MAINTENANCE / REPAIR TROUBLESHOOTING OPERATION ASSEMBLY / INSTALLATION SAFETY / SPECIFICATIONS GETTING STARTED

4

• Do not set up or use the Belt / Disc Sander in dangerous

environments. Do not set up or use the Belt / Disc Sander in

damp or wet locations. Do not expose this machine to rain.

• Make sure your work area is properly lighted.

• Proper electrical connections should be set up for this

machine.

• Extension cords should have a grounding prong and the

three wires of the extension cord should be of the proper

gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of the workplace. Make your workshop

childproof. Use padlocks, master switches or remove switch

keys to prevent any unintentional use of your power tools.

Maintaining your tool

• Always unplug the tool and remove it from its power source

prior to inspection or adjustment. If your machine plugs into

an electrical outlet do not unplug the tool by pulling on the

cord.

• Consult this manual for specific maintenance and adjustment

procedures.

• Keep the tool clean for safest operation. Wood dust build ups

can become combustible.

• Check for damaged parts. A part that is damaged should

be properly repaired or replaced. Do not perform makeshift

repairs. Use the parts list in this manual to order repair parts.

Repairs must be made by a qualified technician.

Know how to use your tool

Dusty work environments may be

hazardous to your health. Always wear a

OSHA/NIOSH approved, properly fitting face mask or

respirator.

The operation of any machine can result

in foreign objects being thrown into the

eyes, which can result in severe eye damage. Always wear

safety goggles complying with United States ANSI Z87.1.

(shown on package) before commencing power tool

operation.

Think safety! Safety is a combination of

operator common sense and alertness at

all times when tool is being used.

• Do not attempt to operate this tool until it is completely

assembled according to the directions in this manual.

• Do not turn ON this machine if parts are missing or damaged.

• It is highly recommended this machine be mounted on a level

surface or stand.

• Replace worn, frayed or torn abrasives, as injury to the user

or machine may result.

• Always keep your hands and face away from moving parts,

belts, discs and pulleys.

• Know your tool. Learn the tool’s operation, application and

specific limitations.

• Never operate the machine without the disc guards in place.

• Completely disconnect this machine from its power source

when changing an abrasive disc or belt.

• Use the right tool for the job. Do not force a tool or

attachment to do a job for which it was not designed.

• To reduce the risk of electrical shock, never use the machine

in rain or allow it to become wet.

• Never attach the Belt / Disc Sander to a dust extraction unit

used for wood sanding if you are sanding metal. The sparks

can cause a fire or explosion.

• Turn the tool off immediately in the case of an emergency.

Completely remove the tool from its power source before

attempting to fix the issue.

• Never leave tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not use the tool as a toy or let children play with it. Care

should be taken when using the tool around children or

animals.

• Avoid accidental start-ups. Make sure that the power switch

is in the OFF position before plugging the machine in or

connecting it into an appropriate electrical resource.

• Do not overreach. Keep proper footing and balance.

• Never stand on the machine. Serious injury could occur if the

tool tips or if the sanding disc is unintentionally contacted.

• Only use recommended accessories. The improper use of

accessories may create a risk of operator injury.

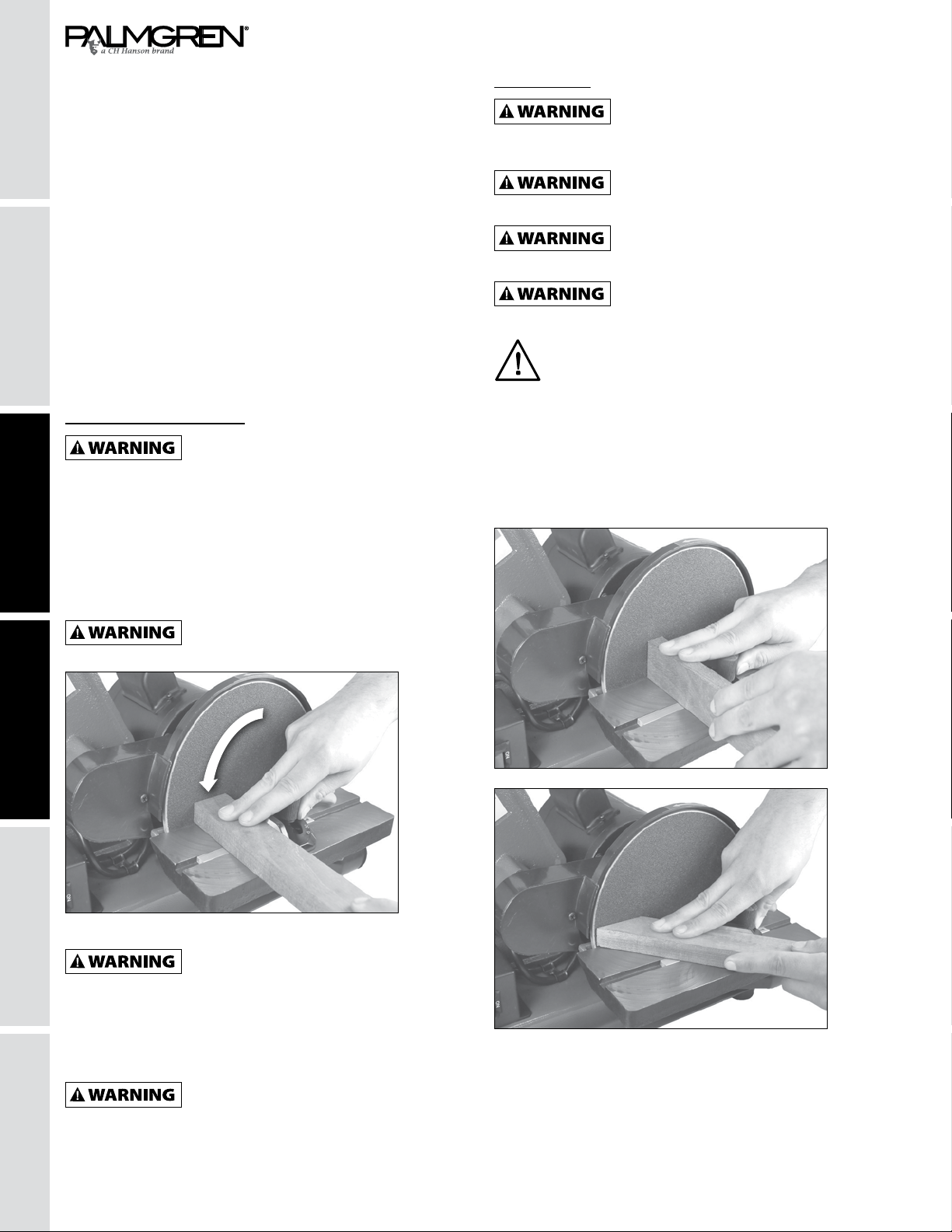

• Handle workpieces correctly to help protect your hands from

possible injury.

• Support your workpiece with the supplied miter gauge or the

work table. “Free-hand” sanding is not recommended.

• Maintain a 1/16” maximum clearance or less between table

and sanding disc or belt.

• Follow OSHA lock-out, tag-out procedures to prevent

accidental machine starts.

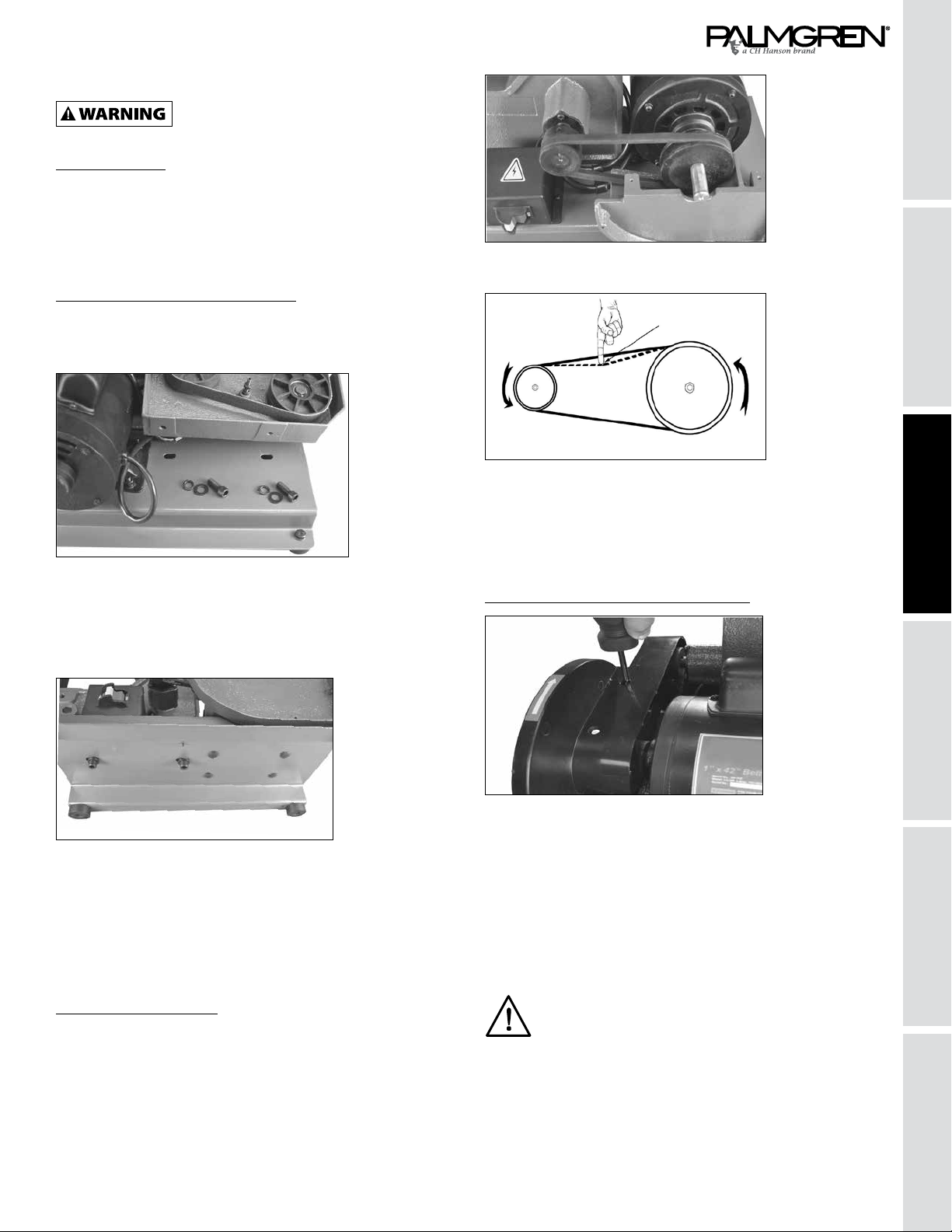

Electrical connections

Make sure the tool is off before plugging it

into a power source to prevent accidental

starts.

Do not permit fingers to touch the

terminals of plug when installing or

removing from outlet.

Electrical safety

• Double insulated tools are equipped with a polarizing three

pronged plug (one blade is wider than the other.) This plug

will fit in a polarized outlet only one way. If the plug does not

fit fully into the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install a polarized outlet. Do

not change the plug in any way.

• Double insulation eliminates the need for the three wire

grounded power cord and grounded power supply system.

Before plugging in the tool, be certain the outlet voltage

supplied is within the voltage marked on the nameplate.

• Avoid body contact with grounded surfaces such as pipes,