BGS technic 9910 User manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

BGS 9910

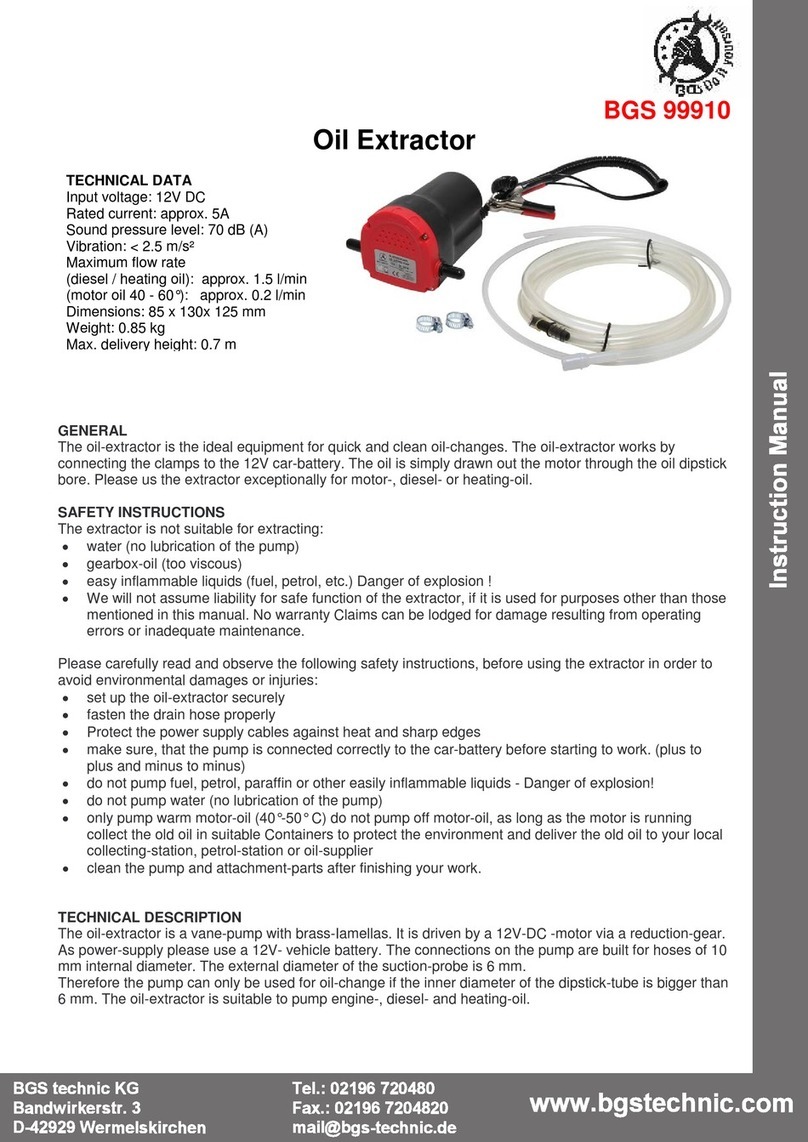

Oil Extractor

GENERAL

The oil-extractor is the ideal equipment for quick and clean oil-changes. The oil-extractor works by

connecting the clamps to the 12V car-battery. The oil is simply drawn out the motor through the oil dipstick

bore. Please us the extractor exceptionally for motor-, diesel- or heating-oil.

SAFETY INSTRUCTIONS

The extractor is not suitable for extracting:

•water (no lubrication of the pump)

•gearbox-oil (too viscous)

•easy inflammable liquids (fuel, petrol, etc.) Danger of explosion !

•We will not assume liability for safe function of the extractor, if it is used for purposes other than those

mentioned in this manual. No warranty Claims can be lodged for damage resulting from operating

errors or inadequate maintenance.

Please carefully read and observe the following safety instructions, before using the extractor in order to

avoid environmental damages or injuries:

•set up the oil-extractor securely

•fasten the drain hose properly

•Protect the power supply cables against heat and sharp edges

•make sure, that the pump is connected correctly to the car-battery before starting to work. (plus to

plus and minus to minus)

•do not pump fuel, petrol, paraffin or other easily inflammable liquids - Danger of explosion!

•do not pump water (no lubrication of the pump)

•only pump warm motor-oil (40°-50° C) do not pump off motor-oil, as long as the motor is running

collect the old oil in suitable Containers to protect the environment and deliver the old oil to your local

collecting-station, petrol-station or oil-supplier

•clean the pump and attachment-parts after finishing your work.

TECHNICAL DESCRIPTION

The oil-extractor is a vane-pump with brass-Iamellas. It is driven by a 12V-DC -motor via a reduction-gear.

As power-supply please use a 12V- vehicle battery. The connections on the pump are built for hoses of 10

mm internal diameter. The external diameter of the suction-probe is 6 mm.

Therefore the pump can only be used for oil-change if the inner diameter of the dipstick-tube is bigger than

6 mm. The oil-extractor is suitable to pump engine-, diesel- and heating-oil.

TECHNICAL DATA

Input voltage: 12V DC

Rated current: approx. 5A

Sound pressure level: 70 dB (A)

Vibration: < 2.5 m/s²

Maximum flow rate

(diesel / heating oil): approx. 1.5 l/min

(motor oil 40 - 60°): approx. 0.2 l/min

Dimensions: 85 x 130x 125 mm

Weight: 0.85 kg

Max. delivery height: 0.7 m

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

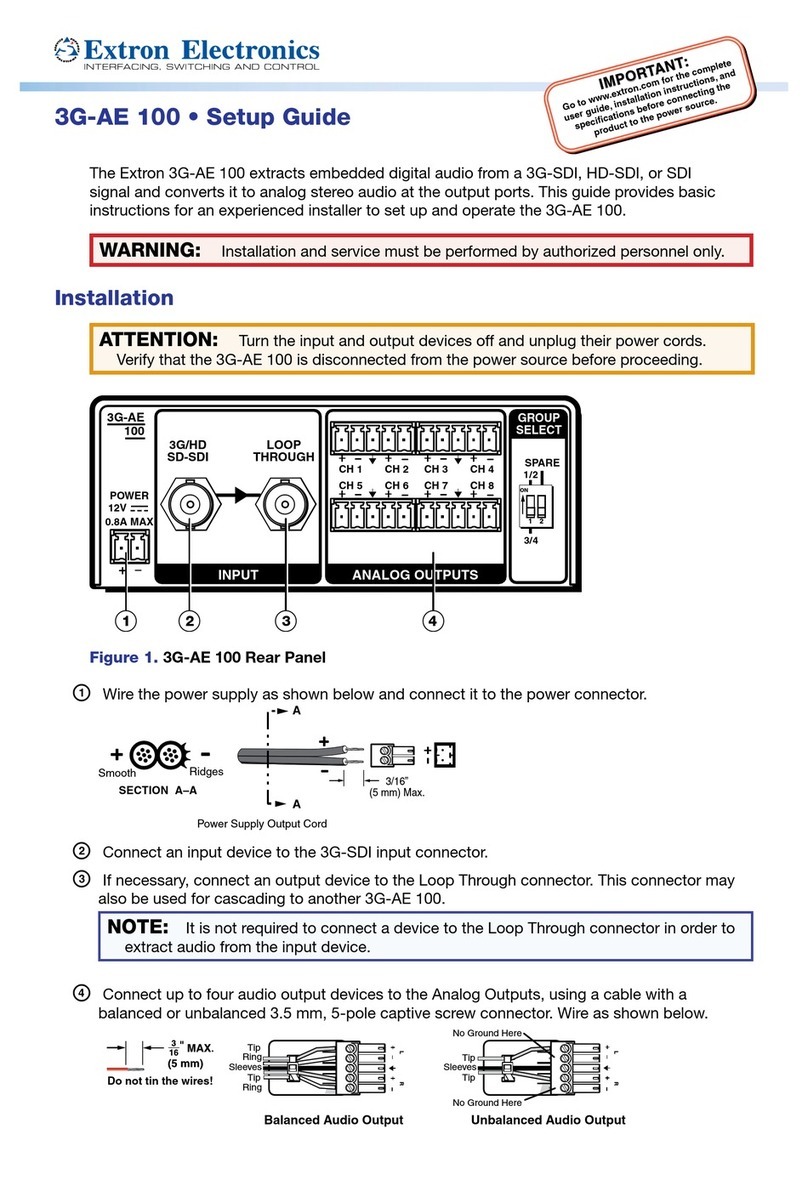

OPERATING

1. Before starting to change the motor-oil, drive the motor until the oil has a temperature of approx. 40°-

50° C. Less temperature will reduce the flow-rate due to the high viscosity of the oil. If the oil is too hot,

the sealings of the pump might be disturbed.

2. Shut down the engine after having reached sufficient temperature.

3. Push the hose with the suction-probe onto the pump socket and push the drain hose onto the drain

socket and fasten both by using hose-clamps in order to avoid the hoses coming loose due to the oil

pressure.

4. Unwind the suction-probe and straighten it properly before inserting through the dipstick-tube into the

engine. Otherwise the pump will draw no or not enough oil.

5. Insert the suction-probe into the oil dipstick-tube and push it gently down to the lowest Position of the

oil pan.

6. Please use suitable Container to collect the old oil and lead the drain-hose into this Container.

7. Connect the oil-extractor to the 12V car-battery. Make sure that the clamps are connected with the

1. correct poles of the battery (red clamp to "plus", black clamp to "minus")

8. Switch the pump on and pump the oil out of the engine.

9. As soon as no further oil is pumped, switch off the pump. Do not let the pump run without oil.

10. Fill the engine with fresh motor-oil according to the maintenance Instruction for your car and check the

oil-Ievel with the oil dip-stick.

11. After finishing your work clean the pump thoroughly by pumping some fresh oil.

12. Remove the hoses from the pump, plug them together and Store the whole unit in a place, where it is

protected against dust.

ATTENTION:

Never let old or fresh oil seep into the ground or into the sewage system. You will harm the environment

and you will make yourself liable for prosecution. Collect the old oil and dispose at your local collecting

station, petrol station or oil-dealer.

COMPONENTS

1. Suction probe 6 mm

2. Suction connector

3. Drain connector

4. Extraction-pump

5. Battery-clamps

6. On-/Off-switch

7. Hose 10 mm

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories

and packaging should be sorted, taken to a recycling centre and disposed of in a manner

which is compatible with the environment.

DISPOSAL

Dispose of this product at the end of its working life in compliance with the EU Directive on

Waste Electrical and Electronic Equipment. Contact your local solid waste authority for

recycling information or give the product for disposal to BGS technic KG or to an electrical

appliances retailer.

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

CE-Erklärung

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

EU-Konformitätserklärung

EC DECLARATION OF CONFORMITY

DÉCLARATION „CE“ DE CONFORMITE

DECLARATION DE CONFORMIDAD UE

Wir erklären in alleiniger Verantwortung, dass die Bauart der:

We declare that the following designated product:

Nous déclarons sous propre responsabilité que ce produit:

Declaramos bajo nuestra sola responsabilidad que este producto:

Ölabsaugpumpe (BGS Art. 9910)

Oil Extractor

Extracteur d'huile

Bomba de aceite

folgenden einschlägigen Bestimmungen entspricht:

complies with the requirements of the:

est en conformité avec les réglementations ci-dessous:

esta conforme a las normas:

EMC Directive 2004/108/EC / Council Directive 93/68/EEC

Angewandte Normen:

Identification of regulations / standards:

Norme appliquée:

Normas aplicadas:

EN 55014-1:2006+A1:2009

EN 55014-2:1997+A1:2001+A2:2008

EN 61000-3-2:2006+A2:2009

EN 61000-3-3:2008

Certification No. : ECE1103050C / LS4037

Test Report : ECE1103050R

Wermelskirchen, den 25.06.2013

ppa.

Frank Schottke, Prokurist

BGS-technic KG, Bandwirkerstr. 3, D-42929 Wermelskirchen

Other manuals for 9910

1

Table of contents

Other BGS technic Scrubber manuals

Popular Scrubber manuals by other brands

Nobles

Nobles Power Eagle 716 Operator and parts manual

Nacecare

Nacecare NX1K CRL8055/100T Original instructions

Ewbank

Ewbank FP1000 Care and use instructions

Kärcher

Kärcher PS 40 Powerscrubber quick guide

Extron electronics

Extron electronics 3G-AE 100 Setup guide

Hillyard

Hillyard TRIDENT B20SC Use and maintenance manual