BGU HS 71 User manual

OPERATING MANUAL

Read through this operating manual carefully be-

fore starting the machine.

Südharzer Maschinenbau GmbH

Helmestraße 94 ∙ 99734 Nordhausen/Harz

Zentrale: +49(0)3631/6297-0 ∙ -111

Internet: www.bgu-maschinen.de

e-mail: [email protected]

Startup

Operations

Maintenance

Accessories

HYDRAULIC LOG

SPLITTER

HS 71

Made in

Germany

2

TABLE OF CONTENTS

1. Introduction 3

1.1 Using the operating manual 3

1.2 Full delivery and transport damage 3

2. Product overview 5

3. Warning and safety pictograms 6

4. Safety instructions 8

4.1 Intended use 9

5. Operation 10

5.1 Mounting the guard brackets 10

5.2 Remarks on the electrical system 10

5.3 Remarks on the hydraulic system 10

5.4 Checking the two-handed controls 11

5.5 Remarks concerning starting up 11

5.6 Safety instructions 12

5.7 Adjusting the splitting length 12

5.8 Adjusting the table 13

5.9 Working with the wood clamps 14

5.10 Working with the log splitter 14

5.11 Releasing jammed pieces of wood 14

6. Transporting the machine 15

7. Cross splitter and splitting wedge expander as accessories 16

8. Maintenance and servicing work 17

8.1 Regular maintenance tasks 17

8.2 Remarks regarding the hydraulic oil 17

8.3 Guides in the splitting column 18

8.4 Wear parts 18

9. Decommissioning and disposal 19

10. Technical specifications 20

10.1 Noise emissions 20

11. Circuit diagram 21

12. Overview of residual risk 22

12.1 Prevention of mechanical dangers 22

12.2 Prevention of electrical dangers 22

13. Problems, causes and solutions 23

14. Warranty 23

15. Guarantee 24

16. HS 71 parts list 25

17. EC declaration of conformity 39

3

1. INTRODUCTION

Thank you for the trust you have placed in us. We are pleased to be

able to count you as one of our valued customers.

The hydraulic log splitter is available in the following variants:

HS 71 (400V), splitting force 7 t

HS 71 (230V), splitting force 6 t

The log splitters are equipped with mechanical two-handed controls.

1.1 Using the operating manual

This operating manual aims to provide you with a way to become fa-

miliar with your new machine. The operating manual is divided into

different sections, as can be seen in the table of contents. The sec-

tions are numbered consecutively, to make it easy to find things quik-

kly. The figures, instructions and technical specifications in this ope-

rating manual reflect the state of the art of the machine construction.

Because the product is subject to ongoing development, we reserve

the right to make changes to the product. If malfunctions occur on the

machine the malfunctions and their probable causes can be rectified

with the help of the following table (see Section 13, „Problems, cau-

ses and solutions“). If you cannot repair the machine yourself, please

contact your dealer or an authorized repair shop. Please note the type

and machine number indicated on the type plate before you contact

your dealer, an authorized repair shop or the manufacturer. This data

is required to rectify the problem or order spare parts.

1.2 Full delivery and transport damage

In case of visible transport damages – evident from damage to the

package or scratched or defective parts on appliances or machines

– it is essential that the damage is noted on the bill of lading: on both

the copy that you receive as well as on the bill of lading that you must

sign.

4

It is also essential that the carrier (driver) countersign. If the

carrier refuses to confirm the transport damages, the best course of

action is to refuse receipt as a whole and notify us about it immedia-

tely. Without a direct note on the bill of lading, any subsequent claims

will not be recognized by the carrier nor the insurer of the transport.

Any hidden transport damages must be reported within two days

at the latest; this means that the delivered goods must be inspec-

ted within this time. Usually, any reports after that will be fruitless.

If hidden damages are suspected, always note on the bill of lading:

„Goods were received subject to suspicion of hidden transport

damages.“ Insurance companies and carriers often react with suspi-

cion and they refuse any indemnification. For that reason, try to pro-

vide clear evidence of the damage (possibly with a photo).

Thank you for your understanding and help regarding this matter.

regarding this matter.

5

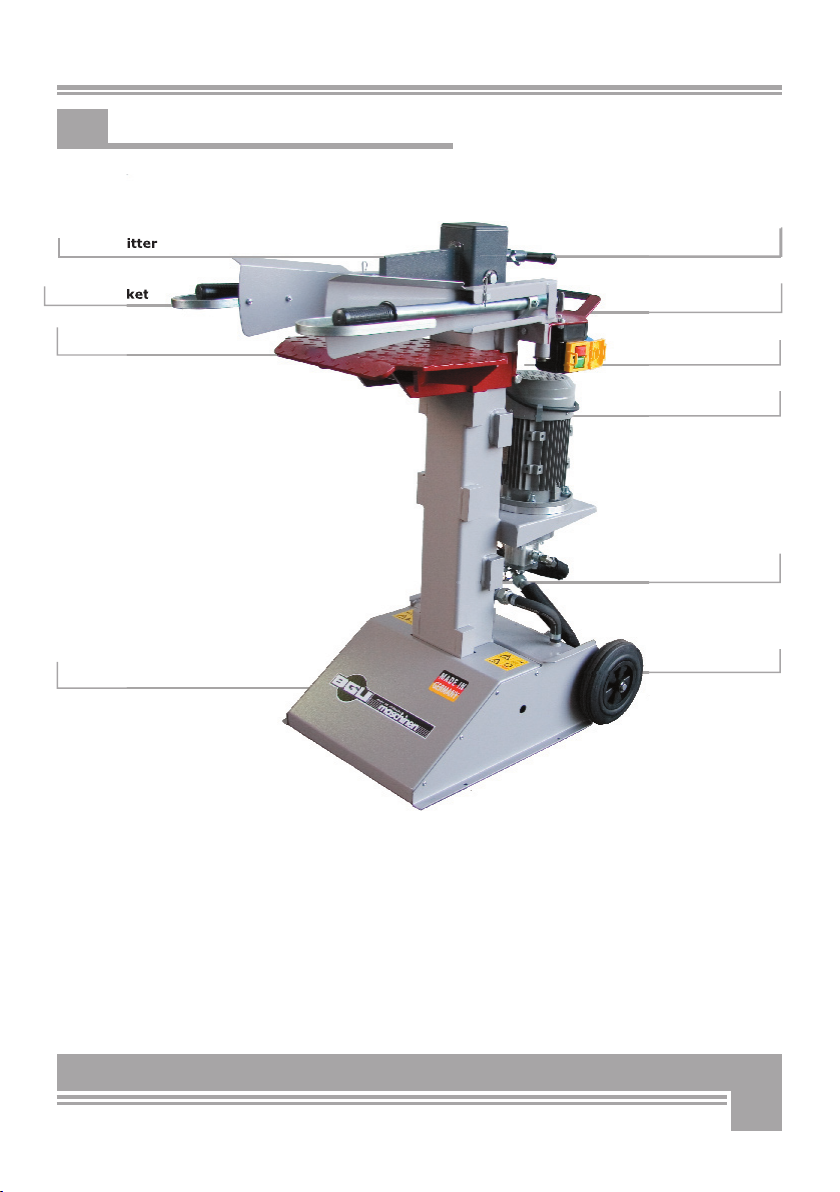

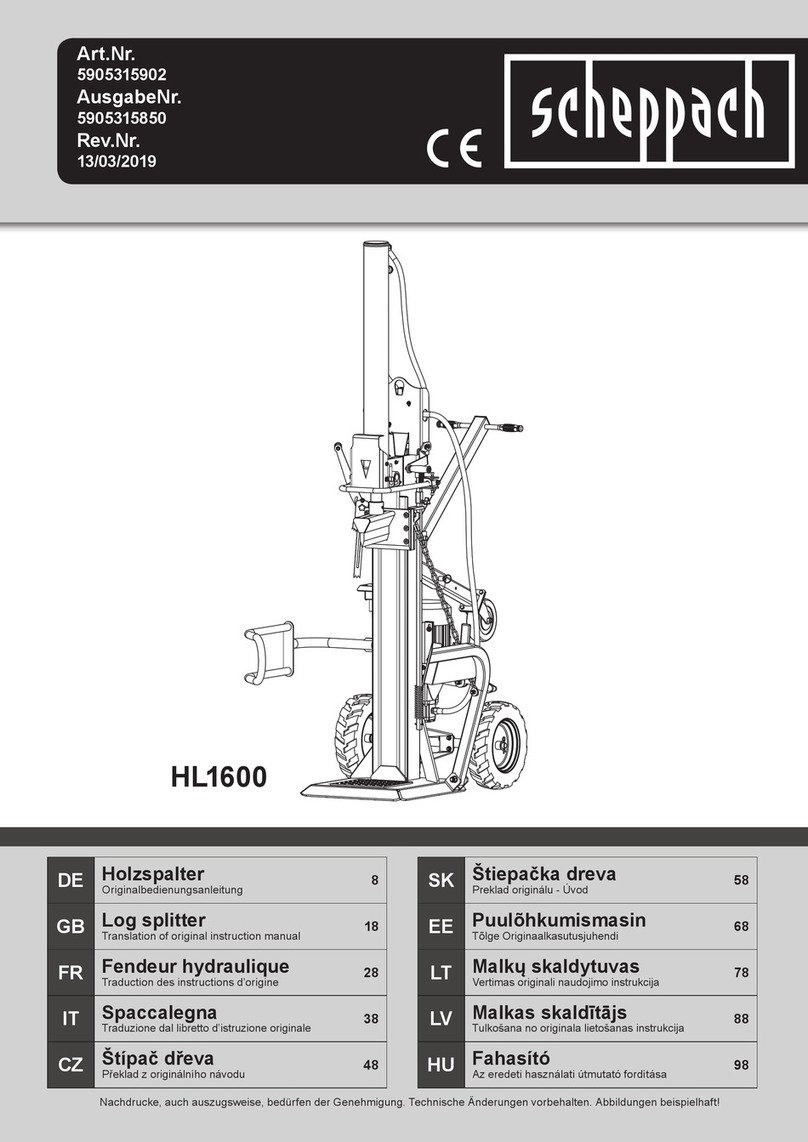

2. PRODUCT OVERVIEW

Operating arms

Wheels

Switches-

Transport handle

Motor

Splitting column

Table

Stand

Guard bracket

Cross splitter

uard bracket

Cross splitter

6

3. WARNING AND SAFETY LABELS

4. "pmax 200 bar" label for 230V

"pmax 220 bar" label for 400V

This label displays the max. operating pressure.

7

8

Servicing, setup, maintenance and cleaning as well as trans-

porting the machine may only be performed with the motor

turned off and machine parts at a standstill.

In order to minimize hazards and avoid damage, it is essential that

the instructions regarding operation, assembly, maintenance, repair,

malfunctions and similar are complied with. Moreover, the machines

may only be operated, maintained and repaired by persons who are

familiar with the machine and who have been instructed regarding the

hazards. Pertinent accident prevention regulations and any general-

ly recognized safety, occupational health and road traffic regulations

must be complied with.

Persons under 18 years of age may not work on splitters. It is permis-

sible, however, to assign such work to persons older than 16 years of

age, as long as this is necessary for the sake of achieving certain trai-

ning objectives and if safety is guaranteed by the supervision of other

skilled personnel.

The work site must be organized and maintained in such a way that

safe working is possible.

The work site must be kept free of obstacles (tripping hazards). Grit/

sand is to be strewn on slippery and slick areas; sawdust and wood

ash are unsuitable for this. The machine must be set up on level, even

and firm ground.

• The work site must be adequately illuminated.

• A level and stable area with adequate freedom of movement is re-

quired for working.

• Work on the electrical system may only be performed by a qualified

electrician.

• The operator of the machine is required to wear personal protective

equipment, safety boots, snugly-fitting clothing, suitable gloves and

protective goggles.

• The log splitter may only be operated if all of the protective guards

installed or intended by the manufacturer are in place.

• Never leave the running machine unattended.

The work site around the log splitter and/or the routes for transpor-

ting wood to and from the machine must be organized and maintained

in such a way that safe working is possible.

4. SAFETY INSTRUCTIONS

9

4.1 Intended use

The log splitter is designed for operation by 1 person. One machi-

ne may never be operated by two or more persons. The „HS 71“ log

splitter is intended solely for splitting firewood into smaller pieces in

the direction of the grain.

When splitting wood, it is essential to ensure that the wood to be split

is placed only on the splitting table‘s checkered plate.

Any other use does not comply with the „intended use.“ The manufac-

turer is not liable for any kind of damage stemming from this; the risk

is borne solely by the user.

In order to rule out hazards and prevent damage, it is essential that

the instructions regarding installation, operation, maintenance, repair

and similar are complied with.

Only pieces of wood with a minimum diameter of 70 mm and a maxi-

mum diameter of 330 mm may be split.

All warranty claims will expire if the machine is used inappro-

priately.

The manufacturer will not be liable for damage to the machine

and for injury to persons caused by improper use.

10

5. BEDIENUNG

Abb. 2

Abb. 1

2

1

3

4

Abb. 3

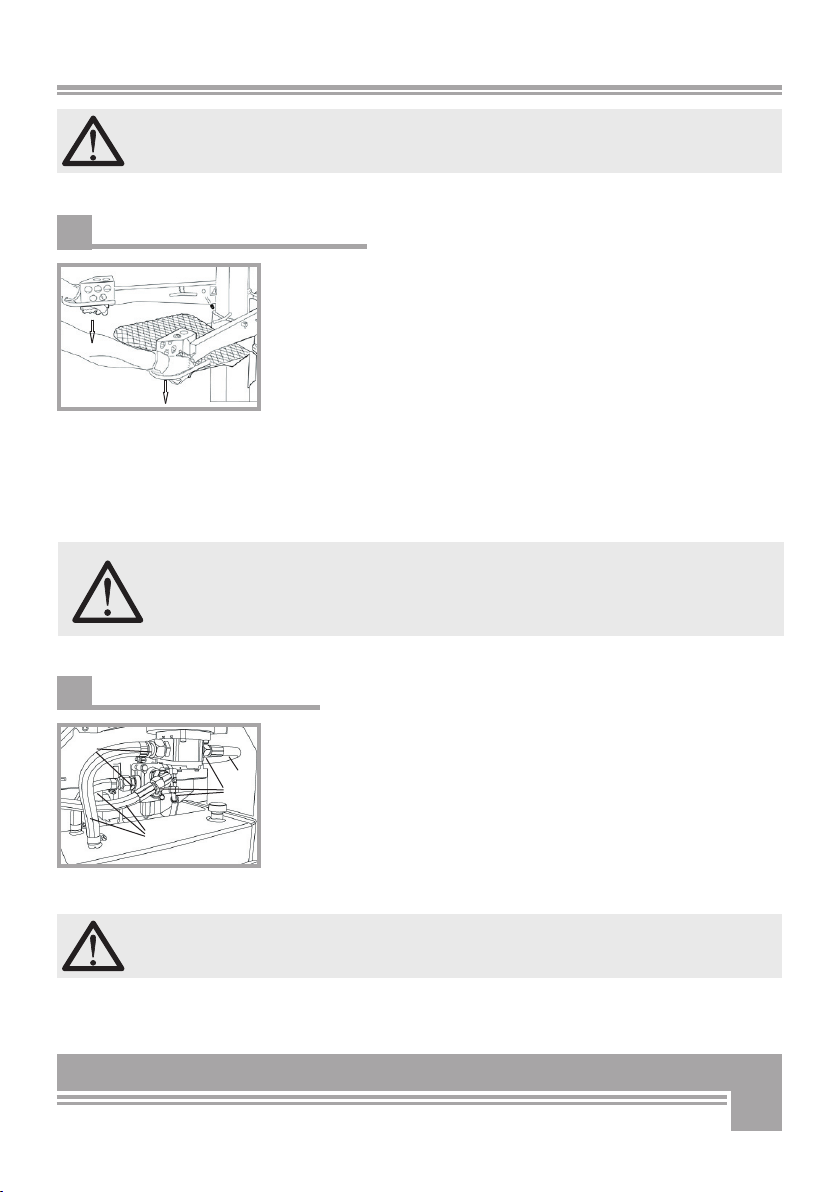

5.1 Mounting guard brackets

Before using the log splitter the first time, the guard brackets (1)

must be mounted onto the operating arms (see Fig. 1). For transport

reasons these are only pre-mounted to the operating arm with one

screw (2). Fasten the guard bracket (1) to the operating arm with two

screws (2) each (see Fig. 1). Tighten both screws (2) firmly!

5.2 Remarks on the electrical system

At a length of 25 m (three-phase motor 400 V), the power cable must

have a diameter of 2.5 mm². Please note that the log splitter‘s ground

conductor must be connected, otherwise it will not operate.

For 400V motors, the direction of rotation is to be checked by swit-

ching it on and off briefly before beginning work. The direction of ro-

tation must match the arrow on the motor‘s ventilation cover. If the

direction of rotation does not match the arrow on the ventilation co-

ver, it must be changed using the phase switch (see Fig. 2) in the po-

wer cable.

For AC motors (230V). a minimum cable diameter of 2.5 mm² is ne-

cessary for a cable length of a maximum of 10 m.

5.3 Remarks on the hydraulic system

The hydraulic oil tank (see Fig. 3) can be found in the base of the log

splitter. The oil tank (4) is filled with hydraulic oil at the plant. Care

must be taken when the log splitter is tipped far to the back during

transport, because oil can leak out of the filling nozzle (3). Refer to

page 17 for the replacement of hydraulic oil.

At low temperatures the oil in the hydraulic system is still very vis-

cous. Working (splitting) immediately at such temperatures can lead

to damage to the hydraulic system. In order to ensure problem-free

operation of the hydraulic system at low temperatures, the splitter

shouldfirst be run in idle for 10 - 20 min. to allow the hydraulic oil to

warm up.

11

Abb. 5

6

6

5

5

Abb. 4

5.4 Checking the two-handed controls

Log splitters are equipped with mechanical two-handed controls. The

purpose of this is to ensure that the operator has no way to reach in-

to the splitting area when working with the machine (see Fig.4). The

two-handed controls should be checked before each use. Both control

levers must be pressed downward to begin the splitting operation. The

splitting wedge travels downward.

Letting go of a control lever will cause the splitting operation to be

halted. The splitting wedge must now remain in its position and may

not return to its initial position.

Letting go of both control levers will cause the splitting wedge to re-

turn to its initial position (at the top).

The splitting wedge is not permitted to travel downward if only one

control lever is actuated. When control levers are released, they must

return automatically to their initial position.

The splitter may not be started up if a malfunction is found in

the two-handed controls (due to mechanical causes such as

bent arms).

5.5 Remarks concerning startup

The log splitter must be checked for external damage each time be-

fore it is started.

The hydraulic hoses (5) and all connection points (6) on the hydraulic

system must be inspected to detect any potentially leakage and to eli-

minate them (see Fig. 5).

All safety systems/guards must be mounted on the machine. They

may not be removed or disabled. If malfunctions or defects become

evident, the machine may not be started up until they have been rec-

tified.

The machine may not be started if the hydraulic system shows

leakage.

The control valve is set at the manufacturing plant; further ad-

justments may not be attempted.

12

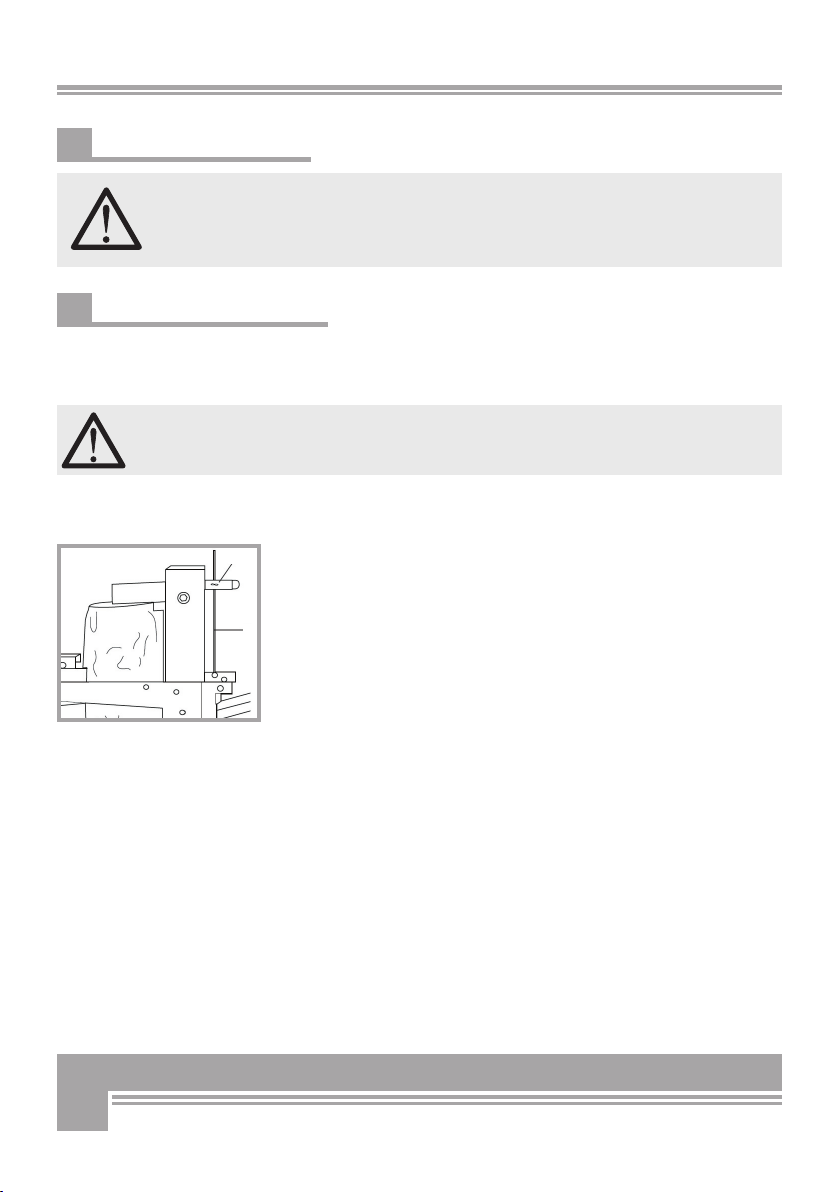

Proceed as follows to modify the lift-height of the splitting wedge:

Move the splitting wedge to the desired height. Pressing on a control

arm causes the splitting column to remain at the desired height. Now

shut off the motor. The splitting column remains at the desired height.

Now loosen the wing bolt (7) at the handle (behind the splitting co-

lumn) and pull the control rod (8) out as far as possible. Use the wing

bolt (7) to clamp the control rod (8) at the desired height, and then

tighten the wing bolt firmly.

Now the log splitter can be switched on again. Now the splitting

wedge cannot extend to its maximum length anymore, because it is

limited by the control rod (8).

To reset the maximum splitting length, it is necessary to loosen the

wing bolt (7). Now the splitting wedge can extend to its maximum

length again. After that tighten the wing bolt (7) firmly again.

Abb. 6

8

7

5.6 Remarks concerning safety

The log splitter must be set up on a firm and even surface. The

work site must be kept free of wood scraps and obstacles (trip-

ping hazards). Grit/sand is to be strewn on slippery and slick

areas. Never reach into the splitting area when the splitting

wedge moves.

5.7 Adjusting the splitting length

When the log splitter leaves the factory, it is set to its maximum split-

ting length. When the motor is switched on, the splitting wedge travels

automatically to its maximum height.

The lift can be limited in cases where it is necessary to split wood

whose height is clearly below the maximum lift of the log split-

ter. The lift height can be adjusted to any level..

13

The bolt is then to be inserted in the existing holes of the table holder

and secured with the wing nut (11; Fig. 9).

(It is only possible to insert the bolt in the holes if the table was

mounted properly.)

At the bottom holder, the table can be mounted only without the se-

curing bolt (valve is in the way). Take particular care to ensure here

that the hooks on the back of the table latch in behind the holders

above them.

Abb. 9

11

9

Abb. 7

Abb. 8

10

5.8 Adjusting the table

Logs ranging from 550 mm to 1065 mm can be easily split by adjus-

ting the splitting table. The table can be adjusted to three heights, wi-

thout the need for tools.

To adjust the table, unscrew the wing nut (9; Fig.7) on the table

mount/column and remove the bolt from the hole. Now the table (10;

Fig. 8) can be easily raised and removed by pulling it forward.

To mount the table (10; Fig. 8), it must again be slightly raised at

the front. Place the table on the holders on the stand at the height

that matches the wood you are splitting, and slide it to the back in a

tipped-up position. Lower the table at the front, and ensure that the

hooks on the back of the table latch in behind the upper holders.

14

Abb. 10

12

13

B

B

A

5.9 Working with the wood clamps

Wood clamps (12) are attached to the operating arms to hold wood in

place during the splitting operation (see Fig. 10).

Because of the attached pressure springs (13), the wood clamps can

adapt variably to logs of any size (see Fig. 10).

The log must be aligned centrally in the wood clamps to ensure opti-

mum functionality and proper splitting.

5.10 Working with the log splitter

Place the wood to be split on the splitting table and press both opera-

ting arms (A) inwards (see Fig. 10). This will fix the wood in place.

Both control levers must be pressed downward (B) simultaneously to

begin the splitting operation. This will set the splitting wedge in moti-

on.

Both control levers (B) must be pressed during the entire splitting ope-

ration.

Release the control levers to cancel the splitting operation. The split-

ting wedge will travel back to its initial position. Once the splitting

operation is finished, release both control levers so that the splitting

wedge can travel back to the top (B).

The split wood may only be removed from the splitting table after the

splitting wedge is back in its initial position.

If necessary, clear the wood scraps and chips from the table before be-

ginning the next splitting operation.

Ensure that the wood to be split is always placed on the table

straight. Note that wood that is full of branches can splinter. Never

use any wood that has not had its branches removed.

5.11 Releasing jammed pieces of wood

Sometimes the wood is not completely split through and it is pulled

upward by the splitting wedge as it travels to the top. If this happens,

allow the splitting wedge to travel back to its initial position, and then

switch off the log splitter. Now the wood must be knocked away. This

can be accomplished with a hammer.

15

On electrically-powered machines, always remove the power

plug before changing locations.

It is very easy to transport the log splitter. An axle with two wheels is

attached at the back.

To transport the log splitter, tip it backward slightly until the wheels

are touching the ground (see Fig.11).

The motor guard can also serve as a handle.

There is a transport handle situated near the top of the splitting co-

lumn.

When transporting the splitter, it is advisable to drive the splitting

wedge right to the bottom.

The two control levers should be bound together at the front so that

they do not accidentally swivel around during transport.

6. TRANSPORTING THE MACHINE

Abb. 11

16

Available as accessories* for our log splitters are a cross splitter and

a splitting wedge expander (as additional purchases).

The cross splitter splits the firewood into 4 parts in one operation. The

splitting wedge expander allows improved and faster splitting of the

wood.

Both accessory parts are simply slid onto the splitting wedge and

clamped in place with a star-shaped knob (M12).

When mounting the cross splitter, ensure that the inclined side of the

crosswise blade is facing the operator.

Splitting wedge expander: Item No. 90303

Cross splitter: Item No. 90302

Ensure that the cross splitter and the splitting wedge expan-

der are fully slid onto the splitting wedge and secured in place

with the screw.

If the cross splitter or the splitting wedge expander are not complete-

ly slid onto the splitting wedge, they can slip forward during operation

and injure the person operating the machine. It is also possible that

the machine becomes damaged.

If possible, the cross splitter should not be used for hardwood (fruit

trees, beech), because this kind of wood presents the cross splitter

with much more resistance and is more likely to trigger the pressure

relief valve in the hydraulic system and cause the wood to jam.

The diameter of the wood must be a minimum of 200 mm if the

cross splitter is used, otherwise the log splitter could be dama-

ged. Moreover, the wood clamps must be secured in the positi-

on furthest to the back using a cotter pin.

* Accessory parts are not included in the basic equipment and are available at

additional cost.

7. CROSS SPLITTER AND SPLITTING WEDGE

EXPANDER AS ACCESSORIES

Abb. 12

17

8. MAINTENANCE AND

SERVICING WORK

Please perform maintenance, servicing and cleaning only

after the machine has been turned off (pull plug out of so-

cket) and machine parts are at a standstill.

8.1 Regular maintenance tasks

The following tasks are to be performed as necessary and/or on a re-

gular basis:

• Clean away wood scraps, wood chips and any other dirt from the

machine

• Grease the splitting column

• Check the level of the hydraulic oil; if there is a loss of oil then

check the leak-tightness of the entire hydraulic system (hoses and

screw connections)

• Lubricate all moving parts

8.2 Remarks regarding the hydraulic

Check the level of the hydraulic oil regularly. Ensure that no dirt or

wood chips have found their way into the oil tank.

Never run the splitter without or with insufficient oil. If a lack of oil

causes air to enter the circulation system, the splitter will begin to

work incorrectly (jerking and erratic), and the hydraulic pump can be

damaged.

The first oil change must be performed after approx. 25-30 hours of

operation. After that the hydraulic oil is to be changed approx. every

50 hours of operation or at least once a year.

The drain screw can be found on the underside of the oil tank. The fil-

ler screw can be found on the upper right of the tank.

Recommended hydraulic oils: - HLP 46,

DEA HD B 46, Shell Tellus 10-46, Esso Nuto H 46

When changing the oil be sure to collect the old oil in a suitable con-

tainer. Ensure that the container you use is oil-resistant and has a

minimum capacity of 7 liters. If the container is smaller, you can drain

the oil in multiple stages.

Old oil is harmful to the environment and must be properly dis-

posed of.

After filling the oil tank, run the log splitter three to four times to al-

low air to escape out of the hydraulic circulation system; then replace

the tank cap.

18

8.3 Guides in the splitting column

If squeaking sounds can be heard while running the log splitter, it

is necessary to grease the polyamide guides in the splitting column

tracks. A standard commercially-available grease can be used for this.

The squeaking sounds should cease after doing this.

After the polyamide guides have worn out, if the splitting column be-

gins showing signs of excessive play to the column tracks, the polya-

mide guides must be replaced.

8.4 Wear parts

• Item No. 53057 Top guide

• Item No. 53058 Bottom guide

19

When the machine has reached a condition that it cannot be used

anymore and must be scrapped, it is necessary to deactivate and dis-

mantle it. This means that it must be converted into a state in which it

cannot be used anymore for the purpose for which it was constructed.

In the scrapping process the recycling of the machine‘s basic materi-

als must be kept in mind.

These materials may potentially be reusable in a recycling process.

The manufacturing company assumes no responsibility for potential

injury to persons or damage to property that stem from the re-use of

machine parts, if these parts are used for purposes other than those

for which they were originally intended.

Deactivation of the machine:

All deactivation or scrapping work must be performed by persons who

were trained for this.

● Block each movable machine part and dismantle the machine down

to its individual parts

● Send all components to controlled disposal facilities

● Drain fuel out of the tank and dispose of it in an environmentally

friendly way

● Remove rubber parts from the machine and bring them to a facility

that takes them

No residual risk exists anymore after all movable parts have been

deactivated and blocked.

Electrical components are considered special/hazardous waste and

must be disposed of separate from the machine. If a fire occurs in the

electrical systems of the machine, fire extinguishing equipment is to

be used that is certified for this purpose (e.g. powder extinguishers).

9. DECOMMISSIONING AND DISPOSAL

20

10. TECHNICAL SPECIFICATIONS

*Splitting force can fluctuate by ± 10%.

10.1 Noise emissions

The noise emissions were determined as guide in compliance with the

general rules for assessing the noise emitted by technical equipment

for agricultural and forestry at the work site as well as the general in-

structions for measuring the noise emitted by technical equipment for

agricultural and forestry, with the following parameters:

Measurement point at the front edge of the machine, 1600 mm high,

1000 mm ahead of the machine

Max. noise emission, idle: 75 dB(A)

Max. noise emission, full throttle: 80 dB

Technical specifications Unit 230 V 400 V

Splitting height mm 550/750/1065 550/750/1065

Ram stroke mm 500 500

Min. wood diameter mm 70 70

Max. wood diameter mm 330 330

Splitting force* t 6 7

Max. operating pressure bar 200 220

Motor power rating P1 kW 2,2 3,0

Nominal current A 13,1 4,8

Speed RPM 2660 2840

Rated voltage V 230 400

Backup fuse A 16

Total height, extendet mm 1570 1570

Total height, retracted mm 1100 1100

Width mm 570 570

Depth mm 940 940

Weight kg 132 126

Oil capacity (tank/system) l 5,0 5,0

Table of contents

Other BGU Log Splitter manuals

Popular Log Splitter manuals by other brands

Scheppach

Scheppach HL800VARIO Translation from the original instruction manual

Scheppach

Scheppach HL1800GM Translation from the original instruction manual

Mr.Paldu

Mr.Paldu Horizontalspalter 550 operating instructions

Scheppach

Scheppach HL1600 Translation of original instruction manual

Homelite

Homelite UT49103 Operator's manual

Craftsman

Craftsman 247.77640 Operator's manual