BGU USP 13-6 User manual

USER’S MANUAL

Carefully read entire manual before operating

the log splitter!

Südharzer Maschinenbau GmbH

Helmestraße 94 ∙ 99734 Nordhausen/Harz

Zentrale: +49(0)3631/6297-0 ∙ -111

Internet: www.bgu-maschinen.de

e-mail: [email protected]

- Set-up

- Use

- Maintenance

- Accessories

UNIVERSAL LOG

SPLITTER MODELS

USP 13 - 6, USP 16 - 2, USP 22-2

We manufactu-

re in Germany

2

CONTENT

1. INTRODUCTION 4

1.1 About the manual 4

1.2 Delivery and transport claims 4

2. PRODUCT OVERVIEW 6

(model usp 13 HZE-6) 6

6

3. WARNING LABELS AND SAFETY DECALS 7

4. SAFETY 9

4.1 Mandatory application field 10

5. ABOUT THE MACHINE 11

6. OPERATING INSTRUCTIONS 12

6.1 Adjusting the ram stroke length 12

6.2 Two-speeds operating mode 13

6.3 Function of the safety bracket 13

6.4 Setting the machine ready to work 14

6.5 Operating temperature 14

6.6 Working with the intermediate table 15

6.7 Temperature 15

7. TransportATION 16

7.1 Attaching the splitter to the adjustable three-point linkage 17

8. START-UP 18

8.1 Electric power mode 18

8.2 Three-point hitch mode 18

8.3 Tractor drive (PTO) 19

8.4 Direct connection to tractor hydraulics 19

9. REPAIRS AND 20

MAINTENANCE 20

9.1 Ordinary maintenance 20

9.2 Recommended oil types: 20

10. DISMOUNTING/DISPOSING OF AN 22

OBSOLETE MACHINE 22

11. TECHNICAL DATA 23

11.1 Noise emessions 23

12. WIRING DIAGRAM 25

13. OTHER AREAS OF POSSIBLE DANGER 26

13.1 Mechanical dangers 26

13.2 Electrical dangers 26

3

14. attachments 26

14.1 Radio-controlled winch FSW 750 D (Optional Art. Nr. 96010) 26

14.2 Tow bar with steering wheel (Optional Art. Nr. 94757) 26

14.3 Hydraulic log lifter (Optional Art. Nr. 94721) 26

14.4 Intermediate table (Optional) 27

14.5 Snap-in 4-ways wedge (Optional rt. Nr. 94716) 27

14.6 Mechanical log lifter (Optional Art. Nr. 94711) 27

15. LEGAL WARRANTY 28

16. EXTENDED WARRANTY 28

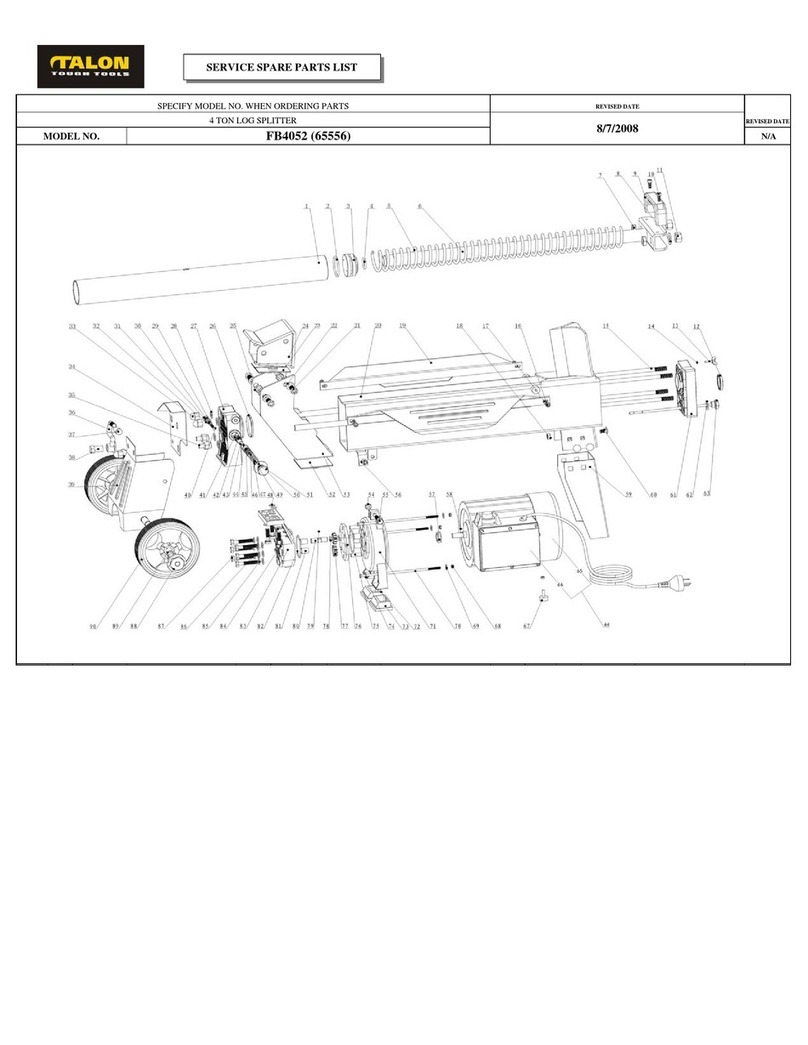

17. Ersatzteilliste 29

18. EC-STATEMENT OF COMPLIANCE 30

4

1. INTRODUCTION

Dear customer,

thank you very much for your trust and preference in choosing our

equipment and joining the number of our best customers in the world.

We are confident that our equipment will be up to all your expectati-

ons and assure you a long lasting quality and performance.

Our range of hydraulic log splitters includes various different models

of different splitting force:

USP 13 H - 6 USP 16 HZ - 2

USP 13 HZ - 6 USP 16 HZE - 2

USP 13 HE - 6 USP 22 HZ - 2

USP 13 HZE - 6

1.1 About the manual

Please take time to read this manual and learn to how operate and

maintain the splitter safely. For your easier reading this manual is laid

out in several sections. The sections are progressively numbered and

listed on the “content” page. The information, pictures and technical

data in this document reflect current or planned product features,

functions, and characteristics as of the publication date. Because of

on-going product improvements and feature additions, information in

this document is subject to change without notice. If you are experi-

encing a problem or functional trouble on your machine, please read

the “trouble-shooting” section 9 to identify possible causes and re-

medies. If the problem or functional trouble is not listed in the trou-

bleshooting chart contained in this manual, ask your Authorized Ser-

vice Centre for service. When you order parts maintenance or repair

services, your Authorized Service Centre, your dealer or eventually

the manufacturer need your machine serial number and engine serial

number. These are the numbers that you have recorded on the pro-

duct identification label of the manufacturer on the machine.

1.2 Delivery and transport claims

Upon delivery of the machine please check for visual machine dama-

ges such as damaged packing or scratched buckled parts. If so, make

a remark on all copies of the delivery bill before signing for accep-

tance. Also have the truck driver sign all copies of the delivery bill.

5

Also have the truck driver sign al copies of the delivery bill.

Should your shipper or the truck driver refuse to accept your claim,

fully reject delivery and make sure to inform us (the manufacturer)

immediately. No claims shall be taken into account by the shipper or

by the insurance company, if a reservation note is not made on the

delivery bill.

All transport damages must be notified within latest 2 days from de-

livery. Therefore delivery must be collected and inspected within this

term. Later claims shall be disregarded. In case of assumed but not

visually clear transport damages, make sure to mark the following

sentence on the delivery bill: „Reserved delivery due to assumed

transportation damages.“

Insurance and shipping companies act with extreme caution in case of

transport damages and sometimes refuse to accept responsibility.

Please make sure to provide clear and exhaustive evidence (photos)

of the claimed damages.

Thank you in advance for your help and attention to this matter.

6

2. PRODUCT OVERVIEW

(MODEL USP 13 HZE-6)

Ram

Control lever, left hand side

Log fender

Splitting wedge

Lower hitch pin

Control rod

Control lever, right hand side

Upper hitch pin

Vertical beam

Wheel

Oil tank

Floor plate

Safety U-clamp

Piston rod

7

1. Machine safety label

„Before setting-up, servicing, maintaining and clea-

ning the machine, disengage power and stop the

engine. Lock the tool and secure it against acciden-

tal start.“

This safety label reminds users of a pinched hands danger.

2. Machine safety label

„Read, understand, and follow all instructions in

this manual and on the splitter before starting!“

Keep at safe distance from machine moving parts!

3. Operation safety label „ADJUSTING THE SPLIT-

TING SPEED“

This label shows how to operate the control levers

4. Operation safety label „max p 240 bar“

This label shows the max admissible operating pressure.

5. Operation safety label “Pinched hands danger!“

Keep your hands off all moving machine parts! Pinched hands hazard

in the wedge dangerous area.

6. Maintenance label „Lubricate every 10 h“

7. Machine safety label „Direction arrow“

The motor must be turning in the same direction as shown by this ar-

row.

8. Machine safety label „Mind this direction arrow“

The motor must turn in the same direction as shown by this arrow.

3. WARNING LABELS AND SAFETY DECALS

p max 240 bar

8

9. Warning label (only on PTO powered version)

max. 520 Rev./min.

This label shows the max admissible number of PTO shaft revolutions.

10. Production label „Product identification“

This label shows the company details of the manufacturer and the

main machine technical data.

11. Identification label

“BGU-maschinen” manufacturer’s logo

12. Personal safety label

„Wear suitable protective cloths and boots“

13. Personal safety label

“WARNING! Always wear safety gloves” Wearing safety gloves.

14. Safety-alert symbol

„Danger: beware in this area!“

15. Personal protection sign

Mind these instructions for safe operation!

16. Position safety bar

This label indicates the position of the safety strap:

Transport position / working position

max. 520 U/min

9

Strictly perform installation, set-up, maintenance, cleaning

and transportation with the motor switched off and the machi-

ne firmly secured against accidental operation. Immediately

disconnect power off the machine in case of any eventual fault

or trouble.

Users shall strictly comply with these operation, set-up, maintenance,

repair and trouble-shooting instructions in order to assure safe ope-

ration and no damages to the equipment. Moreover we recommend

to let the machine be run only and strictly by trained and skilled staff

who must be familiar with the applicable occupational safety and

health administration rules as well as applicable transportation rules.

Incorrect use of the saw can cause serious injury or death.

No person under school leaving age should operate a log splitting ma-

chine. Those who have reached school leaving age but are below the

age of 18 may operate a circular saw if supervised by a competent

person of 18 years or over. The machine shall be installed and kept in

a suitable location selected by the customer for safest operation.

Machine instability can result in injury or severe damages. To ensu-

re stability during operation make sure to choose a flat, dry floor free

from any tall grass, brush or other interferences. The working area

around the machine must be kept as clear as possible from surroun-

ding tripping obstacles and slippery foundation floors should be duly

treated (do not use saw dust or wood ash for this purpose).

Make sure that the equipment stands on a safe stable foundation.

● Due and proper illumination of the working site must be provided at all times.

● Ensure that a wide but confined area is available around the machine

and assure maximum working freedom

● A skilled licensed electrician must be asked for any repair of the electric system

● Operators must wear steel toe safety shoes and snug-fitting tear resistant

work cloths

● No additional customised protections or tools should be provided on board of

the machine, other than the ones designed and supplied by the manufacturer

● NEVER leave the machine unattended with the running motor

Compliance to the applicable occupational safety and health administration

rules as well as applicable transportation rules must be assured at all times.

Operator‘s hearing protection, safety glasses, safety shoes and

gloves, close fitting cloths and other adequate protection means are

strongly recommended. Make sure that all access ways are properly

maintained so that wood can be safely delivered, loaded and shipped.

4. SAFETY

10

4.1 Mandatory application field

The log splitter is strictly designed for one-man operation. Never al-

low more than one person approach and work on the machine at the

same time.

This splitter is conceived for splitting short and long logs for firewood

preparation only. BEWARE: no crossgrain splitting is permitted. Always

split grain-wise and never split one log on top of the other. Make sure

to load your logs firmly on the floor plate against the vertical beam.

Any other use or splitting method is considered by the manufacturer

as “misuse”. In case of misuse the manufacturer will not be liable for

any injuries or damages and the operator will be held entirely

responsible.

Please make sure to comply with these set-up, operation and mainte-

nance/repair instructions in order to avoid happening of any injury or

dangerous condition.

11

5. ABOUT THE MACHINE

The log splitter is equipped with two-hands safety control.

This professional upright log splitter has own inbuilt hydraulic system

with pump and and oil reservoire into the vertical beam. The machine

comes from the factory with a first oil fill. A special level gauge on one

side of the beam provides for convenient oil level checkup.

The manufacturer performs default setting of main control valve be-

fore shipment so that no more adjustment is required on site.

This splitter is available in different versions with different power drive

systems to match with any operating requirement and condition of the

customers.

Make sure to secure the hydraulic ram to the beam, before you start-

up the splitter. The ram has an hydraulic cylinder with a flange that

must be secured on the respective upper plate of the beam using the

special fixation bolts. When doing this mind for the nuts (1) that must

be removed before bolting. (fig. 1)

To operate the machine, raise the ram all the way up and make sure

that the bolts keep showing through the flange. At this point hold the

wedge up and secure the assembly by tightening the special hex nuts.

When transporting the machine from one place to the other (or when

you are to store the machine inside) it may be convenient for you to

slide the ram all the way back down to fit into the splitter profile thus

saving a lot of space. When doing this make sure to first remove po-

wer from the splitter disconnecting all power sources (that is discon-

necting the driveshaft or the power cord).

Fig. 1

1

12

6. OPERATING INSTRUCTIONS

Fig. 3

Fig. 2

3

2

Locate your splitter only on firm, level ground. Site must be

free of slippery surfaces and tripping obstacles. The location

you choose should be flat, dry, and free from any interference.

Slippery foundation floors should be duly treated. For increa-

sed stability and safety, make sure to always load chunks on

their flat sawcut face.

Electrical specifications:

Before starting to work, quickly switch the 400V motor on and off to check that

rotation is performed in the direction shown by the arrow on the motor casing.

Should rotation be performed in the opposite direction, immediately stop the mo-

tor and use a phase inverter to switch the polarity in the plug of main power cord

using a phase changer. Operating the splitter while the motor turns in the wrong

direction may cause major, even permanent damages of the hydraulic pump!

Correct placement of the log on the pressure (floor) plate is a man-

datory condition for safe and efficient splitting. Be sure that the

body of the log is lying firmly against the vertical beam of the log

splitter and the end of the log is well supported by the pressure

plate. If the log tends to wobble, reposition it by turning it. Before

loading the next log on the machine and start a new cycle, clean

eventual residual chips and splinters away from the pressure plate.

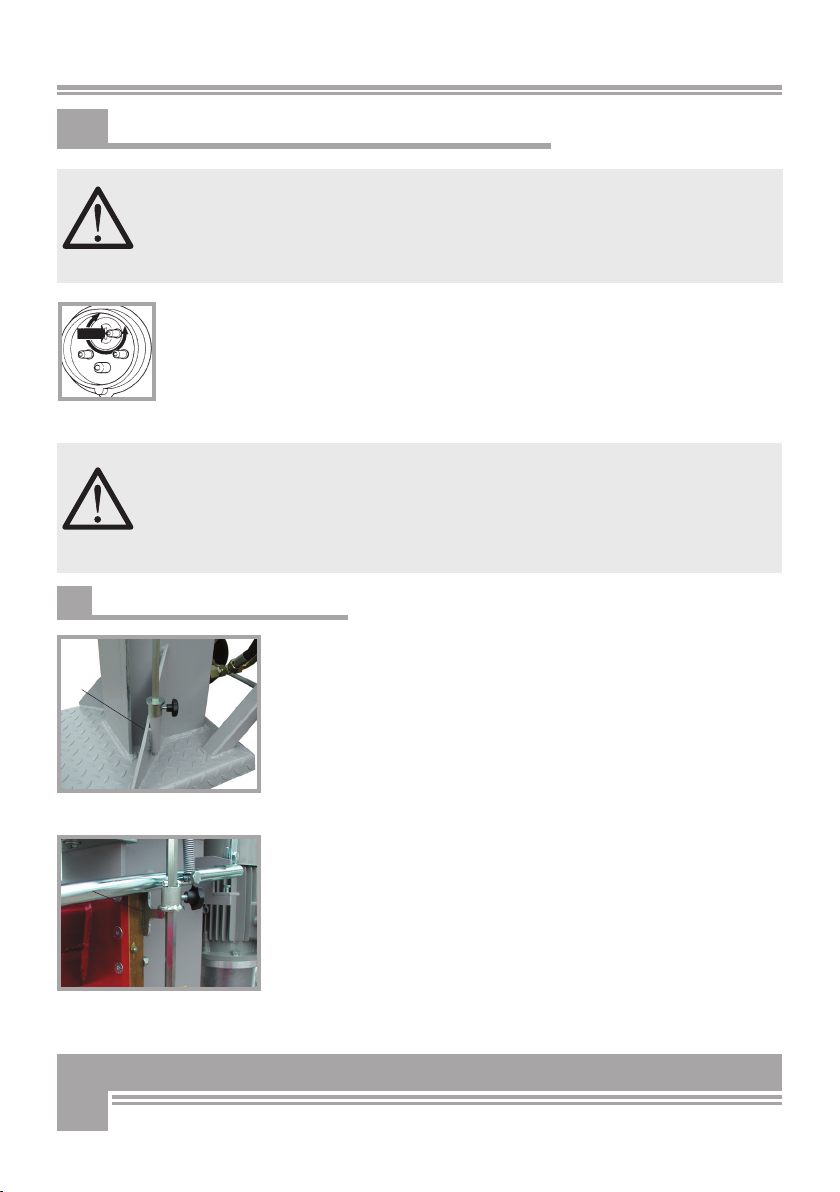

6.1 Adjusting the ram stroke length

The ram travel is factory set to the maximum log capacity before

shipment. You just need to start the motor and the ram will slide au-

tomatically up to the maximum travel stroke.

In order to avoid dangerous hitting of the wedge against the pressure

plate on the floor, lift the lower stop-bush (2) up. (Fig. 2) The control

rod is duly scaled in order to facilitate a precise setting of the stroke.

BEWARE: the wedge will only travel down to the position set by the

stop-bush on the control rod.

For splitting full cord logs, slide the lower stop-bush (2) all the way

down so that the ram can slide over the entire stroke through the log.

If you move the upper stop-bush (3) down, the ram will no loger rai-

se all the way up and will stop as it reaches the position of the upper

stop-bush. (Fig. 3).

Use the upper handle located on the left-hand side of the beam to

secure the log central under the wedge. At the same time push the

handle on the righthand side down to activate the cylinder valve and

operate the splitter. In this situation, the splitter will stop and the

wedge will come to an immediate stop, if just one of the handles is

released.

13

6.2 Two-speeds operating mode

Press the control handle completely down to drive the ram down at its

fast-speed. If no throuhg-splitting is required, the ram must be ope-

rated at its slow speed (=more power). In order to do so, slightly re-

lease one of the two levers (preferably the right-hand one). When

doing so, the main control valve will switch over to max-power mode

instead of fast-speed mode. (Fig. 4).

Normal splitter operation will require the fast-speed mode. Just in ca-

se of a tough or very irregular log not being able to be split, you may

set the machine to slow-speed in order to gain power and perform th-

rouhgsplitting of the log.

If both handles (3 and 4) are released at once, the ram will slide au-

tomatically back to the initial position (Fig. 5), the control valve will

switch off and return to its neutral setting as soon as the ram reaches

its highest position.

Never place your hands on top of the log and never reach within the

splitting area on the machine, while the wedge is being operated.

Should any emergency arise and stopping be required, simply set the

control handles free from your grip. When doing this, the ram will

immediately travel all the way back up.

If a log is jammed on the wedge, it will hit against the safety U-clamp

as the wedge slides up. This will make the control valve switch to neu-

tral position preventing further operation and consequent possible da-

maging the splitter.

Logs that cannot be split through their entire length will jam to the

wedge and be lifted up, as the wedge slides up. BEWARE: check for

the clamping claw on the right-hand handle to avoid tearing.

On each side of the splitter vertical beam there are two log fenders

(6) specifically designed to avoid tipping over of the log sticks while

splitting is being completed (Fig.6).

Fig. 6

Fig. 5

Fig. 4

34

5

6

6.3 Function of the safety bracket

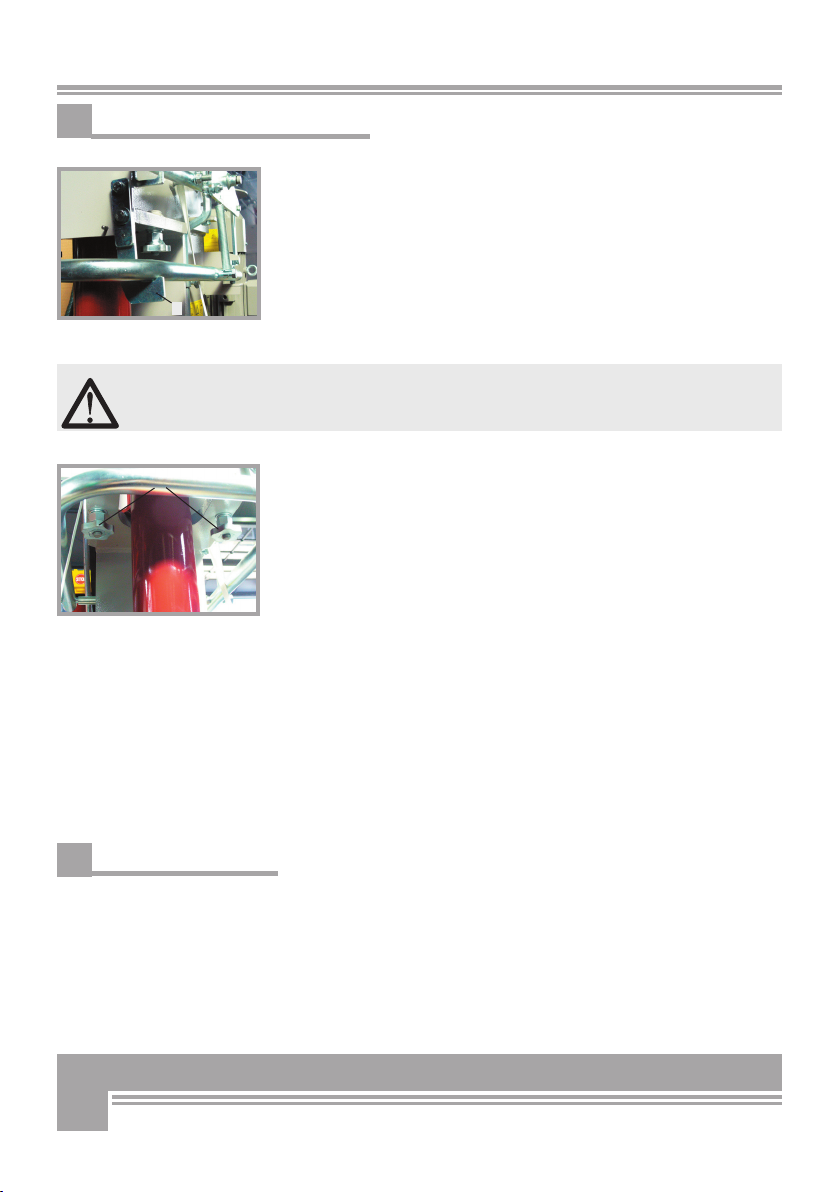

Called by the safety bar, (see Figure 1, point 2), it is possible that

one without a second person the splitter or vice versa brings the

transport position into the working position.

Before the operating levers are operated for splitting, must first of

Safety bar unlocked - being released (see Figure 7).

14

Abb. 7

Abb. 8

8

7

6.4 Setting the machine ready to work

To convert the machine from transport to splitting asset :

1. Engage the safety U-clamp →

Hook up the clamp to its catch

(Pos.7,

Fig. 7)

2. Remove (unscrew) both pommel grips (Pos. 8, Fig.8)

3. Perform power connection (electric or PTO)

4. Operate the left handle, pushing and holding it all the way down.

Press and hold the right handle down → to rive the ram all the way

up

Keep carefully rising the ram up all the way against the flange

of the upper cylinder casing. During operation of the safety bar

must be i m m e r hang out!

5.

Tighten both pommel grips (Fig. 8) again,

Release the U-clamp from its catch

→ the splitter wedge moves up:

→ the splitting position is now achieved.

To set the splitter ready for transportation after completing the work:

1. Secure the U-clamp (Fig. 7) →

hook up the clamp in its catch.

2. Operate both handles → let the wedge move down onto a wooden

block purposely located on the floor plate (approximately a 200 mm

thick block to use as safety seating during transportation) → release

both handles.

3. Remove (unscrew) the pommel grips (Fig. 8)

4. Push the left handle down

5. Release the U-clamp, cautiously settle the left handle back into start

position → let the ram move down and when it reaches its lowest posi-

tion push and maintain the handle

6. Secure the C-clamp → hook up

7. Disconnect power

8. Screw knob handles back

6.5 Operating temperature

At low ambient temperature the oil in the hydraulic circuit will thicken.

In this case, it is recommended to avoid sudden start-up (splitting wit-

hout warming the motor up) that could result into damages and trouble

of the hydraulic system. To assure trouble free operation of the hy-

draulic system at low ambient temperature, let the motor run idle and

cycle the unit several times till the oil in the hydraulic loop warms up.

15

6.6 Working with the intermediate table

With hinged intermediate table (accessory) the lower switching jack

ust solved and in the middle hole of the control rod be attached.

Then unhook the safety bar, now can be cleaved. After the operation,

the cylinder is moved upwards, the Abschaltbuchse the control rod

back into the lower hole of the Attached control rod and then removed

the table. The splitter can be brought back into the transport position.

6.7 Temperature

At low temperatures, the oil in the hydraulic system is still very vis-

cous. Instant work (columns) at such temperatures can cause damage

to the hydraulic system. The flawless To ensure operation of the hy-

draulic system, should the Only operated splitter at low temperatures

some idle time be to allow the hydraulic oil may heat up.

16

7. TRANSPORTATION

Abb. 9

Abb. 10

9

10

This machine is conceived for very ergonomic, easy handling thanks

to the special wheel arrangement in the rear bottom part of the ma-

chine. For long distance transportation, the machine can be conveni-

ently handled on the three-point linkage of your tractor.

To perform handling by rolling on its own wheels, first plug the pull-

rod (9) in the upper 3-point hitch and firmly secure it by means of the

pin. At this stage, find safe handling asset by leaning the splitter back

on the wheels till the wheels hit against the ground.

Alternatively lift the splitter using a crane or any equivalent lifting

equipment hooking the special lift bow (10) as shown on figure 10.

To perform transportation on the tractor, first lift the splitter

at least 20 cm above the ground while holding it straight up.

Disconnect power or remove the driveshaft and make sure that

the machine does not infringe the tractor profile nor blinds

tractor lights and signal lights (stop lights, tail lamps, etc...)

during transportation.

For road transportation compliance to the traffic rules of your

country is mandatory.

17

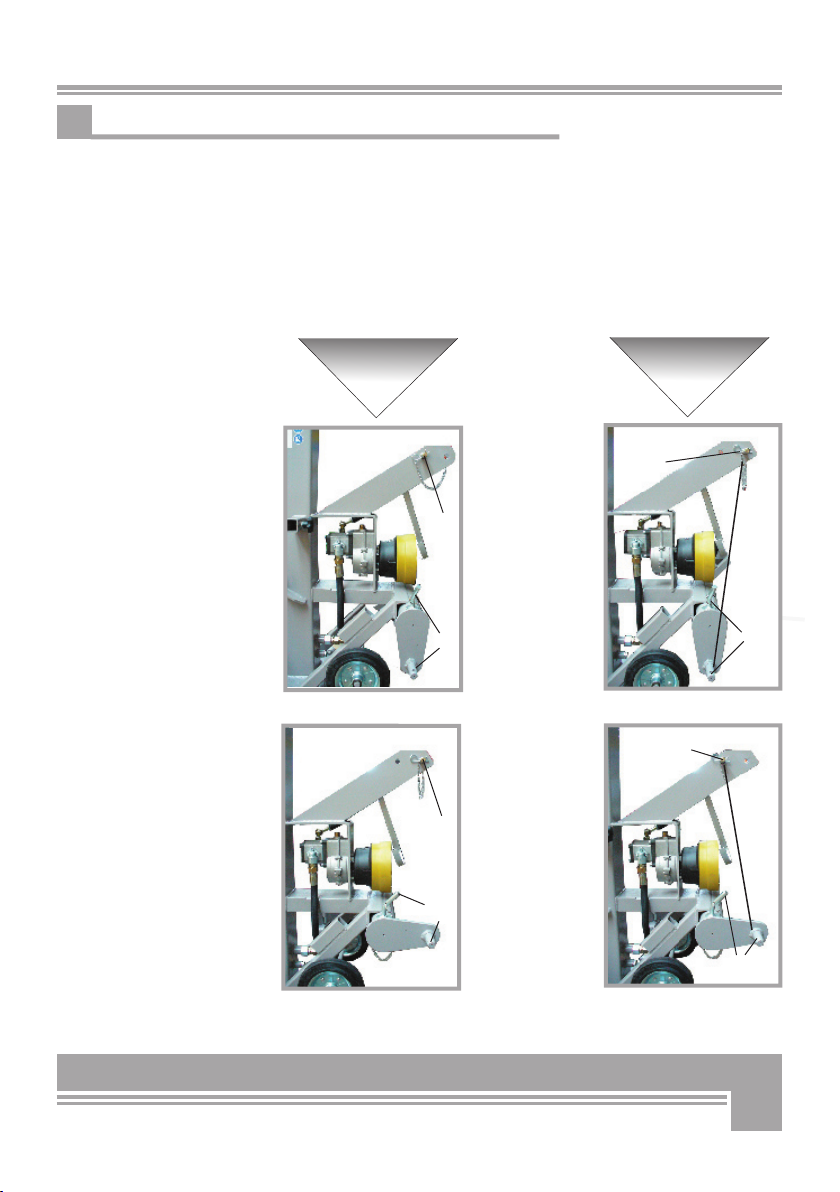

RIGHT PIN

POSITION WRONG PIN

POSITION

Fig. 12

Fig. 11

Fig. 14

Fig. 13

11

12

11

12

11

13

12

11

7.1 Attaching the splitter to the adjustable three-point linkage

Before transporting the splitter on the three-point hitch of your tractor,

check for the correct position of the upper (11) and lower hitch pin (12)

that must be lined up to each other. Accurate fitting of the pins in the

respective holes and precise line-up of their position (Figure 11 and 12)

is mandatory to assure trouble-free hitching. Wrong pins installation

and misalignement (see figure 13 and 14) may cause dangerous strain

of the machine which will void the warranty and release the manufac-

turer from any liability.

18

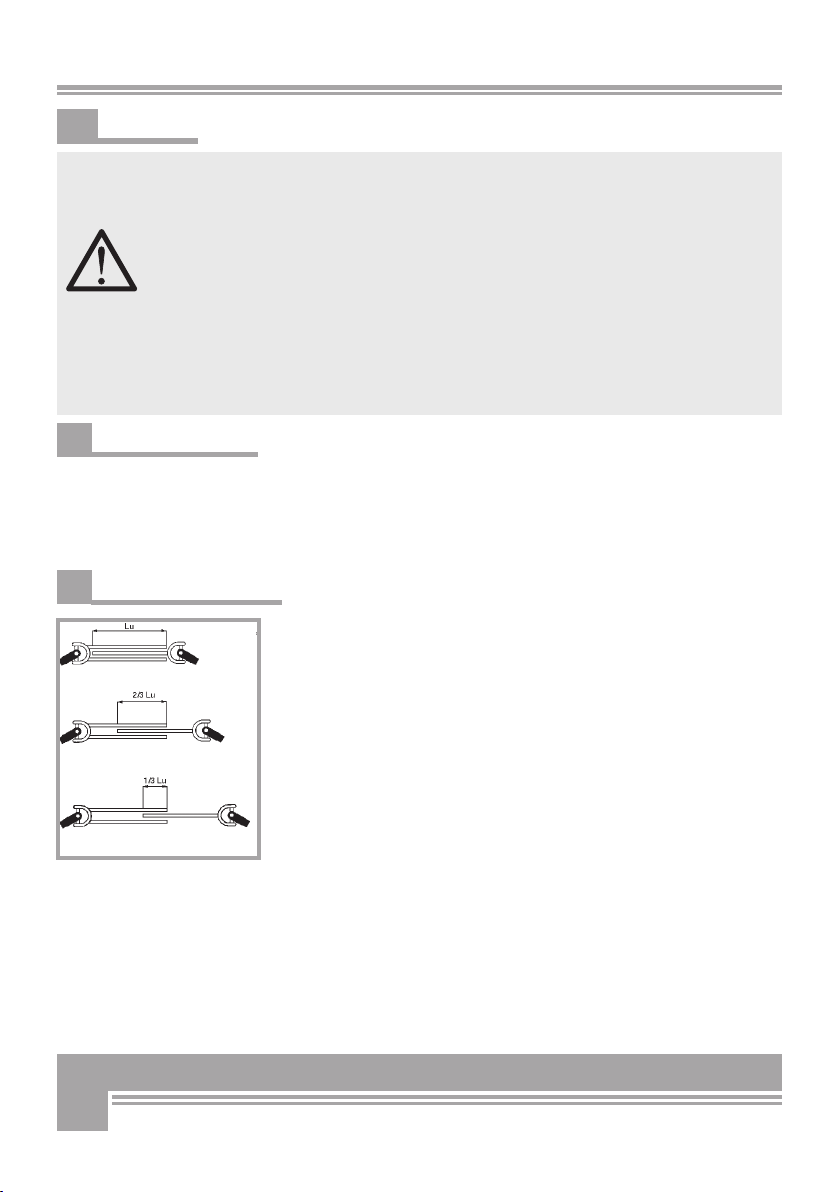

Fig. 15

Lu = pay length

closed length = longest telescopic half, fully

overlapping the shortest one

operating length = joint overlap by approx.

2/3 Lu

Longest (fully extended) length = joint overlap

by at least 1/3 Lu

8. START-UP

Before first use, make sure that the log splitter is in good conditions

and that there are no visual damages. Should any trouble or unusu-

al behaviour be detected, do not start splitting wood until these ha-

ve been fixed. First stop the machine, remove the cause of the trou-

ble and if required let skilled personnel perform a chekup before

you start working again.

For transportation purposes the ram is retracted within the splitter

profile alongside of the vertical beam. Before operating the splitter,

raise the ram up (Chapter 5 - About the splitter) in the initial opera-

ting position.

Periodically check the oil level inside the hydraulic oil tank and fill-

up if necessary. The splitter can be PTO powered by means of a dri-

veline or powered by tractor hydraulics by the hydraulic pump of

your tractor or by own electric motor depending on the version.

8.1 Electric power mode

Before attempting to operate the log splitter, make sure to duly con-

nect it to a power supply network of conformant safety specifications .

Do not switch the motor off till the splitting wedge reaches its upper

start-position.

8.2 Three-point hitch mode

PTO splitter versions must be connected by means of a driveshaft to

the power take off of your tractor. Connection of the driveshaft should

have no bigger play than 10 cm.

The PTO-driven version is equipped with a three-point linkage

to fit on the one available on your tractor. The drive shaft is going to

act as linkage and driving element between the tractor and the splitter

and should be therefore duly mounted and secured by the special pins

available on the machine.

For increased safety make sure that a minimum wrapping of 1/3 of the

total useful length is achieved (see figure 15 on the side).

Do not perform any repair, adjustment, cleaning or maintenance work

whatsoever while the machine is running (disconnect PTO-drive or switch the tractor off)!

Never use a PTO driveline without safety shield or with a damaged

guard and make sure that the shield is of the correct size and length for the drive

shaft. Driveshaft must be of an approved type and installed in compliance with

the instructions of the manufacturer.

PTO-versions are ground-driven, 3-point hitch implements. Lower the

machine to the “field” position when you are ready to use it.

During operation of a PTO powered splitter version, make sure that the splitter is

firmly secured to the three-point hitch of your tractor throughout the entire cycle!

19

8.3 Tractor drive (PTO)

Before uncoupling the processor, make sure to stop the tractor engine

in order to avoid damaging the tractor power drive.c

8.4 Direct connection to tractor hydraulics

Connect pressure to the coupling hose with a red mark and return

flow to the coupling hose with a green mark.

20

9. REPAIRS AND

MAINTENANCE

Make sure that the machine is fully disconnected and all

moving parts are secured before performing any main-

tenance/repair work on the machine. In the event of

any malfunctioning, switch the machine off before trou-

ble-shooting.

9.1 Ordinary maintenance

Make maintenance a regular part of daily operation. The daily mainte-

nance routine needs to include:

• Cleaning of the machine and clearing of all parts from residual wood

debris, chips, dust, bark pieces and eventual other waste.

• Greasing of the sliding pads inside the splitter stand.

• Hydraulic oil check and (in case of leakage) hydraulic hose and fit-

tings check-up to detect eventual oil leaks.

• Lubrication of all moving parts.

Oil or grease the wedge slinding pads after every 10 operation

hours.

9.2 Recommended oil types:

Periodically check the oil level inside the hydraulic oil tank. When doing

so, accurately avoid contaminating the tank with dirt, wood chips, sow

dust etc...Make sure that the splitter never runs without oil or with a low

oil level. When this happens, air is likely to reach inside the hydraulic

loop. Failure to maintain due oil level may cause poor running and irre-

gular splitter operation (very rough, back/forth or up/down motions) as

well as major pump damages. Please schedule your first oil change after

approximately 25-30 operation hours and later ones at least once a year.

Make sure to accurately clean the suction filter at each oil change.

Recommended oil types:

DEA HD B 46, Shell Tellus 10-46, Esso Nuto H 46.

After each new oil fill, operate the splitter and let it run for 2 or 3 complete

cycles before plugging the tank. This operation will help bleeding all residual

air out of the hysdraulic line. No parts or components of this rugged splitter

construction are likely to get damaged during compliant use and handling.

However always check all hydraulic hoses, fittings and couplings to detect

and repair eventual oil leaks. Do not check for leaks with your hand.

This manual suits for next models

2

Table of contents

Other BGU Log Splitter manuals