BETTCHER INDUSTRIES Quantum Flex X750 User manual

Operating Instructions & Parts List for the

Manual# 107013

Issued: January 1, 2018

TMC# 808

For Assistance:

e-mail: [email protected]

BETTCHER INDUSTRIES INC.

6801 State Route 60

Birmingham, OH 44889

U.S.A.

Phone: 440/965-4422

Phone: 800/321-8763

Fax: (440) 328-4535

www.bettcher.com/quantumflex

Page i

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted in any form or any means, electronic

or mechanical, for any purpose, without the express written permission of Bettcher Industries Inc.

Written permission to reproduce in whole or part is herewith granted to the legal owners of the

Quantum Flex™ Trimmers with which these Operating Instructions have been supplied.

Operating Instructions in other languages are available on request. Additional copies of

Operating Instructions are available by calling or writing your Regional Manager, or by

contacting:

BETTCHER INDUSTRIES, INC.

6801 State Route 60

Birmingham, OH 44889

U.S.A.Telephone: 440/965-4422

(In The U.S.A.): 800/321-8763

Fax: 440/328-4535

http://www.bettcher.com

Copyright © 2018 By Bettcher Industries, Inc.

All Rights Reserved.

Original Instructions

The Information Provided In These Operating Instructions Is

Important To Your Health, Comfort And Safety.

For Safe And Proper Operation, Read This Entire Manual

Before Using This Equipment.

Table of Contents

Section 1 ............... Safety

Section 2 ............... Designated Use

Section 3 ............... Installation

Section 4 ............... Instructions for Operation

Section 5 ............... Maintenance

Section 6 ............... Cleaning

Section 7 ............... Service Parts

Section 8 ............... Contact and Document Information

Safety

Manual No. 107013 Safety 1-1

January 1, 2018 Operating Instructions and Parts List for the Quantum Flex® Trimmer

Section 1 Safety

CONTENTS OF THIS SECTION

Signal Words & Signal Word Panels .......................................................................................1-2

Safety Symbols .......................................................................................................................1-3

Safety Recommendations and Warnings ................................................................................1-4

Safety Features .......................................................................................................................1-6

Ergonomic Features ................................................................................................................1-6

Noise and Vibration Levels ......................................................................................................1-6

WARNING

The information provided in these operating instructions is important to

your health, comfort and safety. For safe and proper operation, read this

entire manual before using this equipment.

Please read and save these instructions. Read carefully before

attempting to assemble, install, operate or maintain this product. Protect

yourself, others and equipment by observing all safety information.

Failure to comply with instructions could result in personal injury and/or

damage to the equipment. Any use in applications other than those for

which the equipment was designed and built may result in equipment

damage and/or serious injuries.

Retain this manual for future reference. Be thoroughly familiar with the

controls and proper use of this equipment.

The manufacturer assumes no liability for any unauthorized changes in

operating procedures or for unauthorized changes or modifications made

to the design of the machine or any factory-installed safety equipment,

whether these changes are made by the owner of this equipment, by his

employees, or by service providers not previously approved by Bettcher

Industries, Inc.

Safety

1-2 Safety Manual No. 107013

Operating Instructions and Parts List for the Quantum Flex® Trimmer January 1, 2018

SIGNAL WORDS & SIGNAL WORD PANELS

The signal word definitions provided, comply with the American National Standard for Product Safety

Information in Product Manuals, Instructions, and Other Collateral Materials (ANSI Z535.6-2011).

This technical manual is printed in black and white.

DANGER

Indicates a hazardous situation that, if not avoided, will result in death or

serious injury.

(The signal word Danger is in white letters on a safety red background)

WARNING

Indicates a hazardous situation that, if not avoided, could result in death

or serious injury.

(The signal word WARNING is in black letters on a safety orange

background)

CAUTION

Indicates a hazardous situation that, if not avoided, could result in minor

or moderate injury.

(The signal word CAUTION is in black letters on a safety yellow

background)

NOTICE

Indicates information considered important, but not hazard-related (e.g.

messages relating to property damage).

(The signal word NOTICE is in italicized, white letters on a safety blue

background)

Safety

Manual No. 107013 Safety 1-3

January 1, 2018 Operating Instructions and Parts List for the Quantum Flex® Trimmer

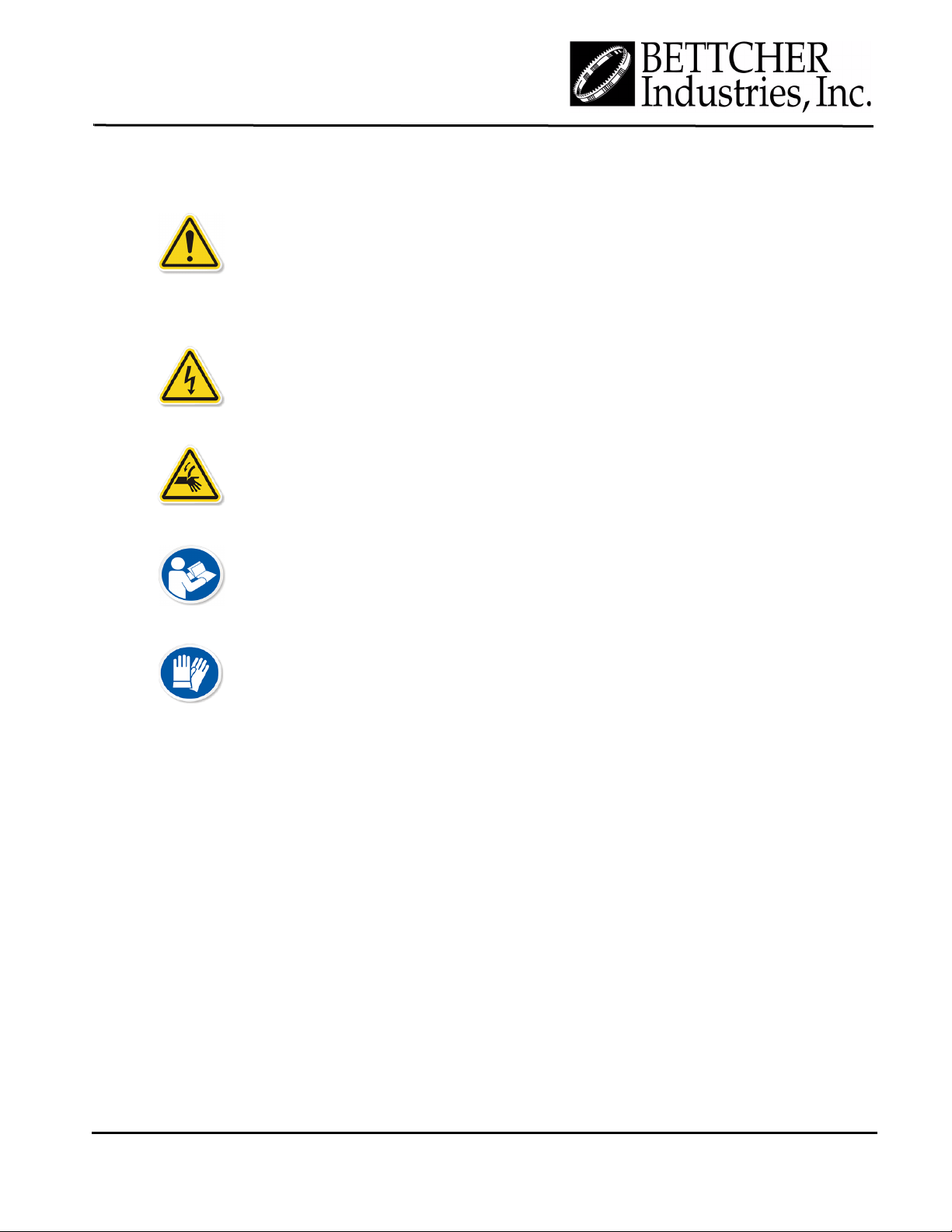

SAFETY SYMBOLS

Symbols are harmonized with ANSI Z535.4 and ISO 3864-2 standards. Warning symbols are presented on a

safety yellow background. Mandatory action symbols are presented on a safety blue background.

This technical manual is printed in black and white.

The safety alert symbol indicates a potential personal injury hazard. It is

not used for messages related to property damage. The safety alert

symbol may be used alone or in conjunction with a signal word in a

signal word panel

Danger of electrical shock

Blade hazard, keep hands clear

Read operator's manual

Protective safety gloves must be worn

Safety

1-4 Safety Manual No. 107013

Operating Instructions and Parts List for the Quantum Flex® Trimmer January 1, 2018

SAFETY RECOMMENDATIONS AND WARNINGS

WARNING

The manufacturer assumes no liability for any unauthorized changes in

operating procedures or for unauthorized changes or modifications made

to the design of the machine or any factory-installed safety equipment,

whether these changes are made by the owner of this equipment, by his

employees, or by service providers not previously approved by Bettcher

Industries, Inc.

Use only replacement parts manufactured by Bettcher Industries, Inc.

Use of substitute parts will void the warranty and may cause injury to

operators and damage to equipment.

The use of parts other than those listed in the parts list for the specific

model may cause blade lock-up, resulting in an unsafe operating

condition.

WARNING

Sharp blades may cause cut injury!

For proper protection of hands, a protective glove should be used when

operating this equipment and during the handling of blades. Metal mesh

gloves are recommended for the free hand.

Keep hands away from moving blade.

WARNING

To avoid personal injury, always disconnect the power cord before

performing any adjustments, disassembly/assembly, troubleshooting or

cleaning.

All electrical repairs should be completed by a qualified electrician or

approved service provider.

Always turn off the Whizard® drive unit and place the handpiece in the

hanger bracket. Never lay the handpiece down on the workstation or let it

hang free by the driveline or flexshaft and casing assembly. Never place

the handpiece in the hanger while the blade is still revolving.

Always disconnect the power and remove the tool from the driveline or

flexshaft and casing assembly prior to servicing.

Safety

Manual No. 107013 Safety 1-5

January 1, 2018 Operating Instructions and Parts List for the Quantum Flex® Trimmer

SAFETY RECOMMENDATIONS AND WARNINGS (CONTINUED)

WARNING

If at any time this machine does not appear to operate normally or

exhibits a marked change in performance, it should be immediately shut

down, unplugged, and tagged as “UNSAFE” until such time as proper

repairs are made and the machine again operates normally.

WARNING

Avoid use of this machine in standing water.

WARNING

Long or repeated use of various power tools vibrating excessively is

suspected of contributing to certain hand, wrist or forearm disorders in

susceptible individuals. If excessive vibration occurs, it is an indication

that there are worn parts that need replacement.

If your Quantum Flex™ Trimmer develops unusual vibration,

do not continue to use it without first undertaking corrective action as

outlined in the troubleshooting guide in this operating instruction.

NOTICE

Whizard® Series II flexshaft and casing assemblies are not compatible

with Quantum Flex™ Tools. Whizard® Series II flexshaft and casing

assemblies must be converted prior to use with Quantum Flex™ tools.

Safety

1-6 Safety Manual No. 107013

Operating Instructions and Parts List for the Quantum Flex® Trimmer January 1, 2018

SAFETY FEATURES

All Quantum Flex™ tools have been designed for use with an optional disconnect which will stop

blade rotation when the trigger/lever is released. This trigger/lever has been designed in such a

way that minimal grip force is required for operation, using three fingers.

ERGONOMIC FEATURES

Small, Medium, and Large Handle sizes are available to help improve the operator's grip and

comfort. Fitting the correct size handle to the worker's hand is a very important step. Quantum

Flex™ tools can be configured in both right and left handed configurations.

Optional Thumb Support - An adjustable thumb support is available to ensure a proper and

comfortable fit while providing added control and stability of the tool during use.

Whizard® Micro- Break Hand Strap - This strap has been designed to allow the user to relax the

fingers between work cycles while maintaining control of the trimmer. This is beneficial to the

operator to reduce exposure to mechanical stresses.

NOISE AND VIBRATION LEVELS

Forces applied by the worker are greatly reduced via the drive motor and limited to guiding the

rotating knife blade.

The noise emission value is less than 79 dB(A)

Vibration of the handpiece is less than 1.1 m/sec2

No negative side effects have been reported

Designated Use

Manual No. 107013 Designated Use 2-1

January 1, 2018 Operating Instructions and Parts List the Quantum Flex™ Trimmer

Section 2 Designated Use

CONTENTS OF THIS SECTION

Designated Use .......................................................................................................................2-2

Machine Specifications ............................................................................................................2-2

Recommended Operation .......................................................................................................2-3

Function ..................................................................................................................................2-6

WARNING

The manufacturer assumes no liability for any unauthorized changes in

operating procedures or for unauthorized changes or modifications made

to the design of the machine or any factory-installed safety equipment,

whether these changes are made by the owner of this equipment, by his

employees, or by service providers not previously approved by Bettcher

Industries, Inc.

Use only replacement parts manufactured by Bettcher Industries, Inc.

Use of substitute parts will void the warranty and may cause injury to

operators and damage to equipment.

The use of parts other than those listed in the parts list for the specific

model may cause blade lock-up, resulting in an unsafe operating

condition.

Designated Use

2-2 Designated Use Manual No. 107013

Operating Instructions and Parts List the Quantum Flex™ Trimmer January 1, 2018

DESIGNATED USE

The Quantum Flex™ Trimmers are specifically designed for use with the Whizard Quantum® Drive

Unit, Whizard® Ultra Drive Unit and the Whizard® UN-84 Drive Unit. They are used for removal of fat

and tissue, the recovery of lean meat from fat and as a universal cutting tool in the meat industry.

WARNING! Any use in applications other than those for which the Quantum Flex™ Trimmer was

designed and built may result in serious injuries.

MACHINE SPECIFICATIONS

Quantum Flex™ Trimmers are highly effective for use in the meat industry, designed with the highest

possible standards for safety, ergonomics and production. These versatile machines, with their carefully

engineered and durable cutting edge, bring uniformity and consistent yield control to all operations. This

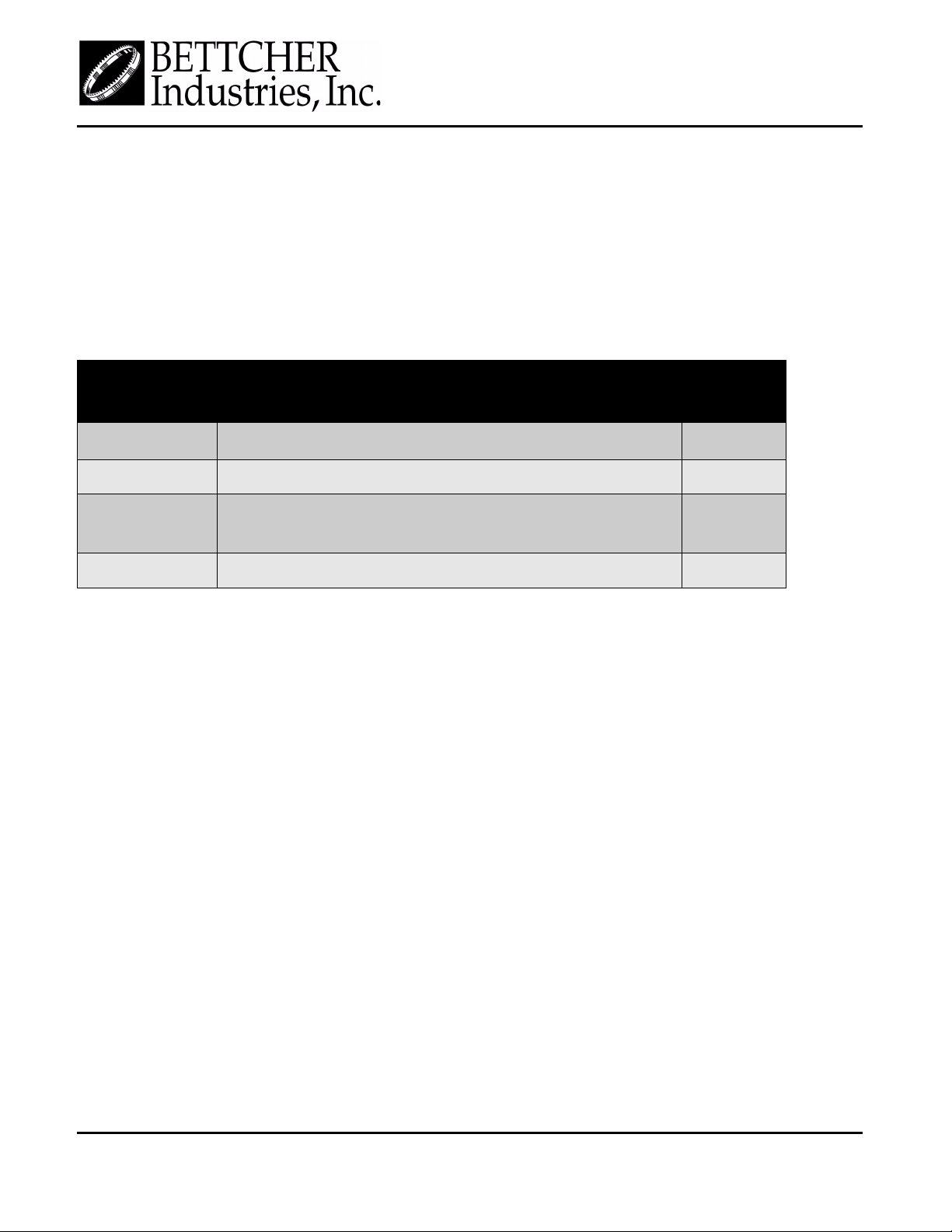

Operating Instruction covers the following models:

.

MODEL USE

X750 Bone Trimmer

X850 Defatting Machine

X880 (B & S) Primal Fat Shaper

X1850 Defatting Machine

X1880 Primal Fat Shaper

1000 Defatting Machine

1300 Primal Fat Shaper

1400 Ham Finisher

1500 Skinning Machine

Designated Use

Manual No. 107013 Designated Use 2-3

January 1, 2018 Operating Instructions and Parts List the Quantum Flex™ Trimmer

RECOMMENDED OPERATION

Quantum Flex™ Trimmers are made for several recommended operations. Ensure that you are using the

correct tool for your specific application. The following recommendation list is not intended to be a total

and comprehensive listing, but is offered as a guide. Additional applications are possible.

Model X750

Model X850 / X1850

Model X880-B / X1880 With Adjustable Depth Gauge

FOAM INDUSTRY PORK KILL PORK CUT

Remove defects

Flash trimming

Remove cheek meat

Remove blood clots from jowls

Remove diaphragm lean

Removal of picnic hearts

BEEF POULTRY PORK PROCESSING

Recover lean from fat

Trim lean from rib caps

Trim beef tripe

Defatting turkey skins

Defatting turkey thighs

External ham defatting

Internal ham defatting

Defat pork loins

Remove oyster meat

*PORK KILL

Removing leaf lard

BEEF BONING/FABRICATING

Removing dirt and hair

Slaughter floor

Prior to loading

Upon receiving

Prior to fabrication

Final trim on primal fat shaping

Designated Use

2-4 Designated Use Manual No. 107013

Operating Instructions and Parts List the Quantum Flex™ Trimmer January 1, 2018

RECOMMENDED OPERATION (CONTINUED)

Model X880-S / X1880 with adjustable depth gauge

Model X1000

Model X1300

HOG KILL / HOT CUT / HAM

PROCESSING

TOP ROUNDS / BOTTOM

ROUNDS / BRISKETS /

CUBE STEAK MATERIAL

TURKEY

Remove skin or hair patches

Trimming pork loins and

Canadian backs

Internal and external defatting of

hams

Removing membranes and light

fat covering

Defatting turkey thighs

HOG CUT BEEF SLAUGHTER

Defat hams, picnics and butts

Removing lean from:

Picnic Face - Fat Backs

Clear Plates - Bootjack

Jowls shoulder end of belly

Belly (Wire muscle - Pickle pocket)

Plate Trim

Defatting hot beef externally and internally

Kidney fat, heart fat, pelvic fat and cod fat

BEEF KILL BEEF BONING /

FABRICATION HAM BONING

Pizzle cord removal

Removing external fat

Primal Fat Shaping:

Strips

Sirloin Butts

Ribs

Defat navels (Pastrami)

External defat of hams

External defat of pork

shoulders

Designated Use

Manual No. 107013 Designated Use 2-5

January 1, 2018 Operating Instructions and Parts List the Quantum Flex™ Trimmer

RECOMMENDED OPERATION (CONTINUED)

Model X1400 with adjustable depth gauge

Model X1500 with adjustable depth gauge

PORK PROCESSING BEEF PROCESSING

Defatting:

- Whole hams

- Shoulders

- Canadian Backs

Removing beater marks

Scraping leaf lard

Carcass hair & dirt removal

Defatting:

- New York strips & sirloin butts

- Rounds and ribeyes

PORK PROCESSING BEEF SLAUGHTER

Removing skin patches from bellies

Defatting:

- Whole hams

- Pork loins

Defatting hot beef externally

Hair and dirt removal

Designated Use

2-6 Designated Use Manual No. 107013

Operating Instructions and Parts List the Quantum Flex™ Trimmer January 1, 2018

FUNCTION

Quantum Flex™ Trimmers are durable and efficient, promoting higher yields for meat and

poultry trimming. Quantum Flex™ Trimmers are superbly designed for ease of handling while

reducing operator fatigue.

A vertically hung motor drives a flexible shaft. The flexible shaft drives a rotating blade in the

handpiece via a gear and pinion. Forces applied by the worker are greatly reduced via the drive

motor and limited to guiding the rotating knife blade.

Unpacking and Installation

Manual No. 107013 Unpacking and Installation 3-1

January 1, 2018 Operating Instructions and Parts List for the Quantum Flex™ Trimmer

Section 3 Unpacking and

Installation

CONTENTS OF THIS SECTION

Contents ..................................................................................................................................3-2

Work Station ............................................................................................................................3-3

Optional Thumb Support and Handle Adjustment ...................................................................3-4

Optional Whizard® Micro-Break Hand Strap and Adjustment .................................................3-7

Optional Disc Gauge or Depth Gauge Installation ..................................................................3-8

Optional Post Handle Kit .........................................................................................................3-9

Attaching Quantum Flex™ Trimmer to the Whizard Quantum® Driveline or Whizard® Flexshaft and

Casing Assembly ..................................................................................................................3-10

The Disconnect Casing .....................................................................................................3-10

Non-Disconnect Models .................................................................................................... 3-11

Attaching Whizard Quantum® Driveline to the Whizard Quantum® Drive Unit ......................3-12

Attaching the Whizard® Flexshaft and Casing Assembly to the Whizard® UN-84 or Whizard® Ultra

Drive Unit ..............................................................................................................................3-12

Preparation for Operation ......................................................................................................3-13

Unpacking and Installation

3-2 Unpacking and Installation Manual No. 107013

Operating Instructions and Parts List for the Quantum Flex™ Trimmer January 1, 2018

CONTENTS

The following parts are included with each Quantum Flex™ Trimmer. Please check when

unpacking and advise your local Bettcher Industries representative if the delivery is incomplete.

Models X750, X850, X880, X1850, X1880, X1000, X1300, X1400 and

X1500

PART

NUMBER DESCRIPTION QTY

100642 Whizard® Special Steel 1

100660 Special Stone for Sharpening 1

102609 13.5 oz. Cartridge of Whizard Quantum® High Performance

Grease

1

101300 Operating Instructions & Spare Parts List 1

Unpacking and Installation

Manual No. 107013 Unpacking and Installation 3-3

January 1, 2018 Operating Instructions and Parts List for the Quantum Flex™ Trimmer

WORK STATION

The work station for each operator should be designed so that the operator's movements in

performing the job are natural and easy. A sideways sweeping motion with the Quantum Flex™

Trimmer is preferable to a reaching motion. Long reaching motions and high muscle strain

should be avoided if possible. Also, a proper working height is needed to avoid excessive

shoulder and back exertion.

Refer to your appropriate Whizard® Drive Unit manual for instructions on the proper placement

and installation of your Whizard® Drive Unit.

NOTICE

Correct installation is extremely important to achieve maximum efficiency

for both the Quantum Flex™ Trimmer unit being used and the operator.

Incorrect installation may possibly hamper the operator's movements

and cause undue wear or damage to the driveline and parts of the unit.

CAUTION

Improperly hung drive units may result in excessive operator effort &

decrease in mobility. Increased fatigue & loss of efficiency may occur.

Unpacking and Installation

3-4 Unpacking and Installation Manual No. 107013

Operating Instructions and Parts List for the Quantum Flex™ Trimmer January 1, 2018

OPTIONAL THUMB SUPPORT AND HANDLE ADJUSTMENT

Your Quantum Flex™ Trimmer has been supplied with a spacer ring or optional thumb support. If

using the optional thumb support, the operator's thumb should be fully supported and rest

comfortably in the support. The thumb support has been optimized to fit most hands comfortably.

Fitting the correct size handle to the grip of an operator's hand is a very important step when

trying to reduce risks associated with cumulative trauma disorders. NOTE: S,M,L markings on

handle.

Here is a very simple procedure to determine correct handle size:

STEP 1 - Assemble three (3) knives each with a different size handle.

STEP 2 - Allow the user to hold the knife and apply the grip pressure normally used during the

job operation.

NOTE:If the operator normally wears a glove, this process should be done with all the gloves

used in normal operation.

The operator should choose the handle that is most comfortable. Allow the operator to work with

this handle on a tool for several days. If the operator is not comfortable with the handle selection,

allow the operator to try a different size.

This manual suits for next models

9

Table of contents

Other BETTCHER INDUSTRIES Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use