BESTEAM Bestis 1000 Operating instructions

Bestis 1000-10000

User – and Maintenance Manual

Version 1.5

2

EU DECLERATION OF CONFORMITY

WE HEREBY ASSURE THAT THE MACHINE DESCRIBED

BELOW IS MANUFACTURED IN ACCORDANCE WITH EU-

MACHINERY DIRECTIVE 2006/42/EY.

THIS DECLERATION IS NOT VALID, IF MODIFICATIONS

OR REFORMATIONS ARE MADE TO THE MACHINE THAT

ARE CARRIED OUT BY OTHER THAN THE

MANUFACTURER OF THIS MACHINE OR A

REPRESENTATIVE OF THE MANUFACTURER.

BESTEAM OY

Nyrhintie 7

FIN-28760 PORI

Tel. (02) 631 9102

Fax. (02) 631 9101

Machine Description:

Bestis Welding Positioner

Model Bestis Welding Positioner

The Year of Manufacture 2014

Applied Directives EU Machinery Directive 2006/42/EY

(government decree 400/2008)

Harmonized SFS-EN 349, SFS-EN 418, SFS-EN

982,

EN norms SFS-EN 1037, SFS-EN 1050, SFS-EN

1088, SFS-EN 60204-1, SFS-EN

12100-1, SFS-EN 12100-2

In Pori, Finland 22.8.2014

Ilpo Salminen

Managing Director

3

CONTENTS

1 GENERAL....................................................................................................................... 5

2 SAFETY INSTRUCTIONS............................................................................................. 6

3 INSTALLMENT AND DEPLOYMENT........................................................................ 7

3.2 Deployment............................................................................................................... 7

4 USER GUIDE................................................................................................................ 11

4.1 Mounting the workpiece ......................................................................................... 11

4.2 Controlling devices................................................................................................. 11

4.2.1 Main central ..................................................................................................... 11

4.2.2 Remote control................................................................................................. 12

4.2.3 Foot switch....................................................................................................... 13

4.3 Using the load chart and load calculation............................................................... 14

5. ERROR NOTIFICATIONS......................................................................................... 15

5.1. The machine`s start button`s light is blinking rapidly........................................... 15

5.2. The machine`s start button`s light is blinking slowly............................................ 15

5.3. The machine`s start button`s light is blinking irregularly...................................... 15

5.4. The machine`s start button`s light is not on........................................................... 15

6 MAINTENANCE.......................................................................................................... 16

6.1 Maintenance-, check up- and cleaning tasks........................................................... 16

6.2 Maintenance of the electrical device....................................................................... 16

6.3. Maintenance of the hydraulics............................................................................... 17

6.4. Maintenance of the mechanics............................................................................... 17

4

READ FOLLOWING NOTIFICATIONS WITH CARE

BEFORE YOU USE THE WELDING POSITIONER!!

BE CAUTIOUS AND COMPLY WITH GENERAL INSTRUCTIONS GIVEN ON

LIFTING WORKING!!

THE WORKPIECE MUST BE ELECTRICALLY GROUNDED. ALLWAYS USE

THE MACHINE`S OWN ELECTRICAL GROUND CONNECTION AND

FURTHER GROUND-CONNECT DIRECTLY TO THE WORKPIECE, IF

WELDING CURRENT EXCEEDS 500 AMPERES OR THE PIECE IS LARGE.

USE GROUND

CAPLE 70-95 (ABI-

CM 70-95 OR

EQUIVALENT) TO

THE MACHINE`S

OWN GROUND

CONNECTION

CHECK THE SUFFICIENT GROUND CONNECTION OF THE WORKPIECE

BEFORE BEGINNING TO WELD. THE MANUFACTURER IS NOT

RESPONSIBLE FROM CONSEQUENCES RESULTING FROM AN ABSENCE

OF GROUND CONNECTION NOR INSUFFICIENT OR INCORRECT GROUND

CONNECTION.

THE WELDED WORKPIECE MUST NOT TRANSFER HEAT TO THE TABLE

PLATE. THIS IS TO PREVENT DAMAGES FROM OCCURRING TO THE

MACHINE BEARING DUE TO THE THERMAL EXPANSION.

WELDING DIRECTLY TO THE TABLEP LATE IS STRICTLY PROHIBITED!

THE WELDING POSITIONER MUST BE CONNECTED TO A PLUG THAT

CONTAINS RESIDUAL-CURRENT DEVICE!

COMPLY WITH USER MANUAL AND LOAD CHART WITHIN THE MACHINE.

CAREFULLY GET TO KNOW THE LOAD CALCULATION PRACTICES.

5

1 GENERAL

Bestis- welding positioners have been designed for effective handling of different

kinds of workpieces and materials. The welding positioner lifts, tilts and rotates

workpieces to a position, where for example welding, assembling and surface

finishing are carried out in a best manner. If the machine is used in a different

purpose, please ensure its` applicability to this purpose by contacting the

manufacturer or manufacturer`s representative.

The positioners of Bestis- product family have three-axis setting: height, tilt angle

and rotation. The rotation, height adjustment and tilting are carried out by

operating with light-weight remote control. All the models have been

manufactured in accordance with the work safety regulations of the EU.

1. Machine frame

2. Lifting bar

3. Rotation equipment

4. Table plate

5. Tilting cylinder

6. Lifting cylinder

7. Hydraulic set

8. Main central

Note! Because of the work safety reasons, the manufacturer recommends to use

lifting brackets (4 brackets), that are located in the corners of the machine, when

lifting the machine. If the customer demands to install a bracket to the middle of

the machine, using this bracket is at customer`s own liability and risk.

6

2 SAFETY INSTRUCTIONS

The user of the welding positioner ultimately is in charge of the safety

precautions that concerns the user or other people next to the machine. Only

persons that are familiar with the functions of the machine are allowed to operate

the machine, and the given instructions must be applied. We recommend that the

person operating the machine should possess the occupational safety card.

Operating the machine incorrectly resulting in incorrect functions or incorrect

functioning segment might cause an abnormal situation, in which the user as well

as the equipment may be damaged. All types of working, standing, walking etc.

under the workpiece is strictly forbidden.

1. Everyone operating the machine must be well aware of

•operating the machine and correct electrical grounding

•the location of the EMERGENCY SWITCH-OFF (HÄTÄSEIS)

•functions of the machine

•valid work safety regulations

2. Before starting the machine, it must be attended that

•the work area contains no people, who have not been assigned to

work with the machine

•nobody is looking directly at the electric arc

•the electrical grounding has been carried out in accordance with the

given instructions

3. The workplace must be

•suitable for using the machine

•clean and free of any random objects

4. Personal safety equipment

•always use instructed personal equipment, for example safety

goggles, fireproof clothes and safety gloves

•Be careful in using baggy clothes, belts, bracelets etc. that may get

stuck with the machine or workpiece

5. General

•Check that the ground cable has been sufficiently connected and

especially that there no loose connections

•Only the experts of electrical engineering are allowed to fix and

maintain electrical devices

•The necessary fire protection and prevention equipment must

accessible from a place clearly marked

•Lubrication and maintenance of the machine is prohibited while

operating the machine; comply with the given maintenance

instructions

7

3 INSTALLMENT AND DEPLOYMENT

IMPORTANT!

Read all the machine manuals and safety instructions with care before unpacking

or installing of the machine!

NOTE! Make sure that installment is carried out by a qualified person.

3.1 Handling and storing the machine

The machine has been packed on platform suitable for lifting- and/or trucking

handling. The machine must be lift from the 4 brackets located in the corners.

Unpack the machine and check its` visible condition. You are allowed to operate

and store the machine in humidity controlled facilities with a temperature over

+10 °C.

3.2 Deployment

READ THE FOLLOWING NOTIFICATIONS WITH CARE BEFORE THE

DEPLOYMENT:

BE CAUTIOUS AND COMPLY WITH GENERAL INSTRUCTIONS GIVEN ON

LIFTING WORKING!!

THE WORKPIECE MUST BE ELECTRICALLY GROUNDED. ALLWAYS USE

THE MACHINE`S OWN ELECTRICAL GROUND CONNECTION AND

FURTHER GROUND-CONNECT DIRECTLY TO THE WORKPIECE IF

WELDING CURRENT EXCEEDS 500 AMPERES OR THE PIECE IS LARGE.

USE GROUND

CAPLE 70-95 (ABI-

CM 70-95 OR

EQUIVALENT) TO

THE MACHINE`S

OWN GROUND

CONNECTION

8

CHECK THE SUFFICIENT GROUND CONNECTION OF THE WORKPIECE

BEFORE BEGINNING THE WELDING. THE MANUFACTURER IS NOT

RESPONSIBLE FROM CONSEQUENCES RESULTING FROM AN ABSENCE

OF GROUND CONNECTION NOR INSUFFICIENT OR INCORRECT GROUND

CONNECTION.

THE WELDED WORKPIECE MUST NOT TRANSFER HEAT TO THE TABLE

PLATE. THIS IS TO PREVENT DAMAGES FROM OCCURRING TO THE

MACHINE BEARING DUE TO THE THERMAL EXPANSION.

WELDING DIRECTLY TO THE TABLEP LATE IS STRICTLY PROHIBITED!

THE WELDING POSITIONER MUST BE CONNECTED TO A PLUG THAT

CONTAINS RESIDUAL-CURRENT DEVICE!

COMPLY WITH USER MANUAL AND LOAD CHART WITHIN THE MACHINE.

CAREFULLY GET TO KNOW THE LOAD CALCULATION PRACTICES.

1. Place the welding positioner on an even and sustainable ground that is

constructed from unbreakable concrete, whose material strength is 30 N / mm²

minimum.

2. Make sure that there is a sufficient working space around the machine. Also

notify the shapes and dimensions of the workpieces; the handling are of the

workpiece must be free from objects.

3. Get to know the technical data and performance regarding the machine, and

comply with them. Check the weight of the workpiece and its` centre of mass in

relation to the machine`s rotation and tilting axis (see the calculation instructions

and load chart).

4. Make sure that there is a free access to the work spot.

5. Connect the remote control cable to the connector in main central. Before

connecting, check that the main switch is in 0-position.

6. Check that the EMERGECY SWITCH-OFF –button in the remote control is

pressed down.

7. Connect the machine to an electrical grid.

•240/400 V 3-phase 16 A

8. Turn the power on from the main switch of the machine.

9

9. Lift or turn the remote control`s EMERGENCY SWITCH-OFF button up and

push the green start button, after which the green light should be seen in the

button.

10. Test the functions of the machine with the remote control before mounting the

workpiece.

•rotation

•tilt

•lift

11. For welding, connect the ground cable to the ground socket located in the

machine frame. The machine has one ground socket. If you weld with higher

welding current that 500 amperes, further ground-connect directly to the

workpiece.

12. After you have checked the functions of the machine, you may mount the

workpiece to the T-slot in the table plate. The workpiece should be mounted on

table plate in a way that the central mass of the workpiece is closest as possible

to the center of the table plate.

13. MAKE SURE THAT THE WORKPIECE IS WELL-MOUNTED IN THE TABLE

PLATE.

14. Make sure that there is sufficient free space to handle the workpiece. Do

consider the trajectories of the workpiece in different positions of the table plate..

15. You may begin working with the machine, but please continuously observe

the functions of the machine and the mounting of the workpiece.

17. After you have finished working with the workpiece, switch the machine off.

10

18. Make sure that the workpiece will not drop from the table plate, when

demounting the workpiece. Demount the fixtures and lift the workpiece from the

table plate with care, after making sure that the workpiece is no more mounted in

the table plate.

19. Clean the table plate after you have finished working with it.

11

4 USER GUIDE

4.1 Mounting the workpiece

•Mount the workpiece to the T-slots in the table plate using proper

mounting methods; for example using right-sized T-slot nuts.

•Make sure that the mounting is firm throughout the working process.

Secure the mounting regularly!

4.2 Controlling devices

4.2.1 Main central

1. Main switch

2. Start button

3. Selection switch for the foot switch functions

4. Foot switch socket

5. Remote control socket

6. Power socket

12

4.2.2 Remote control

All the machines come with voltage protected 24 V remote control. The machine

functions are set via remote control.

1. Lifting the table plate

2. Lower the table plate

3. Tilting the table plate forward

4. Tilting the table plate backward

5. Rotating the table plate clockwise

6. Rotating the table plate anticlockwise

Continuous clockwise rotation: Press button (5.) and hold it. Next press button

(6.) and release button (6.), after which you can release button (5.). After this the

table plate continuously rotates clockwise, during which the rotation speed can

be adjusted from the knob-controller located in the front end of the remote. The

continuous rotation is stopped by pressing buttons (5.), (6.) or . The continuos

anticlockwise rotation can be employed by following the procedure above in

reverse order.

AFTER AN EMERGENCY SWITCH-OFF SITUATION, IT MUST BE FIRST

ESTABLISHED THAT THE IS DANGER NO LONGER EFFECTIVE BEFORE

TURNING THE MACHINE ON!

DO NOT STEER THE WORKPIECE TO THE FLOOR.

WHEN ROTATING THE WORKPIECE, START WITH AS LOW SPEED AS

POSSIBLE ENSURING THAT THE BALANCE POSITION OF THE MACHINE

DOES NOT SHIFT. IF NEEDED, RAISE THE ROTATION SPEED; STILL

PAYING CLOSE ATTENTION TO THE BALANCE POSITION.

NOTIFY THE POSSIBLE DANGER AREAS CAUSED BY THE MACHINE AND

THE WORKPIECE. BE CAREFUL WITH THE MOVING PARTS OF THE

MACHINE AND ALWAYS FOLLOW THE MOVEMENT OF THE MACHINE

THROUGHOUT THE WORKING PROCESS.

13

ALWAYS USE THE NECESSARY SAFETY EQUIPMENT REQUIRED IN

DIFFERENT TASKS AND CIRCUMSTANCES.

SECURE THE MOUNTING OF THE WORKPIECE REGULARLY.

4.2.3 Foot switch

Connect the foot switch to the foot switch socket in main central (see section

4.2.1. Main central)

Once you have connected the foot switch, it is ready to be operated.

WHILE USING THE FOOT SWITCH, KEEP THE REMOTE CONTROL WITHIN

REACH. BY DOING SO, YOU ARE ABLE TO PRESS THE EMERGENCY

SWTICH-OFF BUTTON QUICKLY IN DANGER SITUATION!

1-position: The foot switch is connected to ON-OFF position. By pressing the

pedal, the rotation goes on and by pressing the pedal again, the rotation goes off.

You can change the rotation direction by using the remote control. After this

pressing the pedal results in rotating the table plate to chosen direction. Should

you change the rotation direction, repeat the above again. You can control the

rotation speed from the knob-controller in the remote control.

0-position: Foot switch is turned off.

2-position: The foot switch is turned to the accelerator position, where the

rotation speed of the table plate can be increased by pressing the pedal more.

Changing the rotation direction is done in similar manner as in the 1-position.

14

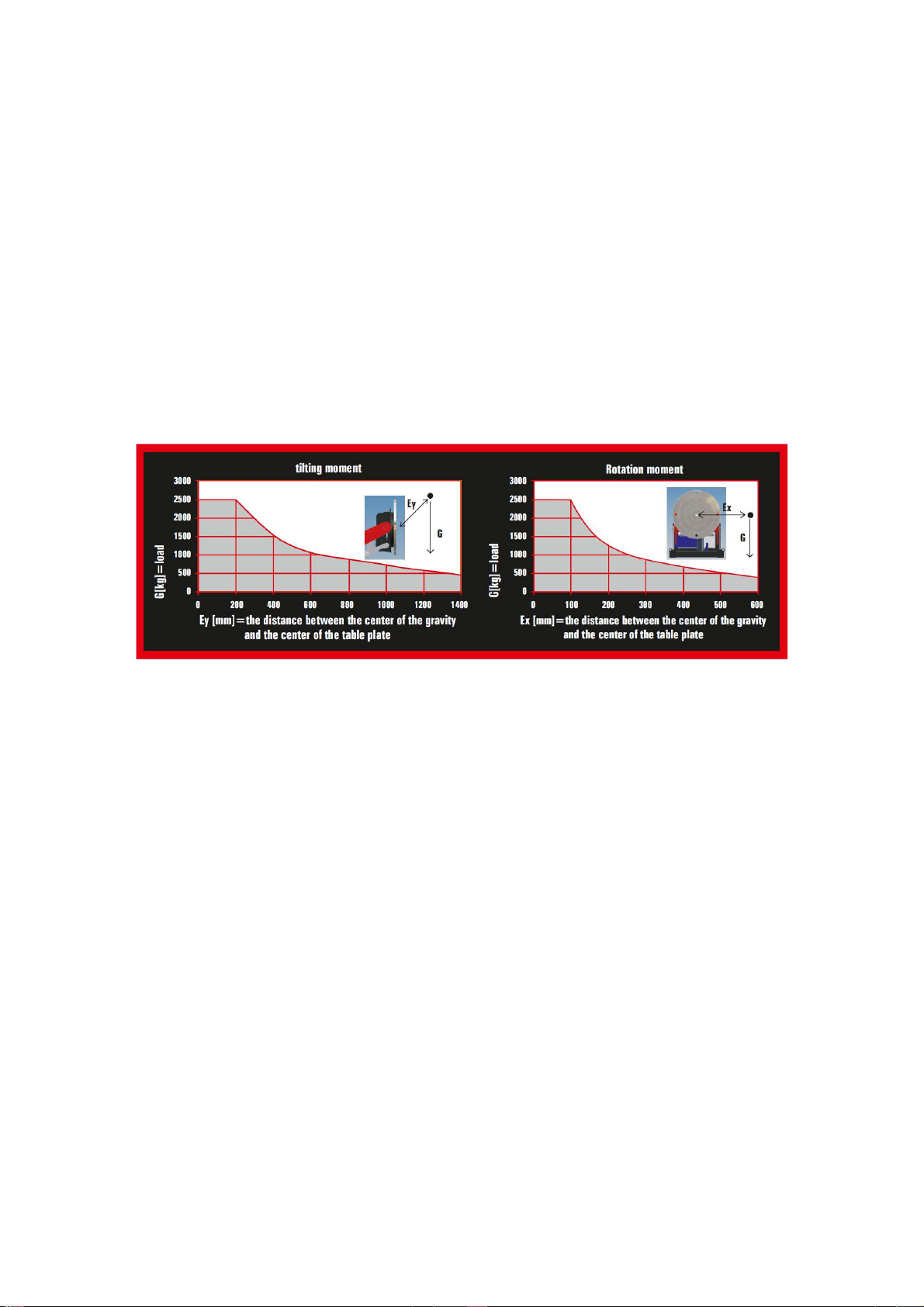

4.3 Using the load chart and load calculation

A load chart has been drawn from each of the welding positioner. The chart

demonstrates that maximum rotation- and tilting moments. This chart can be

found from a sticker that is in the machine frame.

The x-axis describes the distance of the mass center (mm) and the y-axis

describes the load (kg). Max load curve has been drawn to the chart; the load

must be in the permitted area (seen as grey area in the chart).

The load moment must always be calculated from the center of the table plate to

the center mass of the workpiece. The mass centre is the point force of the

workpiece`s mass.

Under no circumstances is the center mass of the

workpiece allowed to be behind the center point

of the table!!

When choosing which positioner to use, the moments needed in handling the

workpiece must be compared to the load chart of the respective welding

positioner.

Y = workpiece mass (kg)

X = distance of the workpiece`s mass center from the center point of the table

plate (mm)

15

5. ERROR NOTIFICATIONS

5.1. The machine`s start button`s light is blinking rapidly

The inspection of the remote control`s buttons is done automatically, when the

control voltage is turned on. If some of the buttons are stuck, the start button`s

light blinks rapidly. The error is checked when the control voltage is turned off for

instance by pressing EMERGENCY SWITCH-OFF button. Try to release the

stuck button or contact the manufacturer or manufacturer`s representative.

5.2. The machine`s start button`s light is blinking slowly

If the machine`s start button`s light starts to blink slowly, some of the following

alarms are valid:

1. a hydraulic motor has become overloaded

- check the thermal shield in the main central (2F1)

2. temperature of the hydraulic oil is too high

- wait for the oil to cool down

3. the rotation motor has become overloaded

- check the error from the frequency changer button in the main central

(STOP/RESET)

If the errors continue contact the manufacturer or manufacturer`s representative.

5.3. The machine`s start button`s light is blinking irregularly

If the machine`s start button`s light starts to blink irregularly, both of the

aforementioned errors have occurred. Check the errors in accordance with

sections 5.1. and 5.2.

5.4. The machine`s start button`s light is not on

The control voltage is missing. Press the start button.

16

6 MAINTENANCE

6.1 Maintenance-, check up- and cleaning tasks

Regularly conducted maintenance and operating the machine correctly will

ensure machine`s long lifetime. Thus, carefully comply with these instructions.

Conduct regular check-ups to the machine so it is ready-to-use when necessary.

Bestis- welding positioners employ and connect electrical-, hydraulic- and

mechanical equipment. The technical failures can be avoided the best by taking

care of the proper maintenance, check-ups and cleaning of this equipment.

Contact the manufacturer of manufacturer`s representative if failure situation

occurs!

Check in daily basis

the machine`s general condition

functioning of the motors

suitability of the workplace

abnormal tremor and sounds

overheating

that the protection- and safety structures are on place and in appropriate

condition.

that the hydraulics is compact

Check regularly

cleanness of the table plate

cleanness of the main central

that the retention bolts are tight

quantity of hydraulic oil

condition of the rotation equipment

condition of the cables

condition of the pressure filters

6.2 Maintenance of the electrical device

The manufacturer has set the machine`s parameters on advance. These

parameters must not be changed.

Check the condition of the remote control, cables and sheating. Cables and

sheating must be intact. Broken cables and sheating must immediately be

changed!

In case of an electrical failure contact the manufacturer or the manufacturer`s

representative!

17

6.3. Maintenance of the hydraulics

The functions of the hydraulic set have been set on advance by the

manufacturer. Only hydraulic oil can be increased when needed. Use the normal

46 hydraulic oil.

Cylinder`s shaft must be kept clean and spherical plain bearings kept

lubricated. The bearings should be lubricated every three months depending

from the usage of the machine. If the usage of the machine heavy or the working

cycles are long, we recommend the lubrication to be done even more often.

When operating the machine, it should be checked that there are no leaks in

the hydraulics. If there are leaks in the joints, check that the all the joints are

tight. Otherwise contact the manufacturer or the manufacturer`s representative!

If the light of the indicator above the pressure filter is red, that means that the

pressure filter is full and it must be replaced. A new filter can be ordered from the

manufacturer or from the manufacturer`s representative. Regardless from the red

light, we recommend to change the filter after one year.

6.4. Maintenance of the mechanics

Regularly clean the T-slot in the table plate. Also check that the bolts in the

table plate and in the external gear are tight. If you`ll observe the bolts loosen,

these bolts should be replaced. Before replacing the bolts please contact the

manufacturer or the manufacturer`s representative!

The electrical grounding is carried out by copper ground electrodes that abrade

table plate. Check that the electrodes are attached to the plate. Remove the

protection cover and confirm the movement of the electrodes by pulling them

upwards. If the electrodes are unable to touch the plate, they have been grinded

too much. In this case the electrodes must be replaced.

The bearing of the external gear must be greased in every 800 working hours.

Remove the protection cover. The lubrication nipple can found by removing the

black plastic plug from the bottom of the rotation motor box.

The tilting mechanism and the bearing of the cylinder must be greased in every

800 working hours or when necessary. Both include lubrication nipples. Do not

put too much grease to the spherical plain bearings, in order to prevent the seals

from displacing.

bes_man_Bestis_1000-10000_eng_2015-04

AXSON TEKNIK AB •S. Långebergsgatan 18 •421 32 Västra Frölunda •

Tel 031-748 52 80

www.axson.se

Axson Teknik är certierade

enl. ISO 9001:2008

This manual suits for next models

1

Table of contents

Popular Valve Positioner manuals by other brands

Val Controls

Val Controls IHP24-A user manual

EBRO ARMATUREN

EBRO ARMATUREN EP 501 B quick start

Dresser

Dresser Masoneilan SVI II AP-2 quick start guide

GE

GE SVi 1000 Masonelian quick start guide

Spirax Sarco

Spirax Sarco CVS10M Installation and maintenance instructions

GEM

GEM eSyStep Q50 operating instructions

GF

GF EA25-250 instruction manual

STI

STI IMI FasTrak Compact FTC-I instructions

cascade corporation

cascade corporation 55K installation instructions

Baker Hughes

Baker Hughes Masoneilan 4700P instruction manual

ABB

ABB TZIDC operating instructions

W.E. Anderson

W.E. Anderson PRECISOR II 165EL Series Installation and operating instructions