Foster ECORPO G3 EP1/2H User manual

2www.fosterrefrigerator.com

Three Steps

Operating Instructions

to maintain and service your appliance

Service Function

- Parameters

- Alarm Indicators

- Probe Data

- Relay Test

- Factory Reset

- Wiring Diagrams

Maintenance

Welcome to your interactive

Foster service manual.

Here’s how it works:

To return to the contents

at any point, click on the Foster

logo at the bottom of every page.

3G3 Counters - Service Manual

General Information

All installations must conform to local and municipal regulations and directives. In the case of doubt contact a Foster authorised

dealer or the Foster Technical Department. The information contained in this manual is current at the time of publication and is

subject to change without notice.

General Safety

- Do not store explosive substances such as aerosol cans with a ammable propellant in this

appliance.

- Keep all ventilation openings in the appliance or in the structure of a built in unit clear of any

obstructions.

- Do not use electrical appliances inside the storage compartment.

- Do not use steam cleaners, pressure washers or other jets/sprays of water on or around the appliance.

- The appliance is air tight when the door or drawers are closed therefore under no circumstances should any living body be stored or ‘locked in’

the appliance.

- This appliance is heavy. When moving the appliance care should be taken and correct safe practices followed. The appliance should not be

moved over uneven surfaces.

- The emitted sound level of this appliance is not greater than 70dB(A).

- To ensure stability the appliance should be located on a at, level surface, correctly loaded.

- Do not use mechanical devices to accelerate the defrost process.

- The worktop should not be sat or stood on.

- Where the appliance is tted with drawers these should not be used as a step to assist or gain height.

- Where the appliance is tted with drawers, do not sit or stand in the drawers.

- Care should be taken not to damage the refrigeration circuit and/or system.

- If the supply cord is damaged, it must be replaced by the manufacturer, it’s service agent or similarly qualied persons in order to avoid hazards.

- Care should be taken to avoid prolonged contact with cold surfaces with unprotected body parts, correct PPE to be used at all time.

Climate Class

Climate class indicated on the serial plate shows the ambient temperature & humidity at which this appliance has been tested, for the purposes of

establishing values in line with European standards.

Climate Class Temperature Relative humidity

4 30˚C 55%

5 40˚C 40%

Disposal Requirements

This appliance contains components and materials which can be harmful to the environment if

not disposed of correctly. Disposal of this appliance should be carried out by a suitably licensed

waste contractor in accordance with national laws and regulations which may be in force at the

time.

Electrical Safety

Foster Refrigerator recommends that the equipment is electrically connected via a Residual

Current Device; such as a Residual Current Circuit Breaker (RCCB) type socket, or through a

Residual Current Circuit Breaker with Overload Protection (RCBO) supplied circuit.

4www.fosterrefrigerator.com

Locating the appliance

After unpacking, clean (cleaning directions supplied within this manual) and allow the appliance

to stand for 60 minutes before turning on.

Ensure the appliance is situated on a rm, level surface, away from both hot and cold air

sources, as this will aect its performance.

Place the appliance in a location so as not to exceed the maximum rated ambient

temperature.

The appliance produces warm air when operating normally and requires adequate

ventilation. The dimensions indicated are a minimum.

As the operating temperature has been pre-set no adjustments are required. Allow the

appliance to reach its normal operating temperature before loading with product.

Connect the appliance to a suitable power supply. Do not connect or disconnect the

appliance with wet hands. The appliance will turn on automatically displaying the actual

internal temperature of the appliance. If this does not happen and button 3 is‘pulsing’

press and hold button 3 for 3 seconds to turn on the appliance.

50mm

50mm

5G3 Counters - Service Manual

Display Icons and Buttons

Operating Instructions

1

Standby

Pressing button 3 for 3 seconds will turn the unit on or into standby. When in standby, only button 3 will be displayed. The remainder of the display

will be blank. When operating normally, the display will show the internal temperature and button 3.

Icon Button

1 Compressor running 1 Information menu

2 Keypad locked 2 Increase value

3 Evaporator fans running 3 Standby/Exit/Conrm

4 Defrost in progress 4 Decrease value

5 Alarm 5 Light (If tted)

6/7 Display units Centigrade or

Fahrenheit

8 Auxillary output operation

Note - Buttons 1, 2, 4 and 5 are only visible after pressing button 3

+2

Icon 2 Icon 3

Icon 1

Icon 6

Button 1

Button 2

Button 3

Button 4

Button 5

Icon 7

Icon 8

Icon 5

Icon 4

Appliance internal

temperature

6www.fosterrefrigerator.com

40

KG

Defrost

The appliance has an automatic defrost function and will defrost periodically each day without

any user intervention. This process is normal and does not aect product stored in the appliance.

During defrost the appliance can be used as normal.

Keypad Security Settings

We advise that this function is used to prevent unauthorised adjustment of the appliance and it’s operating temperature.

Press and release button 3. Then press button 1 followed by button 4 to display ‘Loc’. Press button 3 and use buttons 2 and 4 to change the value

to ‘Yes’ to lock the keypad or ‘no’ to unlock it. Press button 3 to save the new value. If button 3 is not pressed the new value will not be stored.

The display will reset after 30 seconds or by pressing button 1.

Shelves, Supports, Loading and Air Flow

The appliance is supplied with adjustable, removable trayslides and shelves.

Each shelf is capable of holding up to 40kg of product evenly distributed.

Do not block air vents with product. A minimum of 25mm should be maintained between the

top of the product and the shelf above.

Do not place product on the base of the appliance. If it is required to store product on the base of

the appliance please contact the Foster parts team to purchase the necessary shelf and spacers.

Always ensure air can circulate around/through the stored product. It is important that for optimal

energy performance that adequate airow is maintained around the perimeter of the shelves, and

around all stored products.

Where the appliance is tted with drawers these should not be used as a step to assist or gain

height.

Where the appliance is tted with drawers, do not sit or stand in the drawers.

Set Point

To display the appliance Set Point, with the display showing the temperature, press button 3. Then press button 1 and with the display showing ‘SP’

press button 3.

To amend the Set Point press button 3. Then press button 1 and with the display showing‘SP’press button 3. Adjust using button 2 and button 4.

Press button 3 to save the new value. If button 3 is not pressed the new value will not be stored.

If the Set Point cannot be adjusted to the value required please contact your authorised Foster dealer for advice.

The display will reset after 30 seconds or by pressing button 1.

Door Lock

To lock the door insert the key and turn 90°, turn in the opposite direction to unlock.

Internal Light (Applicable to models with glass doors)

The light is operated using button 5. Press once to turn on the light and press again to turn o

the light.

7G3 Counters - Service Manual

Controller Menu’s

The controller contains 2 menu levels, user level and service level.

User Level Menu

To access user level settings, press button 3 and then press button 1. The display will show‘SP’. Use buttons 2 and 4 to display the parameter

required. Press button 3 to display the current value. If it is required to amend the value use buttons 2 and 4 followed by button 3 to save the new

value.

User Level Parameters

Mnemonic

Description

SP Appliance Set Point

Loc Keypad Lock

tA Actual air probe value

tE Actual evaporator probe value (Not enabled on all models)

tLo Minimum air temperature during previous 24 hours

tHi Maximum air temperature during previous 24 hours

dEF Time until next scheduled defrost. Displayed in tenths of hours. For example 05.4 = 5 hours 40 minutes

tdy Display resolution

Service Function

2

8www.fosterrefrigerator.com

Service Level Parameters

Mnemomic

Description

MDL Do not adjust

SPL Minimum limit for SetPoint

setting

SPH Maximum limit for SetPoint

setting

SP Setpoint Temperature value to be maintained in the product

HY0 Thermostat OFF -> ON

dierential

In Cooling Mode - ‘MDL’ = ‘HYS’

HY1 Do not adjust

CMD Compressor start delay ‘run’

mode

The time between mains power being applied and the compressor starting when in ‘run’

mode (i.e. following a mains power cut)

CRT Compressor rest time Minimum time compressor is switched o following cycle operation (i.e. pull down, hot

gas defrost)

CT1 Compressor output on time Followed by ‘CT2’ when probe Ta (T1) is faulty

CT2 Compressor output o time Followed by ‘CT1’ when probe Ta (T1) is faulty

PB Do not adjust

IT Do not adjust

DT Do not adjust

CT Do not adjust

AR Do not adjust

CMS Do not adjust

CRS Do not adjust

CRD Do not adjust

CDS Do not adjust

CFF Do not adjust

CSS Do not adjust

CSO Do not adjust

CST Do not adjust

DFM

Defrost start mode

Defrost start mode

‘NON’- defrost function is disabled - no defrosts will occur

‘TIM’ - Time. Defrosting occurs on a time base determined by‘DFT’, accumulated only in

run mode

‘FRO’ - Do not use

‘DoD’ - Do not use

‘TAD’- Do not use

DFT Time interval between defrosts When this time has elapsed since the previous defrost (in run mode), a new defrost cycle

is initiated

DSP Do not adjust

DST Do not adjust

DMI Do not adjust

DLI Defrost end temperature

DTO Maximum defrost duration

DTY

Defrost type ‘OFF’- O cycle defrost (Compressor and Heater OFF)

‘ELE’ - Electric defrost (Compressor OFF and Heater ON)

‘GAS ‘ - Hot gas defrost (Compressor and Heater ON)

DSY

Defrost start synchronization ‘OFF’- none. The defrost will occur without delay

‘LO’ - defrost start will be postponed to compressor cut-out (SOD = max delay)

HI’- defrost start will be postponed to compressor cut-in (SOD = max delay)

SOD Do not adjust

DPD Evaporator pump down At the beginning of defrost, defrost outputs (determined by ‘DTY’) are ‘OFF’for ‘DPD’

seconds

DRN Pause after defrost (evaporator

drain down time)

DDM

Defrost display mode. RT’ - the real / actual temperature

LT’ - the last temperature displayed before defrost initiation

SP’ - the setpoint value

dEF’ - ‘dEF’

Service Level Menu

To access service level menu, press button 3 then press and hold buttons 2 and 4 for 5 seconds and the display will show ‘MDL’. Press button 3 to

display the current value. If it is required to amend the value use buttons 2 and 4 followed by button 3 to save the new value.

9G3 Counters - Service Manual

DDY Display delay The display shows the information selected with parameter‘DDM’during defrost and for

‘DDY’ minutes after defrost termination

FID Evaporator Fans in defrost YES - Fans active during defrost and drain (‘DRN’) and recovery / NO - Fans o during

defrost and drain (‘DRN’) and recovery (fan start based on ‘FDD’ or ‘FTO’- whichever rst)

FDD Evaporator fan re-start

temperature after defrost

FTO Maximum evaporator fan stop

after defrost

FSD ‘Evaporator fan stop delay after

door opens

Time in seconds: ‘-1’ = fan(s) do not stop /‘0’ = fan(s) stop instantaneously / ‘1’-’900’ = fans

stop after prescribed time elapses

FCM

Thermostatic control fan mode ‘NON’- The fans remain ON all the time (subject to door switch operation and defrosts).

‘TMP’- Temperature-based control. The fans are ON when the compressor is ON. When

the compressor is turned OFF, the fans remain ON as long as the temperature dierence

Te-Ta is greater than ‘FDT’

TIM’- Timed-based control. The fans are ON when the compressor is ON. When the

compressor is OFF, the fans switch ON and OFF according to parameters ‘FT1’, ‘FT2’ and

‘FT3’

FDT Evaporator fan compressor

stop over-run

Where Evaporator (Te) -Air (Ta) temperature dierence for the fans to turn OFF after the

compressor has stopped

FDH Temperature dierential for fan

re-start

Example: ‘FDT’= ‘-1’and ‘FDH=3’. If compressor is stopped, the fans are OFF when Te> Ta

‘-1’ (‘FDT’), whereas the fans are ON when Te < Ta ‘-4’ (‘FDT’-’FDH’)

FT1 Fan stop delay after compressor

stop

FT2 Timed fan stop When ‘FT2’ = ‘0’ the fans remain on all the time

FT3 Timed fan run When ‘FT3’ = ‘0’, and ‘FT2’ > ‘0’, the fans remain OFF all the time

ATM

Alarm threshold management ‘NON’ - all temperature alarms are inhibited (the following parameter will be‘ACC’)

‘ABS’ - the values programmed in ‘ALA’ and‘AHA’ represent the real alarm thresholds

‘REL’ - the alarm threshold is obtained by the sum of setpoint, thermostat dierential and

‘ALR’ / ‘AHR’

ALA Low temperature alarm

threshold

AHA High temperature alarm

threshold

ALR Low temperature alarm

dierential

With ‘ALR’ = ‘0’the low temperature alarm is excluded

AHR High temperature alarm

dierential

With ‘AHR’ = ‘0’the high temperature alarm is excluded

ATI Probe used for temperature

alarm detection

PAD

Delay before alarm

temperature warning at power

on

ATD Delay before alarm

temperature warning

ACC

Condenser periodic cleaning When the compressor operation time, expressed in weeks, matches the ‘ACC’ value

programmed, ‘CL’ ashes in the display. With ‘ACC’ = ‘0’the condenser cleaning warning is

disabled

ECO Do not adjust

ESP Do not adjust

EH0 Do not adjust

EH1 Do not adjust

EPB Do not adjust

EDM Do not adjust

EDF Do not adjust

EDL Do not adjust

EDO Do not adjust

EDR Do not adjust

EFD Do not adjust

EFT Do not adjust

EFC Do not adjust

ESD Do not adjust

EFS Do not adjust

EMF Do not adjust

DSM

Door switch mode ‘NON’- when ‘DI1’/’T3A’ = ‘DOR’ there is no response to a state change

‘ALR’- when ‘DI1’/’T3A’= ‘DOR’and the digital input is ON, an alarm is generated after

‘DAD’ minutes

‘STP’ - when ‘DI1’/’T3A’ = ‘DOR’’ and the digital input is ON, in addition to the alarm, the

fans are stopped according to FSD and the compressor is stopped after ‘CSD’seconds

10 www.fosterrefrigerator.com

DAD Delay before door open alarm

warning

CSD ‘Relay 1’ stop delay after door

open

‘0’ … ‘900’- time in seconds (‘-1’ = ‘Relay’does not de-energise / ‘0’= instantaneous / ‘1’-

’900’ = de-energises after prescribed time elapses)

DOT

Door stop overide If the door switch remains open for longer than‘DOT’ minutes, the operating functionaity

returns to normal thermostatic control, howver the alarm will remain. When ‘DOT’= ‘0’,

this function is disabled

DI1

‘DI1’ digital input ‘NON’- Digital Input 1 not active

‘DOR’ - door input

‘ALR’- when the input is activated (set by ‘D1A’) alarm‘Alr’ alarm is generated, the

compressor is stopped and the defrosts are suspended

‘ECO’- Do not use

‘RDS’- Do not use

D1A ‘DI1’ activation ‘OPN’ - on open

‘CLS’- on close

LCM

Light control mode ‘NON’- light output not controlled

MAN’- light output controlled through display operating button (when ‘SR1’, ‘SR2’or ‘RL2’

= ‘LGT’ )

‘ECO’- Do not use

‘DI1’ - Do not use

‘NI1’ - Do not use

‘DI2’ - Do not use

‘NI2’ - Do not use

SR1

SSR1 output operation ‘NON’- Relay output disabled (always O/Open)

‘LGT’ - Output enabled for light control

‘0-1’ - Relay contacts follow the on/standby state of controller

R1’ - Do not use

‘R1F’- Do not use

‘-R1’ - Do not use

‘FAN’- Output enabled for evaporator fan switching

‘-FAN’ Do not use

‘DEF’- Output enabled for defrost switching

‘-DEF’- Do not use

‘ALO’- Contacts open when an alarm condition occurs

‘ALC’ - Contacts make when an alarm condition occurs

‘ACP’- Do not use

‘AFH’ - Do not use

SR2 SSR2 output operation Same operations and selection as‘SR1’

RL2

RL2 output operation - same

operations and selection as

‘SR1’

Same operations and selection as ‘SR1’

ACN Do not adjust

ACF Do not adjust

AHS Do not adjust

AHU Do not adjust

AFT Do not adjust

PMD Do not adjust

MSV Do not adjust

2CD Do not adjust

SB Stand-by button enabling

BOS Button Operation Sounder YES’provides positive feedback (i.e. ‘beep’) every time a display button is pressed, ‘NO’

sounder is silenced during display button operation

RHC Do not adjust

OSA Probe TAir (T1) oset

TE Probe TEvaporator (T2)

enabling

OSE Probe TEvaporator (T2) oset

T3A

DI2 / TAuxiliary Probe Enabling

and Operation

‘NON’- DI2 / Auxiliary probe not tted

‘DSP’ - Auxiliary Probe - general purpose temperature measurement (i.e. stored product

temperature)

‘CND’ - Condenser probe - if measure temperature exceeds value of ‘AHT’ controller will

react as dened by ‘AHM’

‘2EU’ Do not use

‘DOR’ - Digital Input 2 used for door switch operation

‘ALR’- Do not use

‘ECO’- Do not use

‘RDS’- Do not use

11G3 Counters - Service Manual

OS3 Auxiliary Probe 3 oset

D3A ‘DI3’ activation ‘OPN’ - on open

‘CLS’- on close

AHM

Operation in alarm when ‘T3A’

= ‘CND’

‘NON’- Audible and visual alarm is inhibited

‘ALR’- when ‘T3A’= ‘CND’and temp. > ‘AHT’ condenser high temperature ‘HC’ alternates in

the display and the alarm sounder is activated

‘STP’ - in addition to the alarm signal, the compressor is stopped and defrosts are

suspended

AHT Condenser temperature alarm

(referring to TAuxiliary probe)

TLD

Delay for minimum

temperature (‘TLO’) and

maximum temperature (‘THI’)

logging

With ‘TLD’= ‘0’ the logging is disabled

TDS

The temperature probe value

to be displayed

‘TA’- actual Tair (T1) value

TAS’ - actual Tair (T1) value slowed (rate of change toward setpoint = actual value, away

from setpoint = mathematical algorithm applied)

‘A-E’ - the AVG-weighted average between TAir (T1) and TEvaporator (T2) probes

‘T3’ - TAuxiliary (T3) probe value (when‘T3A’ = ‘DSP’, ‘CND’ or ‘2EU’)

SIM Display slowdown. Active when‘TDS’ = ‘TAS’, the SIM value is the controlling arithmetical value.

AVG

The relative weight of T2 in

respect of T1 (when ‘TDS’ =

‘A-E’)

SCL

Readout scale ‘°C’ with non adjustable resolution in User Function Menu

‘°C’with adjustable resolution in User Function Menu

‘°F’with non adjustable resolution in User Function Menu

‘°F’with adjustable resolution in User Function Menu

PRT Modbus communication type RTL or ASCII

ADR FD1-19 address for PC

communication

RFP Return to Factory Parameters. Allow options through‘User Menu’to reset all controller parameters to factory production

values where controller has been programmed by Foster

12 www.fosterrefrigerator.com

Parameter Settings

INTEGRAL REMOTE

Mnemonic

Default

High Temperature Counter Solid Doors

High Temperature Counter Glass Door

Meat Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

High Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

MDL HYS HYS HYS HYS HYS HYS HYS

SPL -2 1 1 -2 -23 1 -21

SPH 10 5 5 5 -15 5 -15

SP 3.5 2 2 -2 -23 2 -21

HY0 3 3 3 3 3 3 3

HY1 0 0 0 0 0 0 0

CMD 30 5 5 5 5 0 5

CRT 90 180 180 180 180 0 0

CT1 4 4 4 5 5 4 5

CT2 7 6 7 5 5 6 5

PB 7 5 5 5 5 5 5

IT 100 100 100 100 100 100 100

DT 0 6 6 6 6 6 6

CT 10 5 5 5 5 5 5

AR 75 70 70 70 70 70 70

CMS 100 100 100 100 100 100 100

CRS 35 90 90 90 90 90 90

CRD 15 10 10 10 10 10 10

CDS 50 60 60 60 60 60 60

CFF 60 60 60 60 60 60 60

CSS 60 60 60 60 60 60 60

CSO 1 12 12 12 12 12 12

CST 60 30 30 30 30 30 30

DFM TAD TIM TIM TIM TIM TIM TIM

DFT 6 6 6 6 6 6 6

DSP -12 -12 -12 -12 -12 -12 -12

DST 4 15 15 15 15 15 15

DMI 2 2 2 2 2 2 2

DLI 10 10 6 15 15 10 15

DTO 20 15 15 20 20 15 20

DTY OFF OFF OFF GAS GAS OFF ELE

DSY OFF OFF OFF HI HI OFF HI

SOD 10 5 5 5 5 5 5

DPD 0 0 0 0 0 0 0

DRN 60 0 0 90 90 0 90

INTEGRAL REMOTE

Mnemonic

Default

High Temperature Counter Solid Doors

High Temperature Counter Glass Door

Meat Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

High Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

DDM DEF SP SP SP SP SP SP

DDY 2 1 2 2 2 1 2

FID YES YES YES NO NO YES NO

FDD 10 10 10 -5 -5 10 -5

FTO 1 1 1 1 1 1 1

FSD 0 0 0 0 0 0 0

FCM TMP NON NON NON NON NON NON

FDT -3 0 0 0 0 0 0

FDH 2 1 1 1 1 1 1

FT1 0 0 0 0 0 0 0

FT2 0 0 0 0 0 0 0

FT3 0 0 0 0 0 0 0

ATM REL REL REL REL REL REL REL

ALA -30 -30 -30 -30 -30 -30 -30

AHA -15 -15 -15 -15 -15 -15 -15

ALR -5 -3 -3 -3 -3 -3 -3

AHR 8 6 6 8 8 6 8

ATI T1 T1 T1 T1 T1 T1 T1

PAD 60 60 60 60 60 60 60

ATD 90 60 60 60 60 60 60

ACC 0 0 0 0 0 0 0

ECO YES NO NO NO NO NO NO

ESP 3.5 3.5 3.5 3.5 3.5 3.5 3.5

EH0 2.5 3 3 3 3 3 3

EH1 0 0 0 0 0 0 0

EPB 10 4 4 4 4 4 4

EDM TAD TIM TIM TIM TIM TIM TIM

EDF 24 12 12 12 12 12 12

EDL 10 6 6 6 6 6 6

EDO 10 15 15 15 15 15 15

EDR 20 0 0 0 0 0 0

EFD 10 10 10 10 10 10 10

EFT 5 1 1 1 1 1 1

EFC NON NON NON NON NON NON NON

ESD 90 60 60 60 60 60 60

13G3 Counters - Service Manual

INTEGRAL REMOTE

Mnemonic

Default

High Temperature Counter Solid Doors

High Temperature Counter Glass Door

Meat Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

High Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

INTEGRAL REMOTE

Mnemonic

Default

High Temperature Counter Solid Doors

High Temperature Counter Glass Door

Meat Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

High Temperature Counter Solid Doors

Low Temperature Counter Solid Doors

EFS 12 15 15 15 15 15 15

EMF 20 30 30 30 30 30 30

DSM ALR STP STP STP STP STP STP

DAD 2 2 2 2 2 2 2

CSD 90 30 30 30 30 30 30

DOT 2 4 4 4 4 4 4

DI1 DOR NON NON NON NON NON NON

D1A OPN OPN OPN OPN OPN OPN OPN

LCM NON NON MAN NON NON NON NON

SR1 NON FAN FAN FAN FAN FAN FAN

SR2 NON NON LGT DEF DEF NON DEF

RL2 NON 0-1 0-1 0-1 0-1 0-1 0-1

ACN 0 0 0 0 0 0 0

ACF 0 0 0 0 0 0 0

AHS YES NO NO NO NO NO NO

AHU 15 15 15 15 15 15 15

AFT 15 15 15 15 15 15 15

PMD NO NO NO NO NO NO NO

MSV 230 240 240 240 240 240 240

2CD 0 0 0 0 0 0 0

SB YES YES YES YES YES YES YES

BOS YES YES YES YES YES YES YES

RHC 0 0 0 0 0 0 0

OSA 0 0 0 0 1 0 0

TE NO NO NO YES YES NO YES

OSE 0 0 0 0 0 0 0

T3A NON NON NON NON NON NON NON

OS3 0 0 0 0 0 0 0

D3A OPN OPN OPN OPN OPN OPN OPN

AHM NON NON NON NON NON NON NON

AHT 0 60 60 60 60 60 60

TLD 30 30 30 30 30 30 30

TDS TAS TAS TAS TAS TAS TAS TAS

SIM 10 10 10 10 10 10 10

AVG 0 0 0 0 0 0 0

SCL oCn oCA oCA oCA oCA oCA oCA

PRT RTU RTU RTU RTU RTU RTU RTU

ADR 1 1 1 1 1 1 1

RFP YES YES YES YES YES YES YES

14 www.fosterrefrigerator.com

Other Information

Alarms/Warnings:

During operation the current temperature inside the appliance will be displayed. At certain times this will change to indicate a particular appliance

operation or fault. The indicators you may see are as follows:

The temperature alarms are either relative to the set point or an absolute value. This is controlled by the value of parameter ‘ATM’. Where the alarms

are relative the low alarm is the set point minus parameter ‘ALR’ and the high alarm is the set point plus‘AHR’. When the temperature has been

outside this value for the value of‘ATD’ the relevant indicator will be displayed.

hi - The internal temperature of the appliance is higher than described above. Ensure that the door is closed and that the air ow inside is not

obstructed by excesive or poor loading of product. The alarm will reset if the temperature falls to a normal level. If this does not happen please

contact your authorised dealer or Foster Service.

Lo - The internal temperature of the appliance is lower than described above. Check to ensure that the appliance has not been loaded with

product at a lower temperature than the normal appliance operating temperature. If this is not the case please call your authorised dealer or Foster

Service.

tA - Air probe has failed.. Call your authorised dealer or Foster Service to arrange for this to be replaced. During this time the appliance cannot

maintain an accurate temperature and all product should be removed and the appliance switched o.

tE - Evaporator probe has failed (not applicable to all models). Call your authorised dealer of Foster Service to arrange for this to be replaced.

PF - The mains power has been removed from the appliance for a period of time and has now been restored. This may have resulted in a rise in

appliance temperature. Caution should be taken when using products stored within to ascertain whether these products are suitable for use. Upon

restoration of the power supply the appliance will resume normal operation and the PF can be cancelled by pressing button 3 once.

HC - The condenser temperature is higher than it should be. If the appliance is being subjected to particularly high ambient temperatures steps

should be taken to reduce this. If the ambient temperature is not high or reducing the temperature does not rectify the fault please contact your

authorised dealer or Foster Service.

Cnd - The condenser clean period has expired. Please contact your authorised dealer or Foster Service.

While in an alarm condition icon 5 will also be illuminated.

(Some indications are only visible periodically during specic appliance operations such as defrost or when activated through use of the appliance).

15G3 Counters - Service Manual

1 - Air probe

2 - Evaporator probe

3 - Condenser probe

Probe Resistance

Length in decimeters

15 = 1.5m

20 = 2m

35 = 3.5m

P1 - Probe 1

P2 - Probe 2

P3 - Probe 3

1 - 1KΩ

2 - 2kΩ

4 - 10kΩ

N - NTC

T - PTC

Manufacture

Month - Year

Probe manufacturer

Probe Indentication

Probe Information

Tx LAEx x-xx Sx xK xx Px

NTC10K Temperature Resistance Table SN4K

TEMP. (°C) R-low (KW) R-mid (KW) R-high (KW)

-30 109.522 113.347 117.294

-25 84.823 87.559 90.374

-20 66.27 68.237 70.255

-15 52.229 53.65 55.104

-10 41.477 42.506 43.557

-5 33.147 33.892 34.651

0 26.678 27.219 27.767

5 21.63 22.021 22.417

10 17.643 17.926 18.21

15 14.472 14.674 14.877

20 11.938 12.081 12.224

25 9.9 10 10.1

30 8.217 8.315 8.413

35 6.854 6.948 7.043

40 5.745 5.834 5.923

The probe is a type 10k NTC. The probes are identical in characteristics with the T1 and T2 identication markings and dierent colours being for

ease of identication and not for functional reasons. Please refer to the image below for probe identication.

16 www.fosterrefrigerator.com

Refrigerant Charge

The refrigerant charge weight can be found on the serial label within the appliance. Where this is not available please refer to the table below. The

information below is correct time of printing but is subject to change without prior notice.

EP1/2H 110gms

EP1/2HRW 110gms

EP1/2M 80gms

EP1/2L 80gms

EP1/3H 110gms

EP1/3HRW 110gms

EP1/3M 108gms

EP1/3L 108gms

EP1/4H 90gms

EP1/4HRW 90gms

EP2/2H 92gms

EP2/3H 95gms

17G3 Counters - Service Manual

Factory Reset

Where the controller was originally programmed by Foster and is dedicated to a specic appliance type it is possible to return the setting to they’re

original programmed state. If the controller was not programmed by Foster this function will return the parameters to the values in original factory

settings.

To reset the parameters:

- Press button 3 to activate the display

- Press button 1 to enter the user level menu

- Press button 2 until the display shows ‘rFp’

- Press button 3 once and ‘rFp’will ash

- Press and hold button 3 for 3 seconds until the display shows ‘End’

The original parameters as described above have now been restored.

If at any point the sequence of button operations and display indications are not completed the controller will, after 30 seconds resume operation

with no changes to the parameters having been made.

Defrost Indication

During defrost icon 4 will be illuminated. The controller display will be determined by the value set in parameter ‘DDM’.

To start a defrost manually press and hold button 3 for 5 seconds. This will turn o the appliance. Continue to hold down button 3 after the

appliance has turned o. After a further 2 seconds the display will indicate a defrost has commenced (icon 4 illuminated) and the button can be

released. While the defrost function is operating the display will be determined by the value set in parameter DDM.

The defrost function will operate until either the time set in parameter DTO or the temperature set in parameter DLI is reached. Where parameter

TE is set to NO defrost will function on a time basis only. Upon completion of the defrost cycle the appliance will resume normal operation with

the current temperature displayed.

Relay Test

The controller contains a relay test function to enable the service engineer to operate individual relays, or a combination of relays for diagnostic

purposes.

To access the relay test:

- Place the controller in standby so that button 3 is pulsing

- Press button 3 once so that buttons 1, 2 and 4 are activated and ashing

- Press and hold buttons 2 and 4 for 5 seconds until the display shows ‘rLy’and buttons 1 to 5 are all illuminated

The controller is now in relay test mode.

To activate relay 1 press button 1. Icon 1 will illuminate. To deactivate relay 1 press button 1 again and icon 1 will switch o.

To activate relay 2 press button 2. Icon 3 will illuminate. To deactivate relay 2 press button 2 again and icon 3 will switch o.

To activate relay 3 press button 4. Icon 4 will illuminate. To deactivate relay 3 press button 4 again and icon 4 will switch o.

To activate relay 4 press button 5. Icon 8 will illuminate. To deactivate relay 4 press button 5 again and icon 8 will switch o.

Multiple relays can be activated simultaneously to enable diagnostics.

Relay function:

Relay 1 - Red icon - Compressor

Relay 2 - Green icon - function determined by parameter SR1. Evaporator Fan

Relay 3 - White icon - function determined by parameter SR2. Where appliance has active defrost SR2 to will be set to DEF for defrost.

Relay 4 - Amber icon - function determined by parameter RL2.

To exit the relay test function press button 3 once.

18 www.fosterrefrigerator.com

Condenser Cleaning

The condenser is a Stayclear condenser which does not require cleaning as regularly as a traditional nned condenser may. Care should be taken

when cleaning the condenser. Never use a wire brush, abrasive or corrosive materials to clean the condenser.

Door Gaskets

Door gaskets should be inspected periodically and cleaned where necessary with a warm damp cloth. Do not use aggressive cleaning materials on

the door gaskets.

Where door gaskets are damaged or not sealing correctly, they are required to be changed. These can be removed by pulling the old gasket from

it’s locating prole and pushing the new gasket into the same location. Where the gasket will not locate securely in the locating prole use a

rubber mallet to locate the gasket securely.

Maintenance

3

This manual suits for next models

8

Table of contents

Other Foster Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

la Minerva

la Minerva C GF2 operating instructions

Blue Seal

Blue Seal EF30 Installation & operation manual

Tecfrigo

Tecfrigo Snelle 400 GS installation instructions

Federal

Federal SSRSP Series Installation & operation instructions

Henny Penny

Henny Penny FlexFusion SpaceSaver Plus FSE-610 installation instructions

Giorik

Giorik 700 Series manual

Hussmann

Hussmann TY3ECRC Installation & operation guide

Duke

Duke FWM3-22 Operator's and service manual

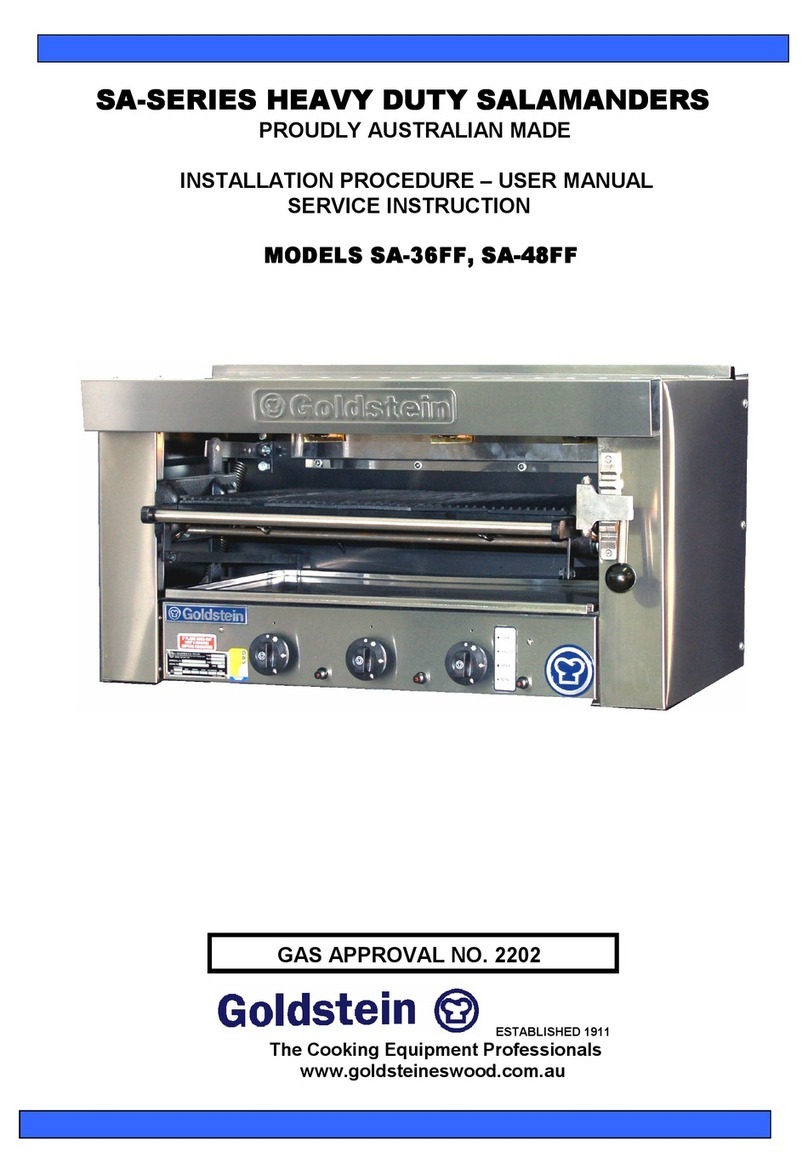

goldstein

goldstein SA-Series INSTALLATION PROCEDURE – USER MANUAL

Apach

Apach BAKERY LINE P Series instruction manual

Hendi

Hendi MASTERCOOK DIGITAL 207345 manual

Porkka

Porkka DHMC Installation and operation manual