HBK FS22SI User manual

FS22SI

Industrial BraggMETER SI

ENGLISH

User Manual

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

HBK FiberSensing, S.A.

Rua Vasconcelos Costa, 277

4470-640 Maia

Portugal

Tel. +351 229 613 010

Fax +351 229 613 020

www.hbm.com/fs

Mat.: -

DVS: A04249 10 E00 00

02.2022

Interrogator version: v3

SW version: 2.6

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

3

FS22SI

TABLE OF CONTENTS

TABLE OF CONTENTS

1 Technical Details 6.................................................

1.1 General Information 6...............................................

1.2 System Components 6...............................................

2 Regulatory and Certification Considerations 7..........................

2.1 Environment Considerations 7........................................

2.1.1 Disposal of your Old Appliance 7......................................

2.2 Laser Safety 7......................................................

2.2.1 Symbols 8.........................................................

2.2.2 Class 1 Laser 8.....................................................

2.2.3 General Precautions Considerations 8..................................

2.3 Certification 9......................................................

2.3.1 CE marking 9.......................................................

2.3.2 Degree of protection 9...............................................

2.4 The marking used in this document 9..................................

3 Operation 11........................................................

3.1 Connectors 11.......................................................

3.1.1 Standard 11.........................................................

3.1.2 Rack-Mountable 12...................................................

3.2 Setting Up 12........................................................

3.2.1 Power Supply 12.....................................................

3.2.2 Optical Connectors 13................................................

3.2.3 Ethernet Connection 13...............................................

3.3 Maintenance 14.....................................................

3.3.1 Wear parts 14.......................................................

3.3.2 Ventilation 14.......................................................

3.3.3 Optical connectors 14................................................

3.3.4 Calibration 14.......................................................

3.4 Switching On 14.....................................................

3.5 Switching OFF 15....................................................

3.6 Operating the Interrogator 16..........................................

3.6.1 Network Properties 16................................................

3.6.2 Resetting the IP Address of the Interrogator 19...........................

3.6.3 Synchronization 20...................................................

3.6.4 Operation 22........................................................

4 Measuring 28.......................................................

4.1 Typical Configuration 28..............................................

FS22SI

TABLE OF CONTENTS

4

4.2 Definitions 28.......................................................

4.2.1 Wavelength 29......................................................

4.2.2 Power 29...........................................................

4.3 Measurement Methods 30............................................

4.3.1 Conventional 30.....................................................

4.3.2 Smart Peak Detection (SPD) 31........................................

4.4 Common Measuring Difficulties 32.....................................

4.4.1 Dirty Connector 32...................................................

4.4.2 Broken Connector 34.................................................

4.4.3 Reflective Fiber Ending 35.............................................

4.4.4 Cut Fiber 35.........................................................

4.4.5 Fuse Failure 36......................................................

5 Remote Communications 39..........................................

5.1 Communication Protocol Syntax 39.....................................

5.1.1 Command Syntax 39.................................................

5.1.2 Common Commands 41..............................................

5.1.3 System Commands 42................................................

5.1.4 Status Commands 43.................................................

5.1.5 Acquisition Commands 44.............................................

5.1.6 Memory Commands 56...............................................

6 BraggMONITOR SI Software Details 58.................................

6.1 Software Version 58..................................................

6.2 Install and Uninstall Software 58.......................................

6.2.1 System Requirements 58..............................................

6.2.2 Software Installation 59...............................................

6.2.3 Software Uninstall 60.................................................

6.3 Running the Software 60..............................................

6.3.1 Network Properties 60................................................

6.3.2 Run as Administrator 60..............................................

7 BraggMONITOR SI User Interface 62...................................

7.1 General Bar 62......................................................

7.1.1 Date and Time 63....................................................

7.1.2 Connecting to the Interrogator 65.......................................

7.1.3 Acquisition 66.......................................................

7.1.4 Software and Interrogator Information 72................................

7.1.5 Exit Application 72...................................................

7.2 Graphical Area 72....................................................

7.2.1 Graphical View 72....................................................

5

FS22SI

TABLE OF CONTENTS

7.2.2 Numerical View 74...................................................

7.2.3 Spectral View 74.....................................................

7.2.4 Configuration 81.....................................................

7.2.5 SCPI Interface 86....................................................

FS22SI

TECHNICAL DETAILS

6

1 TECHNICAL DETAILS

1.1 General Information

The FS22 - Industrial BraggMETER SI with real time embedded Smart Peak Detection

(SPD) is a continuous swept laser scanning interrogator specifically designed to interro

gate Fiber Bragg Grating (FBG) based sensors in industrial environments.

BraggMETER interrogators include a NIST traceable wavelength reference that provides

continuous calibration to ensure system accuracy over long term operation. The high

dynamic range and high output power combined with the Smart Peak Detection (SPD)

allow high resolution to be attained even for long fiber leads and lossy connections.

Multiple sensors can be connected in series in each optical fiber, in combination with one,

four or eight optical channels with parallel acquisition. The FS22 - Industrial BraggMETER

SI is particularly suitable for large scale sensing networks acquiring a large number of

sensors simultaneously and providing 1 S/s acquisition rates with sub picometer resolu

tion.

The BraggMETER is available either in Standard and Rack-mountable formats. This Man

ual applies to the following equipment:

SK-FS22 (1S/s option)

S1-FS22SI-ST/4CH

S1-FS22SI-ST/8CH

HBK FiberSensing interrogators are compatible with catman software, a powerful tool for

data acquisition and processing.

1.2 System Components

The FS22 - Industrial BraggMETER SI set includes:

Standard format Rack-mountable format

- Interrogator

- AC-DC power supply unit 24V

- Ethernet cable (L ~2 m)

- Mounting blocks with M6 screws

- Connector protection caps

- Mounting holes protection caps

- Quick start guide

- Digital support material

- Calibration certificate

- Interrogator

- Power cord

- Ethernet cable (L ~2 m)

- Connector protection caps

- Quick start guide

- Digital support material

- Calibration certificate

7

FS22SI

REGULATORY AND CERTIFICATION CONSIDERATIONS

2 REGULATORY AND CERTIFICATION CONSIDERATIONS

2.1 Environment Considerations

2.1.1 Disposal of your Old Appliance

When the attached symbol combination - crossed-out wheeled bin and

solid bar symbol is attached to a product it means the product is covered

by the European Directive 2002/96/EC and is applicable in the European

Union and other countries with separate collection systems.

All electrical and electronic products should be disposed of separately from

the municipal waste stream or household via designated collection facilities appointed by

the government or the local authorities. The correct disposal of your old appliance will

help prevent potential negative consequences for the environment and human health. For

more detailed information about disposal of your old appliance, please contact your city

office, waste disposal service or distributor that purchased the product.

HBK FiberSensing is a manufacturer registered in the ANREEE - "Associação Nacional

para o Registo de Equipamentos Eléctricos e Electrónicos" under number PT001434.

HBK FiberSensing celebrated a "Utente" type contract with Amb3E - "Associação Portu

guesa de Gestão de Resíduos de Equipamentos Eléctricos e Electrónicos", which ensures

the transfer of Electrical and Electronic appliance waste management, i.e. placing Elec

tronic and Electrical appliances in the Portuguese market, from the manufacturer HBK

FiberSensing to Amb3E.

2.2 Laser Safety

The FS22 - Industrial BraggMETER SI contains a laser in its core. A laser is a light source

that can be dangerous to people exposed to it. Even low power lasers can be hazardous

to a person's eyesight. The coherence and low divergence of laser light means that it can

be focused by the eye into an extremely small spot on the retina, resulting in localized

burning and permanent damage.

The lasers are classified by wavelength and maximum output power into the several

safety classes: Class 1, Class 1 M, Class 2, Class 2 M, Class 3R and Class 4.

FS22SI

REGULATORY AND CERTIFICATION CONSIDERATIONS

8

2.2.1 Symbols

Warning symbol Class 1 Laser symbol

2.2.2 Class 1 Laser

The FS22 - Industrial BraggMETER SI is a class 1 laser product:

«Any laser or laser system containing a laser that cannot emit laser radiation at levels

that are known to cause eye or skin injury during normal operation. »

It is safe under all conditions of normal use. No safety requirements are needed to use

Class 1 laser devices. This product contains a laser within an enclosure that prevents

exposure to the radiation and that cannot be opened without shutting down the laser.

2.2.3 General Precautions Considerations

Everyone who uses a laser equipment should be aware of the risks.

The laser radiation is not visible to the human eye but it can seriously damage user's eye

sight.

The laser is enabled when the interrogator is turned on.

Users should never put their eyes at the level of the horizontal plane of the optical

adapters of the interrogator or uncovered optical connectors.

Adequate eye protection should always be required if there is a significant risk for eye

injury.

When an optical connector is not in use (no optical cable plugged to the interrogator), a

proper connector cap must be used. The optical connectors are subjected to mainte

nance and/or inspection. Please refer to section 4.4.1 “Dirty Connector“ for maintenance

procedure.

Do not attempt to open or repair a malfunctioning interrogator. It must be returned to

HBK FiberSensing for repair and calibration.

9

FS22SI

REGULATORY AND CERTIFICATION CONSIDERATIONS

2.3 Certification

2.3.1 CE marking

This product carries the CE marking and complies with the applicable international

requirements for product safety and electromagnetic compatibility,

according to the following Directives:

SLow Voltage Directive (LVD) 2014/35/EU - Electrical Safety

SElectromagnetic Compatibility (EMC) Directive 2014/30/EU

It is in compliance with the EN61326/EN55011 Emission Radiated Test Class A, under the

Electromagnetic Compatibility Standard.

The corresponding Declaration of Conformity is available upon request.

2.3.2 Degree of protection

In compliance with the IEC/EN 60529 Degrees of protection provided by enclosures is:

SFor the Standard format: IP40 certification (protection against the ingress of solids

larger than 1 mm in diameter).

SFor the Rack-mountable format: IP20 certification (protection against the ingress of

solids larger than 12.5 mm in diameter).

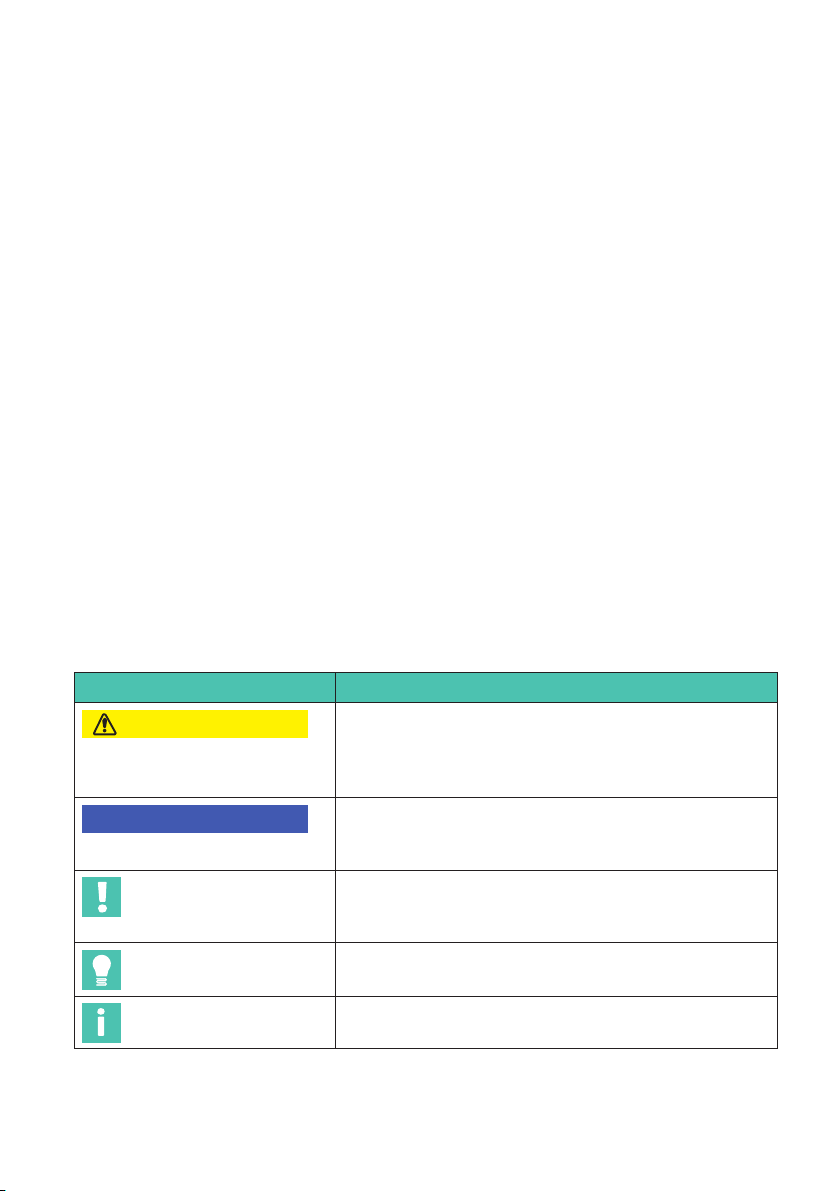

2.4 The marking used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

FS22SI

REGULATORY AND CERTIFICATION CONSIDERATIONS

10

SignificanceSymbol

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

uThis marking indicates an action in a procedure

FS22SI

OPERATION

12

3.1.2 Rack-Mountable

Front view

Back view

Fig. 3.2 Front and back views of FS22SI Rack-Mountable

The connectors and buttons on Fig. 3.2 are:

1ON/OFF Button

2POWER and STATUS LEDs

3Optical Output Connectors

4Power Connector

5Electric fuse

6Safety Power Button

7Fans

8Ethernet Connector

3.2 Setting Up

3.2.1 Power Supply

To start the FS22 - Industrial BraggMETER SI interrogator connect the power cable to the

interrogator Power Connector (number 3on Fig. 3.1 or number 4on Fig. 3.2). To acknowl

13

FS22SI

OPERATION

edge proper power supply, the POWER LED will turn green during 2 seconds after con

necting the power supply.

Information

For the Standard version of the interrogator the power supply must have a minimum of

30 W, with an output voltage between 12-36 v and must withstand a peak of 4 A for at least

4 ms. For the Rack-Mountable version of the interrogator the power must be 100-240 V AC,

50-60 Hz, 1A.

Notice

Powering above the specified limits will damage the equipment. For the Rack-mountable

version there is a fuse protection that can be replaced. please see section 4.4.5 Fuse fail

ure.

Information

The interrogator must be powered using a power supply source not shared with other

equipment's. A replacement AC-DC power supply unit 24 V (1-NTX001) for the Standard

version or Power Cable (1-KAB274) available with different plug formats can be ordered

from HBK.

3.2.2 Optical Connectors

The FS22 - Industrial BraggMETER SI can be purchased either with FC/APC, or SC/APC

optical connectors. number 1on Fig. 3.1 exemplifies FC/APC connectors.

Attention should be paid to the cleaning of the optical connectors. A dirty connector can

compromise the measurement and will degrade the interrogator performance. It is advis

able to frequently clean the connectors using appropriate tools.

FS22 - Industrial BraggMETER SI can have one, four or eight optical channels in parallel.

3.2.3 Ethernet Connection

Connect the Ethernet RJ45 connector directly to a PC using a Ethernet cross-over cable,

or to a network connector using a direct Ethernet cable (in this case, the FS22 - Industrial

BraggMETER SI must be in the same subnet as your Local Network).

Important

The interrogator default network configuration is “10.0.0.10:255.0.0.0:0.0.0.0".

FS22SI

OPERATION

14

3.3 Maintenance

3.3.1 Wear parts

HBK Optical Interrogators have wear parts (such as ventilation fans, optical connector

adapters and batteries) that require minimum running conditions to ensure a correct

operation of the equipment.

Wear parts are covered by a limited warranty as they are components that depend on the

usage and on the environmental conditions the equipment operates in, such as humidity,

temperature and dust.

A periodic maintenance should be planned and managed by the customer considering

the actual operation conditions. Warranty will only be applied to wear parts if the cause of

the defect can be clearly traced back to the material or manufacturing fault.

3.3.2 Ventilation

The FS22SI is an electronic equipment with active ventilation, meaning that it uses fans

for thermal control of the device. Fine dust particles over time can reduce the life time of

optical and electronic components leading to a general degradation of the equipment, so

it is important to prevent dust from entering the device. For that reason the interrogators

should be kept on a controlled environment, far or protected from major dust areas.

3.3.3 Optical connectors

Optical connectors of the interrogator are subject to degradation and can actually break

upon misusage (see section 4.4.2. Broken Connector). If this happens, the interrogator

must be sent back to HBK FiberSensing for repair.

3.3.4 Calibration

BraggMETER interrogators have a built-in NIST traceable gas cell that ensures calibrated

measurements at all time. For this reason, a compulsory periodic calibration is not

required. Nevertheless, for regulatory reasons or internal rules, a periodic certified cali

bration procedure is sometimes required. For those cases, the calibration service is avail

able and can be requested to HBK FiberSensing.

3.4 Switching On

Pressing the ON/OFF button will start the interrogator. The STATUS LED will start blinking

at 2 Hz. After approximately 30 seconds it will start blinking at 1 Hz. This means that the

interrogator is already on and responsive, but the optoelectronic module is still warming

up. After approximately 90 seconds it should stay on permanently. This means that the

interrogator is able to measure.

15

FS22SI

OPERATION

Status LED

Blinking 2 Hz

Status LED

Blinking 1 Hz

Status LED

On

Status LED

Blinking 2 Hz

Status LED

Blinking 1 Hz

Status LED

Blinking 5 Hz

(initialization issues)

CorrectWrong

ON(0s) ~10s >30s <90s ?s

Status LED

Blinking 5 Hz

(measurement issues)

Fig. 3.3 Switching On button actions according to pressured time

Information

If the interrogator does not start correctly, the STATUS LED will blink faster. If this happens

please contact HBK FiberSensing technical support.

3.5 Switching OFF

To avoid accidental shut-down of the interrogator, it is necessary to press the “ON/OFF"

button between 2 and 6 seconds (Fig. 3.4).

If for some reason the 6 seconds are exceeded the user can release the button before 10

seconds are reached and the interrogator will remain ON (Fig. 3.5).

Notice

If the ON/OFF button is pressed more than 10 seconds irreversible changes on the interro

gator configuration are performed.

POWER LED

blinking at 1 Hz

Fig. 3.4 Power LED while pressing Switching Off between 2 s and 6 s

FS22SI

OPERATION

16

POWER LED

blinking at 1 Hz

POWER LED

ON

Fig. 3.5 Power LED while pressing Switching Off between 6 s and 10 s

3.6 Operating the Interrogator

3.6.1 Network Properties

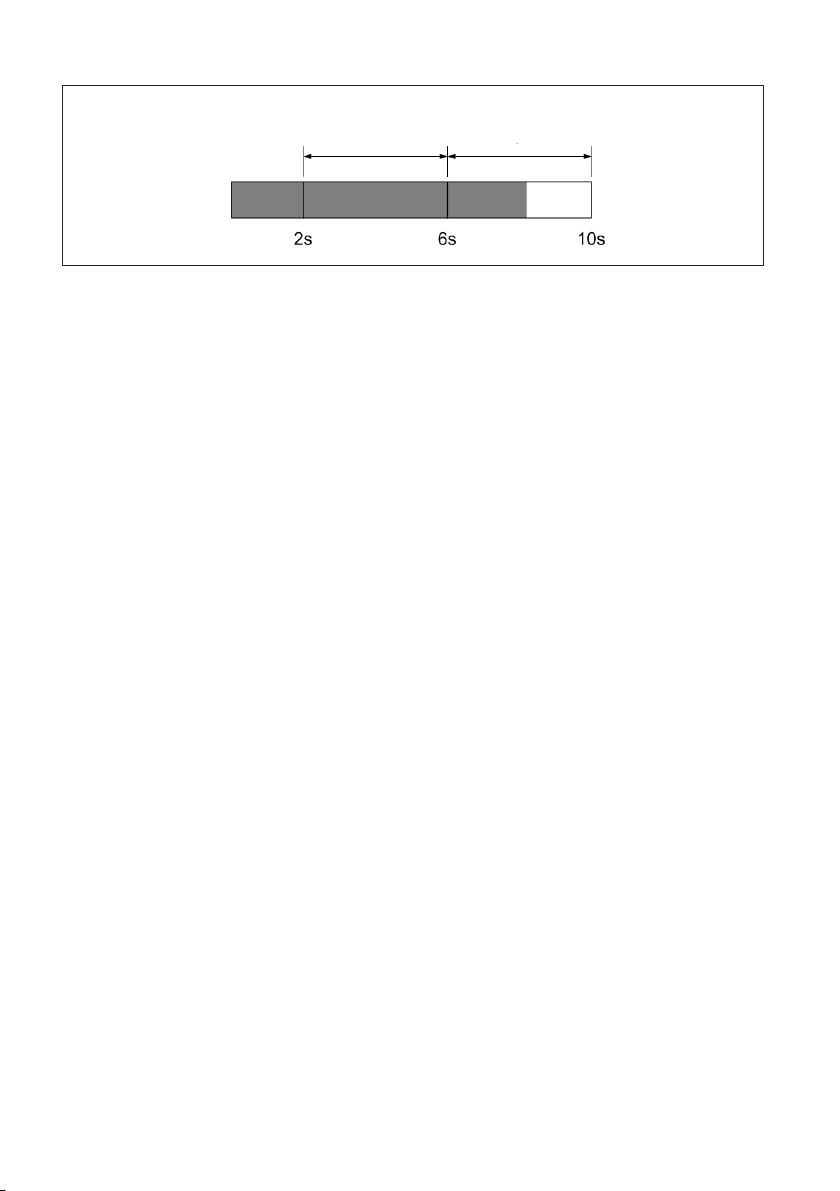

To operate the FS22 - Industrial BraggMETER SI from a personal computer, the PC net

work properties should be set so that both elements are configured in the same subnet.

To configure your personal computer so that it is on the same subnet as the default for

the interrogator, proceed as follows:

uOn the control panel choose Network Connections.

uSelect the LAN connection. The window displayed in Fig. 3.6 will appear. Click on

Properties.

FS22SI

OPERATION

18

Fig. 3.7 Local Area connection properties

19

FS22SI

OPERATION

uSet the IP address and the subnet mask as in Fig. 3.8.

Fig. 3.8 Internet Protocol Version 4 Properties

uPress OK.

3.6.2 Resetting the IP Address of the Interrogator

If for any chance there is the need to physically change the IP address of the interrogator,

there is a reset procedure that consists on pressing the ON/OFF button for more than

10 seconds.

When the button is being pressed for 10 seconds the POWER LED blinks 3 times and

goes OFF. At this moment the ON/OFF button can be released and the reset of IP address

will happen.

FS22SI

OPERATION

20

POWER LED

blinking at 1 Hz

POWER LED

ON

POWER LED

blinks 3 times

and goes OFF

Fig. 3.9 Power LED while pressing Switching Off for more than 10 s

This procedure resets the interrogator changing its IP address to the default and its mea

suring settings to the last stored.

Information

The interrogator default network properties are “10.0.0.10:255.0.0.0:0.0.0.0".

3.6.3 Synchronization

In order to achieve synchronous measurements between different devices the NTP (Net

work Time Protocol) synchronization via Ethernet must be used.

Each optical Interrogator can synchronize its internal clock with an NTP server. It is possi

ble to achieve accuracies of 1ms or higher, depending on whether or not a dedicated NTP

server is being used.

Further information about NTP can be found at http://www.ntp.org.

Measuring Systems Typology

A measurement system can be as simple as a single interrogator or a bit more complex

with combined interrogators with the same or different sampling rates, and interrogators

combined with other equipment.

For the usage of a single interrogator no special synchronization

is needed.

BraggMONITOR SI software can only operate one interrogator at

a time. If an NTP server is running on the same PC as the Brag

gMONITOR SI, the interrogator internal clock – hence Brag

gMONITOR SI – will sync.

If more than one interrogator is used, synchronization becomes

important and if an NTP server is running the equipment will

start synching as soon as a first communication from the server

is received.

Single interrogator

Multiple

interrogators

Table of contents

Other HBK Measuring Instrument manuals