3

1 QUICKSTART GUIDE.....................................................................................4

1.1 Definition of the term "Device" ......................................................4

1.2 Symbols ..............................................................................................4

2 AUTHORIZED USE .........................................................................................5

2.1 Restrictions ........................................................................................5

3 BASIC SAFETY INSTRUCTIONS .............................................................5

4 GENERAL INFORMATION ...........................................................................6

4.1 Contact addresses ..........................................................................6

5 SYSTEM DESCRIPTION ...............................................................................7

5.1 Structure ............................................................................................7

5.2 General description .........................................................................7

5.3 AS interface .......................................................................................8

6 TECHNICAL DATA ........................................................................................10

6.1 Conformity .......................................................................................10

6.2 Standards .........................................................................................10

6.3 Operating conditions .....................................................................10

6.4 Mechanical data .............................................................................10

6.5 Electrical data..................................................................................10

6.6 Electrical data with AS interface bus control (optional) ........11

6.7 Pneumatic data ...............................................................................11

7 OPERATION .....................................................................................................12

7.1 Operating state ...............................................................................12

7.2 Operating and display elements of the positioner ..................12

7.3 Error messages ...............................................................................15

8 ATTACHMENT AND INSTALLATION ...................................................16

8.1 Installation of devices for the explosion-risk area ...................16

8.2 Attachment to a control valve with swivel actuator ................16

9 PNEUMATIC CONNECTION ....................................................................19

9.1 Connection of devices for the explosion-risk area .................19

9.2 Safety instructions .........................................................................19

9.3 Safety positions ..............................................................................20

10 ELECTRICAL CONNECTION ................................................................... 22

10.1 Connection of devices for the explosion-risk area ...............22

10.2 Safety instructions .......................................................................22

10.3 Electrical installation with cable gland ....................................22

10.4 Electrical installation AS interface ............................................24

10.5 LED status display for AS interface .........................................25

11 STARTING UP .................................................................................................25

11.1 Safety instructions .......................................................................25

11.2 Specifying the basic settings ....................................................26

12 TRANSPORT, STORAGE, PACKAGING ............................................. 27

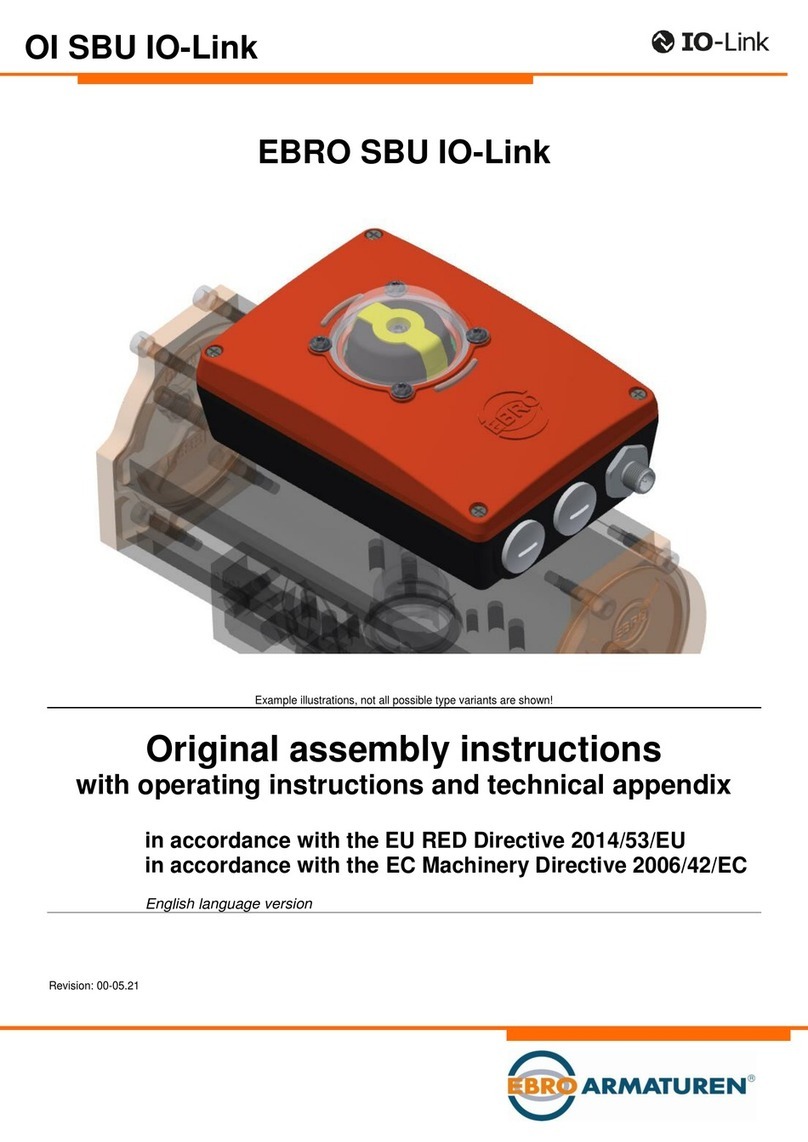

Positioner Type EP 501 B

english

Type EP 501 B