BGU HS 90-2Z User manual

Hydraulikholzspalter

Seite 1

Carefully read entire manual before operating

the firewood maschine!

Operation manual

Südharzer Maschinenbau GmbH

99734 Nordhausen, Helmestraße 94

Service Tel. 0 36 31 / 62 97 104 • Fax 0 36 31 / 62 97

111

E-Mail: [email protected]

Hydraulic log splitter HS 90-2Z

- Set-up & installation

- Use

- Maintenance

- Accessories

Hydraulikholzspalter

Seite 2

Südharzer Maschinenbau GmbH

Helmestr. 94

99734 Nordhausen

Tel: 0 36 31 / 62 97-0 Fax: 0 36 31 / 62 97 111

E-Mail. [email protected]

Internet: www.bgu-maschinen.de

CE – Statement of Compliance

with the CEE Machines Directive No. 98/37/CEE and

and EMV 89/336/CEE

We hereby declare that the equipment described in this manual responds in full to the actual version

brought on the market. We, the manufacturer further declare that this equipment was duly designed and

manufactured in accordance with the actual European Safety and Health Standards settled by the rele-

vant EEC directives as well as the latest electromagnetic standards issued by the European Council of

3.5.89 and later enforced by all member states.

This statement of compliance does not apply to customer modifications of the equipment without

manufacturer’s written approval. The manufacturer shall not be responsible for such modified equipment

and machines.

Machine type: Hydraulic log splitter

Model: HS 90 - 2Z

Production number: See model label

Applicable European Standards: EEC Machine Directive Nr. 98/37 EG

EEC EMV-Directive 89/336 and following modified versions

no.- 91/263 EWG, 92/31 EWG and 93/68 EWG)

Other Standards: To assure full compliance with law requirements, due

considerations was equally taken for the following harmonized

rules:

EN 609-1, EN 61000-3-2, EN 61000-3-3,

Official inspection Institute as per Annexure V of the Machine Directive:

Deutsche Prüfstelle für Land- und Forsttechnik DPLF

Postfach 41035

34114 Kassel

Registered with Nr. 0363

EEC - Specimen Approval Nr.:

27.09.2016

................. ....................................

Date René Pareis - Director

Official user's country language: English (User's release)

Hydraulikholzspalter

Seite 3

Content

Page

1. Introduction ---------------------------------------------------------------------------------- 4

1.1 Delivery and transport claims --------------------------------------------------------------------------------- 4

2. Product overviwe --------------------------------------------------------------------------- 5

3. Safety signs and decals ------------------------------------------------------------------ 6

4. Safety ----------------------------------------------------------------------------------------- 8

4.1 Mandatory application field ------------------------------------------------------------------------------------ 8

5. Operation -------------------------------------------------------------------------------------- 9

5.1 Assembling the hand-guards --------------------------------------------------------------------------------- 9

5.2 Hydraulic specifications ---------------------------------------------------------------------------------------- 9

5.3 Initial check-ups -------------------------------------------------------------------------------------------------- 9

5.4 Start-up procedure --------------------------------------------------------------------------------------------- 9

5.5 Operating safety ------------------------------------------------------------------------------------------------- 10

5.6 Adjusting the ram stroke length ----------------------------------------------------------------------------- 10

5.7 Setting the intermediate short-logs table ------------------------------------------------------------------ 10

5.8 Setting the log clamps ------------------------------------------------------------------------------------------ 10

5.9 Operating instructions ------------------------------------------------------------------------------------------ 11

5.10 Clearing logs sticking to the wedge ------------------------------------------------------------------------- 11

5.11 Splitting on the floor-standing table ------------------------------------------------------------------------- 11

6. Connection and disconnection to PTO drive ------------------------------------ 12

7. Handling and transportation ------------------------------------------------------------ 13

7.1 Handling the splitter on its own caster wheels arrangement ------------------------------------------ 13

7.2 Handling the splitter on a three-point linkage ------------------------------------------------------------ 13

8. 4-ways wedge, splay wedge and wedge extension ---------------------------- 14

9. Repairs and maintenance --------------------------------------------------------------- 15

9.1 Ordinary periodic maintenance ------------------------------------------------------------------------------ 15

9.2 Hydraulic oil ------------------------------------------------------------------------------------------------------- 15

9.3 Sliding pads ------------------------------------------------------------------------------------------------------ 15

10. Technical data ------------------------------------------------------------------------------- 16

10.1 Noise level -------------------------------------------------------------------------------------------------------- 16

11. Other area of possible danger --------------------------------------------------------- 17

11.1 Mechanical dangers --------------------------------------------------------------------------------------------- 17

12. Warranty -------------------------------------------------------------------------------------- 17

13. Troubleshooting --------------------------------------------------------------------------- 18

14. Spare parts list ------------------------------------------------------------------------------ 19

Hydraulikholzspalter

Seite 4

Operating manual

1. Introduction

Dear customer,

thank you very much for your trust and preference in choosing our equipment and joining the number of

our best customers in the world. We are confident that our equipment will be up to all your expectations

and assure you a long lasting quality and performance.

This model "HS 90-2Z" is a PTO, tractor powered splitter with mechanical 2-hands control.

1.1 Delivery and transport claims

Upon delivery of the machine please check for visual machine damages such as damaged packing or scrat-

ched buckled parts. If so, make a remark on all copies of the delivery bill before signing for acceptance.

Also have the truck driver sign al copies of the delivery bill.

Should your shipper or the truck driver refuse to accept your claim, fully reject delivery and make sure to

inform us (the manufacturer) immediately. No claims shall be taken into account by the shipper or by the

insurance company, if a reservation note is not made on the delivery bill.

All transport damages must be notified within latest 2 days from delivery. Therefore delivery must be collected

and inspected within this term. Later claims shall be disregarded. In case of assumed but not visually clear

transport damages make sure to mark the following sentence on the delivery bill: „Reserved delivery due to

assumed transportation damages.“

Insurance and shipping companies act with extreme caution in case of transport damages and sometimes

refuse to accept responsibility.

Please make sure to provide clear and exhaustive evidence (photos) of the claimed damages.

Thank you in advance for your help and attention to this matter.

Hydraulikholzspalter

Seite 5

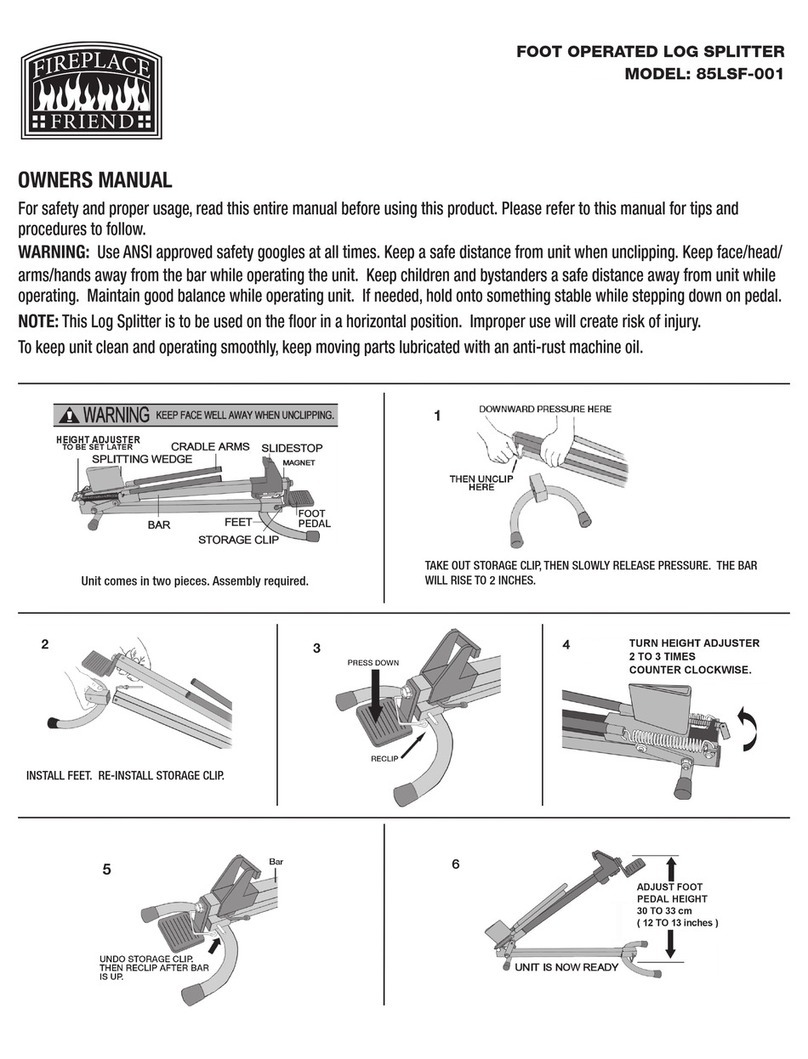

2. Product overview

Construction stand

Short-logs

W e d g e

riser 2-hands control lever Hand guard

Arbor-mounted

gears

Splitting wedge

Caster wheels

Top hitch point

Lower hitch pins

Tank

Floor standing

table

Hydraulikholzspalter

Seite 6

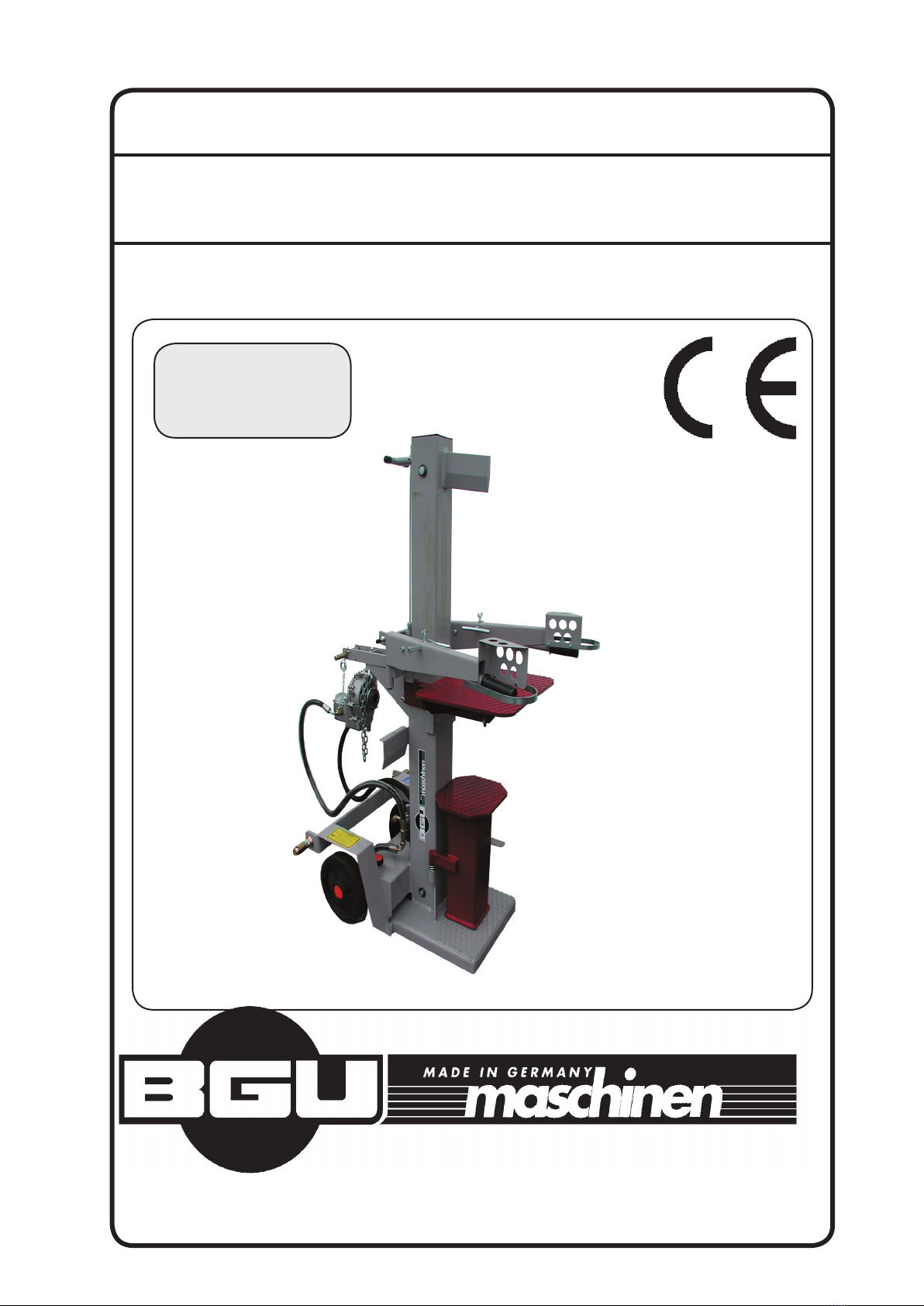

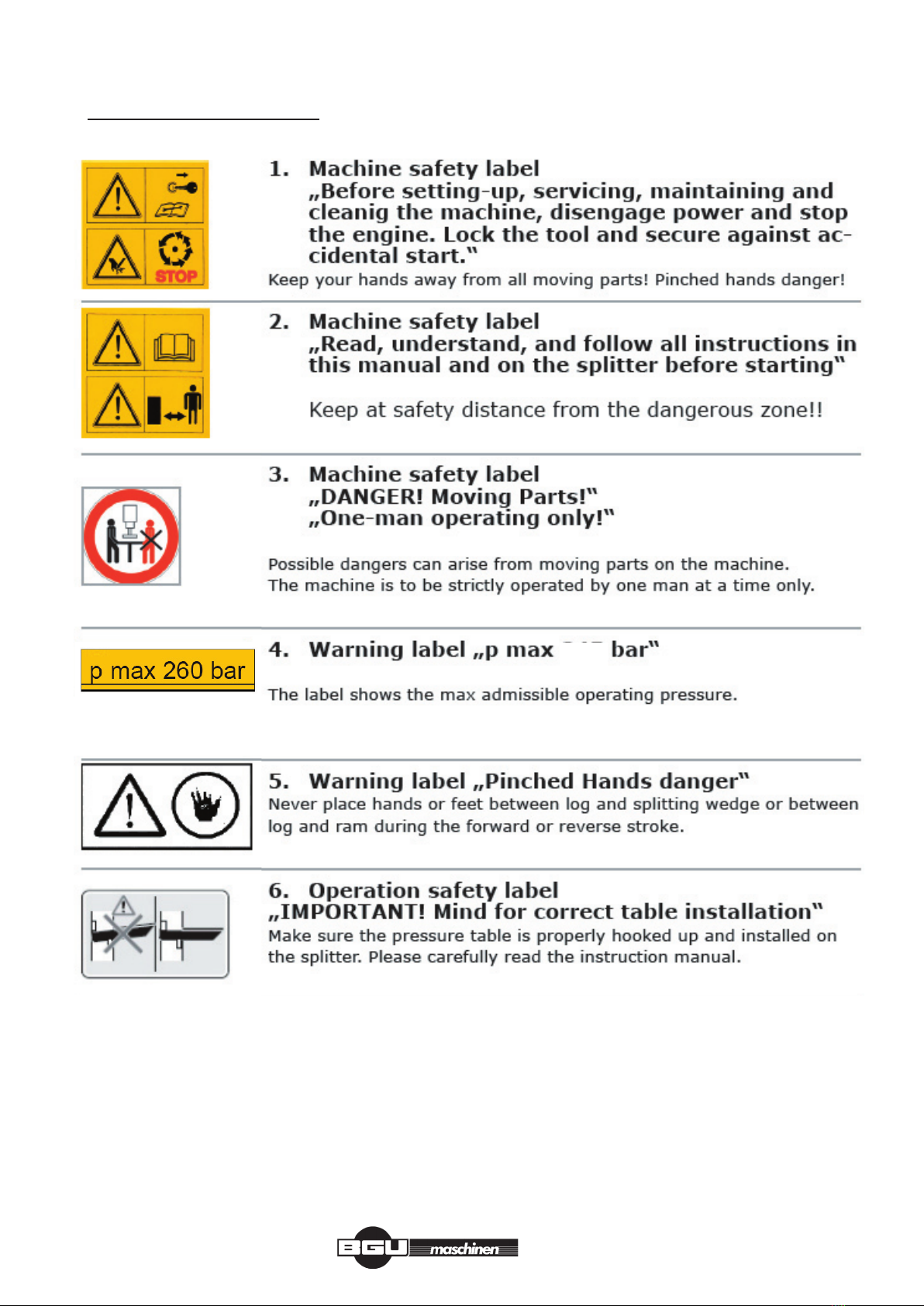

3. Safety signs and decals

260

Hydraulikholzspalter

Seite 7

15. 540

Hydraulikholzspalter

Seite 8

4. Safety

Strictly perform installation, set-up, maintenance, cleaning and transportation with the

motor switched off and the tool firmly secured against accidental operation.

Immediately disconnect power off the machine in case of any eventual fault or trouble.

The user shall strictly comply with these operation, set-up, maintenance, repair and troubleshooting

instructions in order to assure safe operation and no damages to the equipment. Moreover we recommend

to let the machine be run only and strictly by trained and skilled staff who must be familiar with the applicable

occupational safety and health administration rules as well as applicable transportation rules. Incorrect use

of the splitter can cause serious injury or death. Make sure that full compliance is assured at all times with

the general safety and health rules on the workplace as well as the applicable local traffic rules.

No person under school leaving age should operate a circular saw. However, young people in age of 16 or

slightly more may work on the machine providing that they received adequate training, that they carry all

due personal protection safeties and that an adult supervisor keeps standing nearby.

Machine instability can result in injury or severe damages. To ensure stability during operation make sure

to choose a flat, dry floor free from any tall grass, brush or other interferences.

The working area around the machine must be kept as clear as possible from surrounding tripping obstacles

and slippery foundation floors should be duly treated (do not use saw dust or wood ash for this purpose).

Make sure that the equipment stands on a safe stable foundation.

Following precautions must be taken at all times:

- NEVER use your log splitter at night or without sufficient illumination.

- NEVER operate your log splitter on slippery, wet, muddy, or icy surfaces and ensure that a wide but

confined

area is available around the machine and assure maximum working freedom.

- NEVER operate the machine without wearing steel-toed shoes, tight-fitting gloves and tear-resistant

work cloths

- NEVER remove from your log splitters the safety tools and devices mounted on the machine by the

manufacturer

- NEVER exceed the max admissible number of drive shaft revolutions (540 rpm/min)

- NEVER exceed 420 rpm/min if continuous operation is performed.

Always assure compliance with safety, protection and accident prevention rules as well as general road and

traffic rules in the country of use.

Operators should always wear personal protection cloths, steel-toed safety shoes, snug-fitting tear-resistant

work cloths, safety gloves earplugs and safety goggles.

Site must be free of slippery surfaces and tripping obstacles. Make sure that all access ways are properly

maintained so that wood can be safely delivered, loaded and shipped.

4.1 Mandatory application field

The log splitter is strictly designed for one-man operation. Never allow more than one person approach

and work on the machine at the same time.

This splitter is conceived for splitting short and long logs for firewood preparation only. BEWARE: no

cross-grain splitting is permitted. Always split grain-wise and never split one log on top of the other.

When loading logs on the log splitter make sure that the chunk rests entirely and safely on the riffle-plate

table and avoid unsafe methods or splitting other materials than firewood.

Any other use or splitting method is considered by the manufacturer as "misuse". In case of misuse

the manufacturer will not be liable for any injuries or damages and the operator will be held entirely

responsible.

Please make sure to comply with these set-up, operation and maintenance/repair instructions in order to

avoid happening of any injury or dangerous condition.

Hydraulikholzspalter

Seite 9

BEWARE: this unit has a log capacity of min 70 mm and max 450 mm diameter.

5. Operation

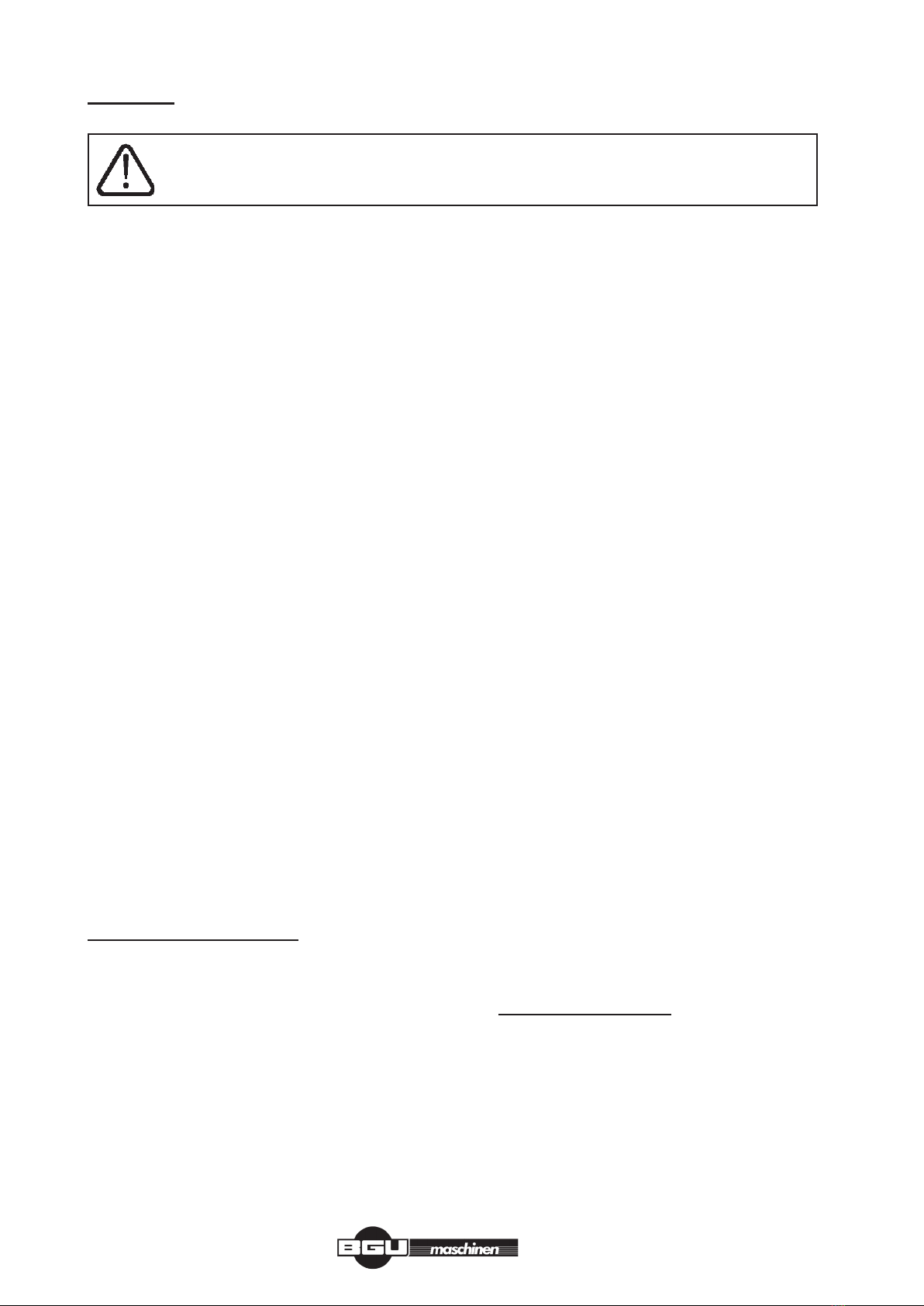

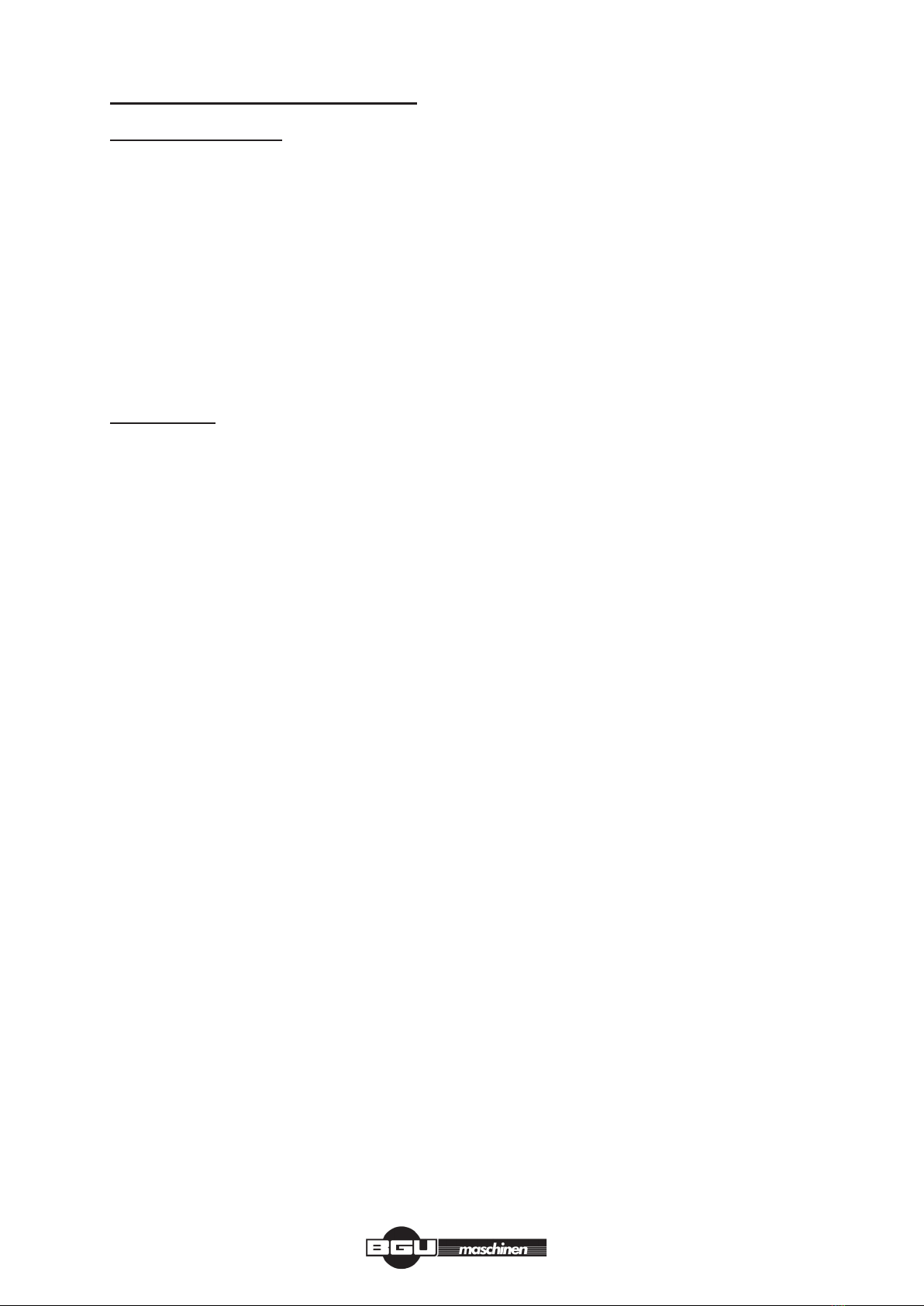

5.1 Hand-guard assembly

Uncrate the machine and assemble the special U-guards

on the control handles before first use and installation.

These hand-guards are delivered loose in the crate by

the manufacturer for packing reasons. After uncrating,

they are to be simply screwed on the control levers. To do

so, fix each guard with two screws (see picture on the

side). Make sure to tight all screws after complete guard

assembly.

5.2 Hydraulic specs

The machine is equipped with own hydraulic oil tank located inside the base-stand and is supplied by the

manufacturer with a first oil fill.

BEWARE: a leaning splitter position during transport may result into oil leakage from the oil plug.

At low ambient temperature the oil in the hydraulic circuit will thicken. In this case, it is recommended to

avoid sudden start-up (splitting without warming the motor up) that could result into damages and trouble

of the hydraulic system.

To assure trouble free operation of the hydraulic system at low ambient temperature, let the motor run idle

and cycle the unit several times till the oil in the hydraulic loop warms up.

Setting of the main control valve is done at the manufacturer before shipping. The unit comes to you

ready for service so that no other adjustment/installation work is required other than assembly of the

hand-guards on the control levers.

5.3 Initial check-ups

The log splitter is equipped with safety two-hands mechanical controls designed for the operator

to keep both hands free from danger and from infringing the moving ram zone during the entire

splitting cycle.

It is strongly recommended to check the operation of the two-hands control every time before a new use.

To do so, engage both handles and hold them down at the same time until the wedge slides all the way

down.

If your system is duly set, the wedge stops upon releasing of just one of the two handles while the ram stops

completing its up/down stroke at once.

On the other hand, the wedge must recommence its upwards travel to the initial start position (all the way

up) as soon as the other handle is also released.

Make sure that the wedge does not travel down when operating only one single lever.

Check that both handles spring back into their normal position when the hand pressure is released.

5.4 Start-up

Before first use, make sure that the log splitter is in good conditions and that there are no visual damages.

Check all hydraulic hoses, fittings and couplings to detect and repair eventual oil leaks. Do not check for

leaks with your hand. Leaks can be located by passing a piece of cardboard or wood around the

suspected leak and looking for discoloration.

Make sure that all safeties and protections are duly assembled on the machine. Do not attempt to

remove or by-pass these safeties!

"Hand-guard assembly"

Hydraulikholzspalter

Seite 10

Should any trouble or unusual behaviour be detected, do not start splitting wood until these have been

fixed.

5.5 WARNING

The location you choose for your machine should be flat, dry, and solid.

Check around log splitter for hazards. Make sure that the area is free of slippery surfaces and

objects to trip over. Slippery and icy floor conditions must be duly treated to assure solid standing

conditions.

Never reach with your hands at pinch points where they can get caught by the travelling wedge!

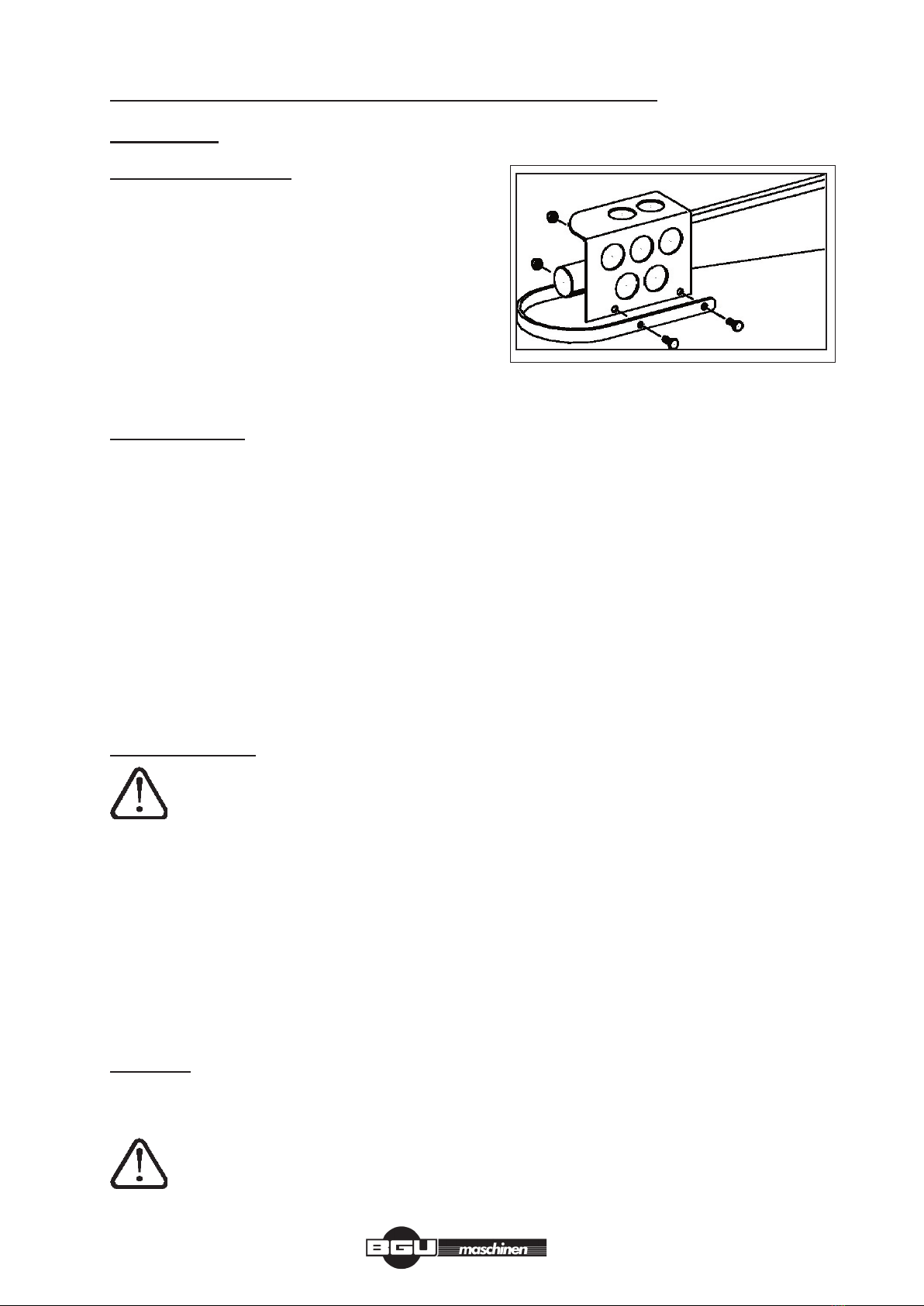

5.6 Adjusting the ram stroke length

The ram travel is factory set to the maximum log capacity before shipment. You just need to start the motor

and the ram slides automatically up to the maximum travel stroke.

Should your chunks be much shorter than your capacity beneath the wedge,

it is possible to adjust the ram stroke accordingly.

Stepless ram stroke adjustment is possible at all times.

RAM STROKE ADJUSTMENT PROCEDURE:

Slide the wedge riser down to the desired stroke length and shut the motor off.

When you do this, make sure to engage one of the control handles in order to prevent

the ram from trigging back to its upper start position.

Now release the wing-nut on the rear grip-handle and pull up the control rod as much as possible. The

ram travel is reduced by an equivalent stroke length as the pulled-up rod length. Once the rod is pulled

sufficiently up to obtain the desired ram stroke, tighten the wind-nut back to the original torque.

Now you can start the splitter motor again and check the ram that should be now completing a shorter

travel than the original full-stroke.

Later ram travel adjustments to the original full-stroke length can be repeated at all times by simply releasing

the wing-nut, pushing the rod back in and tightening the wing-nut again.

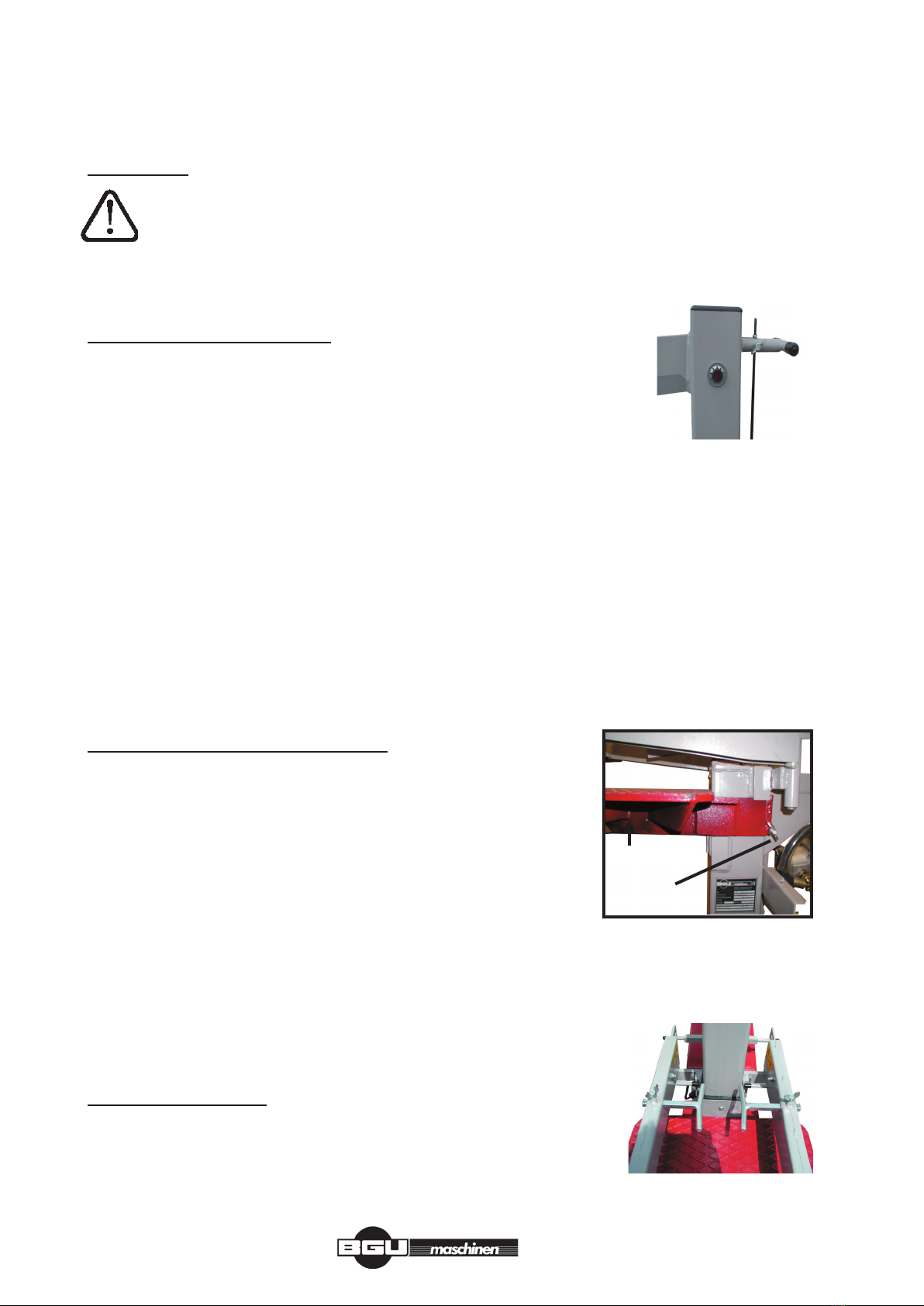

5.7 Setting the intermediate short-logs table

The log splitter is equipped with an intermediate hang-up table for splitting

short logs up to 550 mm long.

Setting-up/removing the short-logs table can be easily performed without

any additional tool or help.

To remove it:

- release the wing-nut on the table mount,

- remove the safety lock pin on one side,

- now, slightly lift the table up and pull it out towards you

To fit it on:

- slip the table onto the lower level mount, grip the front rim of the table

and slightly lift it up, and push it down to the stop,

- now release grip on the front rim and let the table settle down making

sure that the rear table hooks are well and firmly settled on the mounts (see picture on the side)

- Finally slip the clevis back into the special fixation holes on the table mounts and tighten them by means

of the special wing-nuts.

(if the table is duly settled the clevis will fit easily and effortless into the holes)

5.8 Setting the log clamps

In order to hold the log firmly under the wedge during the entire splitting cycle,

use the special log-clamps located on each control handle. Both log clamps

are adjustable depending on log diameter and size and in case of very think logs,

they can be set all inside the cutting area.

Table

Stand

Pin w.

Wing-nut

"Short-logs table

position"

Hydraulikholzspalter

Seite 11

In order to adjust the clamps position, first release the wing-nut on the control

handle and then fit the clamp on each side as desired.

Once adjusted to the desired position, lock the clamps into position by

tightening the wing-nut again.

5.9 Operation

Start the motor and switch the splitter on.

Load a chunk on the table, close the control handles until firmly securing the log by means of the clamps

located on the handles.

Now push both handles down at the same time to start the cycle and engage the ram that will immediately

start travelling down.

DO NOT RELEASE THE CONTROL HANDLES UNTIL THE CYCLE IS COMPLETELY OVER AND THE

LOG IS SPLIT.

Should any emergency arise and stopping be required, simply set the control handles free from

your grip. When doing this, the ram will immediately travel all the way back up.

As soon as the log is completely split, release both control handles and let the ram travel back to

start position and be ready for a new cycle.

Do not attempt to catch the split wood or remove wood sticks from the table by hand until the

cylinder rod stops at its maximum travel position.

Clear the table and remove chips and wood debris from the machine before starting a new cycle.

When loading chunks, make sure that logs sits central and firmly with its sawn end on the table.

Never place your hands on top of the log when loading the log on the splitter.

Do not split wood chunks with lots of branches, first clean it and remove all branches. DANGER : crooked

trunk pieces with green/dry branches may burst under wedge pressure!

Make sure to shut the motor off before leaving the area at work end.

5.10 Clearing logs sticking to the wedge

5.11 Splitting on the floor-standing table

If your logs are up to 550mm long use the floor-type table to split them through in just

one stroke. If they are longer, load the log on the foot plate, pull the two-hands control

handles inwards to firmly hold the log in the central position beneath the wedge. Push

both control handles simultaneously to slide the wedge down as much as possible

through the log that will stick-on. Now push the control levers aside and let the wedge

slide back up with the log suspended on it.

As the ram completes the reverse stroke and stops, swing the floor-type table in,

beneath the wedge and the log sticking on it. Make sure to swing the table all the way

against the splitter stand (see page 5 - Product overview) and to secure it by means

of the special locking lever before operating the wedge again and complete a second

splitting stroke across the log.

Before loading the next log on the foot plate, make sure to swing the floor-type table

wide opened and remove eventual wood chips away from the splitting area.

Lock lever for

floor-type table

Hydraulikholzspalter

Seite 12

6. Connection and disconnection to PTO drive

Make sure to perform accurate connection of your drive shaft both on the splitter and the power input side.

This PTO-driven splitter is equipped with a three-point linkage to fit on the one available on your tractor. The

drive shaft is going to act as linkage and driving element between the tractor and the splitter and should be

therefore duly mounted and secured by the special pins available on the machine.

Press the detent lock inward as you slide the arbor-mounted gears onto the tractor PTO stub shaft. Slide

the machine shaft forward far enough to make sure the detent lock has snapped into the lock position.

Secure the drive shaft with the special retaining chain to avoid dangerous twisting.

Do not perform any repair, adjustment, cleaning or maintenance work whatsoever while the

machine is running (disconnect PTO-drive switch the motor off).

Before stopping the tractor engine, make sure to disconnect the drive shaft in order to avoid damaging the

power drive.

Hydraulikholzspalter

Seite 13

7. Transportation

7.1 Handling the splitter on its own caster-wheels arrangement

Make sure that power is fully switched off and that the arbor-mounted gears have been disconnected before

transporting the machine.

This machine is conceived for very ergonomic easy handling thanks to the special wheel arrangement in

the rear bottom part of the machine.

Before handling the machine around, make sure to tie up the two control handles together to prevent them

from swinging out and accidentally injure/damage persons or other equipment standing nearby.

One man can easily handle the machine on site by himself. Handling asset is leaned back on the wheels

while the operator firmly holds it with one hand on the rear upper grip and the other hand on the cover plate

above the motor.

The splitter is best handled with the wedge fully retracted inside the splitter stand.

4.2 Handling on a three-point linkage

If you wish to handle the machine on the three-point linkage of your tractor (or other equivalent systems)

make sure to comply with below instructions.

Make sure that the machine does not infringe the tractor profile nor blinds tractor lights and signal lights

(stop lights, tail lamps, etc...). If so, you first must provide for additional travel light provisions as required

for road travel in your country.

The same is applicable for all other tools or equipment infringing the tractor profile by 1m in the back and

40cm on the side. In this latter case, suitable clearance lamps must be provided in the front. Make sure to

apply suitable warning sings (white/red) as per DIN Standard 11300 to warn about protruding obstacles

likely to endanger the nearby traffic.

More details are obtainable from the StVO (for Germany) or local traffic Authorities in your country.

Hydraulikholzspalter

Seite 14

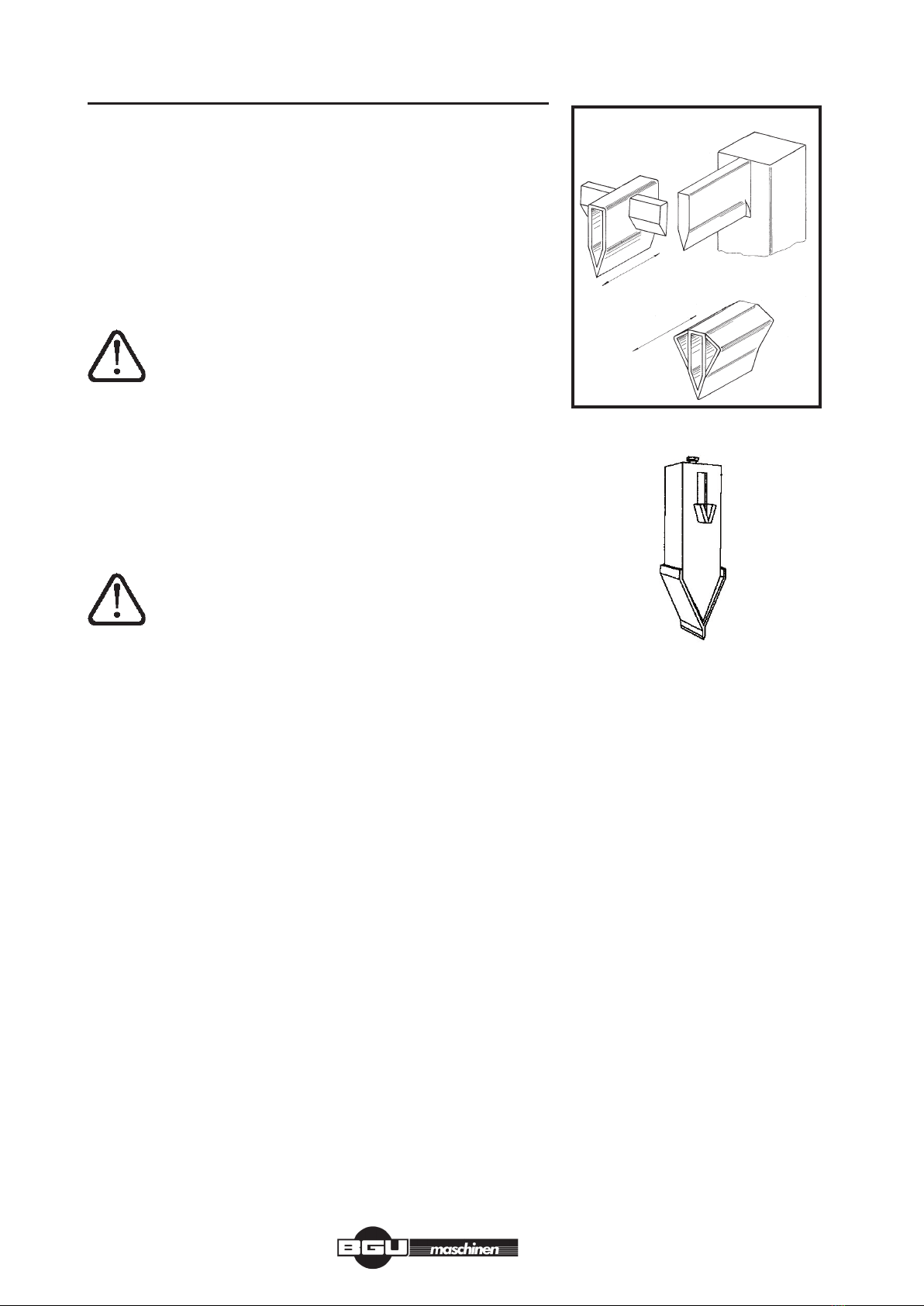

8. 4-ways wedge, splay-wedge and wedge extension

On request, the log splitter can be factory equipped with a 4-ways wedge,

a splay wedge and/or a wedge extension.

The 4-ways wedge is designed for splitting each log in 4 sticks in one

cycle.

The splay wedge can be used for cleaving big, hardwood logs and

facilitates breaking through the log.

4-ways wedge, splay wedge and wedge extension are simply slipped

on the permanent wedge of the machine and secured by means of a

special M12 screw bolt .

BEFORE STARTING THE CYCLE make sure that wedge is

fully slipped-on the permanent wedge and secured in position

with the blade wings facing the operator side.

The removable wedge extension provides a bigger down-splitting stroke

and should be used in combination with the floor-type table to quickly,

safely and effectively split full-cord logs on the floor plate.

DO NOT USE the wedge extension to split short logs on the intermediate

table because the extension would hit against the table quickly damaging

the cutting edge.

BEFORE STARTING THE CYCLE make sure that the 4-

ways/cleaving wedge or extension wedge is fully slipped-on

the permanent wedge and secured in position.

Do not work with a loosened wedge to avoid falling off during

splitting !!

This is a very UNSAFE method and could result in major injuries

to the operator and permanent machine damages.

When using a 4-ways wedge the log clamps on the control handles must

be pulled out of the splitting area below wedge.

Hydraulikholzspalter

Seite 15

9. Repairs and maintenance

Make sure that the machine is fully disconnected and all moving parts are secured before performing

any maintenance/repair work on the machine. In the event of any malfunctioning, switch the machine

off before trouble-shooting.

9.1 Regular maintenance

Make maintenance a regular part of daily operation. The daily maintenance routine needs to include:

- Cleaning of the machine and clearing of all parts from residual wood debris, chips, dust, bark pieces

and eventual other waste.

- Greasing of the sliding pads inside the splitter stand

- Hydraulic oil check and (in case of leakage) hydraulic hose and fittings check-up to detect eventual oil

leaks.

- Lubrication of all moving parts

9.2 Hydraulic oil

Periodically check the oil level inside the hydraulic oil tank. When doing so, accurately avoid contaminating

the tank with dirt, wood chips, sow dust etc...

Make sure that the splitter never runs without oil or with a low oil level. When this happens, air is likely to

reach inside the hydraulic loop. Failure to maintain due oil level may cause poor running and irregular splitter

operation (very rough, back/forth or up/down motions) as well as major pump damages.

Please schedule your first oil change after approximately 25-30 operation hours and later ones after each

50 operation hours or once a year.

The oil drain plug is located on the bottom tank side while the fillercap is on the upper right hand side of

the tank.

Recommended oil types: HLP 46, DEA HD B 46, Shell Tellus 10 - 46, Esso Nuto H 46

When changing the oil, never let used oil drop down on the ground, rather collect whole of it in a sealed

container for due disposal. Oil disposal containers should be of at least 8 l capacity. If you are using smaller

containers, make sure to drain the tank in more than one round to avoid spilling old oil out on the ground.

Used oil is very polluting and should be disposed in accordance with local rules!

After refilling the tank with new oil, let the splitter cycle three or four times and let the air blow out of the

hydraulic loop before closing the cap.

9.3 Sliding pads

Should irregular noisy knocks be heard while the ram is sliding up and down, grease the plastic sliding pads

located inside the splitter stand. Preferably use commercial grease available in your country.

Make a trial test before starting to work again. The noisy knocks should disappear after greasing.

Should you detect an unusually larger gap between the wedge riser and the stand, sliding pads are likely

to be worn out. If so replace them with brand new ones.

Hydraulikholzspalter

Seite 16

10.Technical data

Log length capacity on foot plate [mm] 1350

Log length on short-logs table [mm] 550

Log length on floor-type table [mm] 900

Ram stroke [mm] 500

Minum log diameter [mm] 70

Max log diameter [mm] 450

Splitting power * [t] 9

Max. operating pressure [bar] 260

Max. number of driveshaft rev. [rpm/min] 540

in continuous operation [rpm/min] 420

Overall heigth (Wedge riser up) [mm] 1600

Overall height (wedge riser down) [mm] 1100

Width [mm] 865

Length [mm] 1000

Weight [kg] 176

Oil tank capacity [l] 8

* please account for ± 10% splitting power rates.

10.1 Noise emissions

Noise emissions were measured in accordance with the European directives for the measurement of noise

emissions on the workplace. The measurement was performed by external authorized certification bodies in

compliance with the applicable standards based on applicable rules for agricultural and forestry equipment.

Noise levels were detected and measured 1600mm high above the machine and 1000mm away in front of

it. The detected noise level was:

LpA = 75 dB(A) .

Hydraulikholzspalter

Seite 17

11. Other areas of possible hazard

11.1 Mecahnical dangers

The special two-hands control mechanism minimises risks and dangers related to moving parts on the

machine. An additional safety is provided on the machine in order to prevent working with only one handle

while the other one is being engaged (held down) by some mechanical tool or system.

DO NOT EVER ATTEMPT to remove or by-pass the two-hands control! Danger: operating the splitter without the

safety two-hands control will increase your risk of having your hands pinched during the splitting cycle.

Do not remove any other safety and protection device from the machine.

WARNING: splitting without due safety devices might result into serious injures to the operator or the other

persons around the workplace. Keep hands and fingers clear at all times. Many log-splitting accidents

happen on the return portion of the stroke.

12. Warranty

All BGU machines are covered with warranty terms in accordance with the law. Customers should promptly

notify the manufacturer eventual material or production claims on their detection. While asking for warranty

service, customer should show copy of their purchase invoice or receipt.

The warranty does not cover for faults due to natural wear, temperature or weather agents as well as misuse,

faulty installation or set-up, improper operation and lubrication or acts of vandalism.

No warranty will be given on parts damaged by improper handling, use and application. The manufacturer

is further not responsible for warranty service on machines used for other applications than mentioned in

this manual, altered or modified by the customer or other thirds, or overloaded.

No warranty applies to consumable parts (for instance: wedge and other fittings) and to adjustment/setting

works.

Hydraulikholzspalter

Seite 18

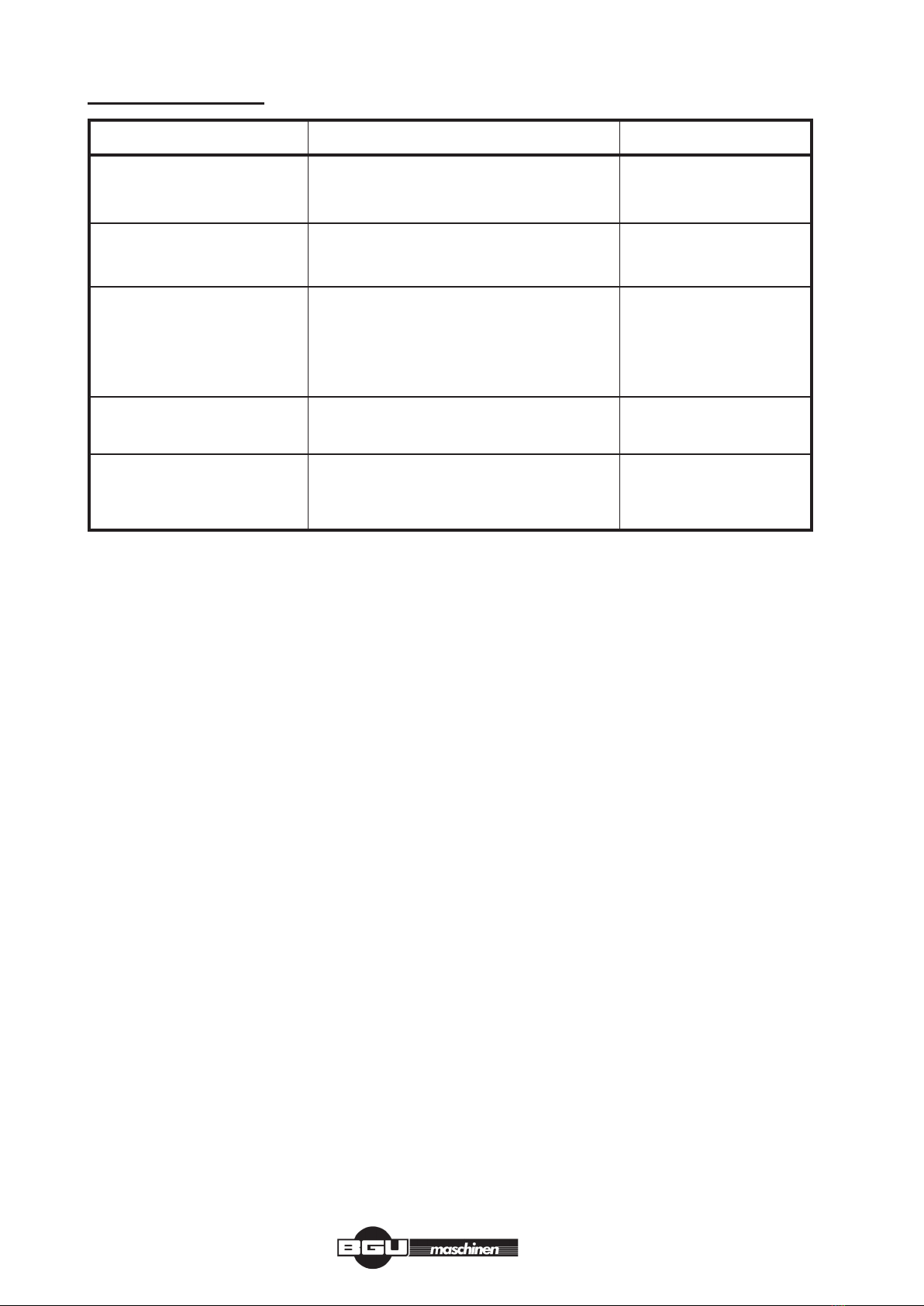

13. Troubleshooting

Type of malfunction Possible origins of the problem Solutions

The wedge doesn't rise - The driveshaft turns in the wrong direction - Check and adjust

- Oil level is too low - Fill new oil in

The wedge doesn't lower - Same as above - Same as above

Wedge moves slowly or - Oil level is too low - Fill oil in

will not extend completely - Wrong valve détente - Adjust valve

on normal log - Pump is broken - Replace pump

- Cylinder gaskets are damaged - Replace gaskets

Ram stops during - Log is too big, crogged or with - Turn/adjust log position

splitting lots of branches

Hydraulic hoses - Oil level too low - Fill oil in

heat-up excessively - Pump is damaged - Replace pump

- Wrong valve détente - Adjust valve

Hydraulikholzspalter

Seite 19

Table of contents

Other BGU Log Splitter manuals