT onVOLUXpump

(option):

▪TELEVOLUX: Remote control of volume/ha with

display.

▪BERJUST 2000: In-cab; volume/hectare, speed

and cumulative data information.

- VALVES BLOCK:

▪BERLOGIC with DUALMATIC: Manually-controlled

valves block.

- REMOTE CONTROL of spraying operation via

4stainlessmotorisedballvalveswithmultireturnunits

(option: 5/6/7 motorised valves).

General electrical shut-off switch on cab-mounted

control box.

- ELECTRIC BOX with multi-pin connectors.

- Glycerine PRESSURE GAUGE, 0/25 bar, diameter

80 mm, with dilated scale.

- WIDE ANGLE DRIVE SHAFT.

- HYDRAULIC UNIT (option).

- ROAD LIGHTS in accordance with highway code.

- QUALIFICATIONS:

- Road(DREAL"RegionalOfcesfortheEnvironment,

Planning and Housing"), overall width 2.55 m.

- Environmental compliance.

- OPTIONS:

▪Adjustable height drawbar.

▪Hydraulic adjustable drawbar.

▪Tape gauge.

▪Electric gauge.

▪Side door.

▪Mudguard.

▪External washing equipment of sprayer.

▪2 work lamps, lighting of the control station,

pre-equipped for gyrolight (AXIALE boom).

▪"DiluNet" residual liquid dilution.

Type of tire RLD boom Axiale 24/28

boom Axiale 30/32

boom

230/95 R48 Standard Standard

270/95 R48 Standard

300/95 R46 Option Option

380/90 R46 Option Option Option

420/85R38(*) Option Option Option

460/85 R38 Option Option Option

6 82.503 TRACKER / TRACKER-S D.P.A

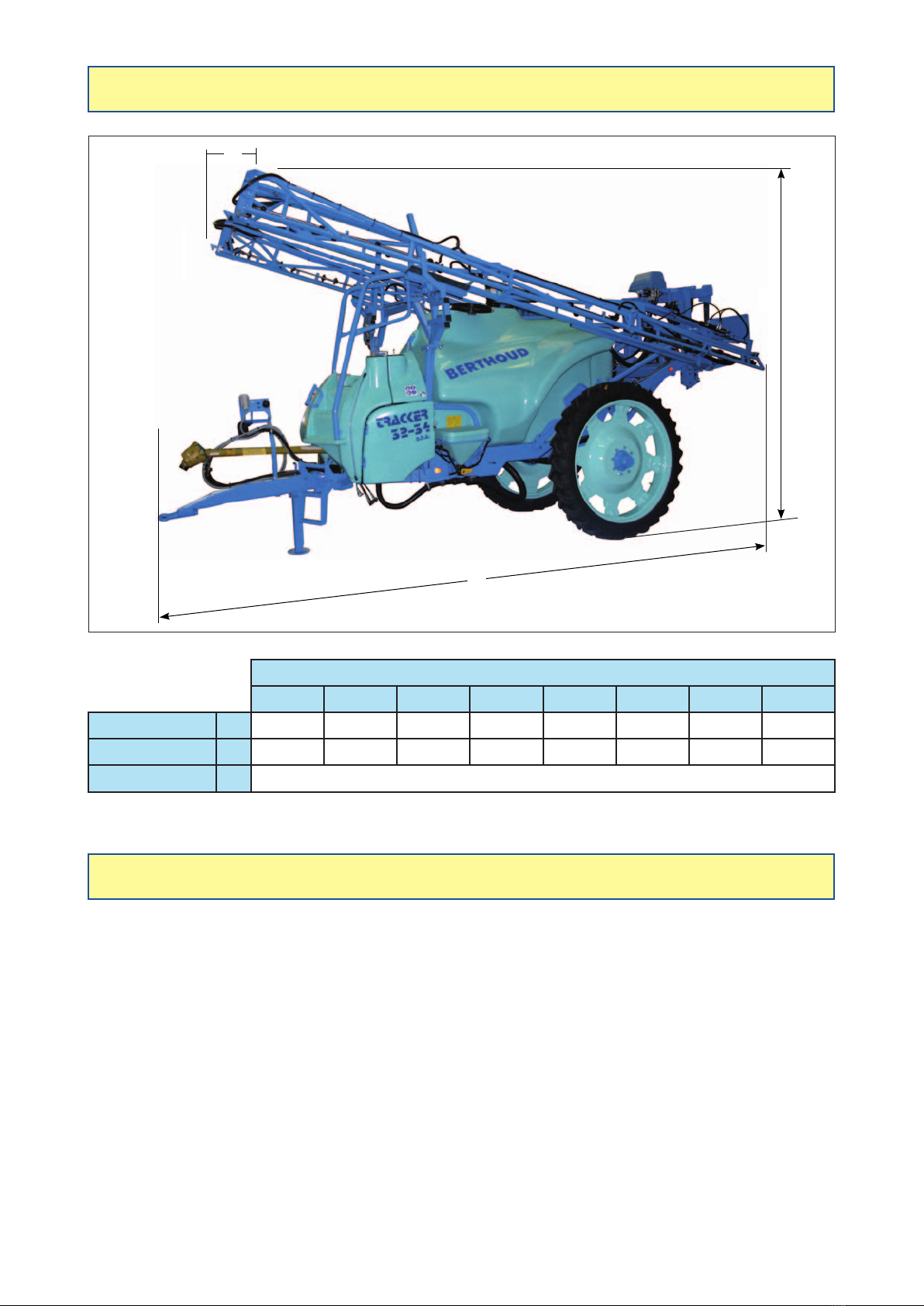

DIMENSIONS

ATMOSPHERIC NOISE EMITTED BY: Trailed sprayer TRACKER / TRACKER-S with D.P.A

regulation

-SoundpressureDriver'senvironmentLPAindB(A):

- Tractor alone = 72.2

- Tractor + sprayer = 72.6

- Sound pressure Peak level:

- Tractor alone = 97.5

- Tractor + sprayer = 100.1

-SoundpowerLWA:

- Tractor alone = 104.4

- Tractor + sprayer = 106.5

Complywiththelegislationinforceanduseear-protectorsifnecessary.

SOUND MEASUREMENTS

C

B

A

BOOMS

RLD 18 RLD 20 RLD 21 RLD 24 Axiale 24 Axiale 28 Axiale 30 Axiale 32

Overall length A6.33 m 6.33 m 6.33 m 6.33 m 7.03 m 7.03 m 8.10 m 8.10 m

Overall height B2.90 m 3.00 m 3.00 m 3.30 m 3.50 m 3.85 m 3.90 m 3.95 m

Overallwidth C2.55 m to 2.90 m according to tires, track and mudguard option

82.503 TRACKER / TRACKER-S D.P.A 7

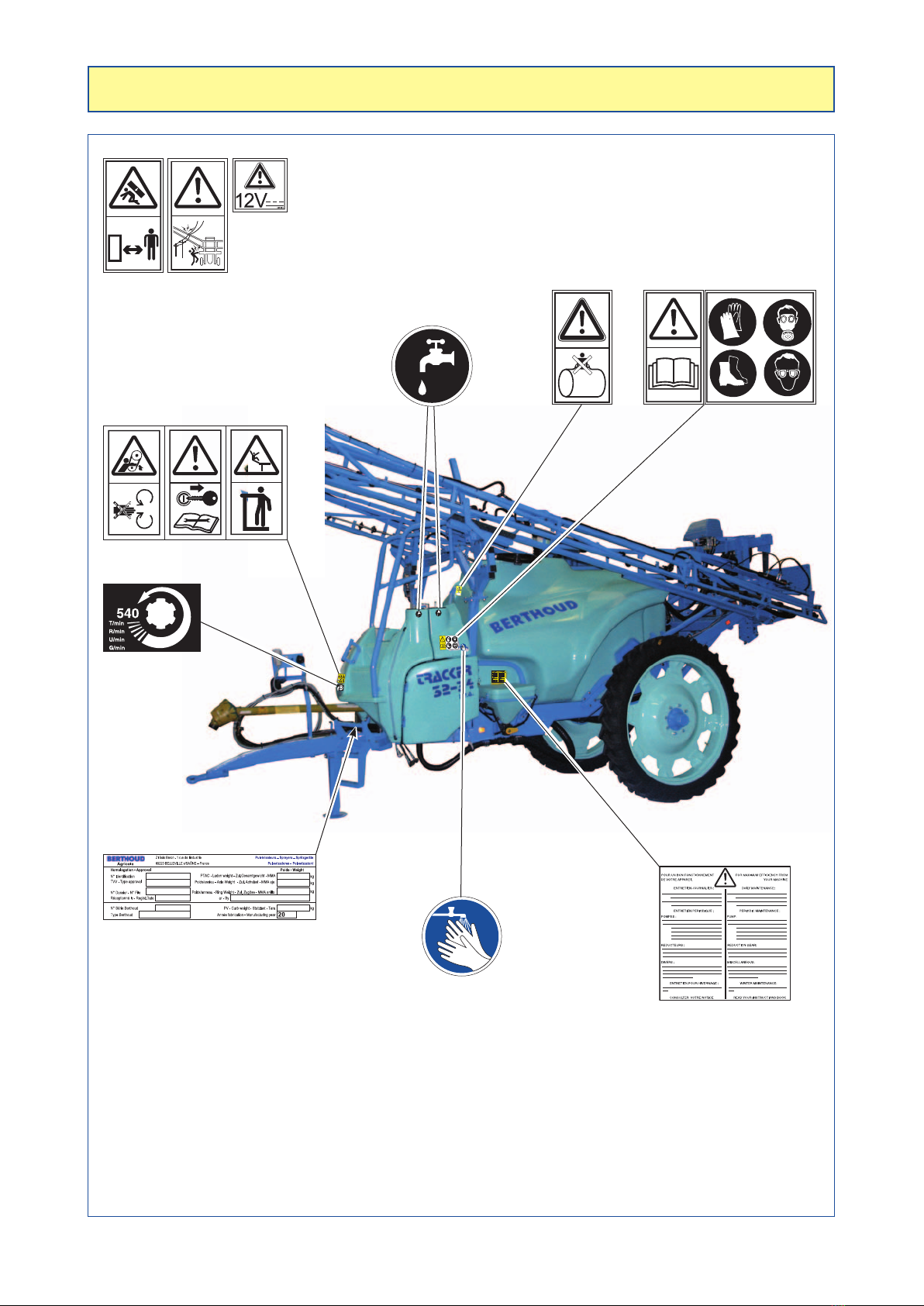

It is very important to keep the safety stickers in location and in good condition as they draw your

attention to possible dangers and refer to the operator's manual.

Check their location on the sprayer and see their meaning in manual No. 82.471 (sprayers safety,

checks and maintenance).

- TRACKER / TRACKER-S D.P.A

540

POSITION OF SAFETY STICKERS

On the chassis, front right side

On control box of the spraying

boom

8 82.503 TRACKER / TRACKER-S D.P.A

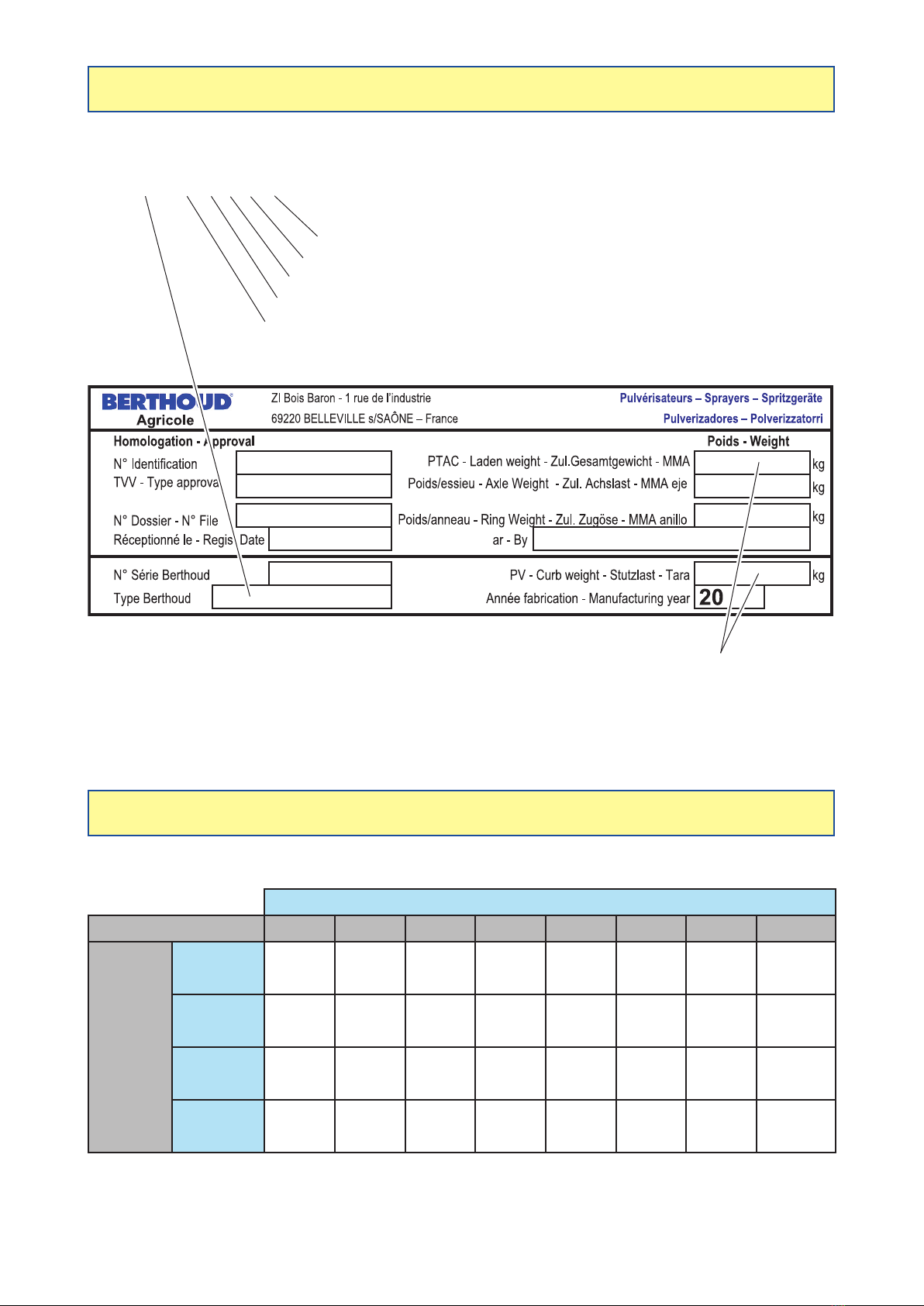

The "Kerb weight" and "Gross

vehicle weight" boxes use the data

in the table below

- The location of the descriptive plate on your sprayer is indicated on the view in page 7.

-Thebox"Type"ismadeupoflettersandgures.

- Example: TRM A 32 AX 24

24 = Width 24 metres (28 = 28 metres)

AX = AXIALE boom (RD = RLD boom)

32 = Rated capacity of the tank 3,200 litres

A= D.P.A - D.P.A TELEVOLUX regulation

TRM =TRACKER MAJOR sprayer (TRR = TRACKER RACER,

TRS = TRACKER R-XS)

DESCRIPTIVE PLATE

TABLE OF WEIGHTS (in kg)

The data below are valid for France only (see the document DREAL).

BOOMS

SPRAYER RLD 18 RLD 20 RLD 21 RLD 24 Axiale 24 Axiale 28 Axiale 30

Axiale 32/33

TRACKER

3200

Kerbweight 2,600 2,623 2,635 2,655 3,115 3,240 3,550 3,580

Gross

vehicleweight 6,425 6,455 6,470 6,495 6,955 7,025 7,390 7,410

Gross

vehicleweight

Axle 5,105 5,130 5,140 5,160 5,525 5,580 5,870 5,890

Gross

vehicleweight

Drawbar

1,320 1,325 1,330 1,335 1,430 1,445 1,520 1,520

Theseweightsareunderstoodas intheheaviest congurationofthemachinery(options, tires,regulation,

suspensions).

82.503 TRACKER / TRACKER-S D.P.A 9

STARTING-UP

THE SPRAYER

Checkingpowertake-offspeed.

Checking tractor advance speed.

Checking engine speed.

Checkingowrate/hectareusingatesttube.

Tractorwheeltraveldistance.

See "Sprayer safety, checks and maintenance" manual No. 82.471.

10 82.503 TRACKER / TRACKER-S D.P.A

2

13

2

13

21

- The length of the drive shaft may need to be adjusted to suit the tractor used with the sprayer.

- Here is the procedure to be followed once the sprayer has been hitched:

- Align the jaw of the universal joint with the shaft of the tractor's power-take off.

- Separate the two half universal joint drive shafts and couple them to the corresponding shaft, putting the

female protector on the tractor side.

- Present the two half universal joint drive shafts side by side.

- Mark and cut if necessary, being sure to leave a 10 mm clearance between the end of the tube and the

heel of the jaw.

-Carefullyledownthetwotubes.

- Grease the contact surfaces.

- Usinga hack saw,cut the protectorsto the samelengthas the half universaljoint driveshafts,which should

allow the half drive shafts to stick out 40 mm in relation to their protectors in the operating position. For

your safety, the two half universal joint drive shafts must have a minimum covering of 300 mm.

-Retthedriveshaftreadyforuse.

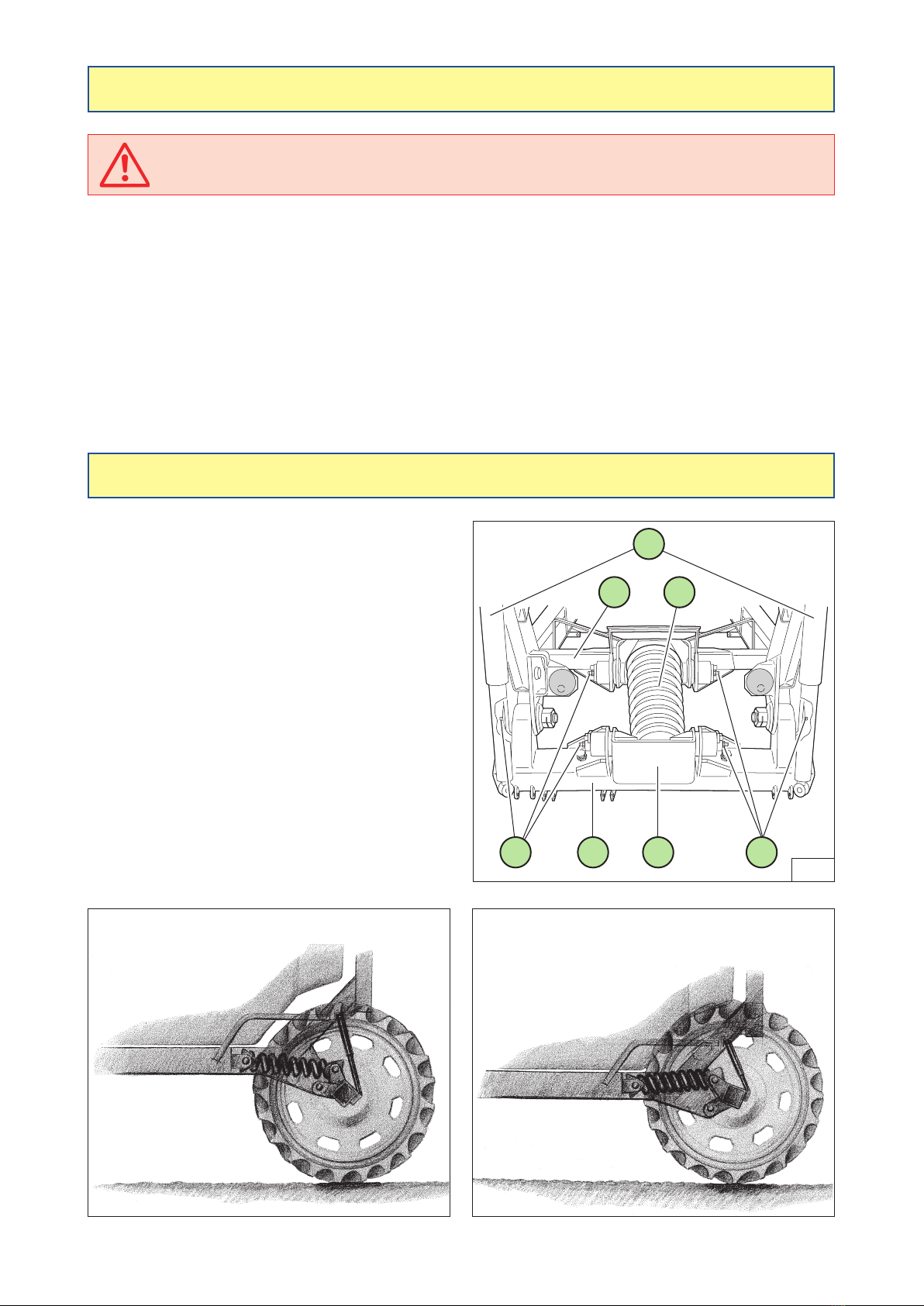

- The sprayers are delivered set at narrow track.

- To adjust the track:

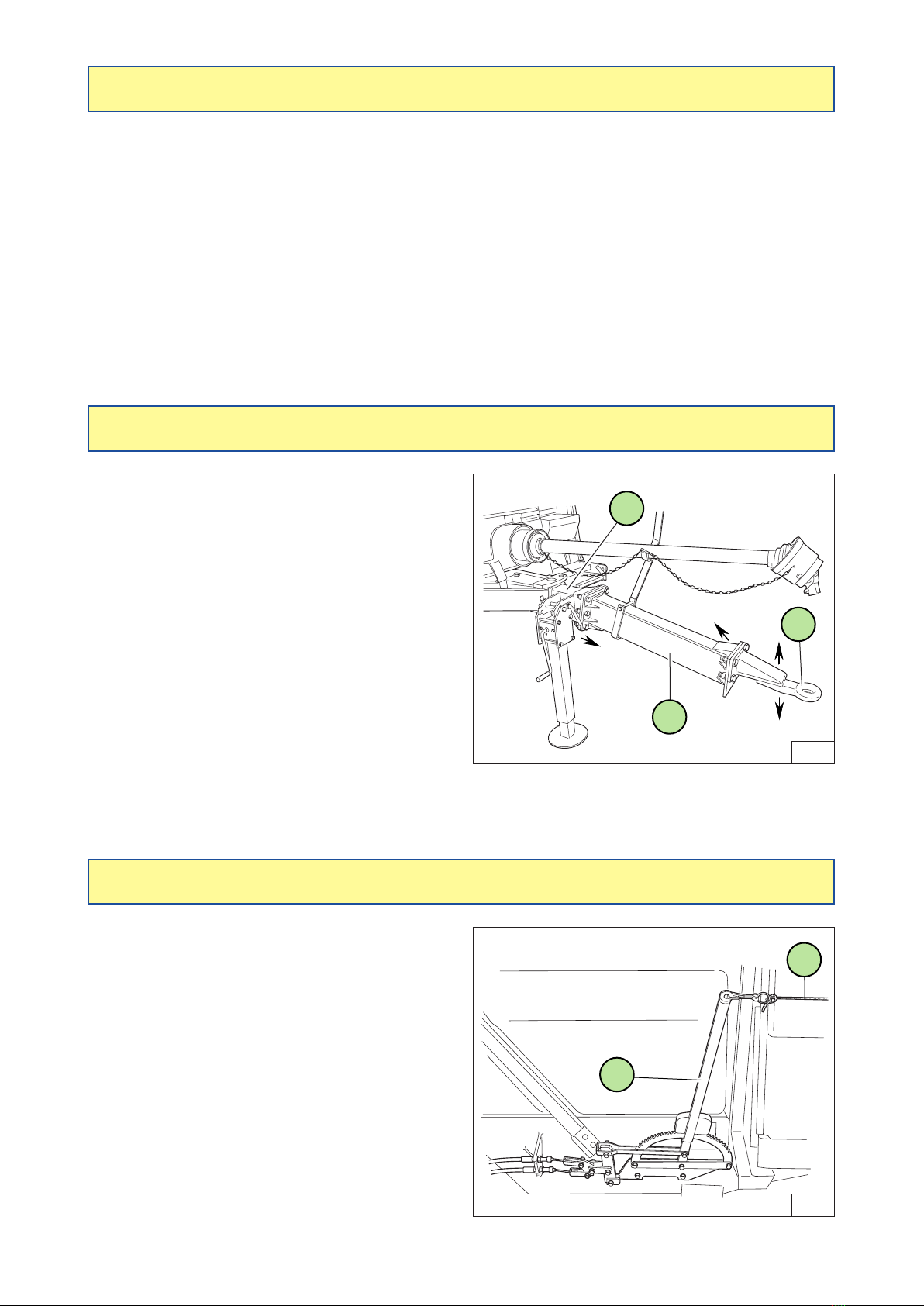

Case TRACKER (gure1):

- Once the nuts (2) are unlocked, slide the semi-

axles (1) in the girder (3).

Case TRACKER-S (gure2):

- Once the screws and nuts (2) are unlocked, slide

the semi-axles (1) in the girder (3).

Then in the 2 cases:

- Measurethe track(accordingto thatofthetractor

and the type of crop).

IMPORTANT:

The tyres must be at equal distance in

relation to the sprayer's centre axis.

-Tightenwellthenuts(2)(gure1)orthescrews

andnuts(2)(gure2):

Tightening torque = 240 Nm.

ADAPTING THE PTO SHAFT

ADJUSTMENT OF THE TRACK WIDTH

82.503 TRACKER / TRACKER-S D.P.A 11

ACTIFLEX suspension in empty tank position ACTIFLEX suspension in full tank position

G

4

2 3

53

1

G

Before using your sprayer for the rst time with phytosanitary product (weedkillers,

insecticideorotherproduct),rinsethesprayercompletely.

-Removethenozzlesiftheyaretted.

- Undo the end plugs on the pipes.

- Fill 1/5th of the volume of the tank with water.

- Spray (Refer to the OPERATION chapter of the pump).

-Removeandcleanthelters.

- Retighten the pipe end plugs.

- Fit the nozzles.

NOTE: Any foreign particles which may be in the spraying circuit will thus be eliminated and there will be no

risk of them blocking the holes in the nozzles.

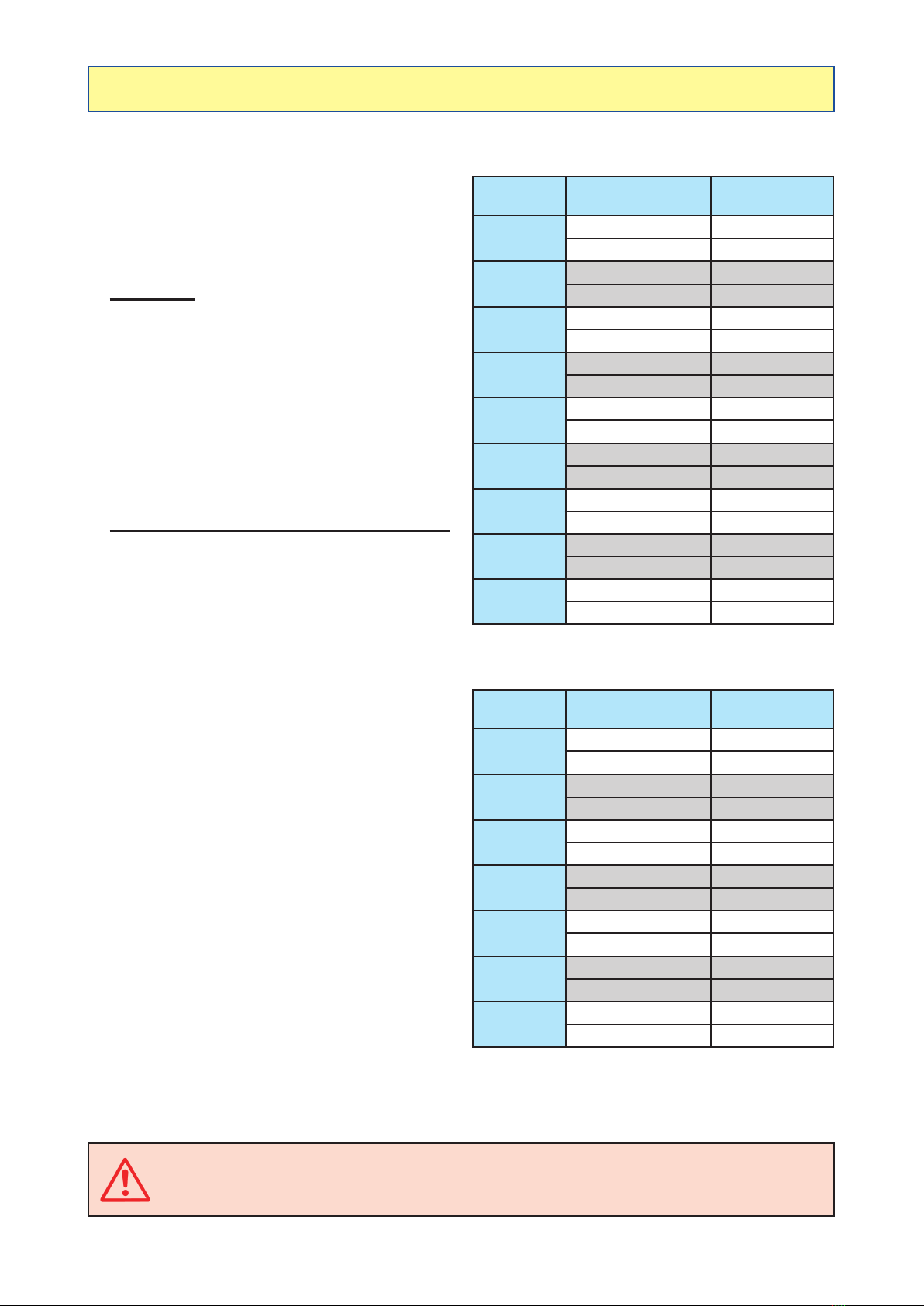

- The patented ACTIFLEX suspension comes as a

standard accessory on the TRACKER-S sprayer.

-Therstspringactionsuspension"delinearized"by

variable stiffness according to the load.

- The ratio and the positioning of a lever arm between

the axle (4) and the base of the spring (5) enable

the spring (3) to constantly adapt to the load (empty

tank/fulltank),toterrainconditions(path,elds,etc.)

for optimal suspension.

- Two shock absorbers (1), between the axle (4) and

the chassis (2), absorb and eliminate any remaining

oscillations.

-

Greaseviathe6greasettings(G)every100hours.

ELF EPEXA 2 or MOBILUX EP2 grease

(Warning: do not use molygraphite grease)

RINSING THE SPRAYER BEFORE FIRST USE

ACTIFLEX SUSPENSION (gure3)

12 82.503 TRACKER / TRACKER-S D.P.A

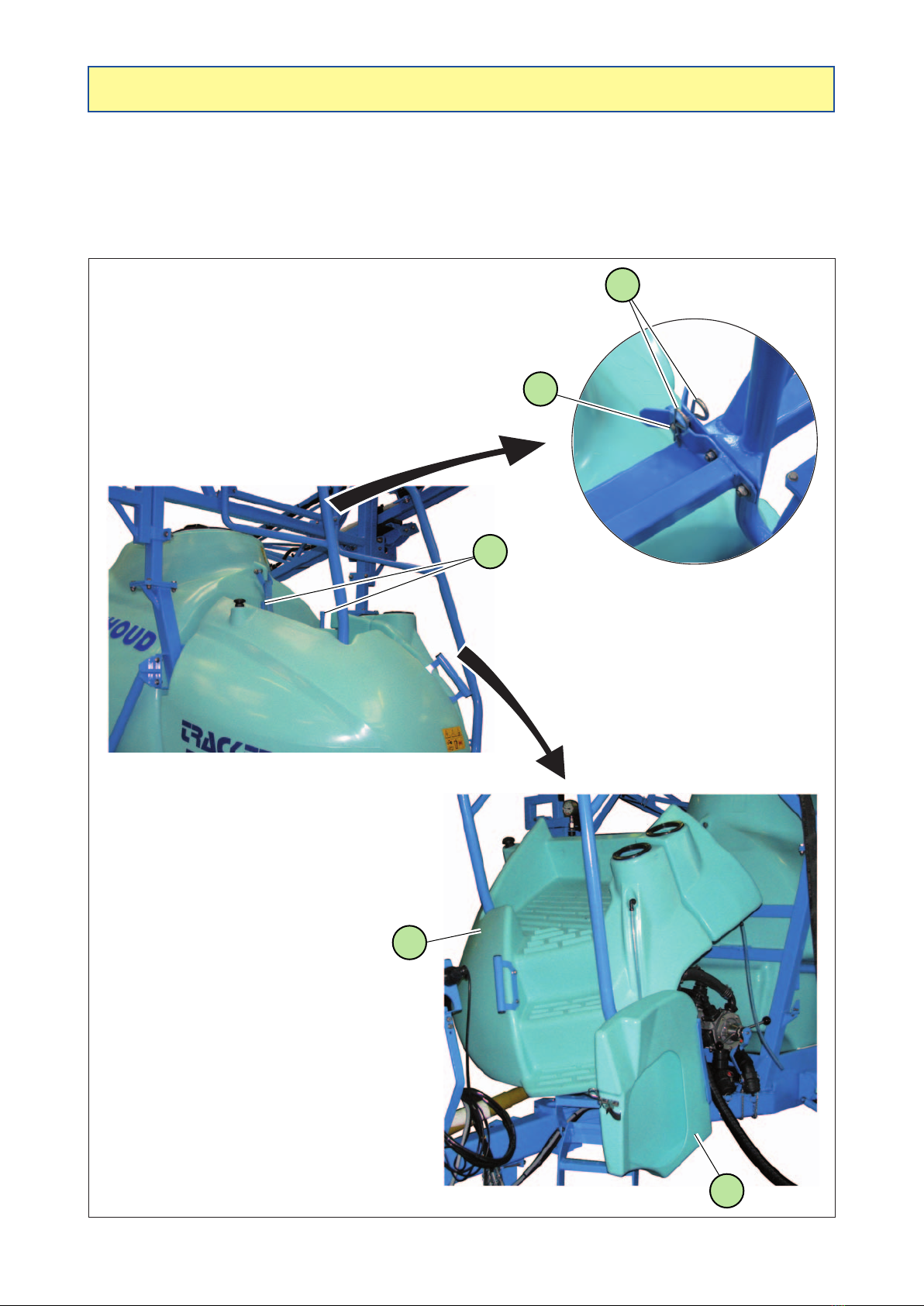

OPENING THE FAIRING

To open the fairing and reach at the control station:

- Unscrew the 2 threaded rods (1).

- Remove the pins (2) and the clevis pins (3).

- Open the protection door (5) of the control station.

- Rock the fairing assembly (4) forward.

2

3

4

5

1

82.503 TRACKER / TRACKER-S D.P.A 13

USING THE SPRAYER

See "NOZAL nozzles"

manual No. 82.467

CHOICE OF NOZZLES

AND

TABLES OF FLOW RATES

TELEVOLUXfunction(option).

See manual No. 82.470

BERJUST2000monitor(option).

See manual No. 82.441

14 82.503 TRACKER / TRACKER-S D.P.A

2

1

5

4

2

3

1

- A parking brake (2) (gure 5) is positioned on the

right-hand side of the sprayer.

- Fromthe tractorcab,you can immobilisethe sprayer

by using the rope (1) linking the brake control lever.

- Couple the sprayer’s drawbar to the tractor hook or coupling pin. The sprayer must be horizontal.

- Attach the end of the drive to the power take-off.

- Attach the small chain of the drive shaft protectors to the position intended for it.

- Raise the jackleg.

- Connect the hydraulic connections.

- Connect the electric connections.

- Release the parking brake.

-Hookthesmallrope(1)(gure5)tractorside(toimmobilisethesprayerincasethecouplingbreaks).

HITCHING THE SPRAYER TO THE TRACTOR

PARKING BRAKE

-Thisdrawbar(gure4)has4settingsfortheeye(1),

providing a total travel distance of 180 mm.

- Adjustments are made by moving the position

of the eye (1) in relation to the spacer bar (2):

(2 positions).

-Tocongurethedrawbarinpositions3and4:

▪Removetheeye(1).

▪Removethespacerbar(2)fromthedrawbar(3).

▪Turnthedrawbar(3)180°.

▪Turnthespacerbar(2)lengthwise.

▪Replace the eye (1) on the spacer bar (2) for

positions 3 and 4.

ADJUSTABLE HEIGHT DRAWBAR (Option)

82.503 TRACKER / TRACKER-S D.P.A 15

-Putthesprayeronaat,hardsurface.

- Put the sprayer in its parking position.

- Tighten the parking brake.

- Disconnect the electric connections.

- Disconnect the hydraulic connections.

- Rest the hydraulic pipes on the sprayer mountings intended for this purpose.

- Disconnect the drive shaft from the tractor.

- Rest the drive shaft on its support so as not to damage its protectors.

- Unhitch the sprayer.

UNHITCHING THE SPRAYER

- Check the condition of the protectors on the drive shafts.

- Make sure that there is no foreign matter into the tank.

- Check the oil levels and the greasing of the various elements (see "Lubrication and greasing" section).

-Checkthecleannessofthelters:

- Suction,

- delivery.

CHECKS TO BE CARRIED OUT EVERY TIME BEFORE

THE SPRAYER IS USED

CAUTION

- For your convenience,

theelectronicunithasbeenprogrammedwiththeoretical

valuescorrespondingto yoursprayer’scharacteristics.

In all cases, you must check and possibly correct the

values programmed.

WHEN STARTING

- Start-up the motor.

- Use switch (1) to power-up the unit (pages 16 and 17).

- Engage the power take-off.

CHECKS

- When starting the campaign, systematically check that the

nozzle pressure is below 3 bar for 1 minute.

- Reprogram the new value. If this is higher than the initial

value by 10%, you must replace the nozzles.

CAUTION

- ALL THE VALVE AND THE INDEXES OPERATIONS

MUST BE CARRIED OUT WITH THE POWER TAKE-OFF

STOPPED.

RECOMMENDATIONS FOR USE

16 82.503 TRACKER / TRACKER-S D.P.A

L

VALID

INSERT

DIRECT

REDUCTION

L / ha

I

0

0

0

M

PRESENTATION OF THE D.P.A CONTROL BOX

WITH TELEVOLUX (Option)

NOTE:

- Fuse: The control box (2) is protected by 3 type fuses Ø 5 mm x 20 mm:

- 5 Amps for the TELEVOLUX board (item 3),

- 10 Amps for the boom control board (item 4),

- 10 Amps for the boom spraying sections control board (item 5).

43

5

TELEVOLUX function

(See manual No. 82.470)

Control box

power switch 1

VOLUX pump

engage/disengage

control switch

72 pin plug

Power cable (battery)

Converter plug

Control switches for

options andAXIALE ED

boom

(See manual

No. 82.438)

2

Spraying control switches

(See page 28)

82.503 TRACKER / TRACKER-S D.P.A 17

Capteur

de

vitesse

Débimètre

-

+

0

0

0

PRESENTATION OF THE D.P.A CONTROL BOX

WITH BERJUST (Option)

NOTE:

- Fuse: The control box (2) is protected by 3 type fuses Ø 5 mm x 20 mm:

- 10 Amps for the boom control board (item 3),

- 10 Amps for the boom spraying sections control board (item 4),

- 3.15 Amps for the BERJUST board (item 5).

BERJUST 2000 monitor

(See manual No. 82.441)

24 or 42 pin plug

Speed sensor plug

Flowmeter plug

Control box

power switch 1

Volux pump

engage/disengage

indicator light

Power cable

(battery, 12 Vdc)

Controlpanelsupport

to be secured in the

tractor cab

AXIALE S.E.H

boom control

selector

(See manual

No. 82.438)

Switch and push-

button of the

options

2 3 4 5

18 82.503 TRACKER / TRACKER-S D.P.A

ADJUSTMENT OF FLOW RATES/HECTARE

Your sprayer is assembled with a "VOLUX" volumetric

pump which is mechanically linked by an angle

transmission, a cardan transmission and a multiplier

to the R.H. wheel rotation.

PUMP FLOW RATE CAN BE MODIFIED IN

2 WAYS

1 - MANUALLY

-Movethelever(3)(gure6)ofthemultiplier(4)

whichislocatedon theinsideofthesprayer'sright

wheel.

▪

Leverinposition(1-Tortoise)=Smallowrates/ha.

▪Leverinposition(2-Hare)=Largeowrates/ha.

▪Neutral between the 2 positions. (To move

from position (1) to the position (2), it may be

necessary to rotate the output shaft (5) by some

degrees).

▪Item (6): Protector and universal joint.

2 - BYADJUSTING THE STROKE OF THE PISTONS

(In2ways,manualorelectric)

- Manually(gure7):

The VOLUX or SUPER VOLUX pump features

twograduateddialsontheleft-handside,together

with an index.

The position of this index indicates the volume/

hectare when multiplied by 100.

Example:

If the index is on 5, the pump is set at 500 l/ha.

Settingtheindex(2):

▪Aspecial wrench and pin are used to adjust the

index.

Thewrench(1)isttedonthepumpshaft.

The pin (3) is inserted in the holes located on

the dial support ring (4).

▪Loosen the 2 nuts (5).

▪While maintaining the shaft with the wrench (1),

pivot the dial with the pin (3) and move it to the

desired graduation.

▪Tighten the 2 nuts (5).

▪Remove the wrench (1) and the pin (3).

- Electric programming (option):

The stroke of the Volux pump pistons is adjusted

using the TELEVOLUX control box (gure 8).

(See manual No. 82.470).

ENGAGEMENT/DISENGAGEMENT OF THE VOLUX PUMP

-Usetheengage/disengageswitchorselector(1)(gure8)locatedontheTELEVOLUXcontrolpanel(indicator

on).

CAUTION: When not used for spraying operations, the VOLUX pump must be disengaged.

(Actuate the switch or the electric selector (1)). Never engage or disengage the VOLUX

pumpwhiledriving.

Boom

width

Required

owrate/hectare

Position of the

lever(3)(gure6)

12 metres from 0 to 700 l/ha 1 - Tortoise

from 700 to 1300 l/ha 2 - Hare

15 metres from 0 to 560 l/ha 1 - Tortoise

from 560 to 1000 l/ha 2 - Hare

16 metres from 0 to 530 l/ha 1 - Tortoise

from 530 to 950 l/ha 2 - Hare

18 metres from 0 to 470 l/ha 1 - Tortoise

from 470 to 830 l/ha 2 - Hare

20 metres from 0 to 425 l/ha 1 - Tortoise

from 425 to 750 l/ha 2 - Hare

21 metres from 0 to 400 l/ha 1 - Tortoise

from 400 to 700 l/ha 2 - Hare

24 metres from 0 to 350 l/ha 1 - Tortoise

from 350 to 650 l/ha 2 - Hare

28 metres from 0 to 300 l/ha 1 - Tortoise

from 300 to 550 l/ha 2 - Hare

30 metres from 0 to 280 l/ha 1 - Tortoise

from 280 to 500 l/ha 2 - Hare

Boom

width

Required

owrate/hectare

Position of the

lever(3)

20 metres from 0 to 535 l/ha 1 - Tortoise

from 535 to 950 l/ha 2 - Hare

21 metres from 0 to 510 l/ha 1 - Tortoise

from 510 to 905 l/ha 2 - Hare

24 metres from 0 to 450 l/ha 1 - Tortoise

from 450 to 800 l/ha 2 - Hare

28 metres from 0 to 380 l/ha 1 - Tortoise

from 380 to 680 l/ha 2 - Hare

30 metres from 0 to 360 l/ha 1 - Tortoise

from 360 to 630 l/ha 2 - Hare

32 metres from 0 to 335 l/ha 1 - Tortoise

from 335 to 600 l/ha 2 - Hare

36 metres from 0 to 300 l/ha 1 - Tortoise

from 300 to 525 l/ha 2 - Hare

Flowrate/hectaretable

for VOLUX pump

Flowrate/hectaretable

for SUPER VOLUX pump

82.503 TRACKER / TRACKER-S D.P.A 19

2

45

3

1

8

6

7

56

4

3

1

2

BERTHOUD

L

VALID

INSERT

DIRECT

REDUCTION

L / ha

TELEVOLUX

I

0

00

0

1

L

VALID

INSERT

DIRECT

REDUCTION

L / ha

I

0

0

0

M

1

20 82.503 TRACKER / TRACKER-S D.P.A

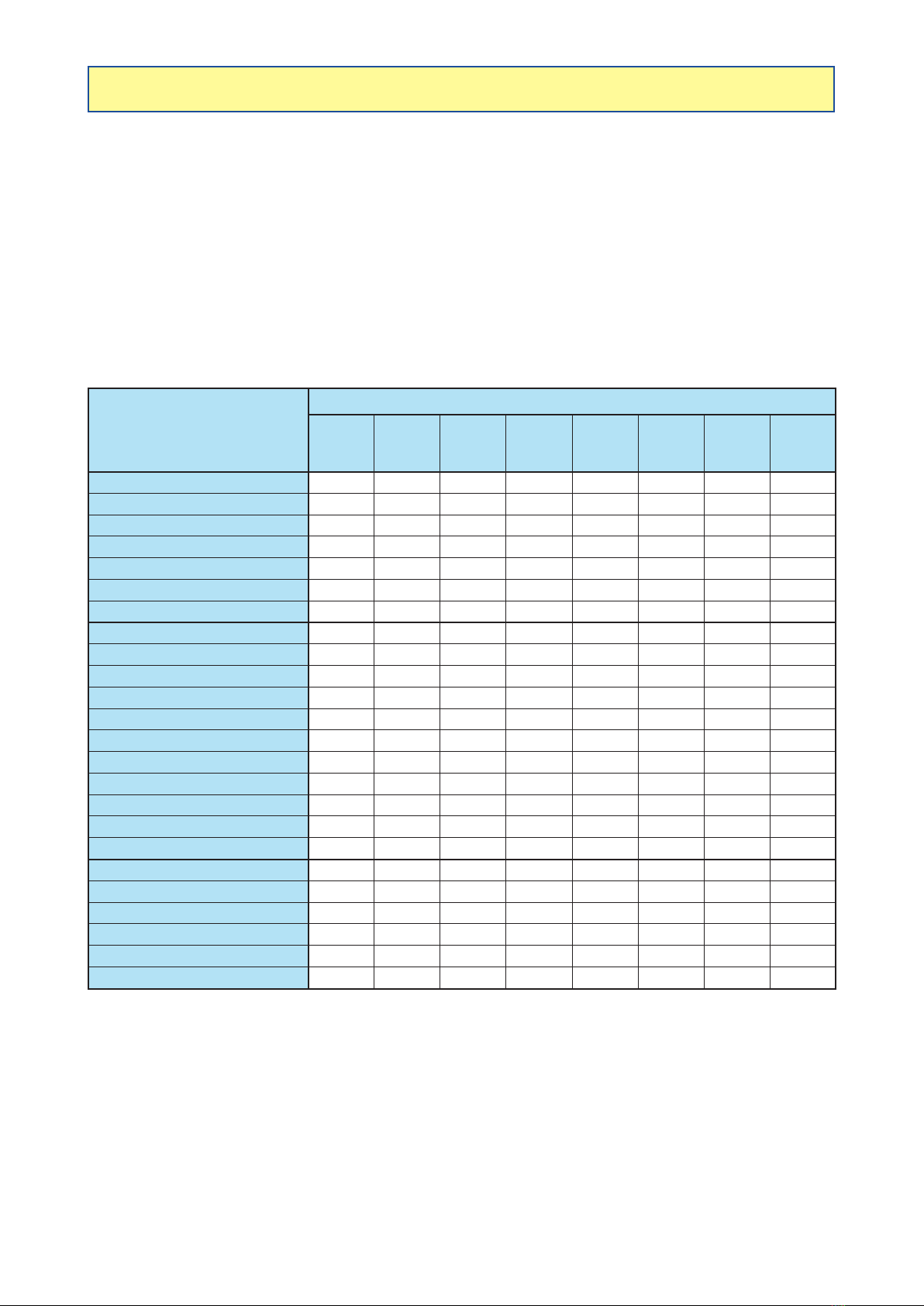

ADJUSTMENT OF THE COMPENSATED RETURN (V.M.m)

SETTING OF TRACKER D.P.A USING MULTIRETURN UNITS

-Inthiscase,theTRACKERdistributorunitismadeupofmotorisedvalves(V.M.m)(4)(gure9)foreachboom

section.

- These valves supply each boom section when they are in "open" position and the return to the tank when

they are in "closed" position.

-

Return to the tank is calibrated by means of multireturns.

- The setting of the multireturns to the tank is set using the table below because this will depend on nozzle type

used and the number of nozzles per boom section.

TABLE FOR SETTING OF MULTIRETURN UNITS

NOZZLE TYPE

Position of crownwheel (with red numbers)

6

nozzle

section

7

nozzle

section

8

nozzle

section

9

nozzle

section

10

nozzle

section

12

nozzle

section

15

nozzle

section

18

nozzle

section

AFX/RFX/ALX/KWIX - green 80° 1.7 2.0 2.2 2.4 2.5 2.8 3.1 3.5

AFX/RFX/ALX/KWIX - yellow 80° 2.2 2.4 2.6 2.8 3.0 3.3 3.7 4.1

AFX/RFX/ALX/KWIX - blue 110° 2.8 3.0 3.3 3.5 3.7 4.1 4.6 5.1

AFX/RFX/ALX/KWIX - red 110° 3.3 3.5 3.8 4.2 4.3 4.8 5.4 6.0

AFX/RFX/ALX/KWIX - brown 110° 3.7 4.0 4.3 4.6 4.9 5.4 6.1 6.8

AFX/RFX/ALX/KWIX - grey 110° 4.1 4.4 4.8 5.1 5.4 6.0 6.8 7.6

AFX/RFX/ALX/KWIX - white 110° 4.8 5.2 5.6 6.0 6.4 7.0 8.0 8.9

INOX 6/10 - white propeller 0.7 0.8 0.9 1.1 1.2 1.4 1.7 2.0

INOX 8/10 - white propeller 0.9 1.1 1.3 1.4 1.6 1.8 2.2 2.5

INOX 10/10 - white propeller 1.2 1.4 1.6 1.8 1.9 2.2 2.5 2.8

INOX 12/10 - white propeller 1.5 1.8 2.0 2.2 2.3 2.6 2.9 3.2

INOX 15/10 - white propeller 1.9 2.1 2.3 2.5 2.6 2.9 3.3 3.6

INOX 18/10 - white propeller 2.3 2.5 2.7 2.9 3.1 3.4 3.8 4.2

INOX 15/10 - black propeller 2.7 2.9 3.1 3.3 3.5 3.9 4.4 4.9

INOX 18/10 - black propeller 3.1 3.4 3.6 3.9 4.1 4.6 5.2 5.7

INOX 20/10 - black propeller 3.4 3.7 4.0 4.2 4.5 5.0 5.7 6.3

INOX 25/10 - black propeller 3.7 4.0 4.3 4.6 4.9 5.4 6.1 6.7

INOX 30/10 - black propeller 4.2 4.6 5.0 5.4 5.6 6.3 7.0 7.8

KWIX 3-holes - yellow 2.2 2.4 2.6 2.8 3.0 3.3 3.7 4.1

KWIX 3-holes - blue 2.8 3.0 3.3 3.5 3.7 4.1 4.6 5.1

KWIX 3-holes - red 3.3 3.5 3.8 4.2 4.3 4.8 5.4 6.0

KWIX 3-holes - brown 3.7 4.0 4.3 4.6 4.9 5.4 6.1 6.8

KWIX 3-holes - grey 4.1 4.4 4.8 5.1 5.4 6.0 6.8 7.6

KWIX 3-holes - white 4.8 5.2 5.6 6.0 6.4 7.0 8.0 8.9

SETTING THE MULTIRETURN UNITS (gure9)

- Slacken nut (1).

- Turn crownwheel (2).

- Place selected mark in front of index (3).

- Tighten nut (1).

Example:

If RedAFX/RFX/KWIX nozzles are used, and if your sprayer is equipped with a boom of 24 metres (4 sections

of 12 nozzles), you must place the multireturn units at position 4.8.

This manual suits for next models

1

Table of contents

Other Berthoud Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Nutriculture

Nutriculture Amazon Aeroponic System Assembly and operating instruction

Colombo

Colombo Twin Master owner's manual

Holzmann

Holzmann HUB25KG user manual

Aitchison

Aitchison Reese Agri UFO SEEDKING Professional manual

GREAT PLAINS

GREAT PLAINS 1205NT Predelivery Manual

Degelman

Degelman Pro-till 26 quick start guide