Page 1

INTRODUCTION

The single point, all purpose duct/immersion temperature sensor utilizes a

precision sensor that is encapsulated in 6 mm (0.236”) OD, 304 series stainless

steel probe and is available in various lengths. All probes provide excellent heat

transfer, fast response and resistance to moisture penetration. A compact ABS

enclosure with a hinged and gasketed cover is provided for ease of installation.

BEFORE INSTALLATION

Read these instructions carefully before installing and commissioning

the temperature sensor. Failure to follow these instructions may result in

product damage. Do not use in an explosive or hazardous environment, with

combustible or ammable gases, as a safety or emergency stop device or in

any other application where failure of the product could result in personal

injury. Do not exceed the device ratings.

MOUNTING (DUCT)

The duct temperature sensor installs directly into any air duct with several lengths

available for a wide range of duct widths/diameters. Please select a suitable installation

area in the middle of the duct wall. To achieve the best reading, do not place in an area

where air stratication may be present. Mount the sensor at least 1.5 m (5 ‘) in either

direction from elbows, dampers, lters or other duct restrictions. Avoid areas where the

sensor is exposed to vibrations or rapid temperature changes.

Once a suitable spot is selected, drill a 9.5 - 12 mm (3/8”- 1/2“) hole for the probe.

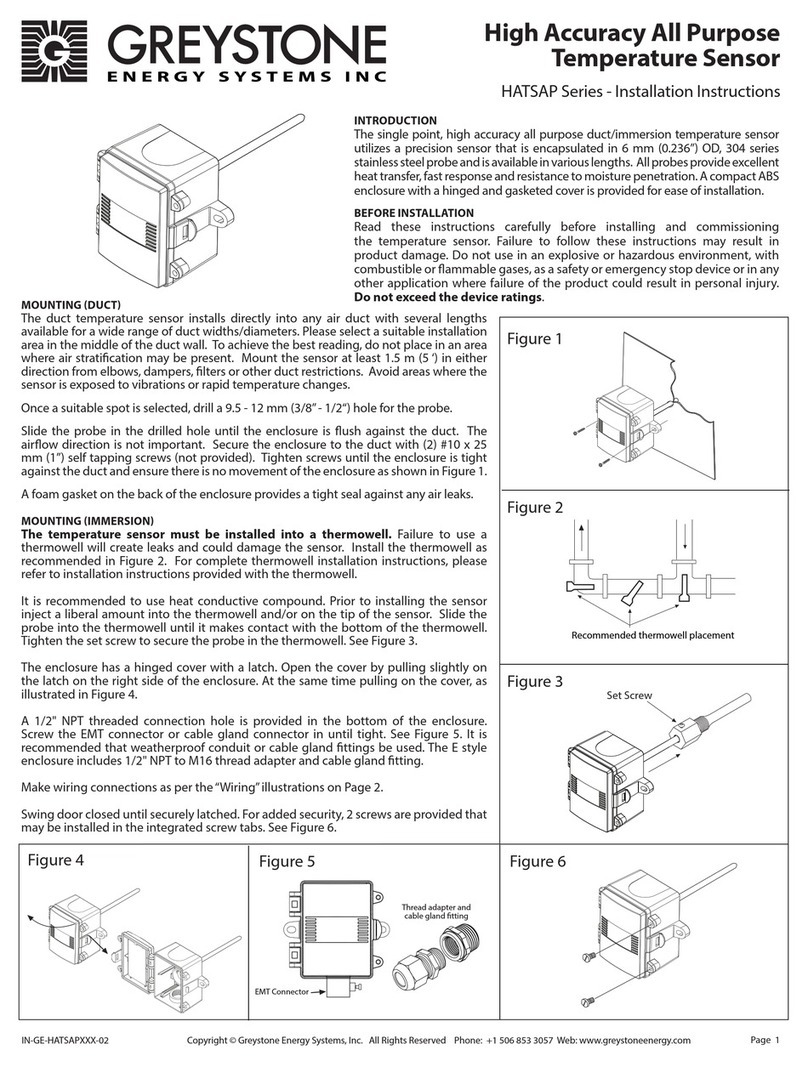

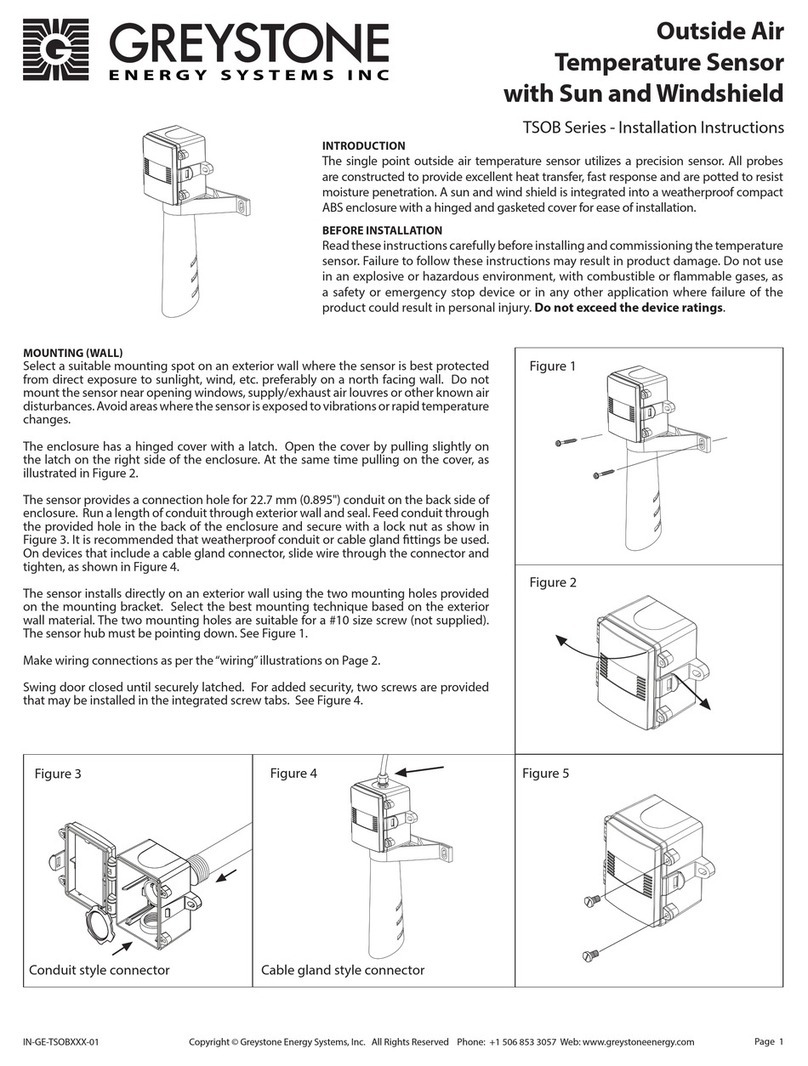

Slide the probe in the drilled hole until the enclosure is ush against the duct. The

airow direction is not important. Secure the enclosure to the duct with (2) #10 x 25

mm (1”) self tapping screws (not provided). Tighten screws until the enclosure is tight

against the duct and ensure there is no movement of the enclosure as shown in Figure 1.

A foam gasket on the back of the enclosure provides a tight seal against any air leaks.

MOUNTING (IMMERSION)

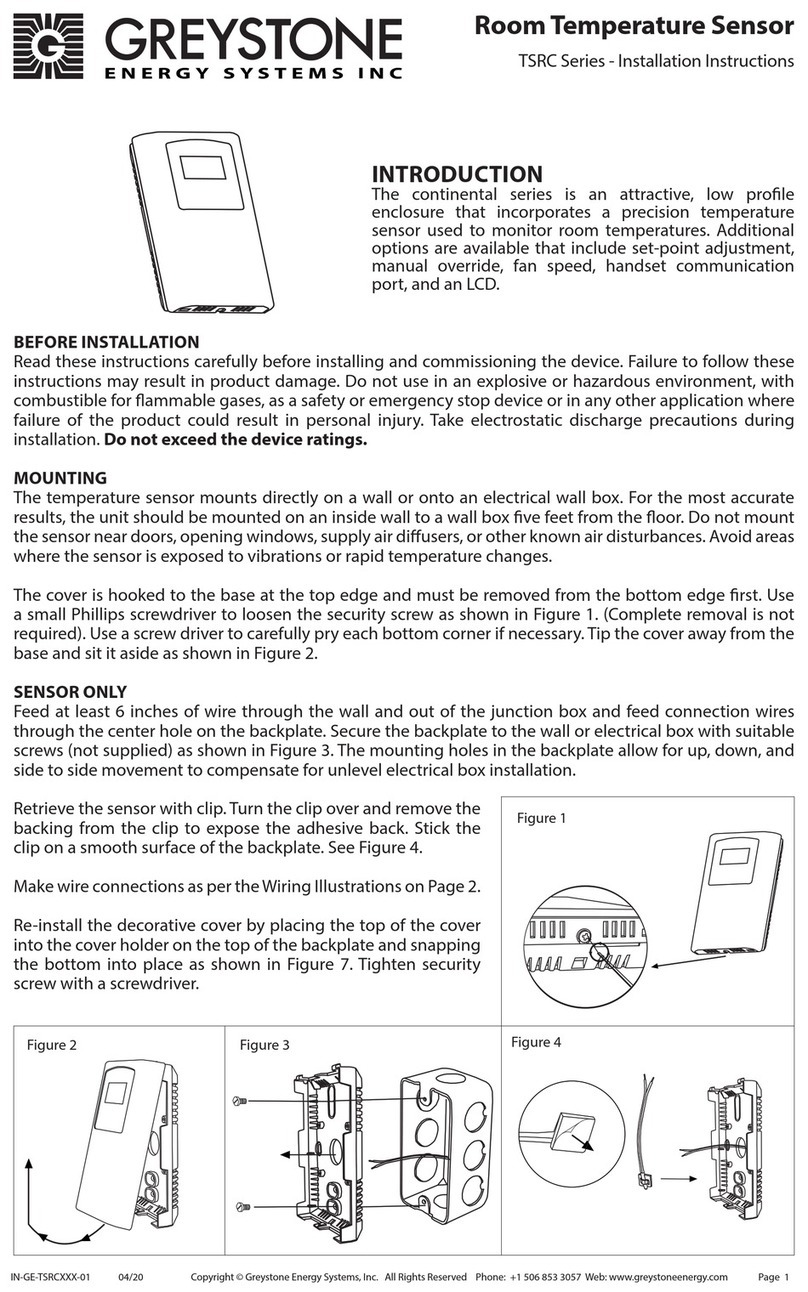

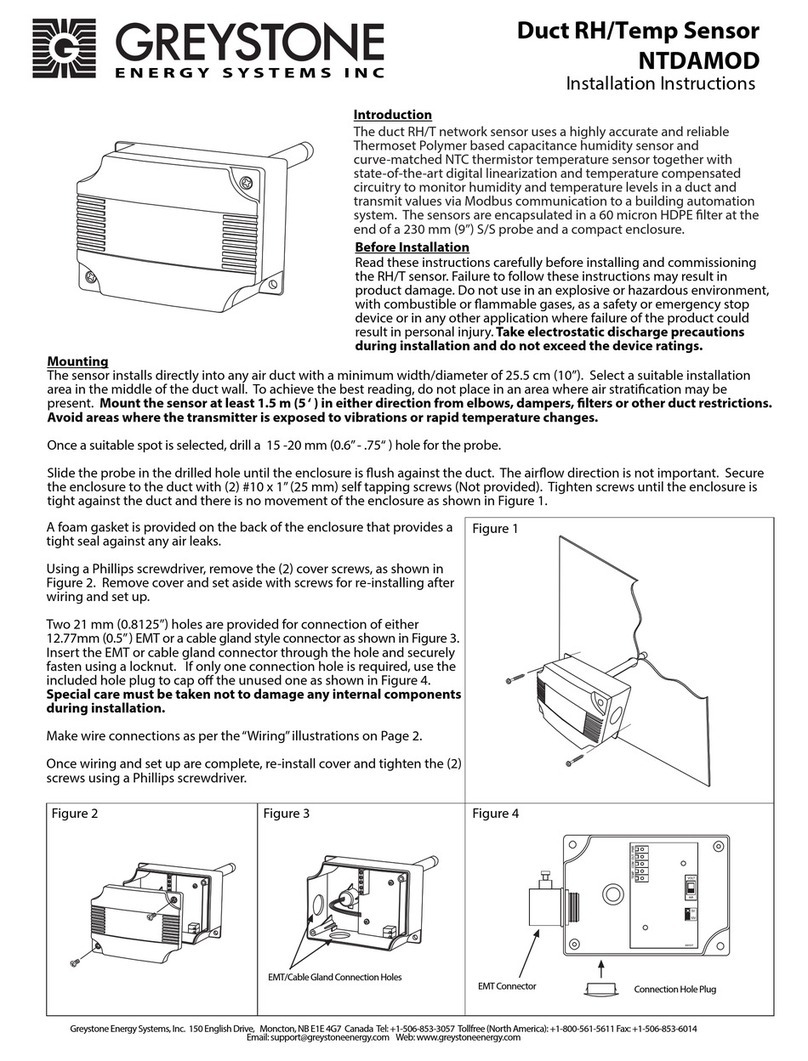

The temperature sensor must be installed into a thermowell. Failure to use a

thermowell will create leaks and could damage the sensor. Install the thermowell as

recommended in Figure 2. For complete thermowell installation instructions, please

refer to installation instructions provided with the thermowell.

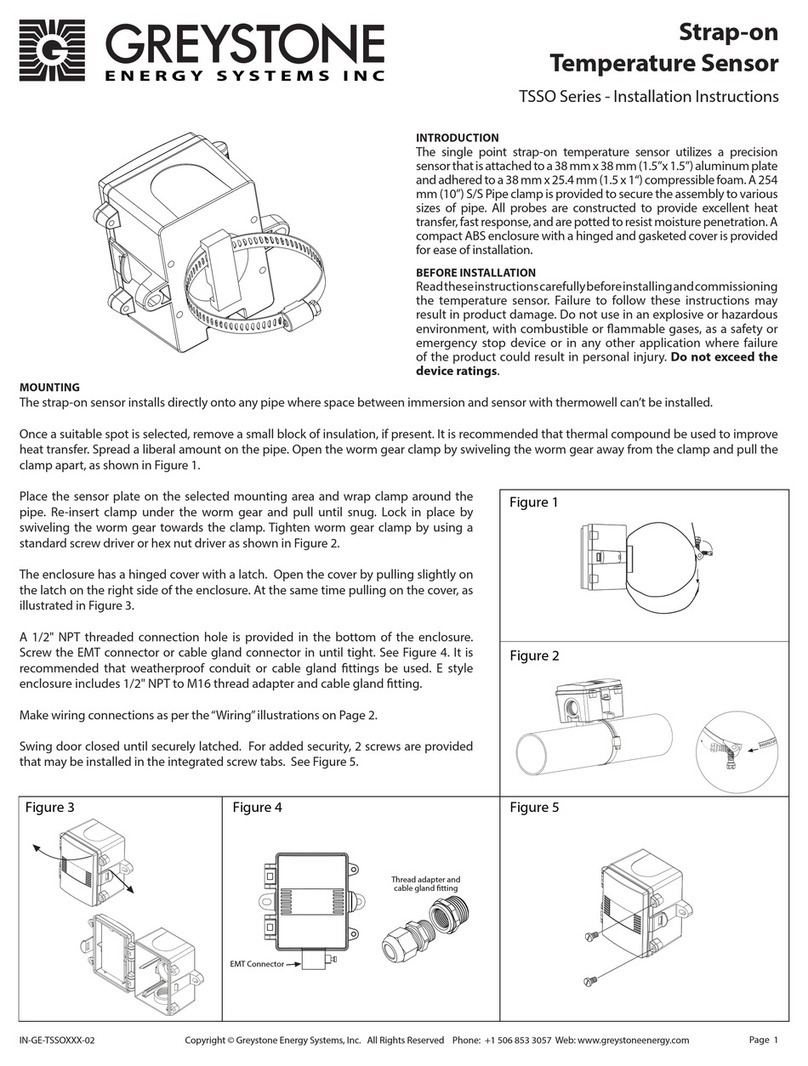

It is recommended to use heat conductive compound. Prior to installing the sensor

inject a liberal amount into the thermowell and/or on the tip of the sensor. Slide the

probe into the thermowell until it makes contact with the bottom of the thermowell.

Tighten the set screw to secure the probe in the thermowell. See Figure 3.

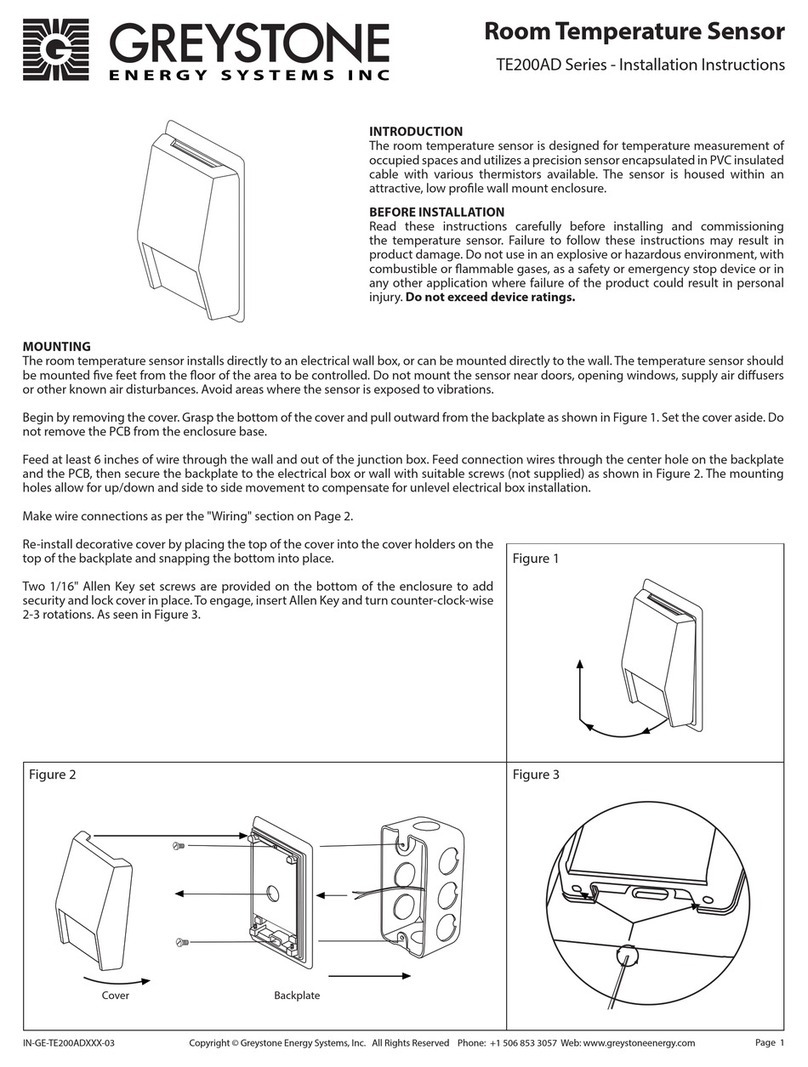

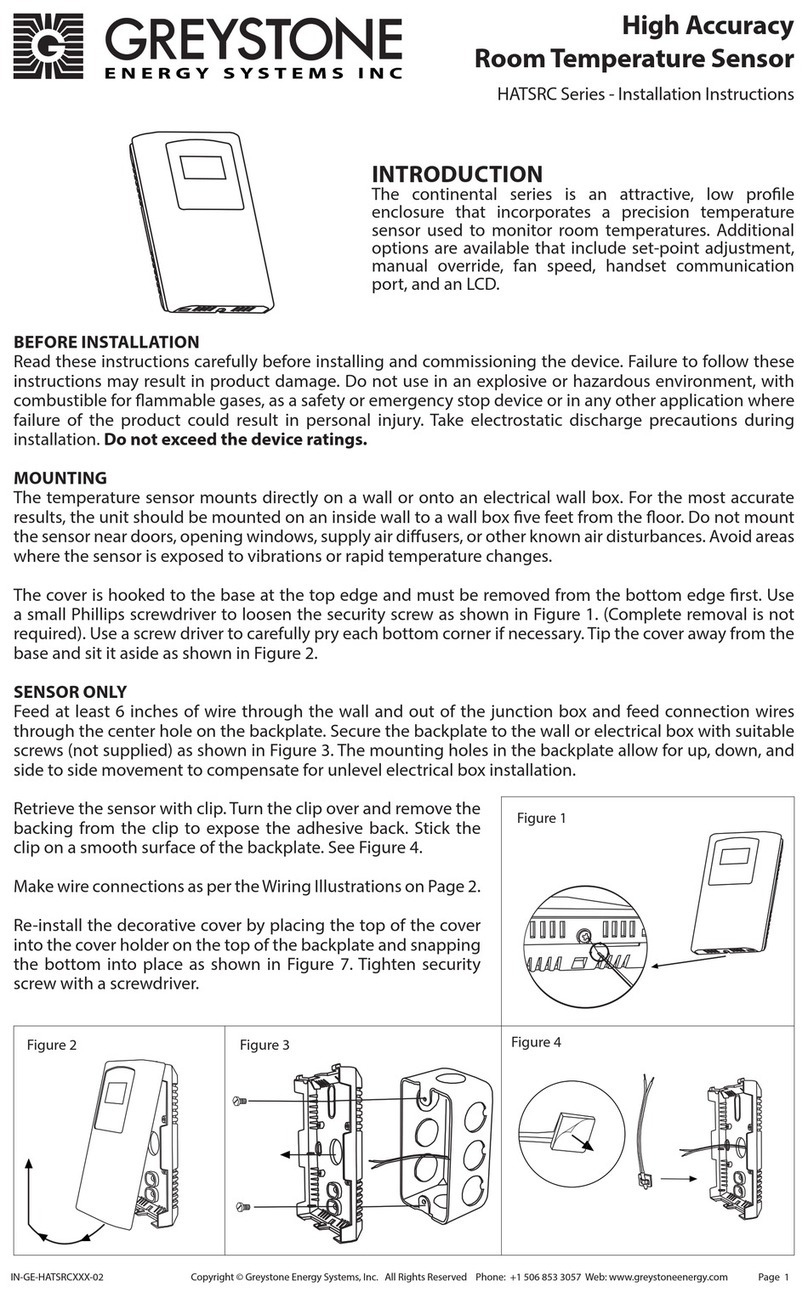

The enclosure has a hinged cover with a latch. Open the cover by pulling slightly on

the latch on the right side of the enclosure. At the same time pulling on the cover, as

illustrated in Figure 4.

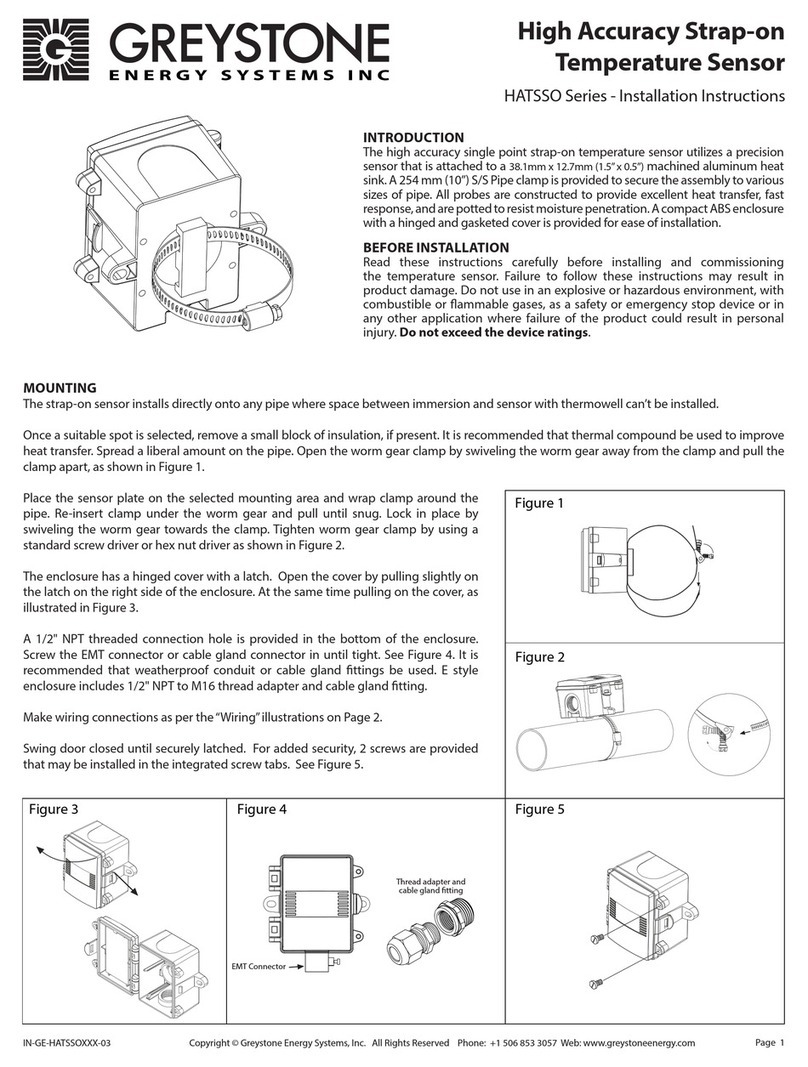

A 1/2" NPT threaded connection hole is provided in the bottom of the enclosure.

Screw the EMT connector or cable gland connector in until tight. See Figure 5. It is

recommended that weatherproof conduit or cable gland ttings be used. The E style

enclosure includes 1/2" NPT to M16 thread adapter and cable gland tting.

Make wiring connections as per the “Wiring” illustrations on Page 2.

Swing door closed until securely latched. For added security, 2 screws are provided that

may be installed in the integrated screw tabs. See Figure 6.

Recommended thermowell placement

EMT Connector

Thread adapter and

cable gland tting

Set Screw

Figure 3

Figure 4 Figure 5 Figure 6

Figure 2

Figure 1

IN-GE-TSAPXXX-01 02/20 Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com

All Purpose Temperature Sensor

TSAP Series - Installation Instructions