BGS technic 8688 User manual

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

Art. 8688

Air Eccentric Sander

SPECIFICATION

Pad Size: 152 mm (6")

Free Speed: 10,000 rpm

Working Pressure: 6,3 Bar (90 psi)

Avg. Air Consumption: 142 L/min (5 CFM)

Air Inlet: 1/4"

min. Hose Ø: 10 mm (3/8")

Weight: 1050 g

Overall length: 225 mm

Noise: LPA: 87dB(A) / LWA: 98dB(A)

Vibration: ah = 8.5 m/s² / K= 1.5 m/s²

IMPORTANT SAFETY INFORMATION

WARNING!

Read and understand and follow all instructions and warnings before operating this tool.

Failure to do so may result in personal injury and/or property damage and will void warranty.

Oil tool before each use 4 to 5 drops of a good grade Air Tool Oil placed in the air inlet is sufficient.

Use proper air pressure and CFM rating listed for this tool.

1. Be sure air is in OFF position when connecting tool to air supply.

2. Always wear approved eye protection when using tools. If raising dust, wear a suitable mask.

3. Use only those accessories that are designed for use with tools.

4. Be sure to disconnect tool from air supply before changing accessories, performing service on

tool, and when not in use.

5. As with any tool, use common sense when operating. Do not wear loose clothing or jewelry that

could become caught by moving parts, causing injury. Operate tool a safe distance from yourself

and others in the work area.

6. Follow air source manufacturers directions for connection of regulators, filters, and other

accessories to air source. Do not install quick couplers directly on tool as they put unnecessary

strain on the air inlet threads possibly causing them to wear out prematurely. Instead, install them

on a short length of air hose attached to the tool.

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

AIR SOURCE

Clean air of correct air pressure is recommended for the power supply for this tool. A maximum of 90

PSI at the tool is recommended for most air tools of this class. Check specifications section for

recommended pressure. (Depending on length of air hose and other circumstances, air pressure at

compressor may need to be increased to 100 PSI to ensure 90 PSI at the tool.) Water in the air hose

and compressor tank contributes to reduced performance and damage of the air tool. Drain the air

tank and filters before each use and as necessary to keep the air supply dry. Hose length over 25”

causes loss in line pressure. Increase hose ID or increase compressor pressure to compensate

for the pressure loss. Use an in-line pressure regulator with gauge if air inlet pressure is critical.

1

Tool

6

Shut Off Valve

11

Air Dryer

2

Air Hose

7

Whip Hose

12

1“ Or Larger Pipe

3

Oiler

8

Connector

13

Air Compressor

4

Pressure Regulator

9

Drain Valve (Drain Daily)

14

Auto Drain

5

Filter

10

½“ or Larger Pipe

15

Drain Valve (Drain Daily)

LUBRICATION & MAINTENACE

Warning!

Oil tool before each use. 4 to 5 drops Air Tool Oil placed in the air inlet is sufficient.

Use proper air pressure and CFM rating listed for this tool.

Drain water from hoses and compressor tank.

Water in the air supply line demage the tool and loss of power.

Clean or replace air filters at prescribed intervals.

TROUBLESHOOTING

Insufficient power:

Probable Cause

Solution

Dirty or clogged air passages Flush and lubricate tool, drain air tank and supply line

Insufficient air supply Increase line pressure, make sure compressor matches

tool's air pressure and consumption needs

Air leakage Use teflon tape at all fittings and joints.

Check tool for worn or damaged o-rings & seals.

Worn/damaged wear & tear parts Replace as necessary

Tool matching Be sure you are using a tool suited for the sanding

requirements of the job at hand.

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

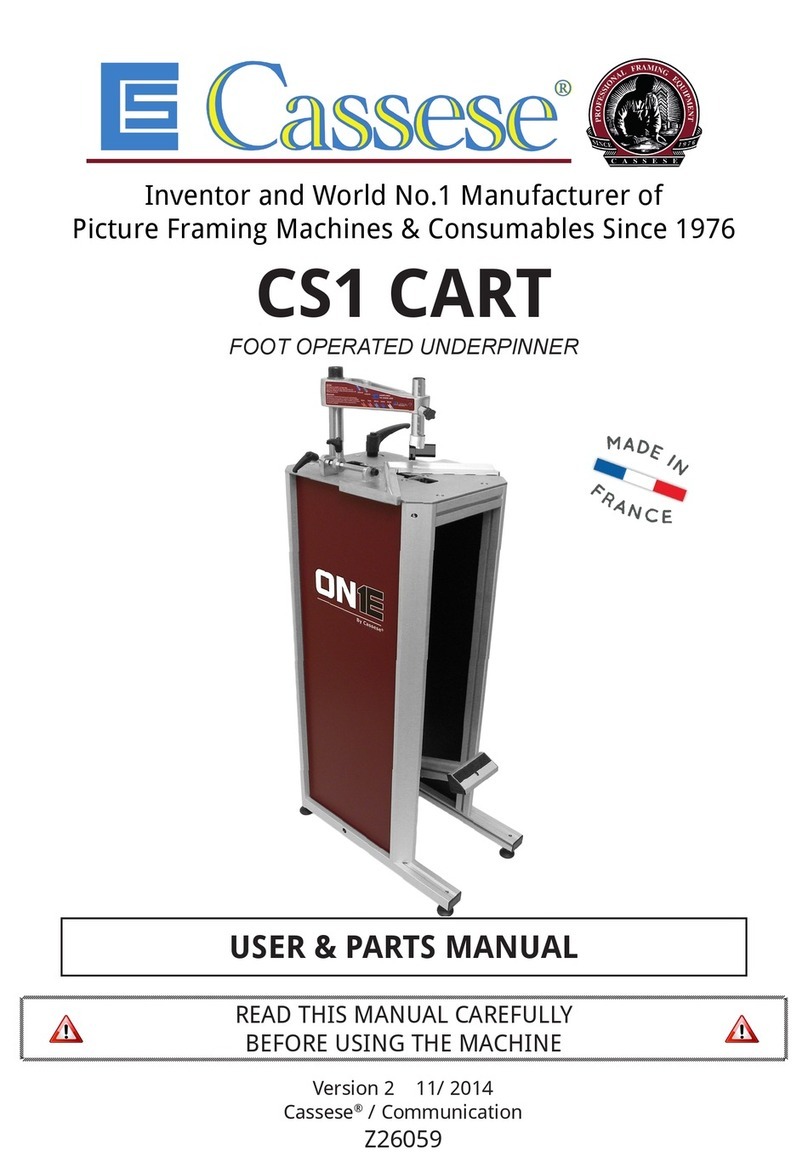

OPERATION INSTRUCTIONS

1. Lubricate the tool before operating.

See “CARE AND MAINTENANCE” section for oiling instructions.

2. Disconnect tool from air supply. (Fig.7)

3. Screw tight by hand at clockwise direction the sanding pad

into the female thread of the bearing stand (Part #21) while

holding the provided wrench on the flats of the stand as

shown. (Fig.1)

4. Mount a sanding paper (not provided) onto the sanding pad.

5. Connect the dust tube to the dust tube connector (Part #32)

and set it secure. (Fig.2)

6. Mount the dust bag to the dust tube by tying the string tight

around the tube end. (Fig.3)

7. Remove the air cap from the tool air inlet and connect the air

supply hose to the tool. Set the air pressure at 90 PSI. (Fig.

4)

WARNING: When connecting the air hose, keep the speed control

knob (i.e. trigger valve - Part #26) in “OFF” position by turning the

knob backwards to the upmost. (Fig.5)

8. Turn the speed control knob forwards to the upmost, hold

the tool by one hand and slowly press down on the trigger by

your palm to the upmost. Then the tool starts to work. (Fig.6)

NOTE You can control the air flow and rotation speed by turning the

speed control knob.

REPLACEMENT OF SANDING PAD

1. Disconnect the tool from air supply. (Fig.7)

2. Rotate with hand counter clockwise the sanding of the

female thread of the bearing stand while holding the

provided wrench on the flats of the stand.

3. Replace a new sanding pad in the same way as said at the

above Point 3 in “OPERATION INSTRUCTIONS” section.

WARNING: Only use sanding pads that have an RPM rating equal

to or greater than the tool itself.

CARE AND MAINTENANCE

The tool should be lubricated daily (or before each use) with air tool

oil (not included).

NOTE: Air tool oil is available at major tool hardware stores. SAE

#10 weight oil or sewing machine lubricant or any other high grade

turbine oil containing moisture absorbent, rust inhibitors, metal

wetting agents and an EP (extreme pressure) additive may be used

as a substitute. Do not use detergent oil. During continuous

operation, the tool should be oiled every 1 to 2 hours. This may be

done using an in-line oiler, or manually. If done manually, proceed

as follows:

1. Disconnect the tool from air supply. (Fig.7)

2. Place a few drops of air tool oil into the air inlet. (Fig.8)

NOTE: Avoid the misuse of thicker oil which may lead to the

reduced performance or malfunction.

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

Fig.7

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

3. Connect the tool to the air supply. Run the tool without load

for a few seconds to distribute the oil through the tool. Any

excess oil may be propelled from the air exhaust area. So

keep the tool away in a safe direction.

4. After operating the tool and before storing the tool,

disconnect the air hose and place 4 or 5 drops of air tool oil

into the air inlet, then re-connect the air hose and run the

tool to evenly distribute the oil throughout the tool for 30

seconds approximately. This will prolong the tool life.

5. Avoid storing the tool in a humid environment which

promotes rusting of internal mechanisms. Always oil the tool

before storage.

6. When the tool is seriously damaged or out of life, it should

be left in a resource recycling can. Never drop it into fire.

Fig.8

1

Main housing

15

Semi-round key

29

Nut

2

Head cover

16

Screw

30

O-ring

3

Washer

17

Bearing

31

Lever

4

Bearing

18

Wool ring

32

Dust tube connector

5

Bolt

19

Washer

33

O-ring

6

Rear plate

20

E-clip

34

Muffler

7

Rotor

21

Bearing stand

35

Dust connector accessory (1)

8

Rotor blade

22

Dust cover

36

Dust connector accessory (2)

9

Cylinder

23

Sanding pad

37

Lubricating ring

10

Front plate

24

Trigger

38

Tilting valve

11

Bearing

25

Trigger bolt

39

Spring

12

O-ring

26

Trigger valve

40

Air inlet

13

Fixing ring

27

O-ring

41

Dust tube

14

Rotating axle

28

Cushion

42

Dust collecting bag

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

CE-Erklärung

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

EU-Konformitätserklärung

EC DECLARATION OF CONFORMITY

DÉCLARATION „CE“ DE CONFORMITE

DECLARATION DE CONFORMIDAD UE

Wir erklären in alleiniger Verantwortung, dass die Bauart der:

We declare that the following designated product:

Nous déclarons sous propre responsabilité que ce produit:

Declaramos bajo nuestra sola responsabilidad que este producto:

Druckluft-Exzenterschleifer ( BGS Art. 8688 )

Air Eccentric Sander

Ponceuse orbitale air comprimé

Lijadora orbital de aire comprimido

folgenden einschlägigen Bestimmungen entspricht:

complies with the requirements of the:

est en conformité avec les réglementations ci-dessous :

esta conforme a las normas :

Machinery Directive 2006/42/EC

Angewandte Normen:

Identification of regulations/standards:

Norme appliquée:

Normas aplicadas:

EN ISO 11148-8:2011

Verification No. SH12111317-V1/AT991L

Report No. SH12111317-001

Wermelskirchen, den 02.05.2013

ppa.

Frank Schottke, Prokurist

BGS technic KG, Bandwirkerstrasse 3, D-42929 Wermelskirchen

Other manuals for 8688

1

Table of contents

Other BGS technic Sander manuals