Bettersafe Guard Angel User manual

Installation Manual

October 2015: Rev 1.0

Installation

Manual

October 2015

Revision 1.0

Installation Manual

October 2015: Rev 1.0

2

General Information

Guard Angel is tested in accordance with BS EN 13374 and BS EN 14122-3.

It is designed for use on roofing areas and raised platforms for access to areas of buildings and

structures that are deemed unsafe to do so otherwise.

The Guard Angel System is not designed for use as an attachment point for fall protection PPE.

The equipment used should be stored in a safe manner and moved to the point of installation in

line with the Manual Handling Regulations in the region of use.

Installation should only be carried out by a trained and competent installer with the permission of

Fall Angel or their appointed representatives. Appropriate safety measures must be taken to

ensure the complete safety of all installation personnel.

All tools used must be in good working order and calibrated and tested where applicable.

Installation Manual

October 2015: Rev 1.0

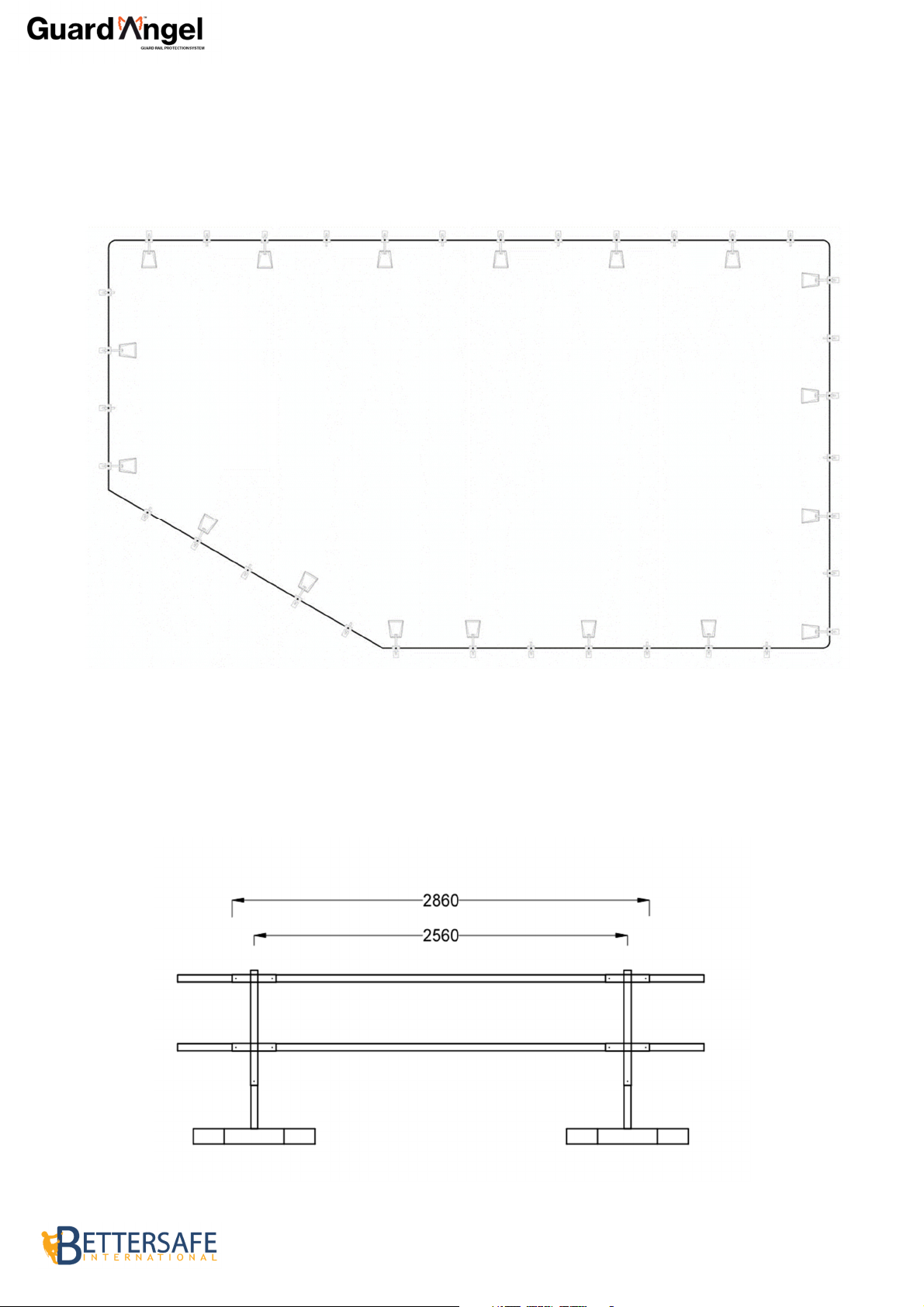

CONFIGURATION

Edge Protection - System Configuration

TYPICAL LAYOUT

INSITU DIMENSIONS

Installation Manual

October 2015: Rev 1.0

TYPICAL CORNER DETAIL TYPICAL WALL TERMINATION DETAIL

TYPICAL ‘D’ END TERMINATION DETAIL TYPICAL END CAP TERMINATION DETAIL

CONFIGURATION

Edge Protection - System Configuration

Free Standing System Shown for Example Only

Installation Manual

October 2015: Rev 1.0

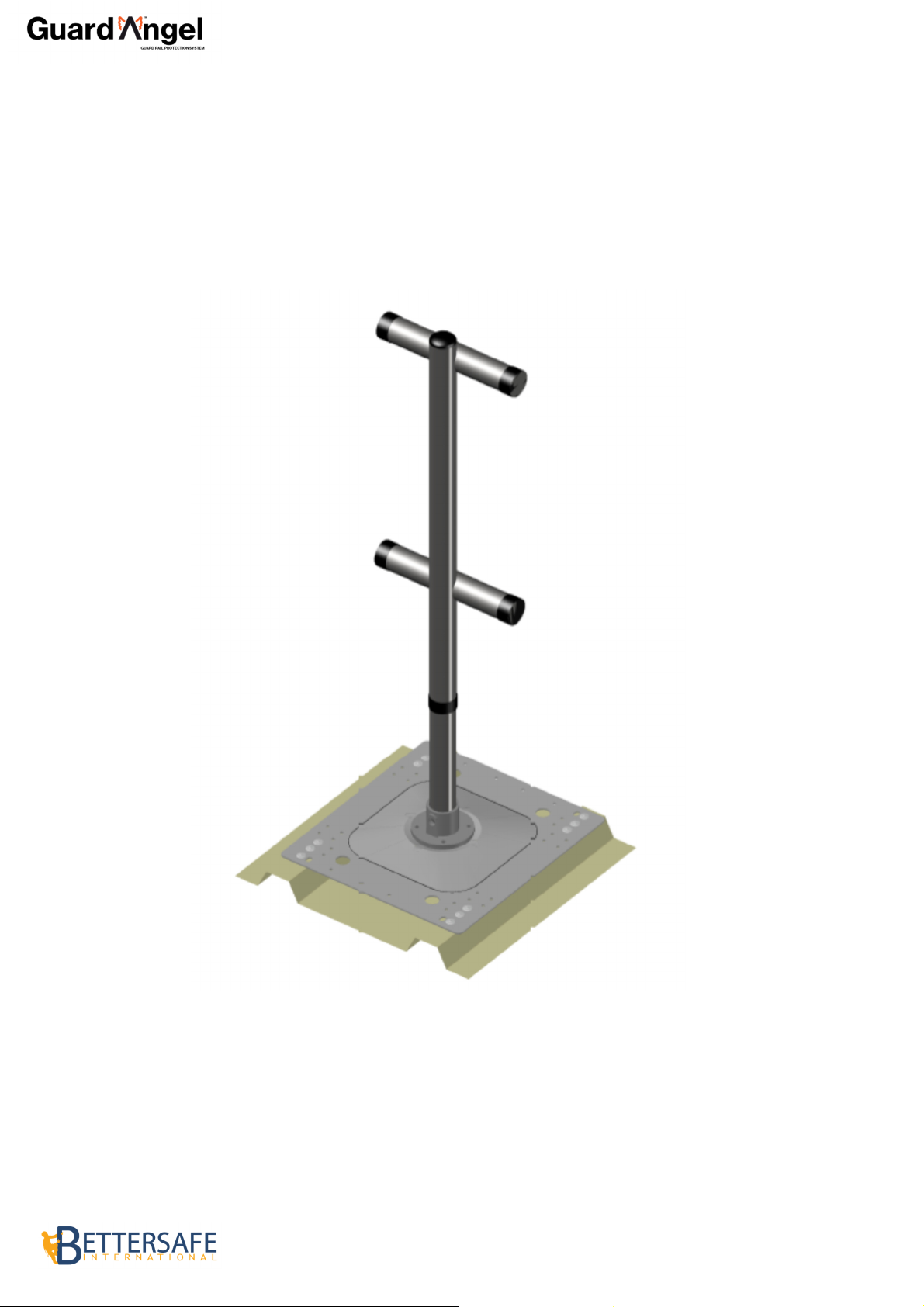

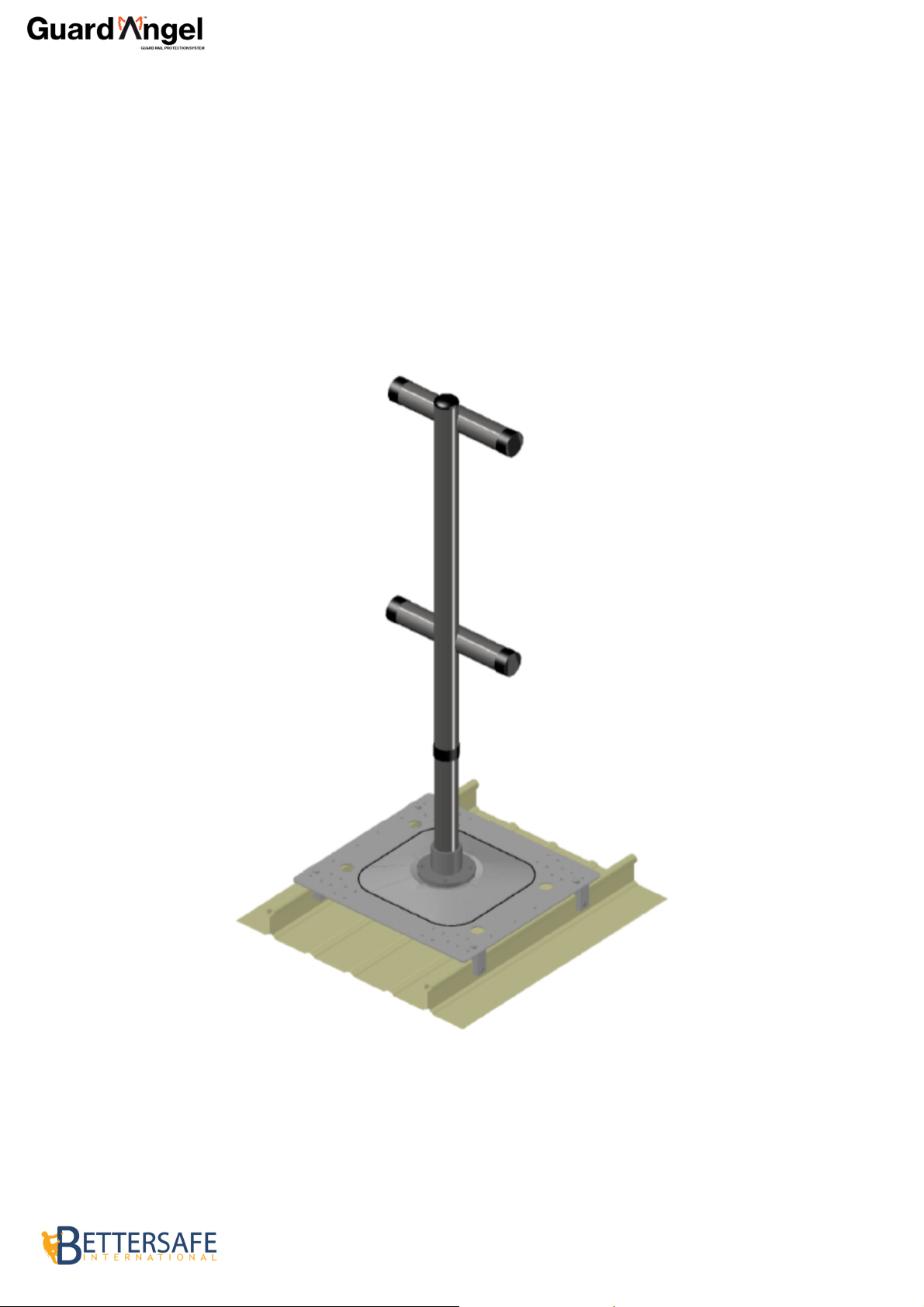

Free Standing System

Installation

Installation Manual

October 2015: Rev 1.0

SPECIFICATION

Free Standing Edge Protection System - Specification

GENERAL DESCRIPTION

The Guard Angel freestanding edge protection system is a cantilevered guardrail system that does not require

any mechanical fixing into the roof surface. This system has been designed and manufactured to fully comply

with current HSE regulations.

MATERIAL

The main and intermediate uprights are fabricated from 2 x 54 mm pre galvanised steel to BS EN ISO 1461,

with the upper and lower cross rails manufactured from 2 x 54mm external diameter pre galvanised steel. The

lower leg sections are manufactured from 3x47.6mm hot dipped galvanised steel. Also available polyester

powder coated.

The rubber counterweight is manufactured from 100% recycled rubber compound with the fixing screws

manufactured from zinc-coated steel.

SAFETY STANDARDS

Our Freestanding guardrail is tested to the following safety standards:

•HSG-33 Health and safety in roof work.

•HSE INDG 284 “Working on roofs”.

•EN ISO 14122 Part 3.

•EN 13374 Class A.

•BS 6399: Part 2 1995 Wind Code.

Installation Manual

October 2015: Rev 1.0

NOTE: Wherever possible the starting point for all installations should be the corners,

remembering to carry out the initial setting out a minimum distance of 2m from the edge of

the roof.

Step 1 - Corner assembly

Begin by assembling a complete corner unit consisting of one weighted upright,

one un-weighted upright, one counter weight, two sweeping 90 deg bends and two handrail

tubes cut to length.

Cut two handrail tubes down to form two tubes at 1200mm and two at 1300mm.

Take the one upright and connect a counter weight to it, Insert one 1200mm tube into

the top of the Top riser coupler and one 1300mm tube into the bottom of the top riser

coupler, fully tightening the screws as you do so. Repeat the process for connecting

the cut tubes to the SUP.

Join the un-weighted upright assemblies using two sweeping bends ensuring that all the

screws are fully tightened.

Using two people carry the corner assembly to the roof edge, being careful to remain

behind the assembly at all times.

INSTALLATION

Free Standing Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Step 2 - Setting out

Starting at the corner, place the 2.5m handrail tubes end to end in pairs along the length of the roof and starting

from the corner alternate a counter weight/upright and an un-weighted upright between each pair of handrail

tubes

Once the weighted uprights and the un-weighted uprights are in place connect a counterweight to the alternate

uprights.

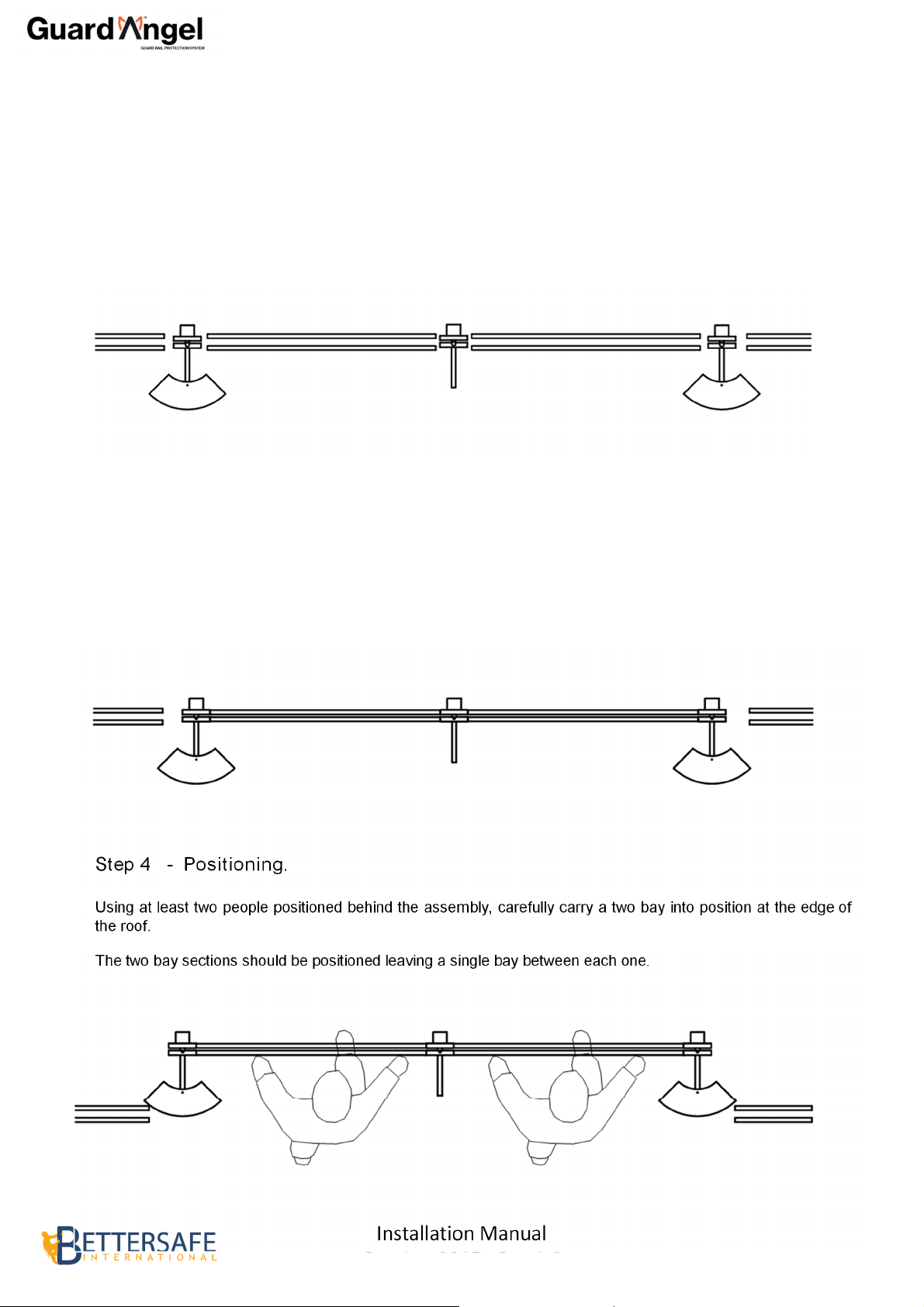

Step 3 - Section assembly

Once the setting out is complete continue to assemble the first 2 bay section by connecting the second and

third pair of handrail tubes to the first and second uprights and fully tighten the screws.

Join these two weighted upright assemblies together using an un-weighted uprights. You now have a

completed two bay section. Repeat the above process until all the two bay sections are assembled.

Step 4 - Positioning.

Using at least two people positioned behind the assembly, carefully carry a two bay into position at the edge of

the roof.

The two bay sections should be positioned leaving a single bay between each one.

INSTALLATION

Free Standing Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Step 5 - Final assembly

Using the remaining handrail piece - in between the two bay assemblies.

By placing one person either side of the opening behind the existing handrail assemblies, connect the

remaining handrail tubes into the top and bottom of the top riser sections on each upright fully tightening the

screws as you go.

INSTALLATION

Free Standing Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

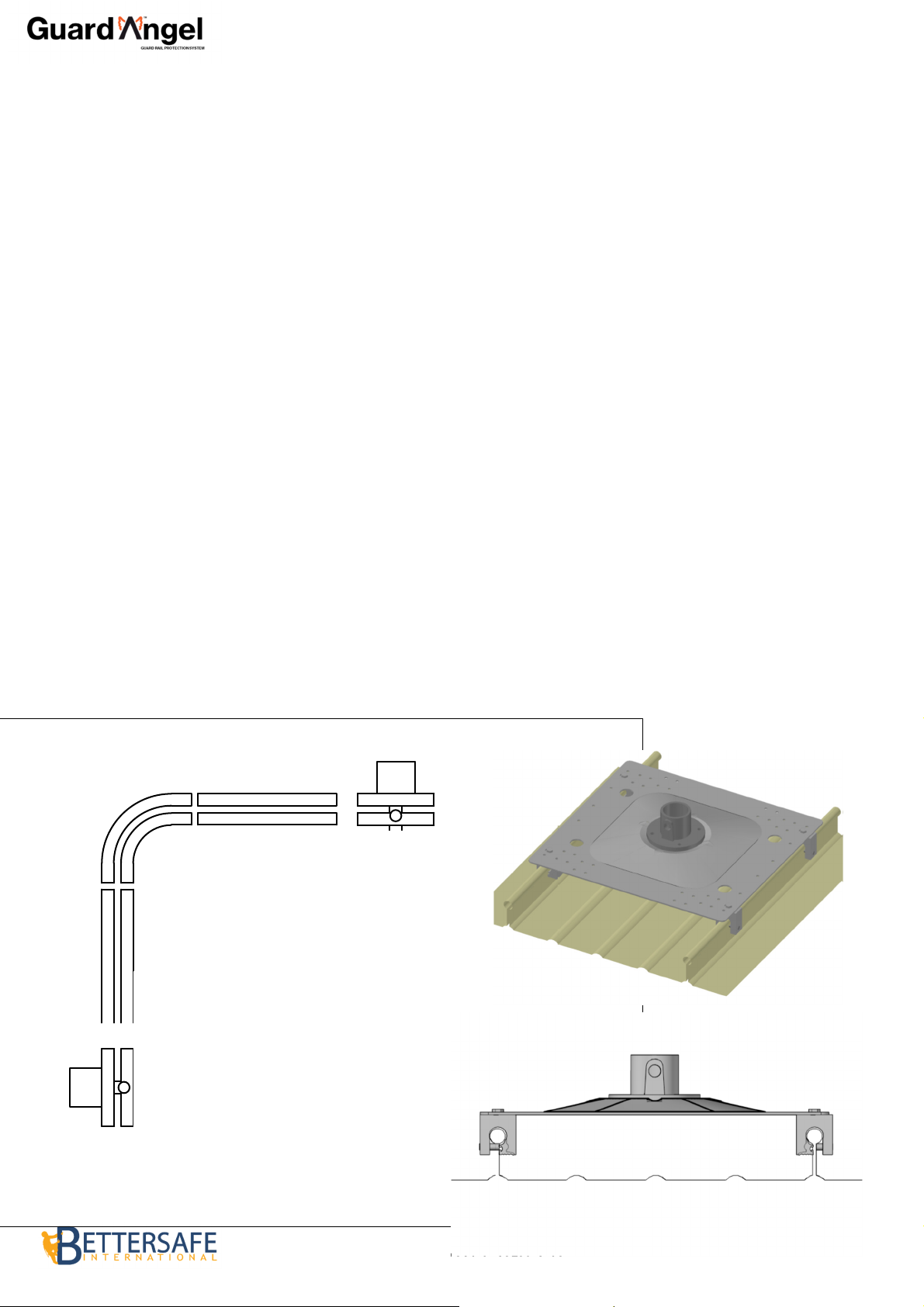

Profiled Roofing System

Installation

Installation Manual

October 2015: Rev 1.0

SPECIFICATION

Profiled Roof Edge Protection System - Specification

GENERAL DESCRIPTION

The Guard Angel profiled roofing edge protection system is a guardrail system that is mechanically fixed into the

exterior roof surface using rivets. This system has been designed and manufactured to fully comply with current

HSE regulations.

MATERIAL

The main and intermediate uprights are fabricated from 2 x 54 mm pre galvanised steel to BS EN ISO 1461,

with the upper and lower cross rails manufactured from 2 x 54mm external diameter pre galvanised steel. The

lower leg sections are manufactured from 3x47.6mm hot dipped galvanised steel. Also available polyester

powder coated.

SAFETY STANDARDS

Our Freestanding guardrail is tested to the following safety standards:

•HSG-33 Health and safety in roof work.

•HSE INDG 284 “Working on roofs”.

•EN ISO 14122 Part 3.

•EN 13374 Class A.

•BS 6399: Part 2 1995 Wind Code.

Installation Manual

October 2015: Rev 1.0

NOTE: Wherever possible the starting point for all installations should be the corners,

remembering to carry out the initial setting out a minimum distance of 2m from the edge of

the roof.

Step 1 - Corner assembly

Begin by assembling a complete corner unit consisting of two uprights, two

sweeping 90 deg bends and two handrail tubes cut to length.

Cut two handrail tubes down to form two tubes at 1200mm and two at 1300mm.

Take the one upright, Insert one 1200mm tube into the top of the Top riser coupler and

one 1300mm tube into the bottom of the top riser coupler, fully tightening the screws

as you do so. Repeat the process for connecting the cut tubes to the SUP.

Join the upright assemblies using two sweeping bends ensuring that all the screws are fully

tightened.

Using two people carry the corner assembly to the roof edge, being careful to remain

behind the assembly at all times.

Fix the base plate to the profile sheet using the specified rivets and sealing washers.

INSTALLATION

Top Fix Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Step 2 - Setting out

Starting at the corner, place the 2.5m handrail tubes end to end in pairs along the length of

the roof and starting from the corner place an upright between each pair of handrail tubes

Step 3 - Section assembly

Once the setting out is complete continue to assemble the first 2 bay section by connecting

the second and third pair of handrail tubes to the first and second uprights and fully tighten

the screws.

Join these three upright assemblies together. You now have a completed two bay

section. Repeat the above process until all the two bay sections are assembled.

Step 4 - Positioning.

Using at least two people positioned behind the assembly, carefully carry a two bay into

position at the edge of the roof.

The two bay sections should be positioned leaving a single bay between each one.

Fix the base plate to the profile sheet using the specified rivets and sealing washers.

INSTALLATION

Top Fix Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Step 5 - Final assembly

Using the remaining handrail piece - in between the two bay assemblies.

By placing one person either side of the opening behind the existing handrail

assemblies, connect the remaining handrail tubes into the top and bottom of the top riser

sections on each upright fully tightening the screws as you go.

INSTALLATION

Top Fix Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Standing Seam Roofing

System

Installation

Installation Manual

October 2015: Rev 1.0

SPECIFICATION

Profiled Roof Edge Protection System - Specification

GENERAL DESCRIPTION

The Guard Angel profiled roofing edge protection system is a guardrail system that is mechanically fixed into the

exterior roof surface using seam clamps. This system has been designed and manufactured to fully comply with

current HSE regulations.

MATERIAL

The main and intermediate uprights are fabricated from 2 x 54 mm pre galvanised steel to BS EN ISO 1461,

with the upper and lower cross rails manufactured from 2 x 54mm external diameter pre galvanised steel. The

lower leg sections are manufactured from 3x47.6mm hot dipped galvanised steel. Also available polyester

powder coated.

SAFETY STANDARDS

Our Freestanding guardrail is tested to the following safety standards:

•HSG-33 Health and safety in roof work.

•HSE INDG 284 “Working on roofs”.

•EN ISO 14122 Part 3.

•EN 13374 Class A.

•BS 6399: Part 2 1995 Wind Code.

Installation Manual

October 2015: Rev 1.0

NOTE: Wherever possible the starting point for all installations should be the corners,

remembering to carry out the initial setting out a minimum distance of 2m from the edge of

the roof.

Step 1 - Corner assembly

Begin by assembling a complete corner unit consisting of two uprights, two

sweeping 90 deg bends and two handrail tubes cut to length.

Cut two handrail tubes down to form two tubes at 1200mm and two at 1300mm.

Take the one upright, Insert one 1200mm tube into the top of the Top riser coupler and

one 1300mm tube into the bottom of the top riser coupler, fully tightening the screws

as you do so. Repeat the process for connecting the cut tubes to the SUP.

Join the upright assemblies using two sweeping bends ensuring that all the screws are fully

tightened.

Using two people carry the corner assembly to the roof edge, being careful to remain

behind the assembly at all times.

Fix the base plate to the profile sheet using the standing seam clamps.

INSTALLATION

Top Fix Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Step 2 - Setting out

Starting at the corner, place the 2.5m handrail tubes end to end in pairs along the length of

the roof and starting from the corner place an upright between each pair of handrail tubes

Step 3 - Section assembly

Once the setting out is complete continue to assemble the first 2 bay section by connecting

the second and third pair of handrail tubes to the first and second uprights and fully tighten

the screws.

Join these three upright assemblies together. You now have a completed two bay

section. Repeat the above process until all the two bay sections are assembled.

Step 4 - Positioning.

Using at least two people positioned behind the assembly, carefully carry a two bay into

position at the edge of the roof.

The two bay sections should be positioned leaving a single bay between each one.

Fix the base plate to the profile sheet using the standing seam clamps.

INSTALLATION

Top Fix Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

Step 5 - Final assembly

Using the remaining handrail piece - in between the two bay assemblies.

By placing one person either side of the opening behind the existing handrail

assemblies, connect the remaining handrail tubes into the top and bottom of the top riser

sections on each upright fully tightening the screws as you go.

INSTALLATION

Top Fix Edge Protection - System Configuration

Installation Manual

October 2015: Rev 1.0

oncrete Structure Fixed

System

Installation

Other manuals for Guard Angel

1

Table of contents

Other Bettersafe Protection Device manuals