Contents

Contents

Chapter 1 PoductInformation.................................................. 1

1-1 Safely Information................. ...... ...... .... ........ ...................................1

1-2 Name plate............................................................................................1

1-3 Technical Specifications.........................................................................5

Chapter 2 Installation of frequency inverter.......................... 6

2-1 Installation environment.........................................................................6

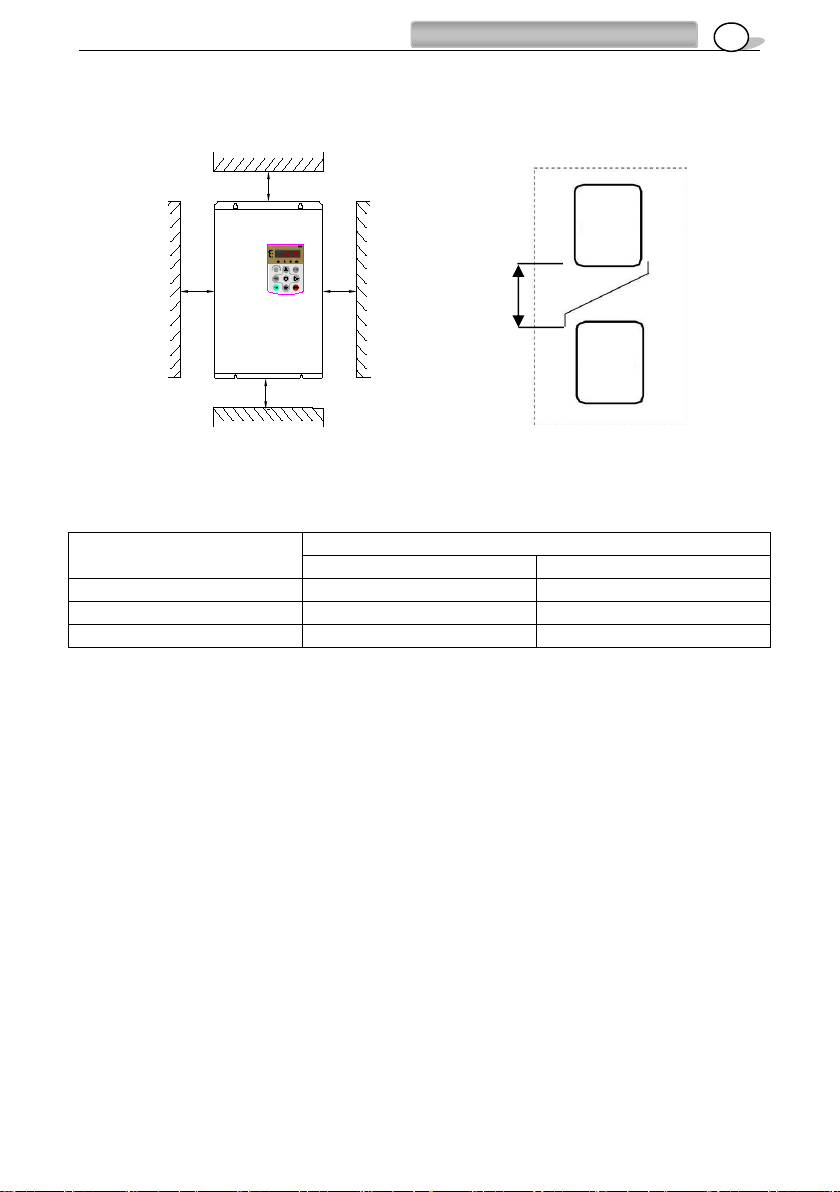

2-2 Installation direction and space..............................................................6

Chapter 3 Wiring.........................................................................8

3-1 Peripheral device connection..................................................................8

3-2 Standard wiring diagram.........................................................................9

3-3 Main circuit terminal description..............................................................10

3-4 Control circuit terminal description..........................................................12

Chapter 4 Keyboard operation..................................................14

4-1 Description of the keyboard panel..........................................................14

4-2 Function code modification, view instructions.........................................15

Chapter 5 Function Code...........................................................18

5-1 Standard function code...........................................................................18

5-2 Monitoring parameter .............................................................................48

Chapter 6 Parameter instruction................................................49

Group P0 Basic function group......................................................................49

Group P1 Motor 1 parameter.........................................................................57

Group P2 Vector control parameter...............................................................60

Group P3 V/F control parameter....................................................................63

Group P4 Input terminal.................................................................................69

Group P5 Output terminal..............................................................................80

Group P6 Start/Stop Control Parameters......................................................86

Group P7 Keypad display..............................................................................90

Group P8 Auxiliary Functions........................................................................93

Group P9 Fault and Protection......................................................................103

Group PA Process Control PID Function......................................................111

Group PB Swing Frequency, Fixed Length and Count.................................116