Deger MultiWinch KL300 User manual

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS,

KL300 MultiWinch

manual

– Let’s Gear Up!

2

Declaration of incorporation

Declaration of incorporation in accordance with the European Machinery Directive 2006/42/EC, Annex II, No. 1B

DE GIER B.V.

WESTLANDSEWEG 9

NL-2291 PG WATERINGEN

THE NETHERLANDS

We hereby declare that pursuant to article 2G the following partly completed machines are exclusively intended to be

integrated into or mounted in another machine or piece of equipment:

national authorities.

This partly completed machine is compliant with the provisions of the following European directives:

The following harmonised standards (or parts of these standards) have been applied:

Safety of machinery: Basic terms, general design principles

EN 60204-1:2018

Safety of machinery: Machinery electrical equipment

Rotating electrical machines

This partly completed machine may only be commissioned if it has been established that the machine into which this

Authorised compiler of the technical documents:

Rob Sandberg

Managing Director De Gier B.V.

Wateringen, 14-02-2023

Index

Declaration of incorporation..............................................................................................................................................2

Index............................................................................................................................................................................................3

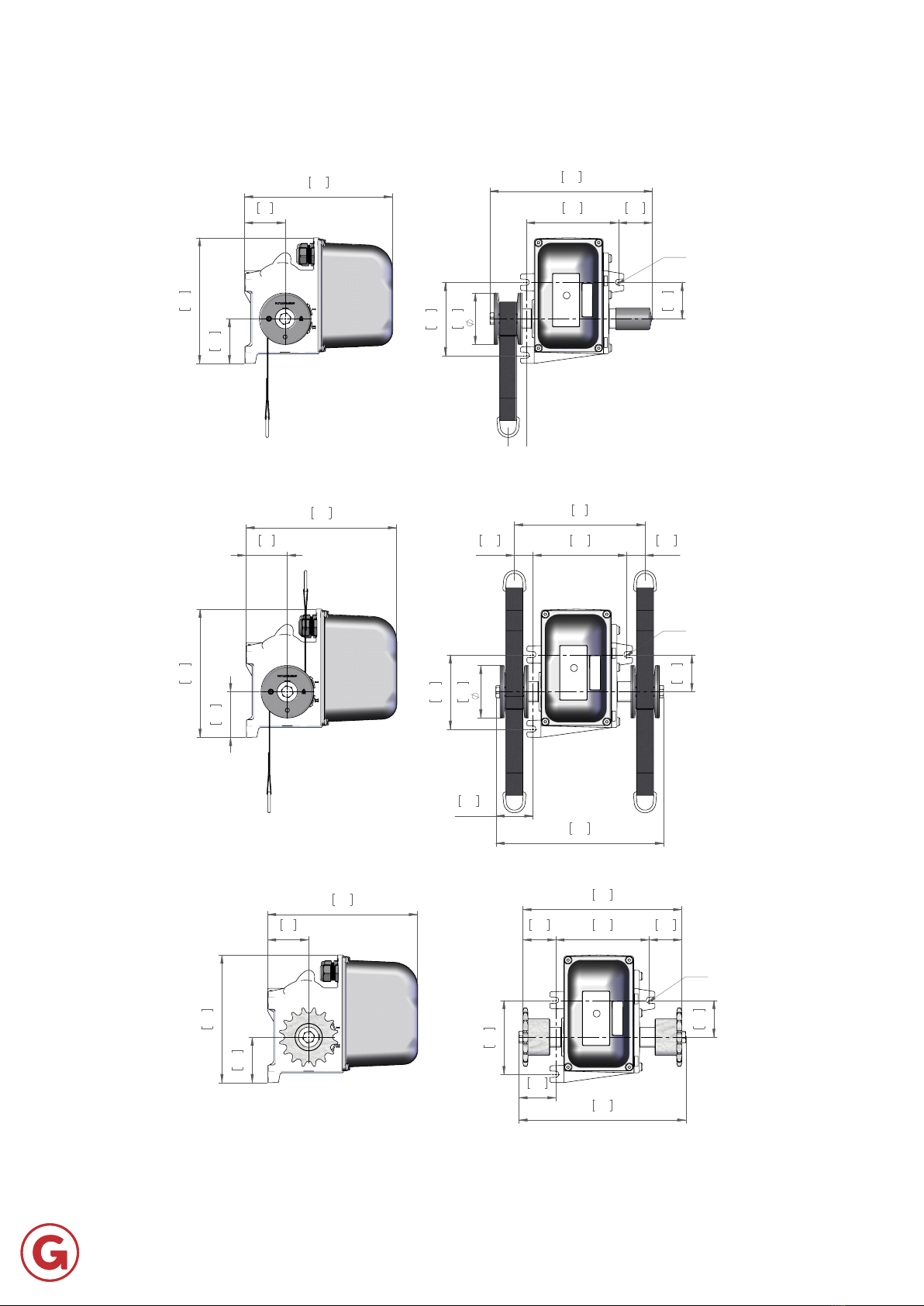

Dimensions................................................................................................................................................................................4

1 Explanation of symbols and safety instructions.......................................................................................................8

2 Product.................................................................................................................................................................................10

3 Instructions for use..........................................................................................................................................................11

4 Installation and mounting instructions....................................................................................................................13

6 Settings................................................................................................................................................................................20

7 Modbus RTU protocol - Register Implementation..............................................................................................26

8 Troubleshooting................................................................................................................................................................29

9 Position of the buttons, LED's and dipswitches....................................................................................................30

10 Wiring diagram...............................................................................................................................................................31

11 Inspection and maintenance.....................................................................................................................................32

12 Warranty............................................................................................................................................................................33

13 LED explanation..............................................................................................................................................................33

14 Glossary.............................................................................................................................................................................34

Thank you

Please pay careful attention to the information in the installation manual during installation and set-up. If you have any

questions or come across problems, please do not hesitate to contact us.

De Gier Drive Systems

4

2.66

68

2.4

61

8.76

222

7.46

190

3.05

78

2.15

55

4.33

110

5.45

139

9.76

248

1.08

28

1.06

27

7.6

193

2.16

55

3x M8

2.66

68

2.4

61

8.76

222

7.46

190

2.15

55

4.33

110

5.45

139

9.76

248

2.16

55

1.93

49

1.91

49

9.29

236

3x M8

2.66

68

2.4

61

8.76

222

7.46

190

3.05

78

2.15

55

4.33

110

2.02

51

5.45

139

9.63

245

1.08

28

3x M8

Dimensions

5

Technical specications

Metric. | Imperial

Maximum output torque Nm | lbf-ft 90 | 66.38

Single winch drum maximum pulling force in reduced power kg | lbs

Double winch drum maximum pulling force in reduced

power (per belt)

kg | lbs

Winch drum diameter

Roll-up speed

Standard speed (½ speed setting via DIP switch) rpm 0,8 (0,4)

revs.

Supply voltage 24 (± 10%)

Power consumption VA 72

Power consumption in reduced power-mode (limited output

torque)

VA 48

Maximum current A 3

Maximum current in reduced power-mode (limited output

torque)

A 2

Protection - Thermal overload 3A

Digital control: bus type -

Analog control: signal (galvanically isolated)

> 2

Action of operating @ signal failure - To pre-set opening position

Weight kg | lbs

-

Housing material -

Ambient temperature

IP rating protection class -

6

Technical specications

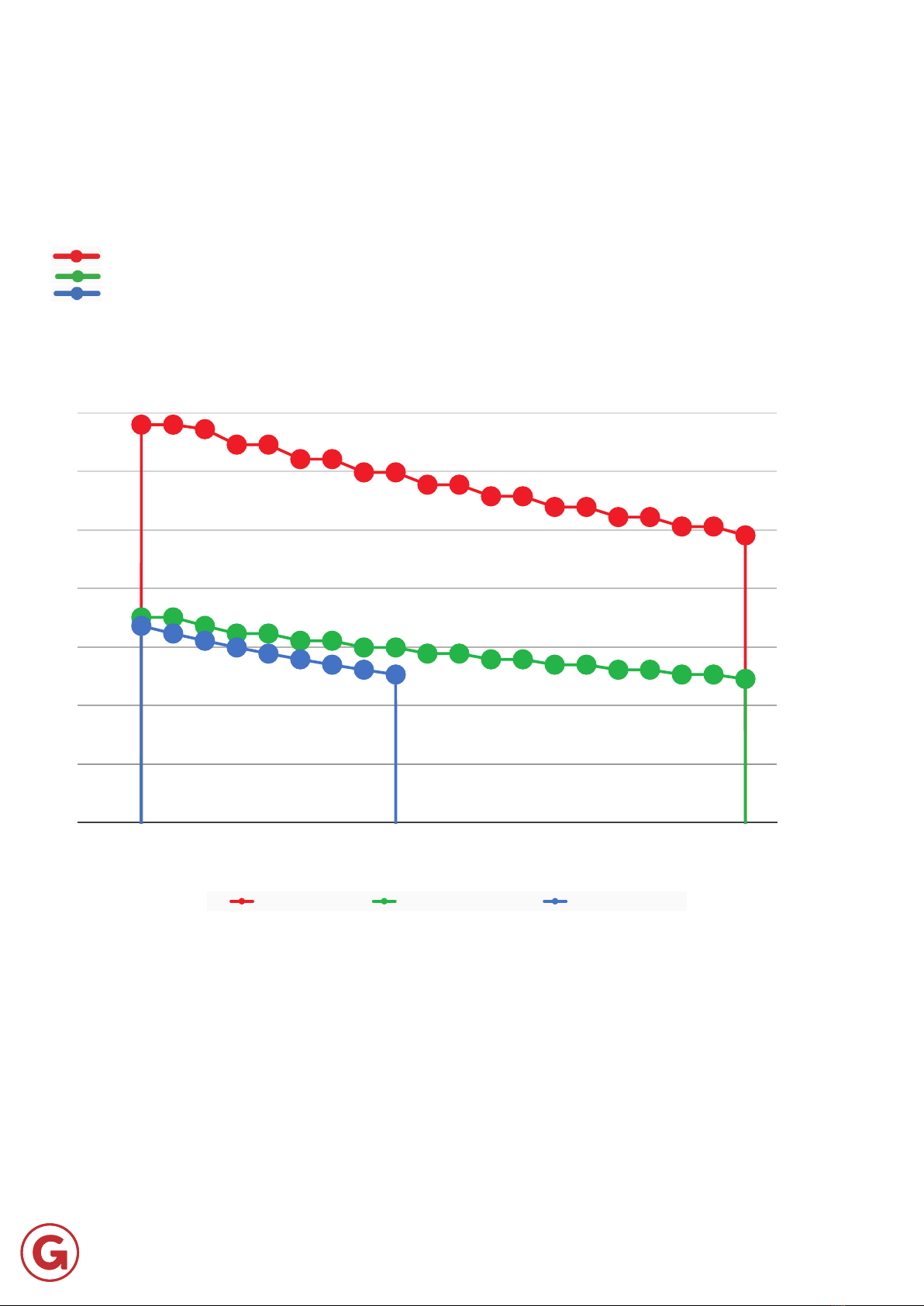

The graphs below shows you the pulling force in relation to the length of the winch belt.

The graph lines show the following:

Displays the graph line of the drum with 1 winch belt [kg]

Displays the graph line of 2 drums with 1 winch belt each [kg]

Displays the graph line of 1 drum with 2 winch belts [kg]

340 340 336

323 323

311 311

299 299

289 289

279 279

270 270

261 261

253 253 245

175 175 168 161 161 155 155 150 150 144 144 139 139 135 135 130 130 126 126 123

168 161 155 150 144 139 135 130 126

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200

Pull force per winch belt

[kg]

Winding length winch belt

[mm]

Pulling force vs Winch belt lenght

[metric]

1 drum with 1 belt [kg] 2 drums, both with 1 belt [kg] 1 drum with 2 belts [kg]

7

Technical specications

The graphs below shows you the pulling force in relation to the length of the winch belt.

The graph lines show the following:

Displays the graph line of the drum with 1 winch belt [lbs]

Displays the graph line of 2 drums with 1 winch belt each [lbs]

Displays the graph line of 1 drum with 2 winch belts [lbs]

750 750 741

712 712

685 685

660 660

636 636

615 615

594 594

575 575 558 558 541

386 386 370 356 356 342 342 330 330 318 318 307 307 297 297 288 288 279 279 270

370 356 342 330 318 307 297 288 279

0 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64 68 72 76 80 84

88

Pull force per winch belt

[lbs]

Winding length winch belt

[inch]

Pulling force vs Winch belt lenght

[imperial]

1 drum with 1 belt [lbs] 2 drums, both with 1 belt [lbs] 1 drum with 2 belts [lbs]

8

Important procedures are emphasised in this user manual in a separate box with the initial lines printed in bold. See

below for an explanation of the various instructions you will encounter in this manual.

Symbol Meaning Unit Metric | Imperial Symbol Meaning Unit Metric | Imperial

T Torque Nm | lbf-ft n Rotational speed rpm

P Power kW | hp L Length mm | inch

U Voltage m Mass kg | lbs

I A v Roll-up speed i

Tip - -

Note - Electrical -

Instruction Explanation

Tip

more practically.

Attention! Remarks with supplementary information for the user. These remarks draw the user’s

attention to potential problems.

Material damage can occur when the procedures are not followed carefully.

Warning!

procedures are not followed carefully.

Risk of injury or death! The user’s life is directly endangered.

Explanation of symbols on the motor gearbox

The following symbols are shown on the motor gearbox

Symbol Meaning Symbol Meaning

No pressure cleaning Read the documentation

Electrically live parts PE connection (earth)

1 Explanation of symbols and safety instructions

9

1 Explanation of symbols and safety instructions

Installation

• Read this installation manual carefully and in full.

•

• Strictly observe the step-by-step procedures set out in the installation manual.

•

maintenance and servicing.

•

material damage due to the high torque of the motor gearbox.

General safety instructions

• With attached or driven components there is a risk of becoming trapped or injured. Amongst other things, the safety

devices or a dead-man vigilance system.

• Do not allow people to stand under or close to suspended loads.

• Attached or driven parts may have a shorter service life than the motor gearbox itself.

•

conditions. We strongly recommend that for hoisting applications you use a motor gearbox equipped with a

mechanical brake and mount a fall-arrest brake on the drive shaft.

• Never loosen screws, couplings or other parts while the drive train is loaded externally.

• Also observe national legislation and guidelines regarding working conditions and safety.

• .

• Despite careful planning and compliance with all regulations, some risks cannot be prevented.

Qualied sta

-

plant or system is always required before work may be carried out.

10

determine all necessary positions. A brushless motor operates according to the step motor principle: if the next position

is not reached, an alarm relay will be activated.

Manufacturer

The address details of De Gier are set out below:

De Gier B.V.

Westlandseweg 9

NL-2291 PG Wateringen

The Netherlands

I : www.degierdrivesystems.com

T : +31 174 – 292 089

Identication plate

Article number

The structure of the article number on the above rating plate is set out below with an explanation of the possible

versions.

CODE SERIES Force

[kg]

Force

[lbs]

Version Voltage

[VDC]

Speed @ 50Hz

[ x 0,1 rpm]

Accessories

P 300 661 1 24 8 L

Possible series

Materials and parts of the gearbox

Gearbox part Materials

Gear wheels, shafts, bearings, retaining rings, … Steel

Gear unit housing, housing parts Aluminium

Worm gears

Shaft seals, sealing caps Elastomer (with steel)

Gaskets Paper based and plastic elastomer

Limit switch and protective cover Plastic

Gear oil Enriched mineral oil

Electronics Various

2 Product

1

2

3

4

6

7

Article number

Production date

Serial number

De Gier barcode

11

3 Instructions for use

Intended use

incoming signal.

Conditions of use

The following conditions of use are applicable when using the motor gearbox.

•

• Max. force on output shaft radial 4000 N | 900 lbf, axial 400 N | 90 lbf.

•

Control and maintenance

• Steel cable and steel cable attachment; these must not show any mechanical damage.

•

• End positions: check whether the end positions are still correct.

• Emergency power supply: check, if present, whether the emergency power supply is still working correctly.

•

Restrictions on use

warranty null and void and relieve the manufacturer of liability for any consequences. In addition, the following

restrictions are applicable with regard to the use of the motor gearbox:

•

• Do not use the motor gearbox to operate parts located in the immediate vicinity (within easy reach) of

•

• Do not use the motor gearbox to operate smoke and heat exhaust ventilation systems compliant with

NEN 6093 or DIN 18232.

• Do not use the motor gearbox to operate automatic doors or gates used by people.

•

do so.

Unintended Use

We expressly warn against the following types of unintended use:

• Do not use the motor gearbox for lifting suspended loads especially in areas in which people are present.

• Do not use the motor gearbox for transporting people (for example, for passenger lifts, etc.).

Transport

To safeguard the service life and correct functionality of our products, the following rules must be followed:

• Transport the gearbox carefully and avoid shocks.

•

12

3 Instructions for use

Storage

To safeguard the service life and correct functionality of our products, the following rules must be followed:

• Ensure that the motor gearboxes are stored in a dust-free and moisture-free environment.

• The relative air humidity of the storage location must be less than 60%.

•

• Avoid sudden changes in temperature to prevent the formation of condensation.

If you wish to store the motor gearboxes for a lengthy period of time, you can use preservatives to protect the

unpainted surfaces, such as threaded holes and mounting surfaces for chain couplings, against corrosion.

Disposal

Drain used oil from the motor gearbox. Used oil must be collected, temporarily stored, transported and replaced

Caution!

to a collection point for waste oil. Avoid prolonged skin contact.

Dispose of housing parts, gear wheels, shafts and roller bearings of the transmission as scrap metal. The worm gears

may contain black non-ferrous metal alloys and must be disposed of accordingly. Dispose of the packaging materials in

accordance with regulations or bring them to a recycling station.

13

Installation positions

Mounting the motor gearbox

If wood screws or wall anchors are used for mounting, the right screws and tightening torques must be determined by

the installer. These mounting materials must provide the same clamping force as the M8 bolts with a strength class of 8.8

4 Installation and mounting instructions

Warning

14

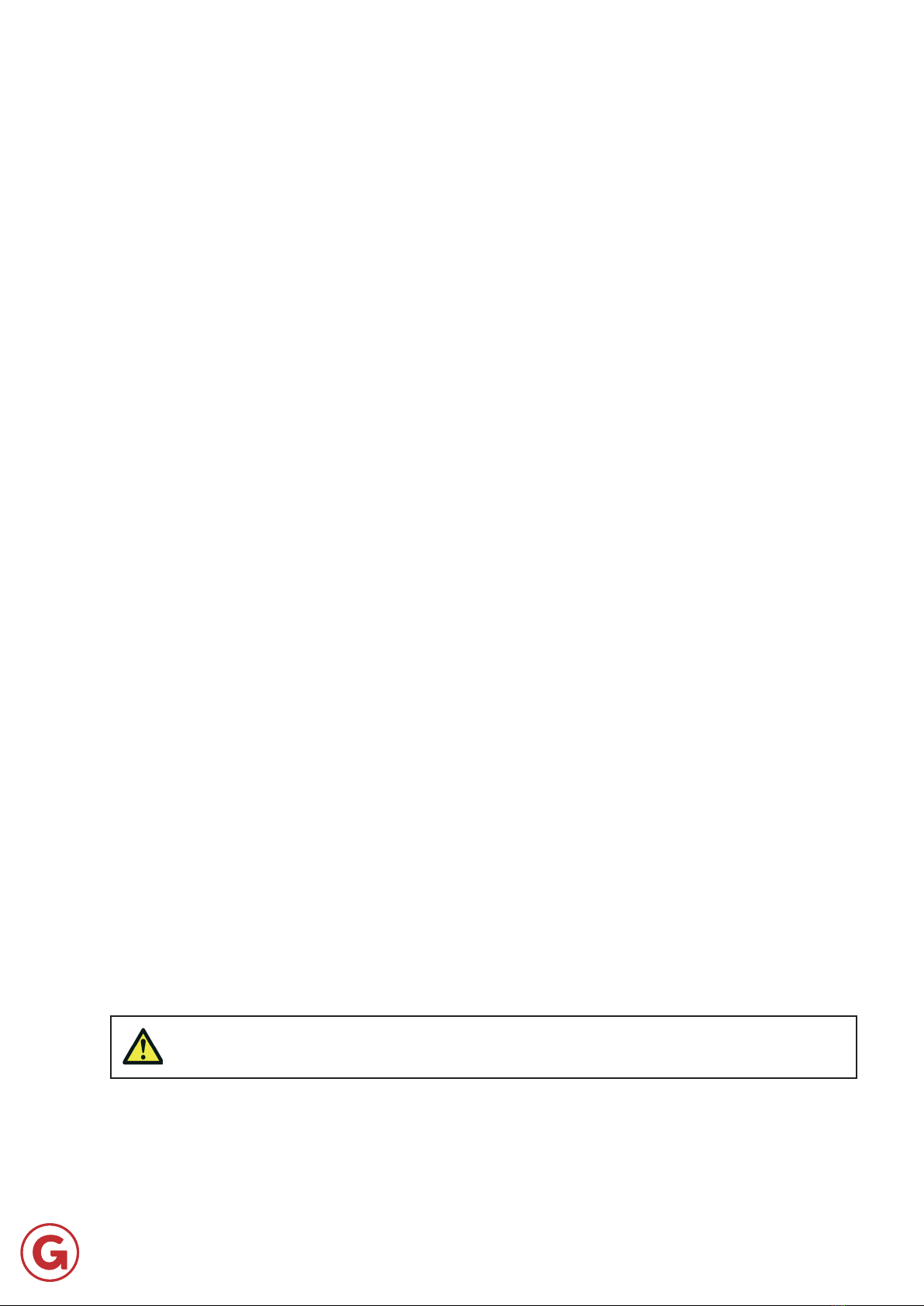

Mounting the belt/cable drum

the key, M10 bolt and ring (included in delivery) and

the M10 bolt.

-

bolts. Apply a torque of approximately 6 Nm | 4 lbf to

Also a cable (max. 3mm | 0,11 inch) can be mounted

on the drum. The cable must be passed through the

clamp to secure the end of the cable.

Pre-winding the drum

Before the drum can be used, it is necessary to pre-wind the belt or cable on the drum.

Drum with a cable: At least 3 revolutions.

Drum with a single belt: At least one revolution.

4 Installation and mounting instructions

15

-90° -90°

+90° +90°

Drum with two belts: At least half a revolution.

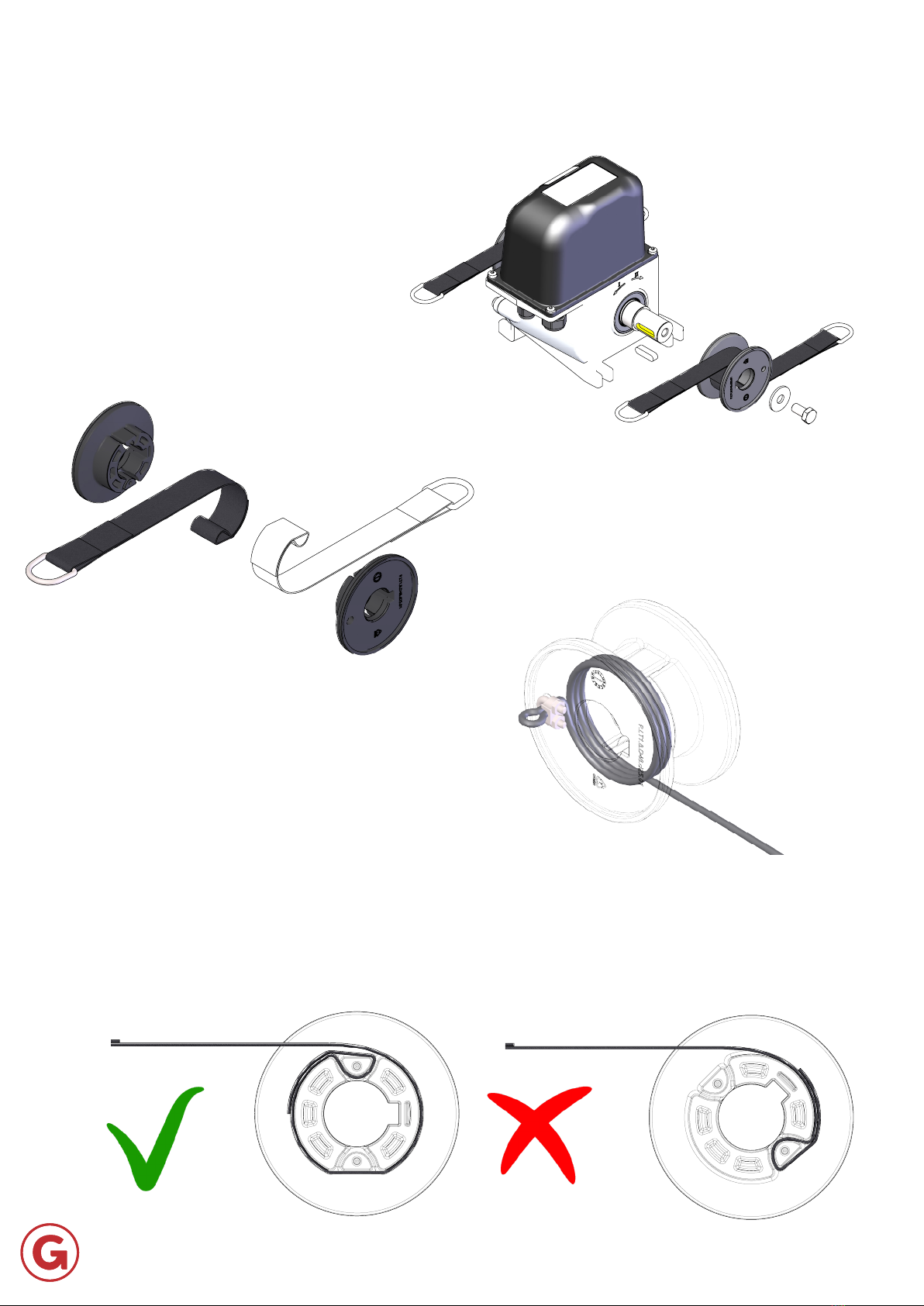

Caution!

Not pre-winding the belt or cable may result in failure and possible injury at high loads.

Allowed angles belt & wire

When two belts are mounted opposite each other on 1 drum, there is no restriction in applied direction of the belts. If

only one wire or belt is mounted on a drum, the allowed directions are limited, as stated below. All other angles are not

allowed.

4 Installation and mounting instructions

Drum on this side

(2 mounting feet)

1.

mounting points on the housing). In this situation it is possible to pull 340 kg | 749 lbs in every direction, as shown in

the picture above.

2.

MultiWinch (the side with two mounting points on the housing as shown in the picture above), but it is not required.

In this situation it is possible to pull 170 kg | 374 lbs with each belt (340 kg | 749 lbs) in total because of the available

3.

mounting point on the housing). This situation it is possible to pull 340 kg | 749 lbs in parallel direction to the

4.

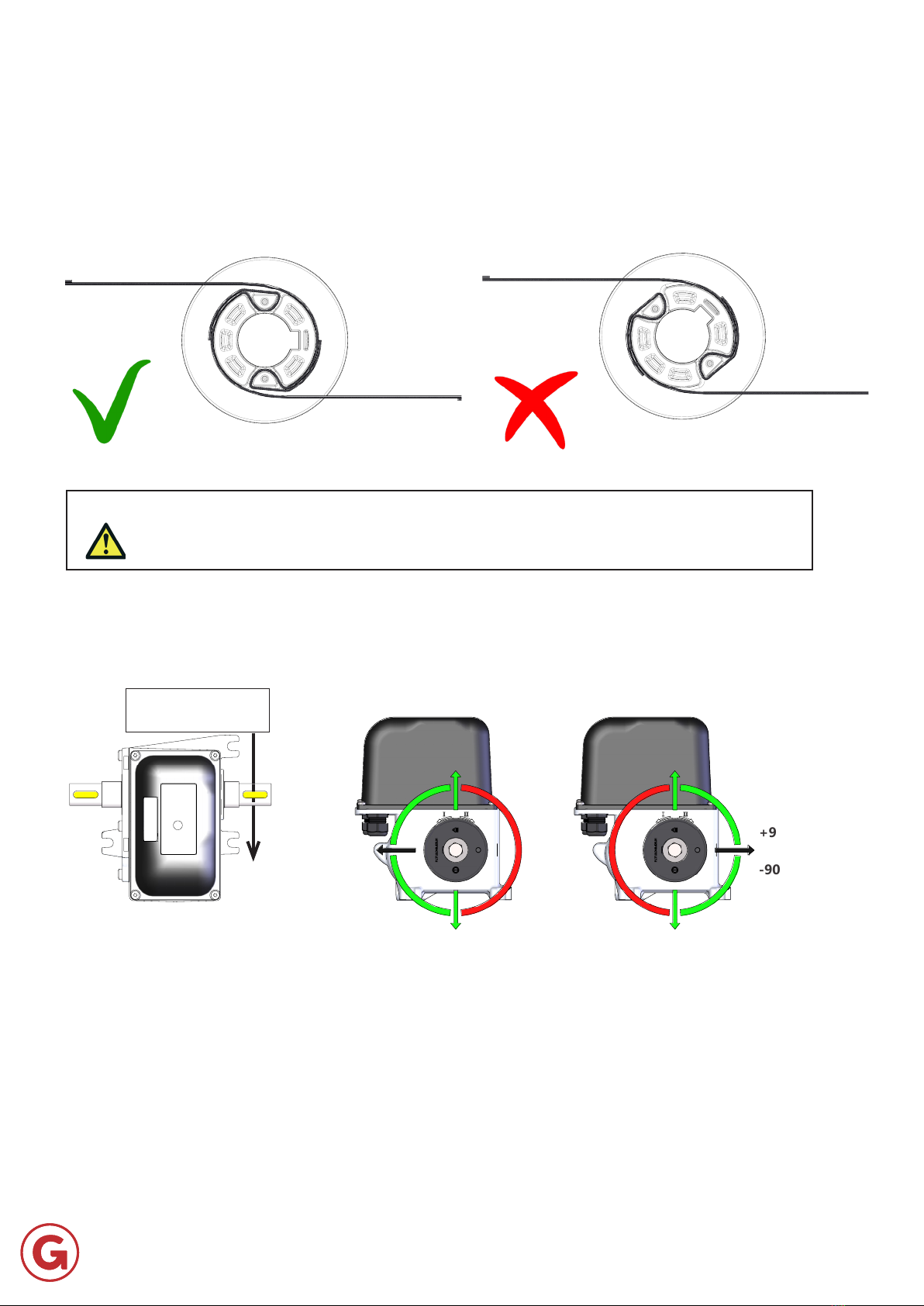

16

+10°

- 10°

+10°

- 10°

4 Installation and mounting instructions

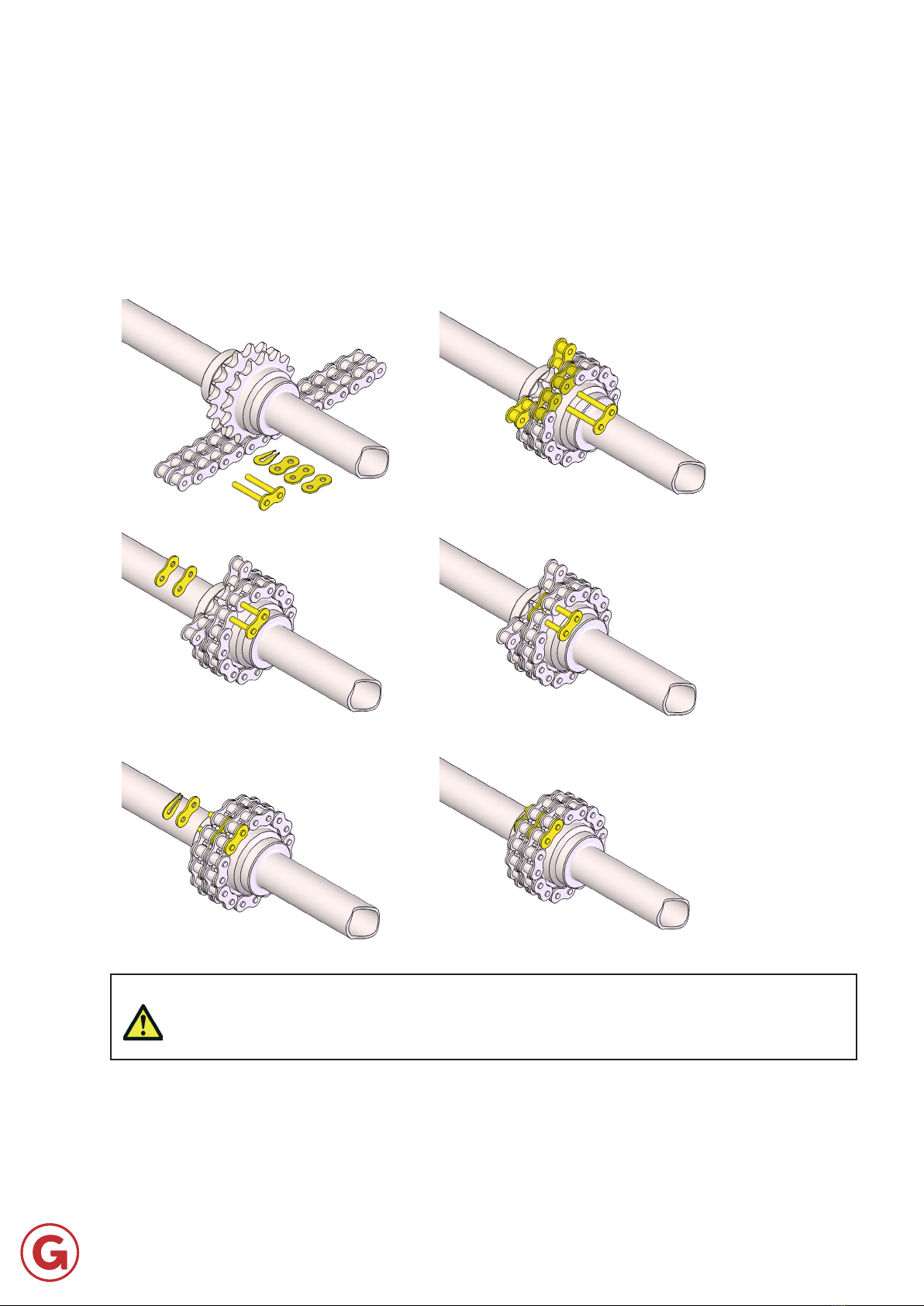

Mounting the chain coupling

The chain coupling can be mounted on both ends of

Use the key, M10 bolt and ring (included in delivery)

to tighten the M10 bolt.

Attention! The drive-shaft and the driven system must be aligned.

Not pre-winding the belt or cable may result in failure and possible injury at high loads.

details below for maximum torque and maximum alignment error.

Type of chain coupling Max. angle Max. torque

420 Nm | 310 lbf

Drum on this side

(1 mounting feet)

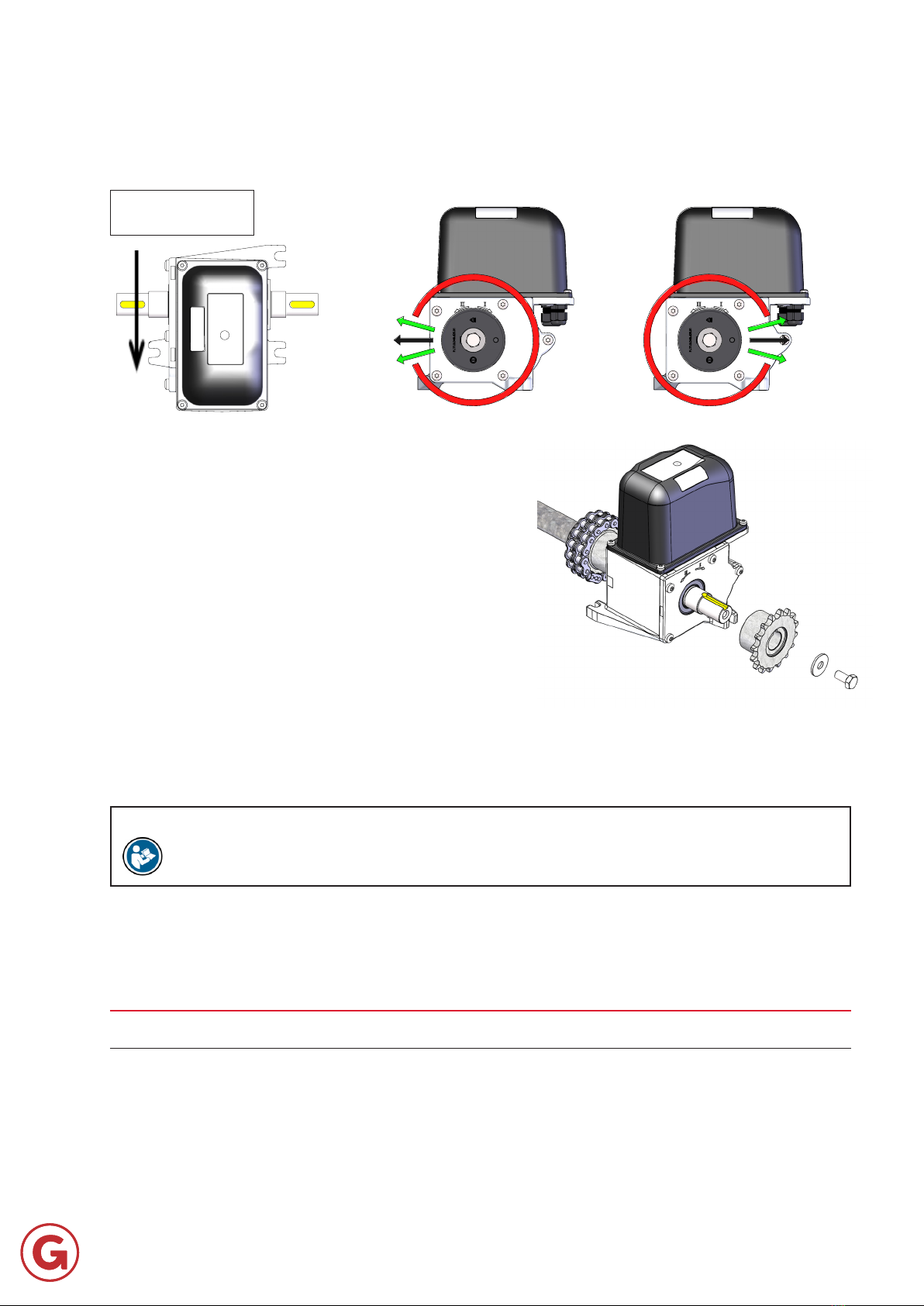

17

1.

2. Turn the chain sprockets of the coupling until the teeth are aligned.

3. Wrap the duplex chain around the teeth of the sprockets, the ends of the chain should be on top of the coupling.

4. Mount the connecting link as shown in the diagram below.

Warning

4 Installation and mounting instructions

18

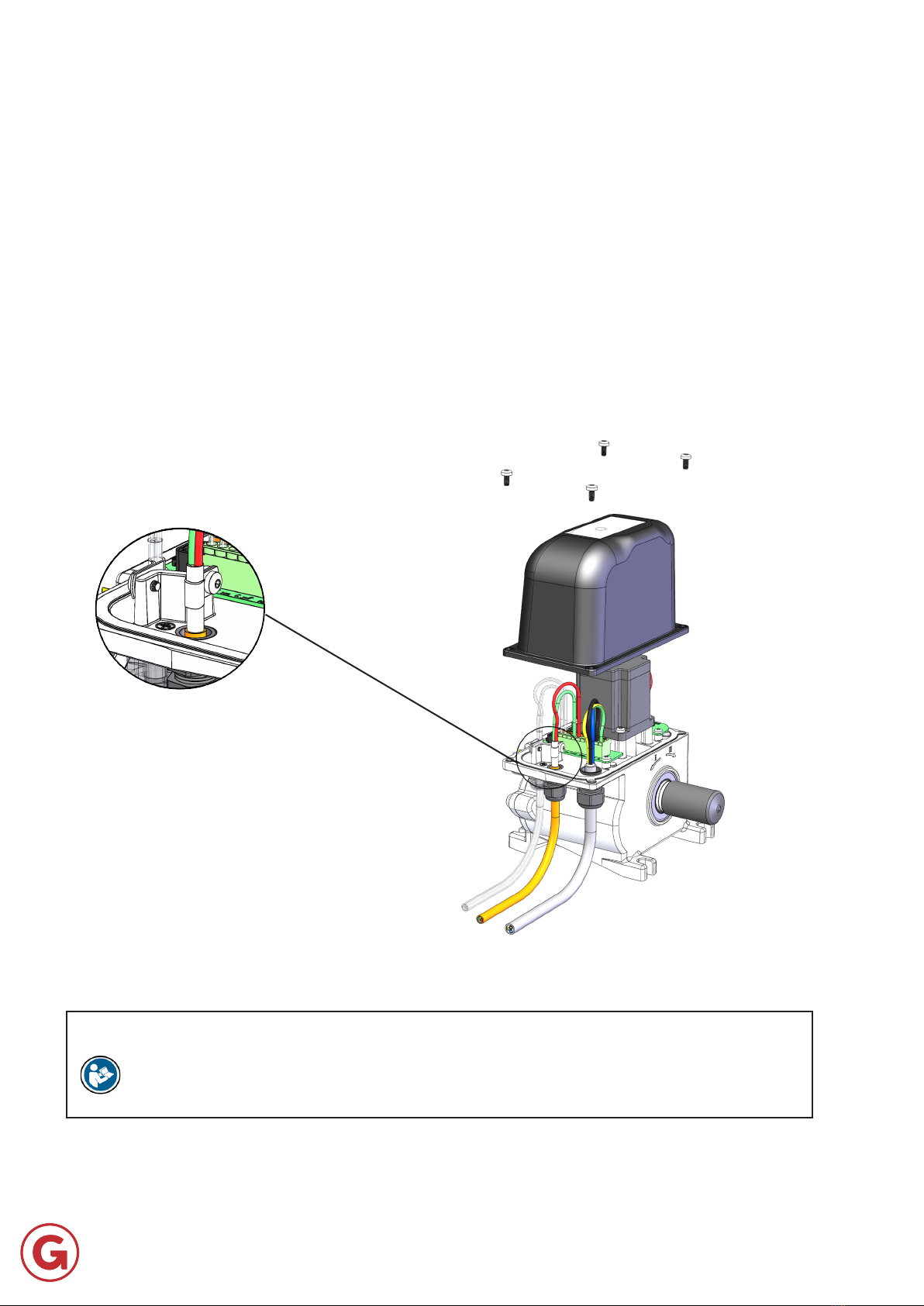

Connecting the cables

1. Remove the plastic protective cover from the gearbox.

2. Insert the cable through the cable glands.

3. Make sure that the cables are free before tightening the cable gland.

4.

cable clamps and M4 screws.

6. It is advisable to seal the cable glands with acid-free kit after cable installation.

7.

Attention!

5 Electrical connection

19

5 Electrical connection

Max cable length

Conductor diameter 24 VDC

(dipswitch 5 = OFF)

24 VDC reduced power mode

(dipswitch 5 = ON)

232 mm | 1,26 inch

2

4,0 mm2 120 m | 394 ft

-

Note: If longer cable lengths are required, compensating for the voltage loss by increasing the supply voltage must be

table).

Attention!

Cable Voltage Min. conductor diameter

see other table

2

Modbus RTU (<1000 m @ max. 9600 baud n.a. 1 x 2 x 0,64 mm2

n.a. 1 x 2 x 0,64 mm2

20

6 Settings

plastic protective cover from the gearbox. The control buttons are placed directly on the control board.

LED’s on the control board

OK I II Description

“I”

“II”

“I”

“II”

Endpositions have not been set

Programming mode: setting 1st endposition (100%)

Programming mode: waiting for correct control signal. Not applicable

for endposition settings for bus

Programming mode: setting 2nd endposition (0%)

Programming mode: setting emergency position

To endposition “I”

To endposition “II”

Table of contents

Popular Winch manuals by other brands

Globestock

Globestock G.Winch Service manual

Harken

Harken Radial Winch 40.2 PT BBB Installation and maintenance manual

Uniforest

Uniforest 45H Instructions for use

Huchez

Huchez MANIBOX VS Series instruction manual

Champion Power Equipment

Champion Power Equipment 13050 Owner's manual & operating instructions

Portable Winch

Portable Winch Greenworks Commercial 82W1 PCW3000-Li user guide

haacon

haacon TANGO WV 300/500 operating instructions

Einhell Global

Einhell Global SHZ 300-2 operating instructions

Champion Power Equipment

Champion Power Equipment C20049F Owner's Manual and Operating Instructions

MW TOOLS

MW TOOLS EBL900 manual

Antal

Antal W 6 Instructions For Fitting

Warn

Warn VRX Operator's manual