BIAX MB 50 Operational manual

16.01.2020

Translation of the original operating manual

This manual must be provided to the user (operator)!

BIAX Schmid und Wezel GmbH

Maybachstrasse 2

D –75433 Maulbronn

Tel.: 07043 / 102-0

Fax: 07043 / 102-78

E-mail: biax-verkauf@biax.de

Web: www.biax.de

Drive unit for flexible shafts

MB 50

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 2 - of -16-

Version 16.01.2020

GB

1 Technical Data

Product name

Drive unit for flexible shafts

Type

MB 50

Order number

010 402 280

Power consumption

3.1 kW

Power output

2.8 kW

Rotational speed

900 –15,000 rpm

Shaft connection

M10 x 30

Rated current

5.2 A

Mains connection voltage

3/N/PE AC 400/230 V

Signal voltage

DC 24 V

Mains frequency

50 –60 Hz

Type of protection

IP 55

Protection class of the motor

I

Insulation class of the motor

F

Noise level LpA

64 dB(A) / KpA = 3 dB

in accordance with DIN EN 60745-2-3

Vibration emission

3.451 m/s² / K = 0.385 m/s²

in accordance with ISO 62841-1

Weight

31.9 kg

2 General Information

This operating manual is a component part of the scope of delivery. It must be kept in a legible condition in the

vicinity of the equipment and be handed over with the equipment in the event of resale.

This operating manual is intended for trained and authorised expert personnel.

We reserve the right to make technical modifications to the unit described in this operating manual within the scope

of product improvements.

Reprinting, translation and copying of this document, in its entirety or parts of it, require prior written permission

from the publisher.

Copyright is property of the manufacturer.

2.1 Obligations of the Proprietor

The proprietor must observe the applicable national accident prevention regulations and technical regulations.

The proprietor must ensure that the unit is only operated by trained, responsible personnel.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 3 - of -16-

Version 16.01.2020

GB

The proprietor must ensure that operators have read and understood the operating manual before they use the

unit.

The proprietor must ensure that unauthorised persons are denied access to the unit.

In-house health and safety regulations must be observed.

3 Intended Use

The drive unit for flexible shafts is used to mount and drive flexible shafts and tools for

grinding

milling

deburring

polishing and

brushing

different materials.

You must make sure that only BIAX products are connected to the drive unit.

The drive unit must not be operated in rooms with explosive or combustible gases, or gases hazardous to health.

Any use of the drive unit for flexible shafts beyond the area of application stipulated, or constructional modifications

to it, are not permitted without prior agreement from Schmid & Wezel. Liability for any consequential damage is

annulled in the case of non-compliance.

4 Safety

4.1 Safety Labels

The following key words are used in conjunction with the safety labels throughout this document to indicate

potential hazards

DANGER

High risk of fatal or severe injury and considerable property damage if the

corresponding safety precautions are not taken!

WARNING

Risk of fatal or severe injury and considerable property damage if the corresponding

safety precautions are not taken!

CAUTION

Risk of minor injury if the corresponding safety precautions are not taken!

ATTENTION

Risk of damage to property if the corresponding safety precautions are not taken!

4.2 General Safety Precautions

WARNING

Read all safety instructions, instructions, pictures and technical data provided with

this power tool. Failure to follow the instructions below can result in electric shock, fire

and/or serious injury.

Keep all safety instructions and instructions for future reference.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 4 - of -16-

Version 16.01.2020

GB

1) Workplace safety

a) Keep your work area clean and well lit. Untidy or badly lit work areas can lead to accidents.

b) Do not work with the power tool in a potentially explosive environment containing flammable

liquids, gases or dust. Power tools produce sparks that can ignite dust or vapours.

c) Keep children and other persons away while using the power tool. If you are distracted, you can lose

control of the power tool.

2) Electrical safety

a) The connecting plug of power tools must fit into the socket. The plug must not be modified in any

way. Do not use adapter plugs together with earthed power tools. Unmodified plugs and matching

sockets reduce the risk of electric shock.

b) Avoid physical contact with earthed surfaces such as pipes, heaters, stoves and refrigerators.

There is an increased risk of electric shock if your body is earthed.

c) Keep power tools away from rain and damp. The penetration of water into a power tool increases the

risk of electric shock.

d) Do not misuse the connecting cable by carrying or hanging the power tool from it or pulling the

plug out of the socket with it. Keep the connecting cable away from heat, oil, sharp edges or

moving parts. Damaged or tangled up connecting cables increase the risk of electric shock.

e) If you are working with a power tool outdoors, only use extension cables that are suitable for

outdoor use. The use of an extension cable suitable for outdoor use reduces the risk of electric shock.

f) If operation of the power tool in a humid environment is unavoidable, use a residual current circuit

breaker. The use of a residual current circuit breaker reduces the risk of electric shock.

3) Personal safety

a) Be attentive, pay attention to what you are doing, and go about your work with a power tool using

common sense. Do not use a power tool if you are tired or under the influence of alcohol, drugs or

medicines. A moment of carelessness when using the power tool can lead to serious injury.

b) Wear personal protective equipment and always use protective goggles. Wearing personal protective

equipment, such as a dust mask, non-slip safety shoes, safety helmet or ear protection reduces the risk of

injury, depending on the type and use of the power tool.

c) Avoid starting up unintentionally. Make sure the power tool is turned off before connecting, picking

up or carrying it to the power supply and/or battery. If you have your finger on the switch when carrying

the power tool or if you connect the power tool to the power supply when it is switched on, this can lead to

accidents.

d) Remove adjustment tools or wrenches before turning on the power tool. A tool or key located in a

rotating part of the power tool can cause injury.

e) Avoid awkward body positions. Ensure a safe working stance and keep your balance at all times.

This allows you to better control the power tool in unexpected situations.

f) Wear appropriate clothing. Do not wear loose clothing or jewellery. Keep hair and clothing away

from moving parts. Loose clothing, jewellery or long hair can be caught by moving parts.

g) If dust extraction and collection devices can be fitted, they must be connected and used correctly.

The use of a dust extraction system can reduce the risk of dust.

h) Do not lull yourself into false safety and do not ignore the safety rules for power tools, even if you

are familiar with the power tool after many uses. Careless actions can lead to serious injuries within

fractions of a second.

4) Use and handling of the power tool

a) Do not overload the power tool. Use the appropriate power tool for your work. With the right power

tool you can work more effectively and safely in the specified power range.

b) Do not use power tools if their switch is defective. A power tool that can no longer be switched on or off

is dangerous and must be repaired.

c) Disconnect the plug from the socket and/or remove a detachable battery before making unit

adjustments, changing insert tool parts, or putting the power tool away. This precaution prevents the

unintentional start of the power tool.

d) Keep unused power tools out of the reach of children. Do not allow anyone to use the power tool

who is not familiar with it or who has not read these instructions. Power tools are dangerous if they

are used by inexperienced persons.

e) Maintain power tools and insert tools with care. Check that moving parts function correctly and do

not jam. Also check whether parts are broken or damaged in such a way that the function of the

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 5 - of -16-

Version 16.01.2020

GB

power tool is impaired. Have damaged parts repaired before using the power tool. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Carefully maintained cutting tools with sharp cutting edges jam less

and are easier to guide.

g) Use power tools, insert tools, etc. according to these instructions. Take into account the working

conditions and the activity to be carried out. The use of power tools for applications other than those

specified can lead to dangerous situations.

h) Keep handles and grip surfaces dry, clean and free of oil and grease. Slippery handles and gripping

surfaces do not allow safe operation and control of the power tool in unforeseen situations.

5) Service

a) Have your power tool repaired only by qualified personnel and only with original spare parts. This

ensures that the safety of the power tool is maintained.

4.3 Machine-related Safety Instructions

WARNING

There is a risk of severe personal injury if the safety information is ignored!

Sparks or chippings can be produced during grinding which could injure the eyes.

Always wear protective goggles while completing the work!

The noise level specified can be exceeded during some working processes.

Wear ear protection!

Always wear respiratory protection when performing work which produces dust and

switch on the dust extraction system at the work location!

Danger of injury from sharp components!

Wear appropriate safety gloves when working!

Danger from snagging and pulling in hair!

Wear a hairnet!

Defective electrical equipment should not be disposed of in domestic waste! Dispose

of the equipment in an environmentally-friendly manner!

4.4 Health

CAUTION –Health disorders!

Vibrations can be transmitted over the entire body, particularly to the arms and hands.

Very strong or continuous exposure to vibration can cause nerve and blood vessel

disorders!

DANGER –Electricity!

Risk of fatal injury by touching live parts.

Work on electrical equipment must only be carried out by authorised electrical experts.

Do not carry out any work on live parts.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 6 - of -16-

Version 16.01.2020

GB

Loose connections, damaged, partially melted and melted through cables should be

replaced immediately.

Do not clamp or squeeze the cables.

Lay cables in such a way that they do not cause tripping hazards and they cannot be

damaged.

Dusts from materials with a lead-content coating, some types of wood, minerals and metals can represent a health

hazard. Touching or inhaling dusts can be the cause of allergic reactions and/or respiratory disorders to the user or

persons in the vicinity.

Certain dust, such as that from oak or beech, are considered carcinogenic, particularly in combination with

additives used in treating wood (chromate wood preservatives). Material containing asbestos may only be

processed by specialists.

When working with these or comparable materials you must provide an extraction system.

Avoid contact with power sources. The machine is not insulated against contact with live parts.

4.5 Handling the Machine

WARNING –Unqualified personnel!

The operating manual is intended for trained expert personnel!

Non-observance of the operating manual can lead to personal injury and equipment failure!

WARNING –Danger of being pulled in!

Only wear close-fitting clothing during work.

Remove all jewellery before starting work.

Always wear a hairnet if you have long hair!

WARNING –Risk of injury!

Hold the tool away from your body when it is switched on!

Do not reach into running tools and be careful when handling them!

Ensure that other persons are at a safe distance from the working area.

Wear personal protective equipment in the work area!

DANGER –Risk of explosion due to mechanical shock and friction sparks!

The drive unit for flexible shafts must not be used in explosion-endangered areas!

DANGER –Risk of explosion due to dust!

While grinding, dust can be created which forms a potentially explosive atmosphere.

Observe the regulations applicable in your country of use for the machining of materials!

Only operate the machine when it is in perfect working order and condition.

Keep the unit away from rain and damp. There is an increased risk of electrical shock if water enters the machine!

When working in the open, only use undamaged extension cables approved for use outdoors!

Make sure the switch is set to OFF before plugging in the mains plug!

Only switch on the machine when the handpiece is ready for use!

It is essential to observe the minimum clamping length of the tools.

Operate the drive unit for flexible shafts only with suitable and undamaged profile grinding wheels, brushes and

carbide burrs.

Observe the stipulated speeds of the drive unit, the handpieces, the flexible shaft and the tools.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 7 - of -16-

Version 16.01.2020

GB

When using carbide burrs and brushes, avoid exceeding the permissible load and circumferential speed in order to

avoid danger to persons or damage to property.

Complete a 30-second test run before starting to use the unit.

Only process a workpiece with the tool, never with other parts of the rotating spindle. Damaged or incorrectly fixed

grinding tools can cause extreme vibration.

It is imperative that you check the tool for any damage after it has been dropped.

Before starting work, and after each interruption, check the machine and tool for signs of damage.

Check the tool is clamped securely in the collet chuck of the handpiece because the tool could become loose and

fly out of the collet chuck!

Only use accessories specially designed and recommended by the manufacturer for this power tool!

Check that the shaft is correctly seated on the drive unit and the handpiece. Incorrect installation can result in

damage to the drive train!

Secure the workpiece in a clamping device or a vice!

Avoid contact with power sources! The device is not insulated against contact with live parts.

Only use the drive unit with an undamaged flexible shaft! Check the components, mains cable and connections for

damages before starting work!

Before changing the tool and during maintenance work, always disconnect the machine from the mains to prevent

uncontrolled startup!

The connecting plug must not be modified. Do not use any plug adapters!

Never remove the handpiece without first turning off the machine! Notice: The tool runs on after being switched off.

Only set the unit down after it has come to a stop!

The electric motor needs longer to stop if there is a power failure.

When setting up the machine, make sure that the machine is standing securely and observe the range of the

flexible shaft!

Do not use insert tools that require liquid coolant!

4.6 Conduct at the Workplace

Keep your place of work tidy.

Work carefully! Do not use the unit if you are tired or under the influence of alcohol, drugs or medicines!

Sparks are caused by grinding and brushing. Remove any combustible objects, substances and materials! Ensure

adequate ventilation!

Always concentrate on the job at hand and keep others away from the work area!

Keep your tools in a safe, secure place and maintain them carefully!

Repair work may only be carried out by authorised specialist personnel.

Use a dust extraction system.

Ensure good lighting and ventilation at the workplace.

Wear a respirator with filter class P2, gloves and protective clothing.

4.7 Behaviour in case of an Emergency

In an emergency, press the "STOP" button.

CAUTION –Machine continues running!

If you pull out the mains plug, the electric motor cannot be braked by the frequency inverter!

The electric motor needs longer to come to a stop.

4.8 Behaviour in case of Accidents

Inform yourself as a matter of routine at regular intervals regarding possibilities for first-aid.

Immediately inform your superior –after injured persons are provided with first-aid –if persons are involved in

accidents or if there is damage to units or buildings.

To enable rescue vehicles to provide efficient help, indicate the level of injury and damage to property.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 8 - of -16-

Version 16.01.2020

GB

Immediately move away from the machine in case of a catastrophe (fire).

Only ever use the identified rescue equipment and rescue routes. Do not use lifts.

5 Transport

Use suitable load suspension devices for transport.

Do not stack machines! This can damage the machine. Parts stacked too high can fall over.

Do not store the machine outdoors or in damp rooms.

6 Startup

6.1 Mounting the Operating Unit

DANGER –Electricity

Installation, maintenance and repair work may only be carried out by authorised and qualified

personnel!

DANGER –Electricity!

Disconnect the machine from the mains before starting any assembly work!

6.1.1 Mounting the Operating Unit on the Machine

DANGER –Electricity!

Do not open the cover of the MB 50 drive unit. Danger due to damage and contamination of

electrical components

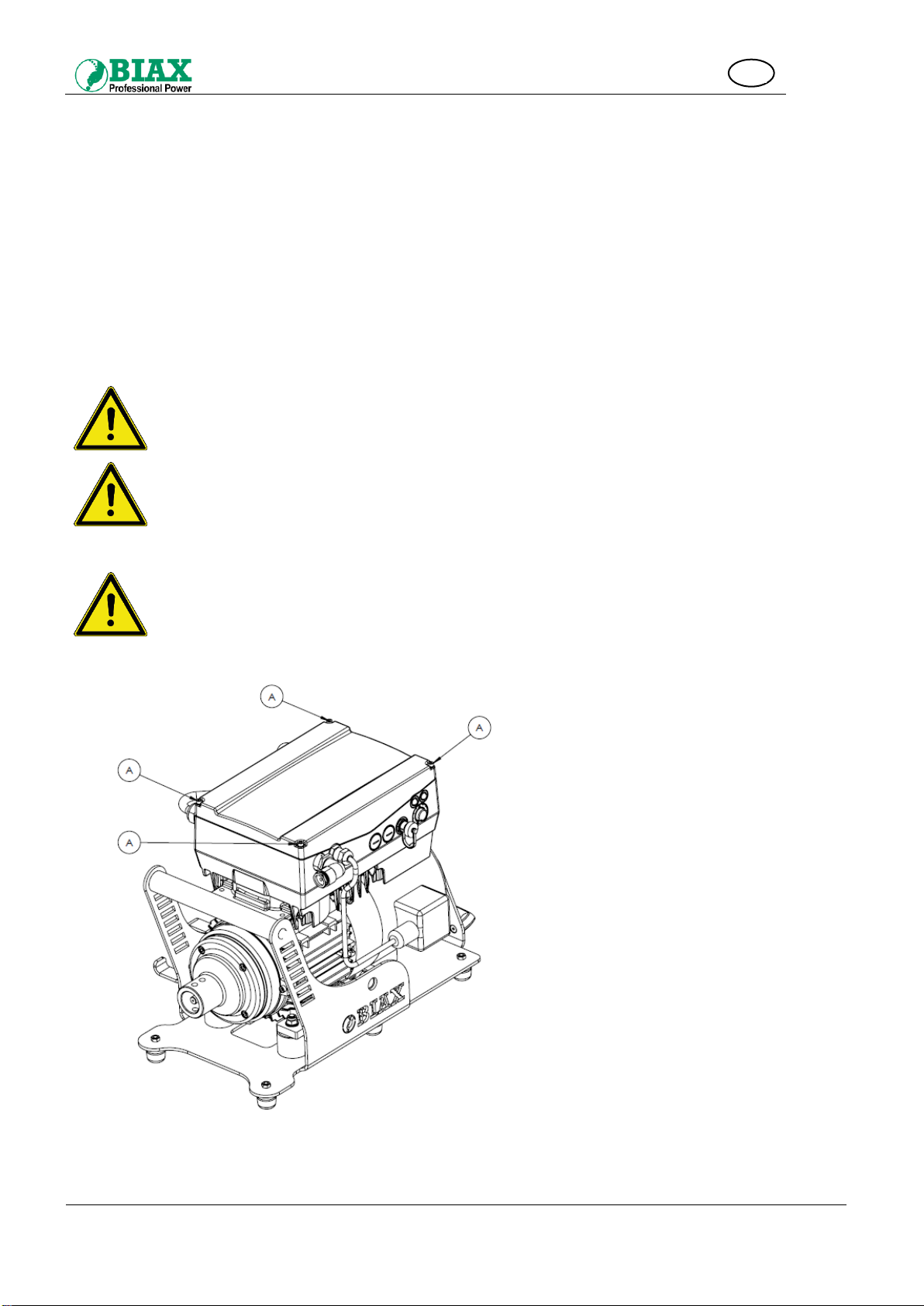

Remove the 4 screws (A) from the drive unit as shown in Figure 1.

Figure 1: Removal of the screws

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 9 - of -16-

Version 16.01.2020

GB

The operating unit with sheet (1) is fixed on the drive unit (5) at 4 points. For this purpose, the spacers (4) are

positioned between the drive unit and the sheet of the operating unit as shown in Figure 2; then they are secured

with the cylinder screws (2) and washers (3) included in the scope of delivery.

Figure 2: Mounting the operating unit on the drive unit

6.1.2 Mounting the Operating Unit for Bench Use

The supplied rubber-metal feet (3) are attached at 4 points. Each foot is bolted to the holder with a nut (1) and a

washer (2) as shown in Figure 3.

Figure 3: Mounting the Operating Unit for Bench Use

6.2 Setting Up

ATTENTION –Danger of tipping!

When setting up the machine, make sure that the machine is standing securely and observe

the range of the flexible shaft!

The machine must not tip over when the shaft is pulled.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 10 - of -16-

Version 16.01.2020

GB

The machine should be installed as near as possible to the workplace. Avoid awkward body positions.

When setting up, make sure that the machine is standing securely and that the ventilation on the housing can be

easily accessed.

The rubber buffers on the stand feet ensure secure standing on a smooth surface.

You can get either a moveable frame or a bench stand for the MB 50.

6.2.1 Mounting the Machine on the Bench Stand or Portable Stand

Figure 4: Mounting on bench stand or portable stand

Place the machine on a stand between the bracket (B).

Mount and fix the stand to the machine with two clamping levers (A) through the holes in the holder (C).

6.2.2 Suspension of the Drive Unit

DANGER –Falling down!

Use a lockable snap hook to prevent the machine from accidentally falling down.

In order to operate the machine suspended, it must be suspended from the hole as shown in Figure 5 with a

suitable load suspension device. A suitable snap hook in accordance with EN 362 must be used to prevent

accidental falling down. The fastener must be selected so as to prevent damage to the machine and to the

fasteners.

Figure 5: Suspension of the machine

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 11 - of -16-

Version 16.01.2020

GB

6.3 Mains Connection of the Machine

DANGER –Electricity!

Before use, check the ratings of the power supply network match those of the machine.

WARNING –Rotating parts!

Only connect the plug to the power supply after the system is ready for operation and the

tool has been clamped in.

Ensure that other persons are at a safe distance from the working area.

Wear personal protective equipment in the work area!

WARNING –Tripping hazard!

Lay the mains connecting cable in such a way that there are no tripping hazards.

The machine is operated on a 3/N/PE AC 400/230 V 50Hz three-phase network.

6.4 Connecting the Flexible Shaft

The flexible shaft is greased and in an operational condition. The flexible shaft must meet the size and strength

requirements. The bend radius must not be less than the minimum bend radius!

The shaft core can be slid out of the protective tube on the motor connection side of the flexible shaft. Therefore,

connect this side first!

Connection according to DIN 42995

(threaded connection M10x30):

Figure 6: Threaded connection flexible shaft

Figure 7: Section threaded connection

Screw a suitable screw (M10) onto the shaft coupling (1), thereby pulling the shaft coupling out of the hose

bush (7).

To secure the shaft coupling, insert the retention pin (2) into the hole (3) and release the screw (M10)

again.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 12 - of -16-

Version 16.01.2020

GB

Block the drive unit motor spindle (4) with the retention pin through the hole (5) in the motor flange (6).

Using the retention pin (2), turn the shaft coupling (1) up to the stop on the motor spindle.

Remove the retention pin (2) from the shaft coupling. Remove the retention pin from the motor spindle (4).

Insert the hose bush (7) into the motor flange (6) until the retaining spring (8) locks into the hole (9) on the

motor flange (6).

The flexible shaft is now connected to the drive unit.

6.5 Releasing the Flexible Shaft

See Figure 6:

Secure the motor spindle with the retention pin through the hole (5).

Depress retaining spring (8) with the retention pin.

Pull the hose bush (7) out of the motor flange (6).

Secure the shaft coupling (1) with the retention pin through the hole (3) and rotate the shaft coupling with

the retention pin from the motor spindle.

6.6 Connection of Handpieces

Claw connection

Place the claw of the handle on an appropriate counterpart of the flexible shaft. Check the position of the

claw.

Tighten the union nut of the shaft by hand.

7 Handling

7.1 Switching On and Off

Danger –Tool bursting!

The tool can burst due to the speed being set too high! Check the set speed before starting.

WARNING –Rotating parts!

Avoid unintentional starting: Always switch the machine off when the plug is pulled out of

the socket or if there has been an interruption in the power supply.

Ensure that other persons are at a safe distance from the working area.

Wear personal protective equipment in the work area!

CAUTION –Risk of injury!

Before switching on, hold the handpiece with clamped tool firmly in your hand! Pay

attention to clothing, hair and objects that may be caught by the tool.

CAUTION –Machine continues running!

The shaft continues to run on after the machine has been switched off. Do not remove the

tool until the spindle is stationary!

ATTENTION –Tool damage due to inappropriate speed!

An overspeed can cause vibrations and lead to damage to the tool and shaft!

When selecting the speed, observe the max. permissible working speed of the tool

manufacturer, the shaft and the handpiece! Only use tools within the permissible speed

range of the machine.

Switching on

Plug in the mains plug before switching on.

Switch on the drive unit control with the rotary switch (1) to "On".

The frequency converter takes a few seconds to become operational.

Use the potentiometer (2) to preselect the speed.

To start the flexible shaft drive, press "START" (4).

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 13 - of -16-

Version 16.01.2020

GB

Now the workpiece can be processed.

Work carefully in the area of corners, sharp edges, cracks, etc.

Prevent insert tools from bouncing off the workpiece and jamming!

Switching off

To stop the flexible shaft drive, press the "STOP" button (5).

Switch off the machine with the rotary switch (1) to "Off".

Figure 8: Functions of the operating unit

7.2 Speed Control

WARNING –Rotating parts!

When adjusting the speed, hold the handpiece with clamped tool firmly in your hand!

Ensure that other persons are at a safe distance from the working area.

Wear personal protective equipment in the work area!

Figure 8:

The display (3) shows the current speed of the drive unit.

The preceding speed may differ depending on the tool and the environment.

The speed can be readjusted during operation.

Readjust the desired speed with the potentiometer (2).

7.3 Tool Change

WARNING –Unintentional starting of the machine!

Switch off the unit before each tool change and disconnect it from the mains!

WARNING –Flying tool!

Do not leave any tool keys inserted!

Check that all keys/wrenches have been removed before starting the machine.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 14 - of -16-

Version 16.01.2020

GB

Only use undamaged tools: Before each use, check the insert tools for splintering, cracks, wear or heavy abrasion.

After falling down, check the machine and the tool for damage.

Only use perfect open-end wrenches for the tool change, otherwise the collet chuck and spindle can be damaged.

There are different tool clamping systems depending on the handpiece:

Tool change with collet chuck ZG 4/6

Figure 9: Tool change collet chuck ZG 4/6

On machines with collet chuck type ZG 4/6, carry out the tool change with keys (scope of delivery).

Hold the spindle with the key (1) and open or close the collet chuck with the second key (2).

Tool change with collet chuck ZG 1/6

Figure 10: Tool change collet chuck ZG 1/6

Fix the spindle in the handpiece using the retention pin (1).

Insert the tool into the clamping device and tighten or loosen the collet chuck with a wrench (2).

WARNING –Flying tool!

The shank must not be less than the minimum clamping length.

Follow the instructions of the tool manufacturer.

Before use, allow the machine to run at maximum speed for one minute!

8 List of Faults

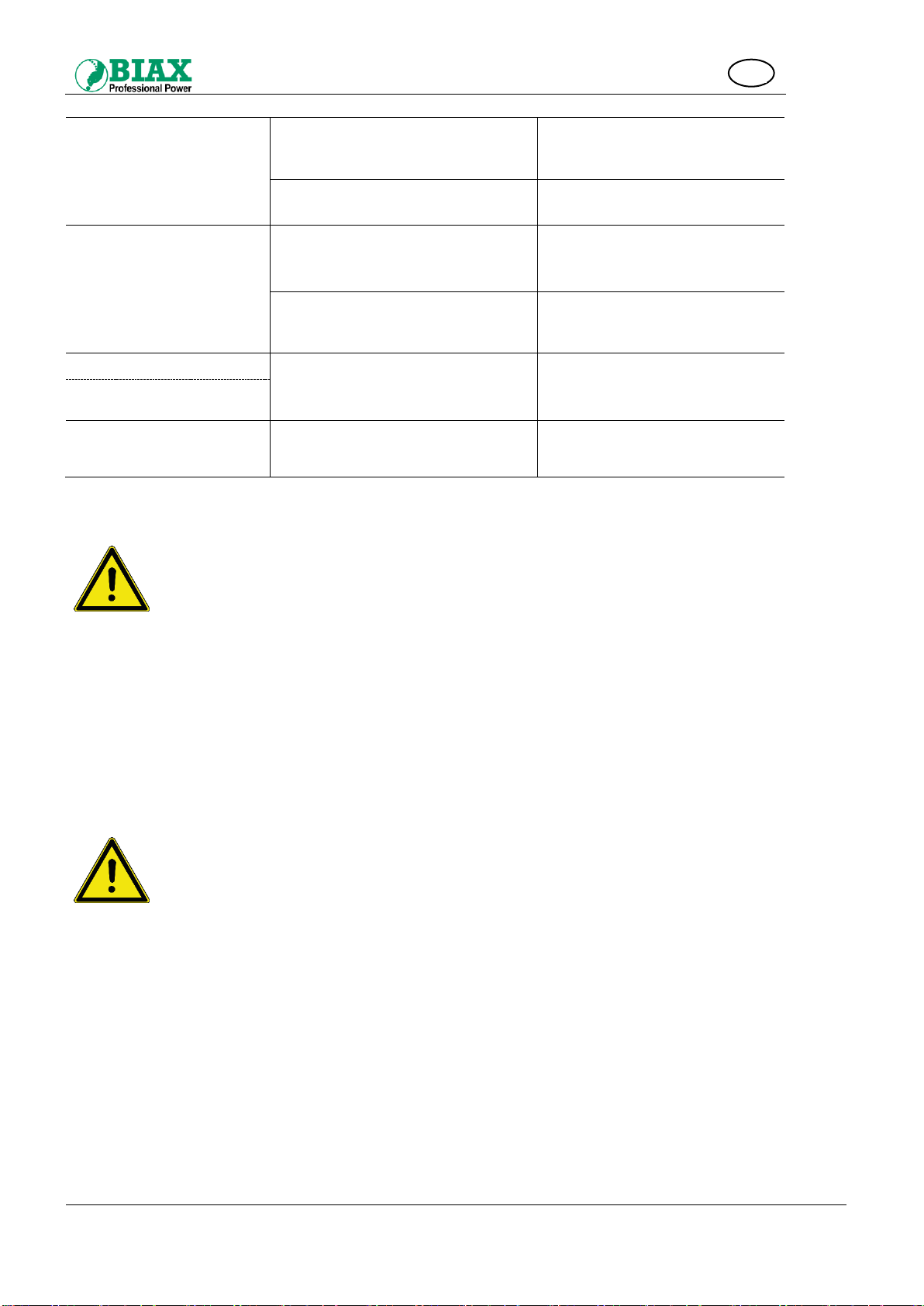

Malfunction

Possible cause

Remedy

Tool doesn't move

Mains switched off

Switch on the mains switch

Broken wire

Disconnect unit from mains and

repair or replace the mains cable

1

2

AUF

ZU

festhalten

$field2Werkstoff-Art:

Abmessung:

Schmid & Wezel GmbH& Co.

75433 Maulbronn

Allgem. Toleranzen

nach

DIN ISO 2768-mK

ISO 8015

$scale1

$din

$field4

$raw Oberfläche:

$ben1

$ben2

$ident

Zeichnungsnummer

Benennung

Werkstoff: $mat

Behandlung:

$shcnt

$sheet

Schutzvermerk ISO 16016

$norm_by

$created_at

$rel_at

$norm_at $rel_by

$created_by

$aet8$aei8

$aet1

$aet7

$aet6

$aet5

$aet4

$aet3

$aet2

$aei3

$aei6

$aei7

$aei4

$aei5

$aei2

$aei1 $aeu1

$aeu8$aed8

$aed1

$aed2

$aed3

$aed4

$aed5

$aed6

$aed7

$aeu2

$aeu3

$aeu4

$aeu5

$aeu6

$aeu7

Urspr.

$source

Ers. f.

$replaces

Ers. d.

$replaced

Maßstab

Gepr.

DatumZust.Änderungen Name

Norm

Name

Bearb. Datum

Blatt

Bl

1

2

ZU

AUF

$field2Werkstoff-Art:

Abmessung:

Schmid & Wezel GmbH & Co.

75433 Maulbronn

Allgem. Toleranzen

nach

DIN ISO 2768-mK

ISO 8015

$scale1

$din

$field4

$raw

Oberfläche:

$ben1

$ben2

$ident

Zeichnungsnummer

Benennung

Werkstoff: $mat Behandlung:

$shcnt

$sheet

SchutzvermerkISO 16016

$norm_by

$created_at

$rel_at

$norm_at $rel_by

$created_by

$aet8

$aei8

$aet1

$aet7

$aet6

$aet5

$aet4

$aet3

$aet2

$aei3

$aei6

$aei7

$aei4

$aei5

$aei2

$aei1 $aeu1

$aeu8

$aed8

$aed1

$aed2

$aed3

$aed4

$aed5

$aed6

$aed7

$aeu2

$aeu3

$aeu4

$aeu5

$aeu6

$aeu7

Urspr. $source Ers. f. $replaces Ers. d. $replaced

Maßstab

Gepr.

DatumZust.Änderungen Name

Norm

Name

Bearb.

Datum

Blatt

Bl

CLOSE

OPEN

hold

OPEN

CLOSE

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 15 - of -16-

Version 16.01.2020

GB

Shaft break

Disconnect unit from mains and

replace flexible shaft, check the

speed if necessary

Motor overload

The motor switches itself off for

self-protection

Tool blockage

Shaft break

Disconnect unit from mains and

replace flexible shaft, check the

speed if necessary

Speed too low

Increase the speed (according to

the tool manufacturer's

specifications)

Tool vibrates strongly

Tool incorrectly clamped

Speed set too high

Clamp tool correctly

Reduce speed

Tool is released from collet

chuck

Machine does not start

Main switch "OFF", switch on

again after 30 sec. (Reset)

9 Maintenance

DANGER –Electricity!

Disconnect the unit from the mains before starting any maintenance work!

The unit is largely maintenance-free.

Check the unit for visible damage before each use.

Clean the cooling fins of the machine and tool regularly (without water!)

Clean the machine of dust every 100 operating hours. To do this, unscrew the hood and vacuum out the interior.

9.1 Flexible Shaft

If the shaft breaks, interrupt work and replace the flexible shaft immediately.

9.2 Other Maintenance

CAUTION –Risk of injury from worn tools!

Check the spindles, threads and clamping devices regularly for wear and for compliance

with the tolerances!

Replace worn tools immediately.

Wear personal protective equipment in the work area!

Before starting work, conduct a visual check of the drive unit, handpiece, flexible shaft and tool.

If defects are detected, return the machine to our head office or one of our authorised service centres for repair.

Protect the unit, particularly the drive and operating elements, from dust and dirt.

Clean the air slots of the machine. The maintenance must be carried out at least once a year. At the latest after

wear and replacement of the carbon brushes.

Use compressed air to do the cleaning.

Translation of the original operating manual

Drive unit for flexible shafts –MB 50

OI NO.: 001 580 674

- 16 - of -16-

Version 16.01.2020

GB

10 Repairs

WARNING –Unqualified personnel!

Repairs are only allowed to be carried out by specialist personnel! Our Service

department is available to you for this.

Only use genuine parts!

In the case of deteriorating performance, the unit must be disassembled and cleaned. Contact your nearest

authorised service centre or our head office directly. We can send the appropriate spare parts lists to the specialist

service centres. Please contact our Sales department in respect of this.

11 Scope of Delivery

Drive unit MB 50

Tool holder

Accessory set

11.1 Special Accessories

Flexible shafts in various sizes and thicknesses depending on application

Handpiece depending on application

Bench stand (turntable)

Portable stand

Table of contents

Other BIAX DC Drive manuals