Seite 6

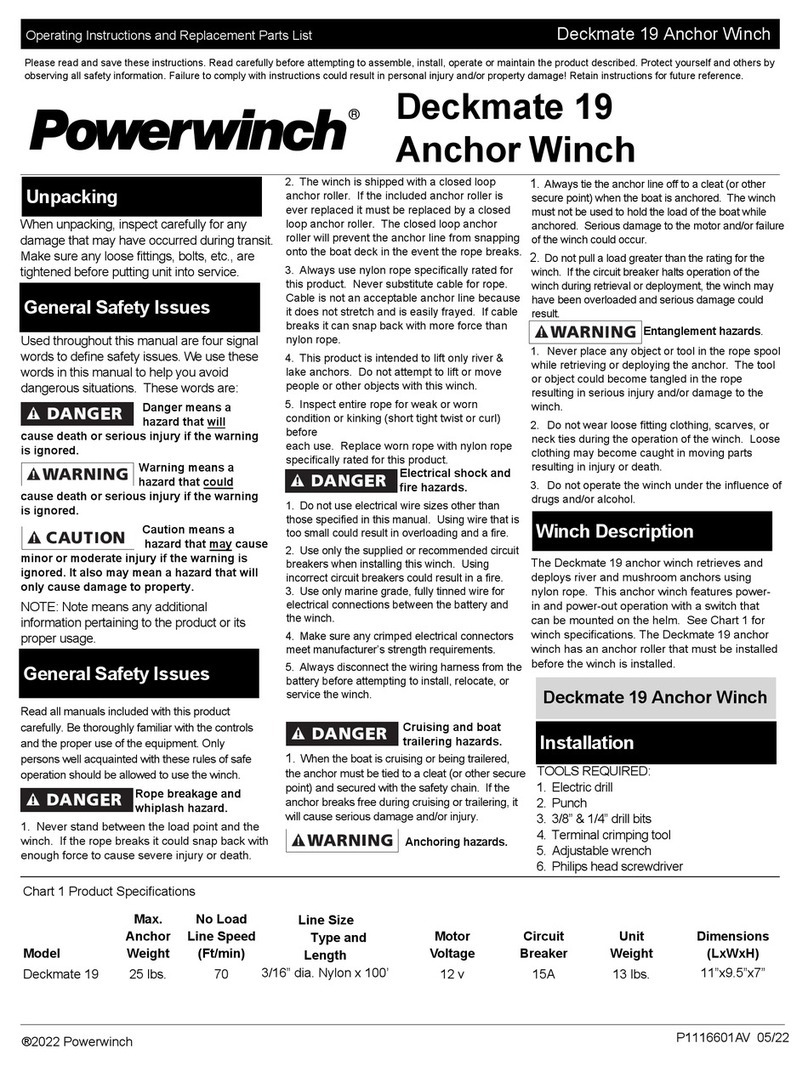

3. Safety rules

Strictly perform installation, set-up, maintenance, cleaning and transportation of the winch with the

power switched off and all moving parts motionless and secured against accidental operation.

The user shall strictly comply with these operation , set-up, maintenance, repair and trouble-shooting

instructions in order to assure safe operation and no damages to the equipment. Moreover, we recommend

to let the machine be run only and strictly by trained and skilled staff who must be familiar with the applicable

occupational safety and health administration rules as well as applicable transportation rules.

No person under school leaving age should operate a forestry winch. Those who have reached school

leaving age but are below the age of 18 may operate a forestry winch if supervised by a competent person

of 18 years or over.

The machine shall be installed and kept in a suitable location selected by the customer for safest operation.

The working area around the machine must be kept as clear as possible from surrounding obstacles and

slippery foundation floors should be duly treated (do not use saw dust or wood ash for this purpose).

Make sure that the equipment stands on a safe stable foundation.

- Due and proper illumination of the working site must be provided at all times.

- Set up the machine on a firm surface and ensure that a wide but confined area is available around the

machine assuring maximum working freedom.

- Mind all operation sings and warning labels on the winch and comply with the instruction given herein.

- Operators must wear steel toe safety shoes, working protective gloves, protective helmet and snug-fitting,

tear-resistant work cloths.

- Never leave the forestry winch unattended

- Before switching power on and putting the winch to work make sure that there are no bystanders in the

dangerous area and that you have good and clear visibility on the work area.

- It very dangerous and strictly prohibited to sit/stand on the winch while transporting it.

- Provide due and correct mounting of the winch.

- Make sure to comply with driving speed requirements for the specific road conditions. Use caution when

changing direction or turning while winching uphill, downhill or across slopes.

- Do not stand in the dangerous area. Assure that nobody stands inbetween winch and tractor, unless the

tractor is safely braked and blocks have been put underneath the wheels to avoid accidental moving.

- Do not remove nor start handling timber before the winch has come to a complete stop.

- Periodically check that all screws and fixations are tightly in place.

- Before putting the winch to work perform a visual checkup of the overall conditions and let a skilled technicial

overhaul and service your winch at least once a year.

- It is strictly prohibited to use the winch for any other application than mentioned in this manual.

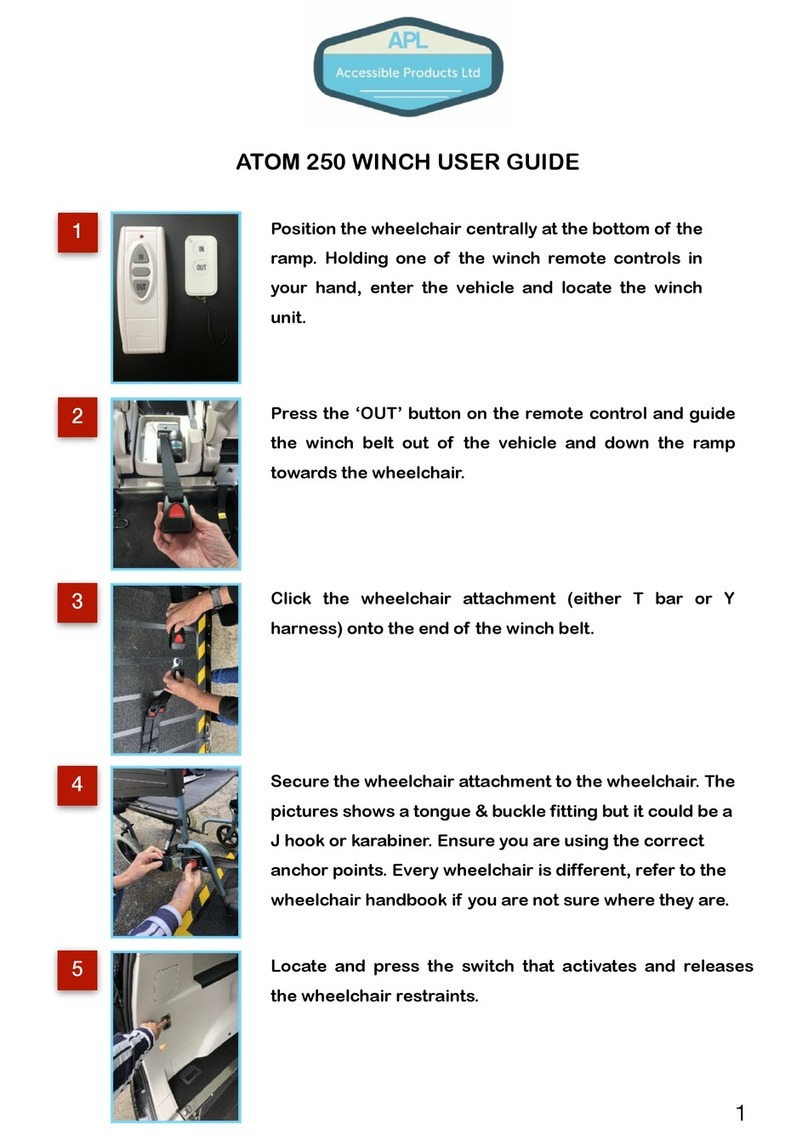

CAUTION: do not use the winch for hoisting applications! (Figure 5)

- Make sure that power is fully disconnected from the winch and that the tractor has been switched off before

performing any repair or work on the winch.

- Never operate the winch without its safeties and protections duly in place.

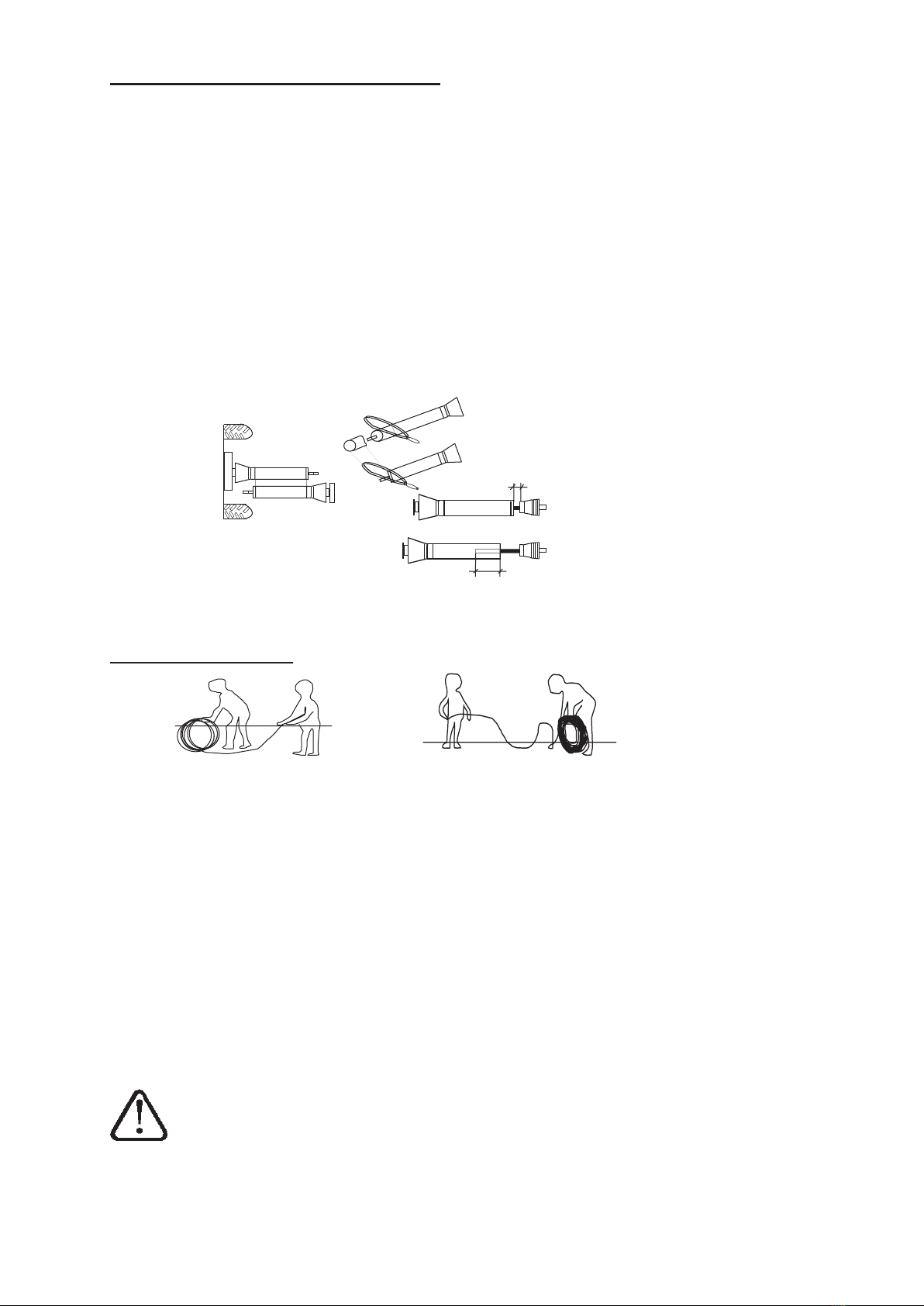

- Strictly use wire rope of adequate crush resistance, strength and quality. Provide for immediate wore rope

replacement, if any fault or anomaly is detected.

- Be sure that your wire rope length provides for a free gap to the upper drum profile of least 1.5 the rope

diameter when fully spooled. In other words, when the rope is fully spooled there should be space left on

the drum for at least two more coils.

- Make sure that your helpers do not put any extra load on the winch without prior informing the tractor

driver.

- Strictly operate the winch from a safe place, at safety distance from the load, the rope and such other

dangers as unfelled trees. The driver seat accounts as a safe place only if a safety screen is provided to

separate the winch from the tractor in such a way that it may not be removed or bypassed.