BGU FSW 3.5 M Product information sheet

ORIGINAL USER’S MANUAL

Carefully read these instructions before starting

to skid with your log winch!

Südharzer Maschinenbau GmbH

Helmestraße 94 ∙ 99734 Nordhausen/Harz

Zentrale: 03631/6297-0 ∙ 7-111

Internet: www.bgu-maschinen.de

e-mail: [email protected]

-Setup & instal -

lation

- Use

- Maintenance

- Accessories

Logging winch

FSW 3.5 M

Mechanical version

2

CONTENTS

1. General information 3

1.1 About the manual 3

1.2 Delivery and transport claims 3

2. Safety pictograms and warning signs 5

3. Safety 6

3.1 Mandatory application field 7

4. PTO-powered operation mode 9

5. Operation 9

5.1 Tractor requirements 9

5.2. Attaching the winch to your tractor 9

5.3 Positioning the drawbar to the PTO shaft 10

5.4 Wire rope installation 10

5.4.1 Unwinding the wire rope 11

5.4.2 Checking the wire rope quality 11

5.4.3 Winding up the wire rope 11

5.5 Skidding 12

5.6 Settings 12

5.6.1 Clutch 13

5.6.2 Prebrake regulation 13

5.6.3 Brake 13

5.6.4 Stretching the drive chain 14

5.7 Lubrication 15

5.8 Troubleshooting 16

6. Repairs and maintenance 17

Instandhaltungsarbeiten 17

6.1 Ordinary maintenance 17

6.2 Effects of overload and misuse 18

7. Dismounting and discarding an obsolete loader 19

8. Technical specifications 20

9. Other areas of possible hazard 21

9.1 Mechanical dangers 21

9.2 Ectrical dangers 21

10. Legal warranty 22

11. Extended warranty 22

11.1

Operation tips for new winches

23

12. Exploded drawing, FSW 3.5 M 24

13. FSW 3.5 M - Spare part list 26

13.1 Part 1 26

13.2 Part 2 27

14. EC Statement of complianc 28

3

1. GENERAL INFORMATION

Dear customer,

Thank you very much for your trust and preference in choosing our

equipment and joining the number of our best customers in the world.

We are confident that our equipment will be up to all your expectations

and assure you a long lasting quality and performance.

Our timber winches are available in different versions of different pull force.

FSW 3.5 M pull force 3.5 t, mechanical control system

All versions are designed and conceived for farming and logging applications.

Any other use shall be considered non-compliant application.The manufacturer

accepts no responsibility for damages caused by non-compliant application. In

this case the operation of the machine is completely at user’s risk.

1.1 About this manual

Please take time to read this manual and learn to how operate and

maintain the loader safely. For your easier reading this manual is laid

out in several sections. The sections are progressively numbered 1

through 14 and listed on the “content” page. The information, pic-

tures and technical data in this document reflect current or planned

product features, functions, and characteristics as of the publication

date. Because of on-going product improvements and feature additi-

ons, information in this document is subject to change without notice.

If you are experiencing a problem or functional trouble on your ma-

chine, please read the “trouble-shooting” section to identify possible

causes and remedies. When you have checked all the possible causes

listed and you are still experiencing the problem, ask your Authorized

Service Centre for help. When you order parts maintenance or repair

services, your Authorized Service Centre, your dealer or eventually

the manufacturer need your machine serial number and engine serial

number. These are the numbers that you have recorded on the pro-

duct identification label of the manufacturer on the machine.

1.2 Delivery and transport claims

Upon delivery of the machine please check for visual machine dama-

ges such as damaged packing or scratched buckled parts. If so, make

a remark on all copies of the delivery bill (including the one for your

own use) and have the driver sign for acceptance before unloading.

4

Have the truck driver accept your claim by hand signing it.

Should your shipper or the truck driver refuse to accept your claim

and countersign the delivery bill, fully reject delivery and make sure

to inform us (the manufacturer) immediately. No claims shall be taken

into account by the shipper or by the insurance company, if a reserva-

tion note is not made on the delivery bill.

All transport damages must be notified within latest 2 days from de-

livery. Therefore delivery must be collected and inspected within this

term. Later claims shall be disregarded. In case of assumed but not

visually clear transport damages make sure to mark the following sen-

tence on the delivery bill : „Reserved delivery due to assumed trans-

portation damages“.Insurance and shipping companies act with extre-

me caution in case of transport damages and sometimes refuse to ac-

cept responsibility. Ple-ase make sure to provide clear and exhaustive

evidence (photos) of the claimed damages.

Thank you in advance for your help and understanding in this matter.

5

2. SAFETY PICTOGRAMS AND WARNING LABELS

1 . Machine safety label

„Read, understand, and follow all instructions in this

manual and on the machine before starting!“

2. Safety pictogram

"Do not infringe the dangerous zone!"

Avoid standing in the dangerous zone between the

tractor and the log loader.

3. Machine safety label

" max 540 min"

This label shows the max admissible number of PTO

shaft revolutions the direction of rotation of the dri-

veline.

4.Danger sing

„No hoisting!“

5. Machine operation sign

"Disconnect the winch, read and comply with

manufacturer’s maintenance instructions.”

6. Identification label

„Product identification“

This label shows the company details of the manufac-

turer and the main machine technical data.

7. Identification label

„BGU-Maschinen” manufacturer’s logo"

8. Operator’s safety label

„Wear steel-toe safety shoes"

6

3. SAFETY

Strictly perform installation, set-up, maintenance, cleaning

and transportation of the winch with the power switched off

and all moving parts motionless against accidental operation.

The user shall strictly comply with these operation, set-up, mainte-

nance, repair and trouble-shooting instructions in order to assure safe

operation and no damages to the equipment. Moreover, we recom-

mend let the machine be run only and strictly by trained and skilled

staff who must be familiar with the applicable occupational safety and

health administration rules as well as applicable transportation rules.

Incorrect use of the winch can cause serious injury or death.

No person under school leaving age should operate a logging winch.

Those who have reached school leaving age but are below the age of

18 may operate a winch if supervised by a competent person of 18

years or over. The machine shall be installed and kept in a suitable lo-

cation selected by the customer for safest operation.

Make sure that the equipment stands on a safe stable foundation.

The working area around the machine must be kept as clear as pos-

sible from surrounding obstacles and slippery foundation floors should

be duly treated (do not use saw dust or wood ash for this purpose).

• Due and proper illumination of the working site must be provided at

all times.

• Set up the winch on a firm surface and ensure that a wide but

confined area is available around it assuring maximum working

freedom.

• Mind all operation sings and warning labels on the winch and comply

with the instruction given herein.

• Operators must wear steel toe safety shoes, working protective

gloves, protective helmet and snug-fitting, tear-resistant work cloths.

• It very dangerous and strictly prohibited to sit/stand on the winch

while transporting it.

• Never leave the winch unattended while at work.

• Before switching power on and putting the winch to work make sure

that there are no bystanders in the dangerous area and that you

have good and clear visibility on the work area.

• Provide due and correct mounting of the winch.

• Make sure to comply with driving speed requirements for the

specific road conditions. Use caution when changing direction or tur

ning while skidding uphill, downhill or across slopes.

7

• Do not stand in the dangerous area. Assure that nobody stands in

between winch and tractor, unless the tractor is safely braked and

blocks have been put underneath the wheels to avoid accidental

moving.

• Do not remove nor start handling timber before the winch has come

to a complete stop.

• Periodically check that all screws and fixations are tightly in place.

• Before putting the winch to work perform a visual checkup of the

overall conditions and let a skilled technicial overhaul and service

your winch at least once a year.

• It is strictly prohibited to use the winch for any other application

than mentioned in this manual. CAUTION: do not use the winch for

hoisting applications! (Figure 5)

• Make sure that power is fully disconnected from the winch and that

the tractor has been switched off before performing any repair or

work on the winch.

• Never operate the winch without its safeties and protections duly in place.

• Strictly use wire rope of adequate crush resistance, strength and

quality. Provide for immediate wore rope replacement, if any fault

or anomaly is detected.

• Be sure that your wire rope length provides for a free gap to the up

per drum profile of least 1.5 the rope diameter when fully spooled.

In other words, when the rope is fully spooled there should be

space left on the drum for at least two more coils.

• Make sure that your helpers do not put any extra load on the winch

without prior informing the tractor driver.

• Strictly operate the winch from a safe place, at safety distance from

the load, the rope and such other dangers as unfelled trees. The

driver seat accounts as a safe place only if a safety screen is provi

ded to separate the winch from the tractor in such a way that it may

not be removed or bypassed.

The work site and the area around the logging winch must be kept

free from hinders and obstacles. Make sure that all access ways are

properly maintained so that timber can be safely skid, loaded and

shipped.

3.1 Mandatory application field

Our logging winches are designed and conceived for farming and tim-

ber skidding applications. Any other use shall be considered non-com-

pliant application. The manufacturer accepts no responsibility for da-

mages caused by non-compliant application. In this case the operati-

on of the machine is completely at user’s risk.

The user shall strictly comply with these operation , set-up, mainte-

nance, repair and trouble-shooting instructions in order to assure safe

operation and no damages to the equipment.

8

M

M

a

a

M

a

M

x

x

3

3

0

0

°

M

M

M

M

a

a

x

x

3

3

0

0

°

• CAUTION: it is very dangerous to stand in front of a tree to be felled and winched away. (Figure 1)

Fig. 1 Fig. 2

• Winching with a pulley originates a three-sides dangerous area where none is allowed to stand

during winching operations. (Figure 2) .

• Never exceed the max admissible pull angle of 30° (Figure 3).

• CAUTION: tip-over risk (Figure 4) when winching on rough terrain or exceeding the maximum

admissible pull angle.

Fig. 3 Fig. 4 Fig. 5

Keep away from the dangerous area!

• You and your helper must establish clear and precise hand signals and review them so everyone

clearly understands.

Pull Stop Let the rope

loose

• If your winch is equipped with lower snatch block, use it also for pulling operations.

• The operator should monitor the load throughout the entire pulling operation. Although winches are

one-man equipment, you should never work alone and a second person should be ready to help in

the event of lack of full visibility.

• Attach your winch to any tractor equipped with road transport tires to avoid infringement of road

travel profi les. If this is not available, provide your towing vehicle with protection chains. Chains are

mandatory on all types of tire for travel on icy or snowy foundations.

• Before disconnecting the winch from the tractor, park on a safe and fl at surface. Drive the winch

down on the special stabiliser foot and hang the driveshaft on the special mount provided on board

of the winch.

• Pinched-hands and injuries danger in the three-point hitching area!

Read this basic guide carefully, familiarize yourself with the operation of your

winch before having to maintain it and be constantly safety oriented!

9

4. PTO-POWERED OPERATION

• Use only and strictly CE approved drivelines duly connected and secured in

compliance with the manufacturer’s instructions.

• Never use a PTO driveline without safety shield or with a damaged guard.

• Make sure that the shield is of the correct size and length for the drive

shaft and is duly mounted on it.

• Use safety chains to secure the shield agaist dangerous rotation and distortion

• Before operating the PTO driveshaft make sure the rpm-number and

direction comply with the one shown by the arrow-sign on the winch.

Take all due measures to avoid unauthorized thirds standing the the

dangerous area of the winch!

Never run the PTO shaft when the tractor motor is switched off! After dismouting

the PTO shaft use the special holder on the winch to safely store it away.

5. OPERATION

This logging winch is designed for skidding applications only. The winch

comprises a welded frame, a main shaft, a chain wheel clutch, a drum

with wire rope, a brake and a snatch-block.

The wire rope is slipped around the timber, the timber is pulled to the

skid and the rope is hung up to the special grooves in the skid by means

of fixation chains. Timber and long tree trunks are so winched to a parking

area for loading on trucks and further delivery.

5.1 Tractor requirements

Do not PTO operate winch at any faster speeds than max. 540 RPM.

To mount your winch to the tractor use three-point hitch CAT I and Cat II only.

5.2. Attaching the winch to your tractor

Make sure that nobody stands in the dangerous area while con-

necting the winch to your tractor

Logging winches can be mounted on any tractor equipped with 3-point hitch of category I or II.

With a special arrangement it is also possible to mount the winch to a tractor with automatic hitch

mechanism on the lower hitch points.

Make sure to strictly use approved IID types and that proper shielding with chain fixation is available.

Make sure to perform accurate connection of your PTO driveline both on winch and power input side.

10

In order to transfer torque from the tractor to the winch you must use a driveline with torque overload

clutch coupler. Mount the winch to the tractor and then secure the stabilisers underneath the lower

hitch points. Finally incline the winch by approximately 20° using the upper hitch bar.

b

a

5.3 Positioning the drawbar to the PTO shaft

The length and height of a tractor drawbar may need to be adjusted to match the implement to the

manufacturer’s specifi cations. It is important to make these adjustments to ensure that the PTO drive-

line does not compress or separate during operation.

To make this adjustment:

• Mount the winch to the tractor!

• Pull the two halves of your shaft apart and respectively mount them to the tractor and to the winch

and perform a crosscheck as shown below (Fig. 6)

• For increased safety make sure that a minimum wrapping of 200mm (b) occurs when pulling the

hitch bar all the way up and down. With the shaft parallel to the ground also make sure that the shaft

doesn’t hit the stand (wrapping (a) should be still at least 20mm).

• For shortening of the PTO shaft, fi rst cut the telescope off and then the external one by the same length.

• Grind both shaft ends, clear chips and dust away and oil all slinding contact areas before fi nal

assembly.

Fig .6

5.4 Wire rope installation

DO! DON‘T!

Remove the small protection grid and then take the cap off (Fig. 8 pos. 7). Now turn the drum to the

right position for releasing and removing the drum screw (Fig. 8). Before lossening of the drum screw,

make sure to engage the brake by shifting the Lever (1) in fi gure (7) to the (AUS) position.

Insert the wire rope through the inlet fairlead (on top) and feed it to the drum by means of the upper

block.

11

Fit the rope into the special groove and tighten the screw (Pos. 8). Now start spooling as described

under pulling procedures.

In order to avoid possible rope damages keep winding up for a while after complete spooling of the

entire rope length, as described under section “Spooling of the wire rope”.

5.4.1 Unwinding the wire rope

After you have correctly installed the winch, you can start spooling the rope off. To accomplish suc-

cessful unwinding:

• Pull the red line (Pos. 2) till the Lever 1 snaps into the AUS position (Fig. 7).

• Release the brake and start spooling the wire rope off.

• If the wire rope is tangled or badly wounded on the drum, first unwind the entire rope length.

Keep running the tractor idle while loading the winch and completely rewinding the rope onto the

drum. Stop pulling as soon as the tractor reaches close to the anchor-point where the rope end was

attached.

• Now disengage the clutch lever.

Make sure that pulling is performed smoothly and without rush movements that could re-

sult into tangling, twirling or kinkling of the rope.

5.4.2 Checking the wire rope quality

• Stricly use brand new ropes.

• Make sure to use ropes of approved quality, suitable strength and compliant to the specifications

identification label.

• Do not use longer ropes than instructed in the technical specifications of this manual.

5.4.3 Winding up the wire rope

Completely spool the rope making sure to wind it tightly and evenly onto the drum and avoiding both

overwinding and underwinding.

Correct winding is accomplished by:

• Simply pulling of a load

• Firmly attaching one end of the cable to a stable anchor-point suitable to withstand the pull force

while the rope starts spooling onto the drum pulling tractor and winch towards the anchored rope end.

It may be convenient to carry out this operation either on a slight gradient with the idled tractor facing

uphill or alternatively with braked tractor.

Wind the rope tightly and evenly onto the drum. Before putting your winch to

work spool the rope off leaving only 3-4 winds on the drum and then rewind

it again! Check the rope over for any signs of damage, flattening, broken

wires, wear and corrosion.

12

5.5 Skidding

Set the hydraulic cylinder of the tractor three-point hitch in its lo-

west position. Firmly settle the winch down on the skid and engage

the tractor manual brake. NEVER start pulling operations before ha-

ving securely and firmly settled the winch in a stable position. Pull the

green line (Pos. 5) to shift the Lever 12 in its EIN position (Fig. 8).

The wire rope will now start to wind up onto the drum. To stop win-

ding simply release and set the green line loose. When doing so, the

brake immediately stops the drum and keeps the load away.

Changes and self-modifications to the mechanism controlling

the brake engagement system (Pos. 1, Fig. 7) are STRICTLY

PROHIBITED, as this may prevent concurrent operation of the

brake and the clutch. NEVER operate (pull) the brake lever

(Pos. 1 in Figure 7) during skidding!

Do not raise the hydraulic cylinder of the tractor three-point

hitch during skidding! (DANGER: you may damage your drive-

line).

Notwithstanding the consistent PTO power speed, the pull force is

subject to variations.

Even at consistent power ratings, the pull force of the winch still de-

pends on the length of the remaining rope spooled onto the drum.

The maximum pull force is obtained with the first rope coils on the

drum. The pull force decreases as the rope winds up on the drum. The

skidding speed is inversely proprotional to the pull force and reaches

the peak speed as the rope is fully spooled onto the drum.

The rated pull force is the largest force produced as the rope starts

winding up onto the drum.

This is also the figure that is shown in the technical data re-

ported on the product identification label on the winch. The

pull force of the winch decreases as the rope keeps winding

further more onto the drum. At fully wounded rope the pull

force of the winch amounts 50-60% of the rated force.

5.6 Settings

1 EIN/ENGAGED

0 AUS/DISENGAGED

1 0

13

5.6.1 Clutch

Before attempting any intervention, make sure to first switch the tractor engine off and

remove the ignition key! Proper clutch settings will ensure optimum pull force. The clutch is set

by the manufacturer during final testing of the product before ship-

ment. However, possible wear of the lining may require some extent of

adjustment as the time passes. Clutch adjustment should be performed

every time when your winch no longer reaches the required pull force.

For clutch adjustment attach a torque wrench to the green line. If you

don’t have any torque wrench available you can also use a spring ba-

lance of sufficient measuring scale. Attach the torque wrench (or sca-

le), apply a 350 N (35 kg) force to the line (Pos. 5, Fig. 8) and make

sure that the clutch slowly shifts towards the winch frame as you ap-

ply the force and stops moving when hitting against the winch. If the

force applied is too small, tighten the nut (Pos. 9, Fig. 8) by turning it

clockwise and making sure that as you do this the clutch lever gradu-

ally shifts towards the winch frame and stops there. Keep tightening

untill the required force is reached that is till the lever 6 backs aways

from the winch. Finally slightly turn the nut anti-clockwise to release it

a litlle bit. Now the clutch is set and ready to work.

Each winch is factory set at the maximum pull force shown on the

product identification label. It is strictly forbidden and very dangerous

to achieve higher settings and run the winch at higher force ratings!

5.6.2 Prebrake regulation

To facilitate winding of the wire rope, perform prebrake regulation

with the screw (10) and respective wingnut (11) (Fig. 8). Exact preb-

rake regulation will also prevent the rope from unwinding excessively

fast or accidentally slipping off the drum. Extreme fast unwinding and

abrupt brake disengagement may cause severe damages to the wire

rope. Exact prebrake regulation occurs when the rope can be effort-

less spooled off the drum. The prebrake arrangement must be disen-

gaged for uphill skidding operations in order to ensure easier

pulling of the rope.

5.6.3 Brake

1 engaged

0 disengaged

CAUTION: tripping of the brake lever occurs when the clutch le-

ver is engaged with the brake lever still in its left-hand position.

01

14

Fig. 7 Fig. 8

5.6.4 Stretching of the drive chains

After the first operation hours you possibly experience some extent of

release of the drive chain that will then need to be restretched.

Stretching is accomplished by first removing the safety guard on it

(Pos.1 - Fig. 9). Then slightly realease the fixation screws on the

mount (Pos. 2 - Fig. 9) and finally access the chain and start stret-

ching it by means of the

special adjustment screw (Pos. 4).

Adjust the chain so that you can still provoke some extent of deflec-

tion by applying one finger tip pressure in the middle. Then make the

PTO shaft turn and check for troublefree and effortless turning.

Properly stretched chains can still be deflected by 1-3 mm by app-

lying your maximum hand force in the middle of the distance between

sheaves.

1

The brake is engaged by means of a nut (3) and a nut (4). When the brake is engaged the lever (1)

shifts into its position EIN (Fig. 7).

First adjust the nut (3) using an open-end spanner until the nut stands approx 5 mm away from the

lever. Then adjust nut (4) till the sliding plate underneath the nut projects 3-4 mm out out of the

winch frame. If you cannot reach the required brake force, repeat the same steps tightening the nut

by further turning it to the right side.

Excessive brake force will cause troublesome unwinding procedures. In this case release the nut by

slightly turning it to the left.

4

1

3

2

Fig. 9

3

3

15

40 h 8 h 40 h 16 h 40 h 8 h 40 h

Fig. 10

5.7 Lubrication

Make sure that the motor is switched off and all moving parts are secured before

peforming any maintenance/repair work on the machine. Improper lubrication

may cause dangerous contamination of the sliding parts and consequent dama-

ges for which the manufacturer holds no responsibility!

The winch is equipped with self-lubricating bearings that require no

further lubrication or maintenance.

Maintenance is mainly required on the engagement/locking mecha-

nism (Pos. 13 - Fig. 7) that needs periodical

checkup. Clean all metal surfaces preferably with WD-Spray like

agents in order to:

• increase lubricant efficacy and

• inhibit formation of humidity, condense water and ice on the leve-

rage and the control rods and therefore prevent consequent functional

troubles.

Lubricate the housing of the upper block every 40 hours.

Provide regular maintenance of the drive chain removing any eventual

residual dirt and slightly greasing it. Use grease suitable for high tem-

perature (it should not melt as common low-price grease) in order to

prevent grease contamination of the sliding clutch surfaces.

Strictly use special spray lubricant for link chains.

Provide PTO shaft lubrication in accordance with the instructions of

the manufacturer (Fig. 10).

Make sure to avoid contamination of the clutch lining with gre-

ase as this may lead to a significat loss of the pull force and

to early wear of the clutch plates that will then need to be re-

placed!

16

5.8 Troubleshooting

Type of malfunction Possible origins Remedies

Winch is not skidding

enough

• Rope is too short

• Wrong clutch setting

• Oil on clutch discs

• Worn-out clutch lining

• Damaged winch drives

• See technical specification

• Reset the clutch

• Clean the clutch lining or

replace clutch

• Replace damaged parts

Brake is not holding • Wrong brake setting

• Oily brake lining

• Braking mechanism is damaged

• Brake collar is worn out

• Adjust the brake force

• Clean both brake collar and contact surface

• Replace eventual damaged parts

• Replace brake collar

Rope is hardly

spooling off

• Wrong setting of the pull force

• The rope is damaged

• The brake collar is damaged

• Adjust rope pull force

• Change the rope

• Replace the brake collar

Winch skids even if the

clutch is released

• Wrong clutch setting

• Damaged drum

• Damaged clutch discs

• Check pull force

• Replace the drum

• Replace the clutch

Repair works require help of a skilled technician or technical service.

All log winches are function and safety tested by the manufacturer

before shipment. Please strictly use original spare parts for replace-

ments. Use of non-original spare parts may lead to functional troubles

or damages that will void the manufacturer’s warranty and liability.

Modification, alteration or deviation to the winch should only be made

by the original manufacturer.

17

6. REPAIRS AND MAINTENANCE

Make sure that the machine is fully disconnected and all mo-

ving parts are secured before performing any maintenance/re-

pair work on the machine.

6.1 Periodic maintenance

Before starting to work with your winch, make sure to perform the fol-

lowing visual inspections:

• Make sure that all screws and nut are tight

• Check for mechanical damages to the winch chassis

• Make sure that all locking pins and rings are in place

• Check for PTO shaft correct installation and connection and make

sure that safety shield and chains are duly in place.

• Check the lower hitch points of the tractor and make sure they are

firmly secured (no cross, horizontal movement).

• Check for clutch proper setting, check the brake and the rope pull

out force

• Make sure to fix any anomaly or problem before starting to work.

Perform the following maintenance works when needed and carry out

periodic checkup:

• Lubricate all moving parts as needed

18

What to do? When to do? How to do?

• Spool the rope out until 3-4 winds

are left on the drum and strongly

pull with load on

• Check the rope fixation

• Only for new winches

• Always when the rope is loose

visually

• Check the chain tension

• Replace the clutch discs

every 48 operation hours if required

or after 3000 operation hours

by customer service

• Replace the brake collar Every time when adjsting the brake

force is no longer possible and

latest after 3000 operation hours

by customer service

• Lubricate the drive chain all 48 operation hours Lithium grease

• Change the oil Every 48 operation hours and then

once a year

• Lubricate the bearings of the up-

per and lower snatchblocks as well

as all other sliding parts

at lease once a month Lithium grease

• Clean casings inside every 100 operation hours or more

frequently in case of hard working

conditions

Loosen all screws and

remove cover making

sure to avoide remo-

ving of the nuts

The winch functionality and safety are tested by the manufacturer. For any re-

pair or intervention on the winch make sure to strictly use original spares on-

ly. Use of non-original parts and spares will void your warranty just as well as

wrong repairs or changes.

6.2 Effects of overload and misuse

• burning of the clutch or brake collar lining

• damaged brake mechanism

• tearing of the chain

• broken rope reel or damaged reel bearing

• damaged power drive/PTO shaft housing

• damaged power drive, PTO shaft or chain wheels

• strain of winch frame parts

• overstrained, cracked, broken lines, rope or Choker-chain

• deformed drum axle.

19

7. DISPOSING OF AN OBSOLETE WINCH

When the winch is fully obsolete and cannot be of any longer use, it

should be duly dismounted ahead of discarding. Certain components

need deactivation and dismantling in order to assure that no further

use is made by other parties and that no worn out parts are recycled

for other applications.

During dismantle be alert for possible recyclable materials and com-

ponents that belong to differentiated waste collection procedures ap-

plicable in your country.

The manufacturer is not liable and undertakes no responsibility for

personal injuries or damages that may result from the recycling of

worn outmachine parts and eventual re-use in other applications diffe-

rent than originally stated in this manual.

Dismantling procedure:

Take good note please: each and every dismantling task must be per-

formed by authorized service centres or trained skilled staff only!

● Pull the machine down into single components

● Lock and clamp all moving machine parts

● Deliver each single component only to authorized waste manage

ment facilities

● Drain oil and fuel out of respective tanks and lines before disposal

of the machine

● Remove rubber and plastic parts from the machine that must be se-

parately disposed of.

Deactivated, clamped moving/driving parts and components are of no

further risk and danger.

Electric components must be separately disposed to avoid substantial

environmental threat. In the event of fire on the electric deployment

system of the machine, use of an explosion-proof extinguish system is

required (for example powder fire extinguishers).

20

Technical data Unit of mea-

surement

FSW 3,5 M

Max skidding capacity t 3,5

Cable winch speed at 300 RPM of the PTO shaft m/s 0,90

Rope length m 70

Compacted steel rope Ø mm 8

Rope tensile strength kN 70

Max cable rewind length with compacted steel rope m/mm 75 / 8

Tractor power requirements kW/PS 12/15

Braking force t 4,40

Width /heigth /depth mm 1020/1150/450

Overall height including safety shield mm 2100

Weight (without rope) kg 252 (226)

Chainsaw holder, peaveys

jacks or axes mount

standard

8. TECHNICAL SPECIFICATIONS

The manufacturer reserves itself the right of product modifications without further notice as a

result of product implementation and quality upgrade.

Table of contents

Other BGU Winch manuals

Popular Winch manuals by other brands

Andersen

Andersen 52ST manual

Champion Power Equipment

Champion Power Equipment SUP2500 Assembly & operating instructions

Deger

Deger MultiWinch KL300 manual

Ramsey Winch

Ramsey Winch DC 34,9 Maintenance manual

Runpotec

Runpotec CW 800 E instruction manual

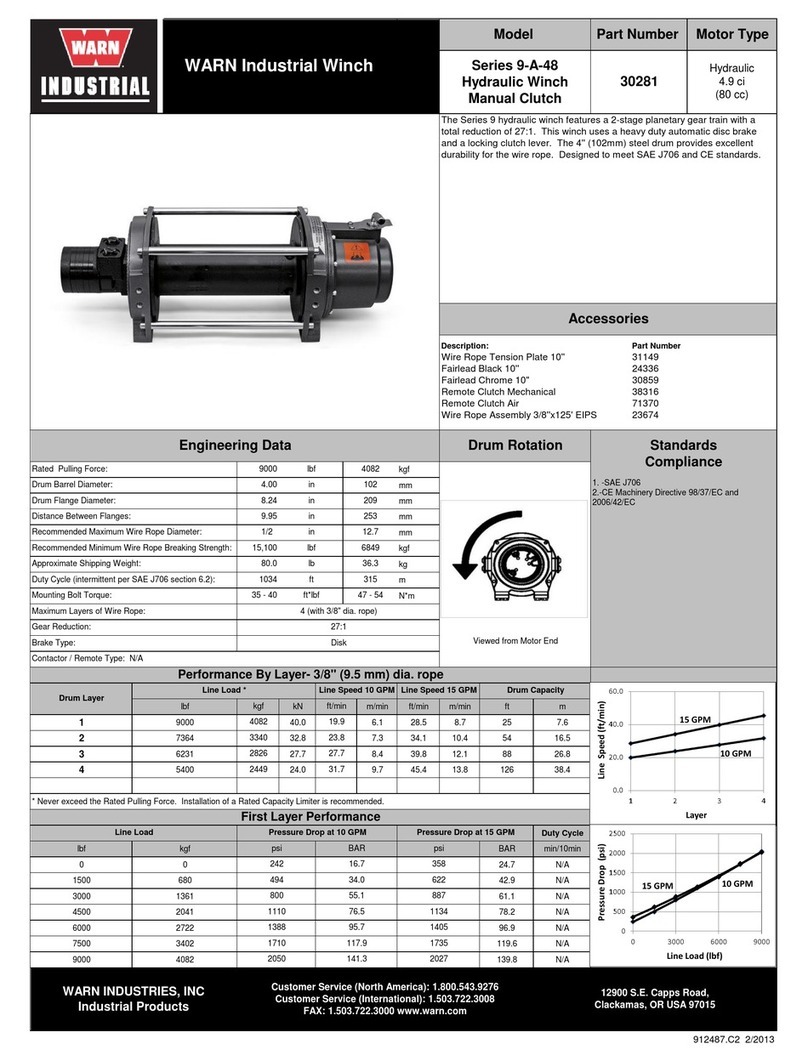

Warn Industries

Warn Industries 30281 quick start guide

Champion Power Equipment

Champion Power Equipment 100776 Operator's manual

haacon

haacon ESF Series operating manual

GEBUWIN

GEBUWIN WW2000 /2D Series operating instructions

haacon

haacon 4202.0,5 operating instructions

Ingersoll-Rand

Ingersoll-Rand Force 5i Series Product information

Paccar

Paccar BRADEN HP125B Installation maintenance and service manual