BETA Electronics RD31 Supplement

The RED LINE SERIES

Installation and operating

instructions

Temperature controller

ATEX reserves the right to make changes without further notice to any products herein to improve reliability, function or design. ATEX

does not assume any responsibility

for any improper use or application of any product or circuit described herein. ATEX

products are not designed, intended, or authorized to be use as components in

systems or applications intended to support or sustain life, or for any other application in which the failure of the ATEX

product could create a situation where personal

injury or death may occur.

5.00 OPERATING PARAMETERS

NAME MEANING SETTING (for PTC std)

SEt Main Set Point Range between «LoS» &

«HiS»

HYS Thermostat differential

(hysteresis

Range 0 … 10 °C

LoS Minimum value for SET POINT

parameter

Range –50 … +100 °C

HiS Maximum value for SET POINT

parameter

Range –30 … +154 °C

Act Thermostat control action:

cold/heat

0: cold;

1: heat.

LoA Low temperature alarm point Range –50 … +100 °C

HiA High temperature alarm point Range –30 … +155 °C

Alr Alarm mode of operation

0: disabled;

1: enables Hit;

2: enables Lot;

3: enables Hit & Lot.

OFS Probe offset. Temp. correction

factor

Range –9.9 … +9.9 °C

dPt Defrost pause time Range 1 ... 254 (see “tis”

ddt Defrost duration time Range 0 … 99 (see “tis”

AcY Anticycling time Range 0 … 254 (see “tis”

Adi Alarm delay on power-on Range 0 … 99 min

unt Measure unit 0: Celsius

1: Fahrenheit

dio Digital input 0 … 2 (optional

tiS Time scale of defrost and

anticycling

0: dPt [h], ddt [m], acy [s];

1: dPt [m], ddt [s], acy [s];

2: dPt [h], ddt [m], acy [m];

3: dPt [m], ddt [s], acy [m];

utd Update time delay Range 0 … 60 s

rES Resolution 0: decimal;

1: unit.

St2 Set point 2 (dio - energy saving Limits between «LoS» &

«HiS»

7.00

PARAMETER DESCRIPTION

SEt – Main Set Point: it’s the required temperature.

HYS - differential hysteresis:

the value that controls the

compressor/heater operation, moving t

he value of the set point in such a

way that the system does not oscillate.

LoS - low limit of set oint:

a limit below which it is not possible to

move the set point value.

HiS - high limit of set oint:

a limit above which it is not possible to

move the set point value.

Act - thermostat action:

describes the way by which the controller

manages the controlled variable. 0: direct/cold action, good for

refrigerating units, 1: inverse/heat action, usable for boiler units.

LoA - low o eration oint of alarm tem erature: a

limit below which

the system goes in alarm and simultaneously the display shows «LoT».

HiA - high o eration oint of alarm tem erature: a

limit above which

the system goes in alarm and simultaneously the display shows «Hit».

Alr - alarm mode of o eration:

the high and low temperature alarms

can be enabled or disabled as required by the installer. The available

options are: 0 = all alarms disabled; 1 = only high temperature alarm

enabled; 2 = only low temperature alarm enabled; 3 = high and low

temperature alarms enabled.

OFS - offset of tem erature: it

is the variation temperature added or

subtracted to the temperature measured by the probe to compensate for

any deviation from the real value.

dPt - defrost ause time: it is the time between th

e start of two

consecutive defrost actions (time cycle .

ddt - defrost duration time: it is

the duration of the defrost in each

cycle. Set ddt=0 to disable any defrost action.

AcY - anticycling delay time: it

is the minimum time between two

successive maneuvers of the main relay (off – on cycle .

It is also the

delay for the first activation of the relay at the start-up.

Adi - alarm delay initialization: delay between the power-

up of the

instrument and the arming of the alarms if enabled.

unt – Measure unit:

it switches the temperature unit between Celsius

and Fahrenheit.

dio - digital in ut mode o eration: (optional no active.

tiS - scale times:

it switches the scale times of the dPt from hours to

minutes, ddt from minutes to seconds, acy from seconds

to minutes and

vice versa.

utd – u date time delay:

it sets the time delay between two display

refreshes.

rES - resolution:

it allows to display the measured value with decimal or

unitary resolution.

St2 – 2dary set oint: No active – it is useful for the

energy saving

option, combined with the dio parameter.

6.00

ANOMALIES SIGNALING

MSG CAUSE OUTPUT

Lot Measured temperature is

lower than «LoA»

The relay status

does not change.

The internal buzzer

will switch on.

HIt Measured temperature is

higher than «HIA»

The relay status

does not change.

The internal buzzer

will switch on.

PrF The probe input line is

open or short circuited

The relay will switch

off

ATEX Industries srl

ATEX Industries srlATEX Industries srl

ATEX Industries srl

Z. . Ponte Rosso - Via Forgaria, 7

33078 S. Vito al Tagliamento – PN - taly

Tel.: +39 0434 85183 r.a.

Fax: +39 0434 85338

web: www.betaelectronics.it

e

-

mail

RD31

Rev.: 07

-

07

-

2006

Cod.: 00990226

by ATEX

Drilling template

4.00 FRONT PANEL FUNCTIONS

4.10 Front anel layout

(standard version RD31-60xx)

4.20 DISPLAY FUNCTIONS

The display has tree digits available, of the seven segment type. During normal working it shows the value of the temperature, while in an alarm

condition it shows the proper indication as described in the «anomalies signaling» table.

Led 1 lights up while the compressor/heater is operating and led 3 during a defrost cycle. In program mode led 3 is blinking.

Note: if alarm is on, press the “6” key to switch off the optional internal buzzer.

4.30 READ / MODIFY FUNCTION OF THE SET POINT

1 Press “↵” and hold it for 3s, SEt is displayed;

2 Press “↵” to view the Set Point value, adjust it by using “5” or “6”;

3 Press “↵” to confirm the data, after 10s the controller will leave the set mode and the data will be stored in the memory.

WARNING: the instrument must not be reset before leaving the set mode, otherwise the new setting will be lost.

Note: it is only possible to choose values for the set point inside the «Los» and «His» range.

4.40 READ / MODIFY FUNCTION FOR THE PARAMETER MENU

1 Press “↵” and hold it for 10s, the code of the first variable “HyS” will appear;

2 Press “5” or “6”to scroll all the parameter codes;

3 While a code is displayed press “↵” to view its content, adjust it by pressing “5” or “6”;

4 Press “↵” to confirm the data, after 10s the controller will leave the set mode and the data will be stored in the memory.

WARNING: the instrument must not be reset before leaving the set mode, otherwise the new setting will be lost.

Note: the new values for time parameters will be active only after the start of the following time cycle.

4.50 HOW TO ACTIVATE MANUALLY A DEFROST CYCLE (only for RD31-5 xx and RD31-6 xx standard – not “OnOff”)

Press and hold for about 5s the “Defrost” key (the right-side pushbutton , the compressor output will switch off and the led 3 will lights on.

4.60 HOW TO SWITCH OFF AND ON MANUALLY THE CONTROLLER (only for RD31-xxxx “OnOff” version)

Instead of the “Defrost” key there is an “On/Off” function. Press and hold for 5s the right-side pushbutton, the controller will switch off (display and

output . Press again the right-side pushbutton to toggle on the controller, it will resume to measure and regulate the temperature.

The instrument can store or not on its memory the “Off status” as per order request. Memorizing the “Off status” the controller stays off also after a

power cut or blackout.

4.70 LOCK / UNLOCK KEYBOARD

Press and hold simultaneously SET and “6” for 10s, in order to lock and unlock the keyboard.

Code displayed for one second: Pof Locked Pon Unlocked

It is possible to change only the Set point value when the keyboard is locked.

3.30

CONNECTIONS

We recommend to use wires of proper gauge, according to the power of the load; in any case do not exceed 2.5 mm2 to avoid damage of the connector.

See the label on top of the instrument for the right power supply diagram connection.

1.0

GENERAL DESCRIPTION

The RD 31 based on the PD Program is a low-

cost controller with

OFF-

Cycle defrost, specifically designed to control refrigerating

static units operating at positive temperatures.

This type of controller is particularly indicated, either for the

manufactures of economi

cal refrigeration units or for contractors /

end-

installers. Applications span from refrigerated cabinets, to

displays, wine show cases, bottle coolers, chafing dish, etc.

The controller can support one input PTC type sensor and offers

one relay output for

the compressor/heater control in order to cool

down or to warm up something, simply changing the value of an

internal parameter.

The instrument can perform the OFF-

cycle defrost function by

shutting off the compressor at regular intervals time, which can

be

programmed from 1 to 99 hours.

On the RD31-50xx and RD31-

60xx standard version, the user has

the possibility to start/stop manually the defrost cycle, by pushing a

front panel key.

Available an On/Off version where the user can switch on and off

the controller by pushing the right side front panel key

(the

controller can or cannot store the “off” status on its memory –

as per

order request) .

This new RD 31 Program controller can work at a decimal point

resolution in the range -9.9…+99.9 °C (°F) and

automatically

switches to unit resolution out of this range.

2

.00 SPECIFICATIONS

DISPLAY: 3 digit, 13.2 mm, high intensity red;

INPUTS: one PTC sensor, KTY81-121 semiconductor type;

opt: PTC 300 sensor, KTY84-130 (polarized ;

opt: with 1 digital input N.O. contact;

MEASURING RANGE: -50 … +150 °C (-58 … +302 °F ;

(-25 … +270 °C if PTC300 input);

ACCURACY AT 25°C: ±0.5°C (±0.9°F + 1 digit;

RESOLUTION: 0.1°C (0.2°F + 1 digit;

TIME ACCURACY: ±5%;

OUTPUTS (max 2): 1 SPDT 8 A, ½ hp 250 Vac relay;

opt. – 1 SPDT 16 A, 1 hp 250 Vac;

opt. – 1 SPST 30 A, 2 hp 250 Vac;

+ opt. 1 SPST alarm relay – 250 Vac 5A res. or buzzer;

POWER SUPPLY: 230 Vac ±10%, 50/60 Hz;

opt.: 115 Vac ±10%, 50/60 Hz; 12 Vac/dc ±10%;

switching 9..24Vac/dc.

ENVIRONMENTAL CONDITIONS:

-operating temperature: –5 … +50 °C;

-storage temperature: –20 … +70 °C;

-relative humidity: 30 … 90 % non condensing;

-no shocks or vibrations;

MECHANICAL DATA:

-rectangular hole panel mounting 70.5 x 28.5 mm;

-plastic housing self extinguishing type UL94V0;

- connections through screw terminal block for max 2.5mm2

wire (or max 4mm2 for rigid wire ; max current 16 A (max

24 A if 2 hp relay is present .

-protection degree: IP64 for the frontal panel.

3.00 INSTALLATION

3.10 GENERAL

The installation must be done only by specialized personnel in according to the rules in force in the country where the controllers are used.

The instrume

nt is conceived for controlling and regulation working not for safety function. It must be installed in a place protected from

extreme vibrations, impact, water, corrosive gases, and where temperature and moisture do not exceed the maximum rating levels in

dicated

in the specifications. The same directions are valid for the probe installation.

3.11 THE THERMOSTAT PROBE

The probe must be installed in a place protected from direct air flow particularly far from fans and doors, so a better average temperature

of

the room will be measured. The probe is not waterproof, it should be placed with its head upward, so that drops would not penetrate into the

bulb and damage the sensor. Maintain the length of the electrical wires as short as possible in order to keep th

e noise picked by them at low

level, otherwise a shielded wire will be needed, where the shield will be connected to the ground.

3.12 ELECTRICAL WIRING

We recommend to protect the power supply of the controller from electrical noise, spikes, and especiall

y from voltage surges and drops. This

can be easily done following these recommendations:

-

separate the power supply of the loads (compressor, heaters, fans, etc from the power supply of the controller. This can alleviate problems

related to voltage dips that can arise during the switch-

on of the loads, that may interfere with the controller’s microprocessor causing

unexpected resets.

-the cables of the probes and the ones of the controller supply or the loads must be separated and not close, to reduce

spikes and noise on

the sensor. This improves the stability of the reading and it also makes the commutation of the device more accurate.

3.13 CRITICAL ENVIRONMENT

For applications in heavy industrial environment these rules should be followed.

- After ha

ving identified the source of noise spikes, it is recommended to apply a line filter to the source in question of the type specifically

designed to solve EMC (Electromagnetic compatibility related problems. Sometimes it may be sufficient an RC type filter

, also called

«snubber» , connected in parallel to the external relay coils, or circuit breakers.

- An independent power supply should be used to power the device in extreme conditions.

3.20 MOUNTING

The controller is a «flush» panel mounted instrument.

We recommend to leave on the rear panel enough room to avoid compression or

excessive bending of the cables.

230 VAC

8A 250VAC (RES)

AC LINE

PROBE

LOAD

Popular Temperature Controllers manuals by other brands

Vaillant

Vaillant VRT 230 Operating and quick start guide

Fuji Electric

Fuji Electric PXR3 Series Operation manual

2VV

2VV STANDESSE Installation

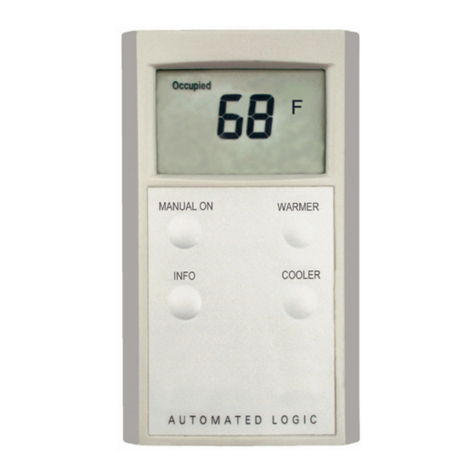

Automated Logic

Automated Logic RS Standard Technical instructions

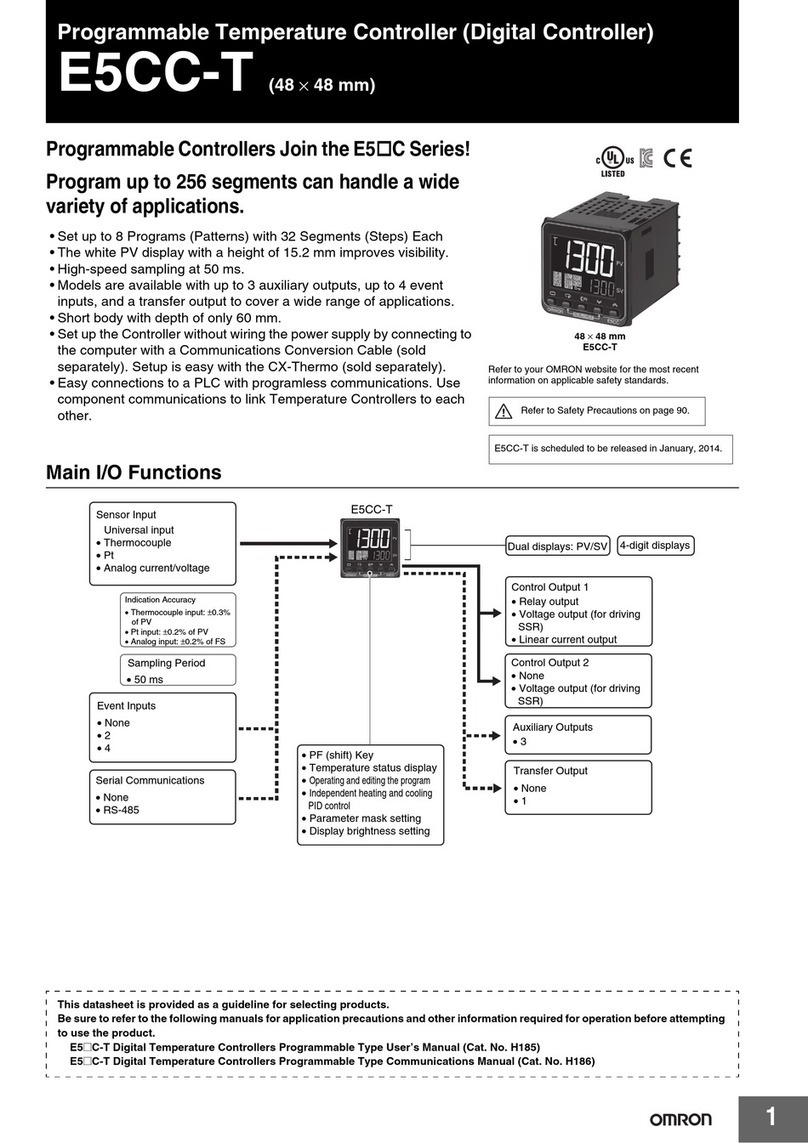

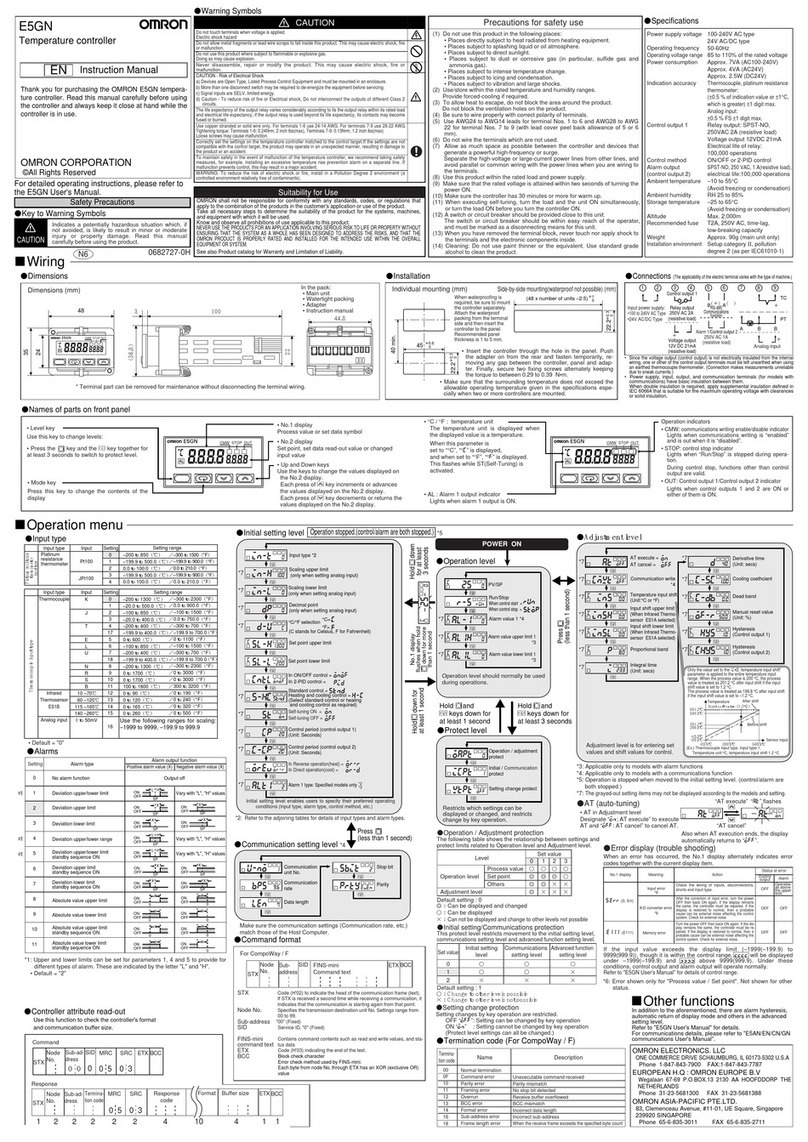

Omron

Omron E5GN instruction manual

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD ESFF Operating Instructions, Mounting & Installation

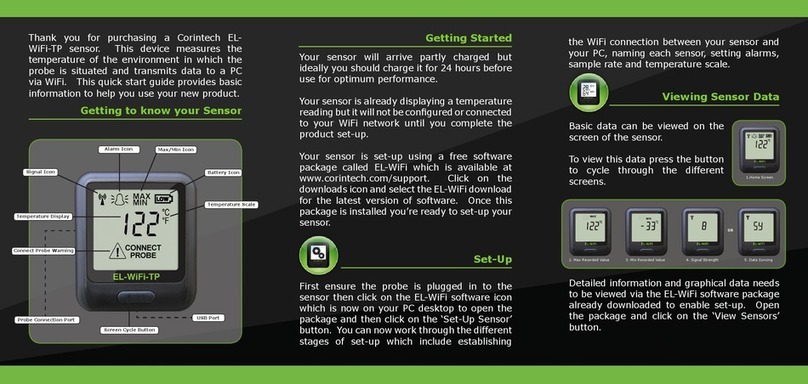

Corintech

Corintech EL-WiFi-TP quick start guide

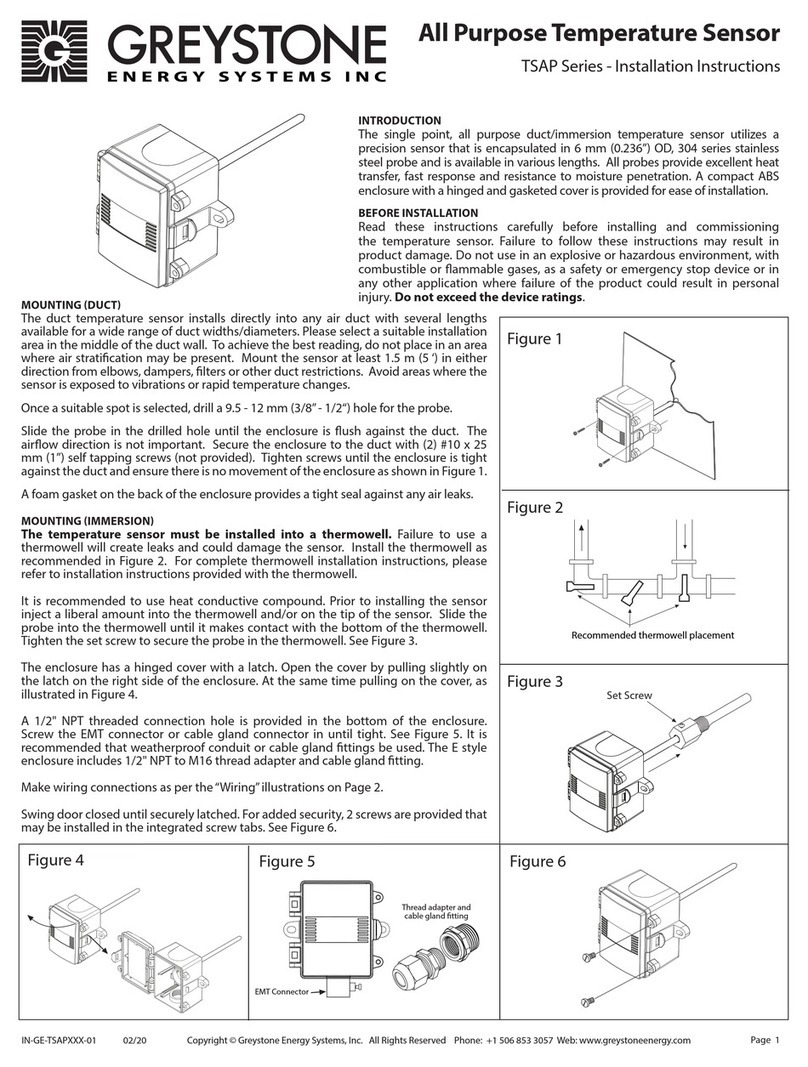

Greystone Energy Systems

Greystone Energy Systems TSAP Series installation instructions

La Crosse Technology

La Crosse Technology WS-7215U instruction manual

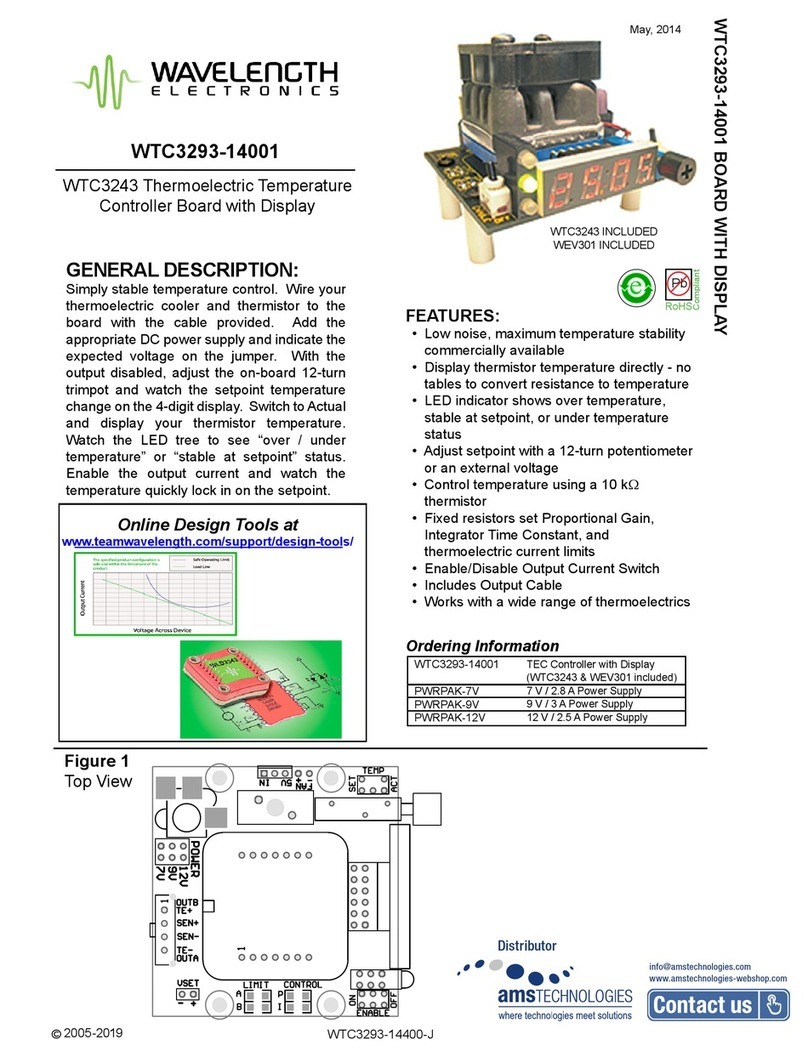

Wavelength Electronics

Wavelength Electronics WTC3293-14001 quick start guide

Hioki

Hioki 9021-01 instruction manual

Uponor

Uponor C-46 Installation and operation manual