BETTCHER INDUSTRIES AirShirz Guide

Operating Instructions & Spare Parts List

Manual # 108057

Re-Issued: September 7, 2006

TMC # 805

For Assistance Contact:

BETTCHER INDUSTRIES, INC.

P.O. Box 336

Vermilion, OH 44089

U.S.A.

Phone: 440-965-4422

800-321-8763

Fax: 440-328-4535

www.bettcher.com

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page i

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted in any form or any means, electronic

or mechanical, for any purpose, without the express written permission of Bettcher Industries, Inc.

Written permission to reproduce in whole or part is herewith granted to the legal owners of the

AirShirz®with which these Operating Instructions have been supplied.

Operating Instructions in other languages are available on request. Additional copies of Operating

Instructions are available by calling or writing your Regional Manager, or by contacting:

BETTCHER INDUSTRIES, INC.

P.O. Box 336

Vermilion, Ohio 44089-336

U.S.A.

Telephone: 440/965-4422

(In the U.S.A.): 800/321-8763

Fax: 440/328-4535

www.bettcher.com

The Information Provided in these Operating Instructions is

Important to your Health, Comfort and Safety.

For Safe and Proper Operation, Read this Entire Manual

Before Using this Equipment.

Copyright 2016 by Bettcher Industries, Inc.

All Rights Reserved.

Original Instructions

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page ii

TABLE OF CONTENTS

SECTION 1.0 Introduction 1

1.1 Machine Specifications 1

SECTION 2.0 Designated Use 2

2.1 Warning 2

2.2 Recommended Operation 3

SECTION 3.0 Function 11

3.1 Machine Function 11

3.2 Safety Recommendations & Warnings 11

SECTION 4.0 Safety Features 13

4.1 Air Supply Quick Disconnect 14

4.2 Blade Latch 14

4.3 Fully Enclosed Finger Loop 15

SECTION 5.0 Ergonomics & Environment 16

SECTION 6.0 Unpacking 16

SECTION 7.0 Installation 17

7.1 Configuration #1-Permanent Mount to 17

End of Air Supply Pipe

7.2 Configuration #2-Mount to Air Hose or Pipe 18

with Standard Quick Disconnect

SECTION 8.0 Instructions for Operation 19

8.1 The Blade Set 19

8.1.1 Blade Installation Sequence 20

8.1.2 Blade Removal Sequence 23

8.2 MicroBreak Strap 25

8.2.1 Adjusting the MicroBreak Strap 26

8.2.2 MicroBreak Strap Removal 26

8.2.3 MicroBreak Strap Installation 27

8.3 Operation and Product Handling 28

8.4 Fault Detection & Correction 30

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page iii

TABLE OF CONTENTS

(Continued)

SECTION 9.0 Maintenance 34

9.1 Daily/Periodic Checks 34

9.1.1 Blade Sharpness 34

9.1.2 Leak Tests 34

9.1.3 Lubrication 37

9.2 Adjustments 39

9.2.1 Finger Loop Post Screw Setting 39

9.2.2 Smoothness Adjustment 40

9.2.3 Stroke Adjustment 41

9.3 Blade Sharpening and Maintenance 43

9.3.1 Steeling the Blades 43

9.3.2 Grinding the Blades 44

9.3.3 Checking Blade Sharpness 47

9.3.4 Adjusting the Blade Nut 48

9.3.5 Replacing Blade Pivot Bushing 50

9.4 Assembly/Disassembly Procedures 51

9.4.1 Cover Removal 51

9.4.2 Cover Installation 52

9.4.3 Blade Latch Removal 52

9.4.4 Blade Latch Installation 53

9.4.5 Disconnecting Master Link 53

9.4.6 Connecting Master Link 54

9.4.7 Servo Linkage Removal 54

9.4.8 Servo Linkage Installation 55

9.4.9 Finger Loop & Spring Removal 57

9.4.10 Finger Loop & Spring Installation 57

9.4.11 Drive Link Removal 59

9.4.12 Drive Link Installation 62

9.4.13 Power Cylinder Removal 63

9.4.14 Power Cylinder Installation 72

9.4.15 Control Valve Removal 73

9.4.16 Control Valve Installation 74

9.4.17 Rear Fitting Assembly Removal 75

9.4.18 Rear Fitting Assembly Installation 75

9.4.19 Air Line Coiled Tubing Replacement 76

9.4.20 Air Line Filter Element Replacement 77

9.4.21 Removing Tubing from Barbed Fittings 79

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page iv

TABLE OF CONTENTS

(Continued)

SECTION 10.0 Cleaning 79

SECTION 11.0 Spare Parts List 82

11.1 Airshirz®Exploded View 82

11.2 Small Power Cylinder Assembly 88

11.3 Large Heavy Duty Power Cylinder Assembly 90

11.4 X-Large Heavy Duty Power Cylinder Assembly 92

11.5 AirShirz® Magnum Exploded View 94

11.6 XX-Large Power Cylinder Assembly 100

11.7 Optional Equipment Available 102

SECTION 12.0 About These Operating Instructions 103

12.1 Other Languages 103

12.2 Document Identification 103

12.3 Software and Duplication 104

SECTION 13.0 Contact Addresses and Phone 104

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page v

THIS PAGE INTENTIONALLY LEFT BLANK

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 1

SECTION 1.0 INTRODUCTION

The Bettcher AirShirz®is a lightweight, yet powerful, pneumatic cutting tool designed to perform

operations previously performed by hand operated scissors or shears. It is highly effective for use

in poultry and industrial environments, designed with the highest possible standards for safety,

ergonomics, and productivity. This versatile tool, with its carefully engineered stainless steel

blades, brings consistent yield control to all operations.

The Bettcher AirShirz® described in this Operating Instruction has been tested

by an independent and certified body, the Pruef- und Zertifiezierungsstelle der

Fleischerei-Beruffsgenossenschaft, Mainz, Germany and complies with

Machine Directive 89/392/EEC and is also in conformity with prEN

12984:1997E "Food Processing Machinery Portable And/Or Hand Operated

Machines and Appliances Equipped With Mechanical Driven Cutting Tools

Safety and Hygiene Requirements", which includes compliance with the

following standards :

EN 292:1991 Parts 1 and 2

EN 31688 Acoustics

ISO 3744 Noise Measurement

EN 28662-1 Vibration Measurement

In addition, the Bettcher AirShirz® is also authorized by the USDA and Agriculture and Agri-Food

Canada for use in federally inspected meat and poultry plants.

1.1 Machine Specifications

Weight :

Power Unit

17 oz. – 24.6 oz. (480 g – 694 g) (Depending on Model)

Blade Set 4 oz. – 9.3 oz. (113g – 262g) (Depending on Model)

Size :

Power Unit

1-3/4 x 4 x 6 inches (4.5x10x15 cm)

Blade Set

Approx. 5 inches (13 cm) (Depending on Model)

Coiled Tubing 8 feet (244 cm) When Straight

Power Supply

Filtered Air At 80 to 120 PSI (5.5 To 8.3 Bars)

Air Usage

Approximately .2 Standard Cubic Ft/Min.

(5.5 l/min.) At 30 Cuts/Min.

Operating Temperature Range

0°C (32°F) to 40°C (100°F)

Exposed Materials

Stainless Steel, Anodized Aluminum, Nylon, Acetal,

Polypropylene, Nitrile, Polysulfone, Polyurethane, and

Polyetheretherketone

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 2

SECTION 2.0 DESIGNATED USE

2.1 Warning

The Bettcher AirShirz®is used for the removal of fat and tissue, the recovery of lean meat

from fat in the poultry industry and as a universal cutting tool in other applications where

manual scissors are used. Any use of this tool other than those applications for which the

AirShirz® has been designed and built may result in serious injury.

WARNING

THE MANUFACTURER ASSUMES NO LIABILITY FOR ANY UNAUTHORIZED DESIGN CHANGES,

MODIFICATIONS,OR USE OF PARTS NOT SUPPLIED BY THE MANUFACTURER OR THE USE

OF

PARTS NOT DESIGNED FOR USE ON THAT SPECIFIC MODEL,AND INCLUDES CHANGES IN

OPERATING PROCEDURES MADE BY THE OWNER OR ANY OF HIS PERSONNEL.

FOR SAFE AND PROPER OPERATION,READ THE ENTIRE

MANUAL BEFORE USING THIS EQUIPMENT.

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

ALWAYS DISCONNECT POWER AND REMOVE

THE BLADE SET PRIOR TO SERVICING.

WARNING

THE BLADES ARE VERY SHARP.WEAR CUT RESISTANT

GLOVES WHILE OPERATING THE AIRSHIRZ

®

.

WARNING

AIRSHIRZ®MAGNUM

AMPUTATION IS POSSIBLE.THE BLADES ARE VERY SHARP.WEAR METAL

MESH CUT RESISTANT GLOVES WHILE OPERATING THE AIRSHIRZ

®

MAGNUM.

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 3

2.1 Warning (Continued)

WARNING

ALWAYS CLOSE THE BLADES AND LOCK THE BLADE LATCH WHEN NOT IN USE.

CAUTION

USE ONLY REPLACEMENT PARTS MANUFACTURED BY BETTCHER INDUSTRIES

,

INC

.

USE OF SUBSTITUTE PARTS WILL VOID THE WARRANTY AND MAY CAUSE INJURY

TO OPERATORS AND DAMAGE TO EQUIPMENT.

2.2 Recommended Operation

There is an assortment of accessories available from Bettcher Industries to adapt the AirShirz®to

particular applications. Blade sets come standard in straight, curved, and ball-tip styles. Multiple

blade configurations allow for a variety of poultry processing applications such as those listed on

the following pages. These blades are not intended for cutting bones.

Special blade sets can be supplied for certain applications by contacting Bettcher Industries. Air

pressure regulators and air filters for industrial compressed air systems are also available through

Bettcher Industries. Food grade lubricants and spare parts are supplied by Bettcher Industries.

(See Section 11.2)

The following recommendations are not intended to be a total and comprehensive listing, but are

offered as a guide. Additional applications are possible.

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 4

2.2 Recommended Operation (Continued)

Straight Blades

Part

Number

Description Typical Application

108498

1-3/8” Straight Blade Assembly (Serrated)

*General Applications

108499

1-11/16” Straight Blade Assembly

*General Applications

108539

2-1/2” Straight Blade Assembly (Serrated)

*General Applications

108169 3-1/4” Straight Blade Assembly

Cut tendons from tenders

*General Applications

108702

3-3/4” Micro-Serrated

Kevlar® and Fiberglass

108053

4-1/4” Straight Blade Assembly

*General Applications

108361

5-1/4” Straight Blade Assembly

*General Applications

* General Applications

Thigh Trim

Mark Tails For Tucking

Breast Trim

Hearts-Livers Separation and Trim-Gizzard

Cut Up Wings (Trim)

House Inspection

Remove Wing Tips

Back Up USDA Inspector

Remove Tails

Mirror Inspection Station

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 5

2.2 Recommended Operation (Continued)

Gizzard Blades

Part

Number

Description Typical Application

108146

4-1/4” Gizzard Blade Assembly

Gizzard Open and Trim

108375

5-1/4” Gizzard Blade Assembly

Gizzard Open and Trim

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 6

2.2 Recommended Operation (Continued)

Ball Tip Blades

Part

Number

Description Typical Application

108209

3-1/4” Short Ball Tip Blade Assembly

J-Cut Turkey Hens / Vent Opening

108055

4-1/4” Ball Tip Blade Assembly

Backup Vent Opener and J-Cuts

108208

4-1/4” Broiler Vent Ball Tip Blade Assembly

Backup Vent Opener

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 7

2.2 Recommended Operation (Continued)

Low Profile Blades

Part

Number

Description Typical Application

108496

2-1/2” Low Profile Straight Blade Assembly

*General Applications

108475

4-1/4” Low Profile Straight Blade Assembly

*General Applications

* General Applications

Thigh Trim

Mark Tails For Tucking

Breast Trim

Hearts-Livers Separation And Trim-Gizzard

Cut Up Wings (Trim)

House Inspection

Remove Wing Tips

Back Up USDA Inspector

Remove Tails

Mirror Inspection Station

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 8

2.2 Recommended Operation (Continued)

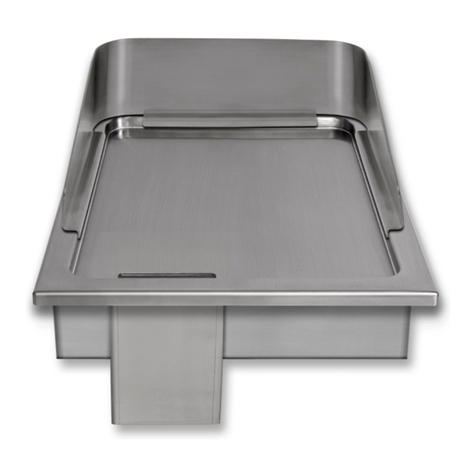

Tabletop Blades

Part

Number

Description Typical Application

108700

Micro-Serrated Tabletop Blade Assembly

Fiberglass and Textiles

108505

Tabletop Blade Assembly

Upholstery

108720

Kevlar® Tabletop Blade Assembly

Kevlar® and Heavy Fabrics

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 9

2.2 Recommended Operation (Continued)

Curved Blades

Part

Number

Description Typical Application

108054

4-1/4” Curved Blade Assembly

*General Applications

108210

4-1/4” Evis Curved Blade Assembly

*General Applications

103799

4-1/4” Reverse Curve Blade Assembly

*General Applications

* General Applications

Thigh Trim

Mark Tails For Tucking

Breast Trim

Hearts-Livers Separation And Trim-Gizzard

Cut Up Wings (Trim)

House Inspection

Remove Wing Tips

Back Up USDA Inspector

Remove Tails

Mirror Inspection Station

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 10

2.2 Recommended Operation (Continued)

Neck Breaker Blades

Part

Number

Description Typical Application

108170

Neck Breaker Blade Assembly

Rework / Salvage Necks

108224

Neck Breaker Inverted Blade Assembly

Rework / Salvage Necks

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 11

SECTION 3.0 FUNCTION

3.1 Machine Function

The smooth actuation of the AirShirz®is achieved by controlling the amount of pressurized air

delivered to both sides of the power cylinder. The servo linkage detects the positions of the

movable blade and the finger loop, and generates a command signal to open or close the blade.

This command signal is delivered to the control valve which then feeds or vents pressurized air to

the power cylinder. The power cylinder drives a rod which rotates the drive link assembly. A

roller in the drive link assembly engages a slot in the movable blade and causes it to pivot,

opening or closing the blades.

The AirShirz®has the advantage of requiring much less hand force to operate, since the actual

cutting power is supplied by air pressure. A second advantage is that it requires less movement of

the operator's hand for a given size cut. The blades will open and close 45° while the finger loop

only moves about 23°.

The AirShirz®is held and operated in the same way as a pair of hand scissors. There is a thumb

hole and a finger loop. The blades close like scissors as the finger loop is squeezed, and open as it

is released. The movement of the blades follows the movement of the finger loop.

A return spring moves the finger loop outward to the "blades open" position, relieving the

operator's finger muscles during this phase of the cutting cycle. Since the AirShirz®gets its

cutting power from the air line, the only force the operator feels during a cut is the force required

to overcome the return spring. Therefore, the amount of exertion by the operator is constant

regardless of the difficulty of the cut.

The basic AirShirz®consists of 3 parts - the Power Unit; the Blade Set; and the Filter/Coupler.

The compressed air supply line should have a standard filter and pressure regulator. A lubricator is

not required.

3.2 Safety Recommendations and Warnings

When used properly, the AirShirz® is safe and easy to use. However, since this is a high powered

cutting device, it can cause serious injury if used carelessly.

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 12

3.2 Safety Recommendations and Warnings (Continued)

WARNING

THIS ENTIRE OPERATION SECTION MUST BE READ

AND UNDERSTOOD BEFORE USING THE AIRSHIRZ

®

.

The blades are driven by linkages connecting them to the power cylinder. These linkages are

driven with a lot of force. Care has been taken in the design of the AirShirz® such that the

operator's fingers will be safely away from any pinch points as long as the unit is held in the

normal manner and operated with cover in place. For left handed users, an additional finger

guard is available to prevent the accidental placement of the finger in the blade opening (part

number 108455).

Never leave the AirShirz®with the blades open as serious injuries could result! When the

tool is not in use or is being handled in any way other than cutting product, (i.e., cleaning,

maintenance, etc.), the air supply should be disconnected at the quick disconnect.

WARNING

LEFT HANDED USERS!

ALL FOUR FINGERS MUST BE KEPT IN THE FINGER

LOOP DURING USE TO AVOID INJURY!

WARNING

IF AT ANY TIME THIS MACHINE DOES NOT APPEAR TO OPERATE NORMALLY,

OR EXHIBITS A MARKED CHANGE IN PERFORMANCE,IT SHOULD BE

IMMEDIATELY DISCONNECTED FROM THE AIR SUPPLY AND

TAGGED AS UNSAFE UNTIL SUCH TIME AS PROPER REPAIRS

ARE MADE AND THE MACHINE AGAIN OPERATES NORMALLY.

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 13

3.2 Safety Recommendations and Warnings (Continued)

WARNING

SHARP BLADES MAY CAUSE CUT INJURY!

ALWAYS DISCONNECT POWER

AND REMOVE THE BLADE SET PRIOR TO SERVICING.

WARNING

THE BLADES ARE VERY SHARP.WEAR CUT RESISTANT

GLOVES WHILE OPERATING THE AIRSHIRZ

®

.

WARNING

AIRSHIRZ®MAGNUM

AMPUTATION IS POSSIBLE.THE BLADES ARE VERY SHARP.WEAR METAL

MESH CUT RESISTANT GLOVES WHILE OPERATING THE AIRSHIRZ

®

MAGNUM.

WARNING

ALWAYS CLOSE THE BLADES AND LOCK

THE BLADE LATCH WHEN NOT IN USE.

SECTION 4.0 SAFETY FEATURES

The AirShirz®is designed to be safe and easy to use. The functions of these features should be

clearly understood before operating this tool.

OPERATING BETTCHER AIRSHIRZ®

INSTRUCTIONS INDUSTRIES, INC. Rev. September 24, 2016

Page 14

4.1 Air Supply Quick Disconnect

The push of a tab will disconnect the twin coiled tubing from the coupler (see Figures #1 and #2).

To reconnect the air, push the couplings back together until the tab on the coupler clicks into

position. (Sometimes it may be necessary to push the tab inward while inserting the connector).

This connector should be disconnected when the tool is not in use.

WARNING

ALWAYS CHECK THAT THE BLADES ARE CLOSED

AND THE BLADE LATCH IS IN THE LOCKED

POSITION BEFORE CONNECTING THE AIR LINE.

4.2 Blade Latch

There is a latching ring just forward of the finger loop. When the finger loop is pulled inward

against the power cylinder, ("blades closed" position), this ring can be rotated down against the

finger loop. (See Figures #3 and #4). In this position, the finger loop will be locked closed and

will be unable to drive the blades once they are closed.

Care should be taken to assure that the blades are closed before locking the blade latch. If the

AirShirz®is connected to the air supply, simply hold the tool as if to make a cut, pull the finger

loop fully inward, causing the blades to close, and rotate the latch to the locked position.

If the air supply is not connected, close the blades manually by squeezing them together with a

gloved hand. Then pull the finger loop fully inward and rotate the latch to the locked position.

This is the normal rest position for handling the AirShirz®, i.e., Blades Closed - Latch

Locked. Failure To Follow This Procedure Can Lead To Serious Injury.

PRESS

TAB

FIGURE # 1

FIGURE # 2

Table of contents

Other BETTCHER INDUSTRIES Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Costan

Costan VELVET CURVE User instructions

Diamond

Diamond Atomix DH42AL/T2V user manual

Berner

Berner BGI40 operating instructions

Henny Penny

Henny Penny FlexFuison GOLD FGE-615 installation manual

Hussmann

Hussmann R3B Installation & operation guide

Lotus

Lotus LIBR.ISTR.BM110E Installation and operating instructions

Fama

Fama FIC 30M operating manual

Vollrath

Vollrath Stoelting SF144 I2 Operator's manual

Diamond

Diamond SA/61G Instructions for use and installation

CARTER-HOFFMANN

CARTER-HOFFMANN CD27 Cleaning, Operating, Maintenance Instructions, Parts List & Warranty

Piper

Piper 7QT-D-T-R-120 Installation and operating manual

Ruhle

Ruhle MPR 400 Original instructions