compEAct S Contents

3

Contents

1Basic information............................................................................................................. 7

1.1 Notes on these operating instructions ........................................................................ 7

1.2 Intended use ............................................................................................................... 8

1.3 Warranty and liability.................................................................................................. 9

2Safety instructions ......................................................................................................... 10

2.1 General notes............................................................................................................ 10

2.2 Safety markings on the compEAct S.......................................................................... 10

2.3 Requirements for the operating personnel ............................................................... 11

2.4 Safety instructions – Transport and commissioning ................................................. 11

2.5 Safety instructions for operation............................................................................... 12

2.5.1 General instructions.................................................................................................. 12

2.5.2 Safety instructions – Protection against explosion and fire ...................................... 12

2.5.3 Safety instructions – Electrical equipment ................................................................ 12

2.5.4 Safety instructions for compressed gas containers and systems ............................... 13

2.5.5 Handling of auxiliary and operating materials and samples..................................... 13

2.5.6 Safety instructions – service and repair..................................................................... 14

2.5.7 Safety instructions for the operation with auto-injector AI and autosampler LS ...... 14

2.5.8 Behavior in case of overpressure faults (gas pressure faults) ................................... 14

2.6 Safety equipment / Behavior during emergencies.................................................... 15

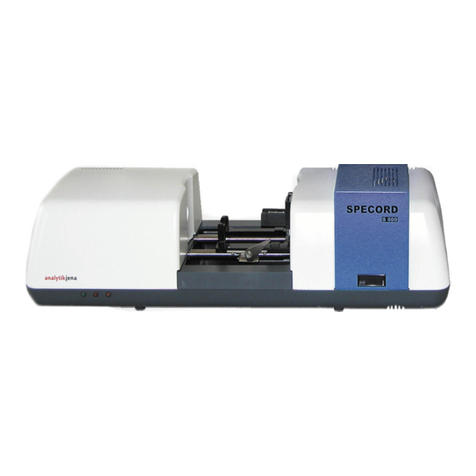

3Function and layout of the compEAct S....................................................................... 16

3.1 Principle of operation................................................................................................ 16

3.2 Layout of the compEAct S ......................................................................................... 17

3.3 Type plate ................................................................................................................. 22

3.4 Sample supply ........................................................................................................... 22

3.4.1 Auto-injector AI......................................................................................................... 22

3.4.2 Autosamplers LS 1 and LS 2...................................................................................... 23

4Installation and commissioning ................................................................................... 25

4.1 Installation conditions............................................................................................... 25

4.1.1 Environmental conditions ......................................................................................... 25

4.1.2 Energy supply............................................................................................................ 25

4.1.3 Gas supply ................................................................................................................. 26

4.1.4 Device layout and space requirements...................................................................... 26

4.2 Supply and control connections ................................................................................ 28

4.3 Installing the compEAct S with sample introduction module.................................... 30

4.3.1 Setting up and connecting the compEAct S............................................................... 30

4.3.2 Connecting the autosampler LS ................................................................................ 31

4.3.3 Connecting the auto-injector AI................................................................................ 32

5Operation........................................................................................................................ 34

5.1 Switching the compEAct S on and off ....................................................................... 34

5.2 Measuring with auto-injector AI............................................................................... 35

5.3 Measuring with LS 1 or LS 2 ..................................................................................... 36

6Maintenance and care................................................................................................... 38

6.1 Maintenance intervals .............................................................................................. 38

6.2 Cleaning the compEAct S and its system components .............................................. 39

6.3 Checking system tightness ........................................................................................ 39

6.4 Adjusting the auto-injector AI................................................................................... 40

6.5 Adjusting the autosampler LS................................................................................... 41

6.6 Combustion furnace maintenance ............................................................................ 42

6.6.1 Removing and cleaning the combustion tube........................................................... 42

6.6.2 Replaceing quartz wool plug..................................................................................... 44

6.6.3 Inserting the combustion tube .................................................................................. 45