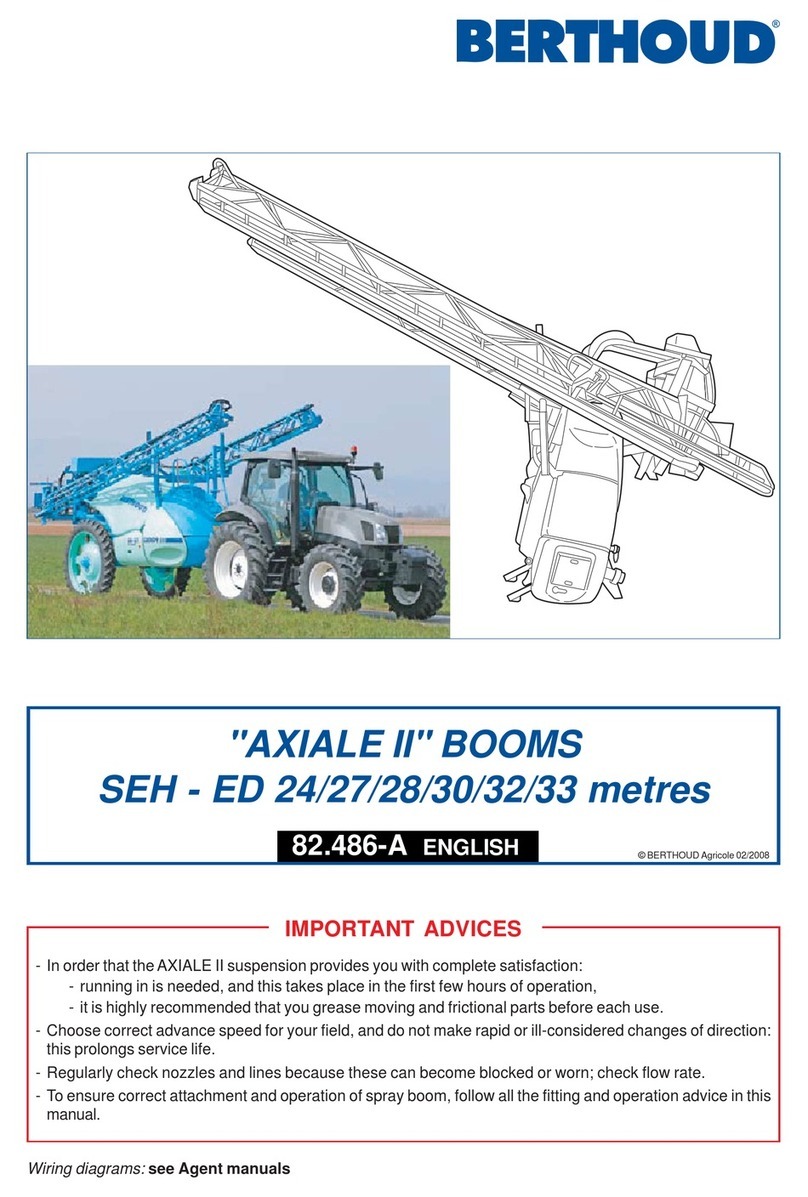

Berthoud BOXER II 3000 A User manual

1

BOXER II - 3000/4000 A Front boom

D.P. TRONIC regulation

(Electronic proportion flow control)

82.428-E ENGLISH

to be read attentively

and kept for further reference

03/2005

Safety, checking,sprayers maintenance : see manual N° 82.471

Nozal nozzles : see manual N° 82.467 AXIALE boom : see manual N° 82.438

DPTronic regulation : see manual N° 82.465 EKTAR boom : see manual N° 82.461

82.471

82.467

82.465

82.438

82.461

2

3

See pages

- GENERAL (see manual N° 82471)

. Technical characteristics of the Boxer 3000/4000A ................................ 7

. Warning................................................................................................... 8

. Descriptive plate ...................................................................................... 9

. Table of weights....................................................................................... 9

. Dimensions.............................................................................................. 10

. Position of safety stickers........................................................................ 11

- STARTING-UP THE SPRAYER (see manual N° 82471)

. Rinsing the equipment before first use .................................................... 14

- CHOICE OF NOZZLES AND TABLES OF FLOW RATES

(see manual N° 82471)

. Presentation of thecontrol box................................................................. 16

- MAIN SPRAYER FUNCTIONS WITH THE DELTAPUMP

. Filling ...................................................................................................... 18/19

. Transferring ............................................................................................. 18/19

. Rinsing the main tank with mains water .................................................. 18/19

. Rinsing the main tank with the rinse tank................................................ 18/19

. Rinsing the spraying circuit with the rinse tank ....................................... 18/19

. Rinsing the spraying circuit with the main tank ....................................... 18/19

- OTHER SPRAYER FUNCTIONS

. Incorporation hopper ............................................................................... 22/23

. Spraying function (agitation).................................................................... 24/25

. Electric gauge ......................................................................................... 26/27

. Handwash tank ........................................................................................ 26/27

. Rinse tank................................................................................................ 26

. Height of the boom .................................................................................. 28

. Agitation................................................................................................... 28

. Foaming into the tank .............................................................................. 28

. Last filling operation................................................................................. 28

. Draining the tank ..................................................................................... 28/29

- BOOM FOLDING/UNFOLDING FUNCTION

(see boom manuals N°82438 and N° 82461)

- MAINTENANCE OF SPRAYING EQUIPMENT (see manual N° 82471)

. Practical recommendations for maintening your sprayer......................... 32

. Checks before spray season ................................................................... 32

. Maintenance after operation .................................................................... 33

. Winter storage ......................................................................................... 33

. Nozzles or filters dirty .............................................................................. 34

. Delivery filter ............................................................................................ 34/35

. Servicing the boom .................................................................................. 36

. Servicing the pump .................................................................................. 36

CONTENTS

- MAINTENANCE DIAGRAMS

. Hydraulic circuits ..................................................................................... 40

. Wiring diagrams ...................................................................................... 41/44

. Notes on parameters ............................................................................... 45

. Notes on treatments ................................................................................ 46

4

5

GENERAL

AND

SAFETY

warning.

Acceptable use of the sprayer.

General safety instructions.

Maintenance.

Counterindications.

Meaning of the safety stickers.

See manual «Safety, Control, Maintenance» N° 82471

6

7

SELF PROPELLED SPRAYER

- Self propelled base with IVECO Diesel engine liquid

cooled. 6 cylinders, 163 HP, 5.9 liters.

(optionengineIVECO6 cylinders, 200 HP,5.9liters).

- Welded frame in square profile.

- GRP tank with flotting gauge, capacity 3000/4000

liters + 5% with baffle and separate 400-liter rinsing

tank.

- Diesel tank 210 Iiters. Oil tank 105 liters.

- Ground clearance 1.15 m (option 1.30 m).

- Fixed track width 1.80 m to 2.70 m.

(in option: Variable wheel track by sliding axles

1.80 m to 2.25 m or 2 m to 2.40 m).

- Wheelbase 3.65 m.

- 4 wheel drive by hydrostatic drive POCLAIN with

brakes et variable delivery pump REXROTH and

hydro-mecanic locking system.

- 4wheelsteeringwithhydrostaticsteeringbyOrbitrol

DANFOSS.

- Wheels 270/95 R 48 adjustable rims

(options: 300/95 R 46 - 460/85 R 38 - 480/70 R 38 -

520/70 R 38 - 520/85 R 38 - 580/70 R 38).

- Speed road: 27.5 km/h. Speed field: 13.7 km/h.

- Hydraulic brakes on the rear wheels.

- Multicontrol joystick for forwad speed, spraying,

boom height and angle control (option for variable

geometry).

- Protected under frame.

- Panoramic pressurized/heated cab, FM/tape radio,

tinted windows, UTAC-approved windshield. Two

activated carbon filters.

- Lighting in compliance with the Highway Safety

Code.

- Gyrolight.

- Pneumatic seat.

- Sound alarm for rear movement.

- Double external control of engine speed. Double

external control of PTO.

- Two front and rear work lamps.

Options on Self propelled sprayer:

Air compressor equipment with air blow gun.

SPRAYING EQUIPMENT for

SELF-PROPELLED BOXER 3000/4000 A

Dual-turbine, rotary DELTA pump for double output,

enabling:

- Filling, agitation, rinse, transfert and spraying.

- Double filtering system:

- filling filter (sieve 8/10° mesh),

- delivery filter (1/4 turn filter, 4/10° mesh).

- Chemical hopper fitted on parallelogram.

- Nivelec gauge.

- Berlogic: Display of valve handle positions of the

various functions.

- Electronic regulation D.P.TRONIC with saved

memory.

- In cab, unic control box with:

- Control display.

- Simple cumuls management and cumuls

management on 10 fields.

- Spraying remote control by:

- 4 motorised valves with stainless steel ball

(AXIALE 24/28 and variable geometry),

- 5 motorised valves with stainless steel ball

(AXIALE 30 variable geometry, EKTAR 30,

EKTAR 32),

- 6motorisedvalves(EKTAR36andEKTAR38),

- 7 motorised valves (EKTAR 42),

- 8 motorised valves (EKTAR 40).

AXIALE Booms:

- Axiale 24, Axiale 24 variable geometry, Axiale 28,

Axiale 28 variable geometry, Axiale 30 variable

geometry, fitted on the front.

- Axiale suspension on pivot with springs and

oscillation shock absorbers.

- Independent folding of outer arms. Angle corrector.

7 rams on Axiale 24 and Axiale 28.

- Independent folding of outer arms. Angle corrector.

Variable geometry. 9 rams onAxiale 24/28 variable

geometry, Axiale 30 variable geometry.

- QUADRIX nozzle holder.

- 2 sets of nozzles KWIX Alumine AFX 110° Yellow

and Blue,

2 sets of liquid fertilizer nozzles KWIX Trifilet Red

and Brown.

EKTAR Booms:

- EKTAR 30, EKTAR 32, EKTAR 36, EKTAR 38,

EKTAR 40, EKTAR 42, fitted on the front.

- Pendulum suspension.

- Independent folding of outer arms. Angle corrector.

Variable geometry. 11 rams and 9 electro-hydraulic

spool valves.

- QUADRIX nozzle holder.

- Nozzles KWIX AlumineAFX 110°.

Options on spraying equipment

of BOXER 3000/4000 A:

- 6, 7, 8, 9 or 10 motorised valves with stainless

steel ball.

- Pneumatically-controlled anti-drip system.

- GESTRONIC control box, management of 99 fields,

filling programming an end of operation alarm or

auto-stop.

TECHNICAL CHARACTERISTICS

8

are therefore essential operations, and you have

every reason to carefully read the details in this

booklet.

"This sprayer has been manufactered using

materials which withstand most plant protection

chemicals currently available on the market.

Nevertheless, BERTHOUD cannot assume

responsibility for any damage resulting from an

incompatibilitty of the crop protection chemicals

or product mixtures with the plastic materials:

(polyethylene, polyvinyl chloride, polypropylene,

Vitton, nitrile polyamide)."

WARNING

Successful treatment depends on correct

operation of your sprayer.

Correct operation depends on accurate

calibration of the equipment, and this requires

careful checking.

When this checking has been undertaken, the

sprayer must be starting-up correctly, this also

being necessary for correct spraying and

operation.

Finally, to be certain that your sprayer can give

you the performance you expect, for a long time,

make sure that you undertake the maintenance

operations required.

CHECKING, STARTING-UP,

OPERATION, MAINTENANCE

PRECAUTIONS WHEN WELDING

When performing welding operations on your

self-propelled sprayer unit, DISCONNECT

the batteries + and – terminals.

It is imperative that the spraying pump be

started with the motor at idle speed.

Because of our policy of constant product improvement,

we reserve the right to modify product specifications or design without prior notice.

9

The "Kerb weight" and "Gross vehicule weight"

boxes use the datas in the table below.

DESCRIPTIVE PLATE

- The location of the descriptive plate on your machine is indicated on the view 3/4, see page 11.

- The box "Type" is made up of letters and figures.

- Example : BOX E 30 SX 28

Year and month of manufacture

The box "N° of series" is made up of 6 figures.

Example : 97 1042 = order number.

28 = width 28 meters (or 24, 30, 32, 36, 38, 40, 42 meters).

SX = AXIALE boom (or EK = EKTAR boom).

30 = Tank capacity 3000 liters (or 40 = 4000 liters ).

E = D.P. TRONIC regulation.

BOX = Self-propelled BOXER.

TABLE OF WEIGHTS

1, rue de l’industrie

69220 BELLEVIE SUR SAONE - FRANCE

EQUIPM ENT BOOM > AXIALE

24 GV AXIALE

28 GV AXIALE

30 GV EKTAR

30 GV EKTAR

32 GV EKTAR

36 GV EKTAR

38 GV EKTAR

40 GV EKTAR

42 GV

KERB

WEIGHT

GROSS

MACHINE

WEIGHT 12400 kg 12400 kg 12400 kg 12400 kg 12400 kg 12400 kg 12400 kg 12400 kg 12400 kg

KERB

WEIGHT 7250 kg 7580 kg 7591 kg 7640 kg 7650 kg

GROSS

MACHINE

WEIGHT 13440 kg 13440 kg 13440 kg 13440 kg 13440 kg 13440 kg 13440 kg 13440 kg 13440 kg

BOXER II

3000 A

4 wheel drive

BOXER II

3000 A

4 wheel drive

10

DIMENSIONS

A

1.80to2.70m

B

C

D

E

GFH

BOOMSSPRAYERS DIMENSIONS (in meters)

ABCDEFGH

2.60

2.60

2.95

2.95

2.95

2.99

2.99

2.99

2.99

2.60

2.60

2.95

2.95

2.95

2.99

2.99

2.99

2.99

11.13

7.28

11.13

3.90

4.31

3.90

1.615

1.52

1.615

5.43

1.55

5.43

1.15

1.15

1.15

1.15

1.15

1.15

1.15

1.15

1.15

1.30

1.30

1.30

1.30

1.30

1.30

1.30

1.30

1.30

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

2.00

2.00

2.00

2.00

2.08

2.00

2.00

2.00

2.00

BOXER 2

3000 A

4 wheel drive

AXIALE 24

AXIALE 28

AXIALE 30

EKTAR 30

EKTAR 32

EKTAR 36

EKTAR 38

EKTAR 40

EKTAR 42

AXIALE 24

AXIALE 28

AXIALE 30

EKTAR 30

EKTAR 32

EKTAR 36

EKTAR 38

EKTAR 40

EKTAR 42

BOXER 2

4000 A

4 wheel drive

11

POSITION OF SAFETY STICKERS

It is very important to keep the safety stickers in location and in good condition as they draw your

attention to possible dangers and refer to the operator's manual.

See the following pages and check their location on the sprayer.

417.465 417.576

Onthehandwashtank

Inthecab

417.586 417.572

417.575

418.630

Onthehopper

1, rue de l’industrie

69220 BELLEVIE SUR SAONE - FRANCE

12

13

STARTING-UP

THE SPRAYER

Checking forward speed.

Checking sprayer wheel circumference.

Checking flow/hectare.

see manual «Safety, Checking, sprayer maintenance» N° 82471

14

RINSING THE SPRAYER BEFORE FIRST USE

Before using your sprayer for the first time with phytosanitary product (weedkillers,

insecticide or other product), rinse the machine completely.

- Remove the nozzles if they are fitted.

- Undo the end plugs on the pipes.

- Fill 1/5th of the volume of the tank with water.

- Spray (Refer to the pump OPERATION chapter).

- Remove and clean the filter.

- Retighten the pipe end nuts.

- Fit the nozzles.

- Any foreign particles which may be in the spraying circuit will thus be eliminated and there will be no risk of

them blocking the holes in the nozzles.

15

CHOICE OF NOZZLES

AND

TABLES OF FLOW RATES

see manual N° 82467

«NOZAL nozzles»

D.P. TRONIC REGULATION

voir notice N° 82465

«D.P.Tronic regulation»

16

I0

PRESENTATION OF THE CONTROL BOX

NOTE

- Fuse: The control box (2) is protected by 3 fuses: diam. 5 x 20 mm:

- 5 Amps for the D.P. TRONIC electronic board (3),

- 10 Amps for the boom control board (4),

- 10 Amps for the boom spraying sections board (5).

Display

Electronic regulation

switches

(see manual 82465)

Control box power

switch

Manual spraying

regulator valve

switch control

7

1

Control switches for

boom

(seemanual:

AXIALE boom N° 82438

EKTAR boom N° 82461)

Plugs

2

4

3

5

6

Manual/automatic mode

switch for regulator valve

Control switch for spraying

(see pages 34 to 39)

17

MAIN SPRAYER FUNCTIONS

WITH

THE DELTA PUMP

ALL THE VALVE OPERATIONS MUST BE DONE WITH THE ENGINE STOPPED.

POWER UP THE CONTROL BOX.

18

FUNCTIONS PUMP (figure 6)

FILLING 1

- Check that the draining orifice is closed (figure 15, page 29).

- Fill the centrifugal pump priming tank with water. To do this, draw the hexagon socket head screw (1) located

on the upper part of the pump body (figure 5).

- Filling without incorporation hopper using:

- Connect the filling pipe (T1) on the quick-fitting union (4).

- Turn all the valve handles to position .

- Put the pipe (T1) into the liquid to be suck.

- Trip the switch which enables the spraying pump to be engaged.

- Engine speed should kept high enough to permit the filling operation (approximately 2,500 rpm).

When the filling operation is finished, turn valve handle (4) to horizontal position, disconnect the filling

pipe (T1), replace the plug on the quick-fitting union.

- Filling with incorporation hopper using: (see page 22)

TRANSFERRING 6

- To transfer the liquid contained into the tank to another one, proceed as follows:

- Connect the transferring pipe (T2) to the quick-fitting union (7).

- Turn all the valve handles to position .

- Trip the switch which enables the spraying pump to be engaged.

- Engine speed should kept high enough to permit the filling operation (approximately 2,500 rpm).

RINSING THE MAIN TANK WITH MAINS WATER 7

- Pump stopped:

- Connect the mains water hose (T3) to the quick connector (6).

- Turn all the valve handles to position .

- Open the water supply.

- Drain the tank (figure 15, page 29).

RINSING THE MAIN TANK WITH THE RINSE TANK 8

- Pump stopped:

- Turn all the valve handles to position . NOTE: For valve No. (2) place the handle in the "dashed"

position during 2 minutes, then turn the handle to the normal position .

- Power up the control box, (reference 1, figure 11, page 25).

- Stop spraying: switches (2) and (4) (figure 11, page 25).

- Trip the switch which enables the spraying pump to be engaged.

- Engine speed should be held at 1,400 rpm for proper rinsing.

- Drain the tank (figure 15, page 29).

RINSING THE SPRAYING CIRCUIT WITH THE RINSE TANK 9

- Pump stopped:

- Turn all the valve handles to position .

- Power up the control box, (reference 1, figure 11, page 25).

- Open spraying: switches (2) and (3) (figure 11, page 25).

- Trip the switch which enables the spraying pump to be engaged.

- Engine speed should be held at 1,400 rpm to obtain proper rinsing pressure.

This operation is not enough when changing chemical products.

RINSING THE SPRAYING CIRCUIT WITH THE MAIN TANK

- When changing chemical product.

- Put 300 liters of clear water with a cleaning product (All Clear type) in the main tank.

- Turn all the valve handles to position (pump startup) during 1 minute.

- Then, turn all the valve handles to position (hopper) except valve (6) which is to be placed in position

during 1 minute.

- Finish by turning all the valve handles to position (spraying).

- In the 3 cases:

- Power up the control box (reference 1, figure 11, page 25).

- Program the control box on CONSTANT PRESSURE (3 bar) (see manual N° 82465).

- Open spraying: switches (2) and (3) (figure 11, page 25).

- Trip the switch which enables the spraying pump to be engaged.

- Engine speed should be held at 2,500 rpm to obtain proper rinsing pressure.

1

6

7

888

9

11

84

2

19

RIN‚AGECUVE

AVECEAUDU

RESEAU

RIN‚AGECUVE

AVECCUVEDE

RIN‚AGE

RIN‚AGE

CIRCUITDE

PULVERISATION

NETTOYAGE

FILTREDE

REFOULEMENT

DEMARRAGE

POMPE

REMPLISSAGE

10

9

8

7

6

1

2

3

4

5

11

TREMIE

ASPIRATION

CUVE

TREMIE

ASPIRATION

EXTERIEUR

PULVERISATION

AVEC

BRASSAGE

PULVERISATION

SANS

BRASSAGE

P.D.F.ARRETEE

P.D.F.3000tours/min

P.D.F.3000tours/min

P.D.F.ARRETEE

TRANSFERT

45

11

9

6

7810

910

45

11

245

11

6

4

12

83

1235

78911 6

13

8

245

11 6

123456

91011

2345

78910

7

6

1

11

13

7

78910

89

236

7

1

8

10

10

76

4

1

2

7

3

5

5

1

6

○○○○○○○○○○

T1T3T2

20

This manual suits for next models

1

Table of contents

Other Berthoud Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions