bibox Firepen 3D User manual

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

1

USER MANUAL

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

2

TABLE OF CONTENTS

A. SETTING UP YOUR Firepen 3D PRINTER

1. Attaching Power Supply and Powering On

B.Firepen 3D printer AT A GLANCE

1. 3D printer Diagram

2. Specifications

3. Touch Screen panel

C.FIRST USE

1. Installing Spool Holder and Mounting the Filament Spool

2. Preheating the Extruder

3. Loading Filament

4. Leveling the Build Platform

D.MAKING AN OBJECT WITH 3D printer

1. Making a Test Object from the SD Card

Appendix

Using Slicer Software Cura(一)

1. Installing Software

2. Software Settings

3. Tutorial of parameter setting

4. Software operation

Display and Controller(二)

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

3

*Its very important to see to that, the Power socket that the Firepen 3D printer connects to, can source

atleast upto 15A current and 220V AC supply. Also, see to that, this power socket isn’t sharing with other

electrical appliances. Under supply of current can cause malfunction of the Firepen 3D printer unit.

A. SETTING UP YOUR Firepen 3D PRINTER.

1.Attaching Power Supply and Powering On

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

4

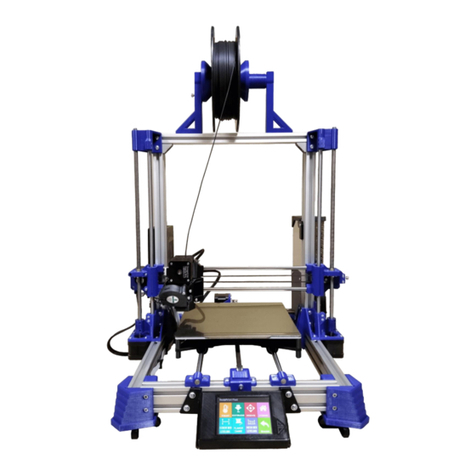

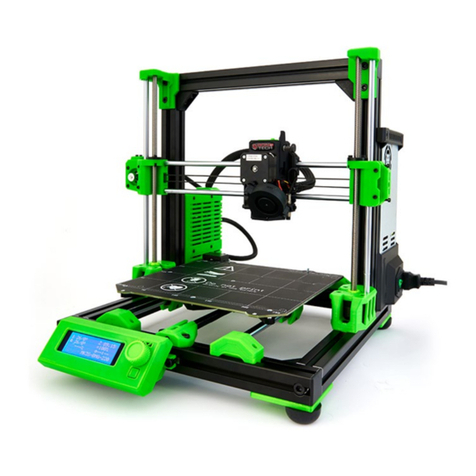

B.Firepen 3D printer AT A GLANCE

1. 3D printer Diagram

Extruder

Gantry rod

Drive bearing

Y axis motor

Build plate screws

Build plate

Build platform

Threaded rod

X axis motor

Touch Screen

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

5

Feed tube

Filament Out

Detector

Spool holder

Power input

SD card slot

USB port

Power switch

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

6

2. Specifications

Machine model

Firepen 3D P220 printer

Machine Color

Black & Red

Display

Full color Touch screen

Language

English

Print Technology

Fused Filament Fabrication (FDM/FFF)

Layer resolution

0.05-0.4mm

Nozzle diameter

0.4mm

Positioning Precision

Z: 2.5 microns X Y: 11 microns

Print speed

20-180mm/s

Filament diameter

1.75mm

Filament

PLA/ABS/TPU/HIPS/PETG/Wood/Carbon Fiber/Z-Marble/Twinkling/Silky

AC Input

220V-110V

Supplied software

Repetier-Host

File types

.stl/.obj/.dae/.amf

Save fomat

g code

Connectivity

USB, SD card

Print dimensions

200*200*200mm

Weight

21kg

Desktop space

420*420*460mm

Nozzle quantity

One

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

7

3. Touch Screen panel

Progress bar

Model name

Runtime stats

Heated bed

temperature

Nozzle temperature

Tools (Allows you to

change the temperature

setting for the extruder

or heated bed, fan speed,

and pause or stop printing)

Fan speed

Current temperature/ Set temperature

Tips: Go to Appendix for Display and Controller

C.FIRST USE

1. Installing Spool Holder and Mounting the Filament Spool:- Take out the spool

holder from the accessory box, Attach the spool holder at the back side of the

machine.

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

8

2.Preheating the Extruder

Go to the Touch screen panel and select Preheat > Add.

Add the extruder to 200℃. Wait for the extruder to heat to the set temperature.

Please press Add or Dec button to heat the extruder before start printing, or the

extruder won’t be heated.

( Nozzle 1 - 200/200 shows the current temperature and the set temperature of

nozzles. Press E1 button, the display will show for the temperature of heated bed.

Press 1 ℃button to choose the increase rate 1℃/5℃/10℃of heat temperature for

each press.)

3. Loading Filament:-

After the extruder reaches 200° C, press the knob on Filament Out Device to the

left, Take and straighten the end of the filament, insert it through the device into the

extruder. The machine will alarm all the time if the knob is not pressed to the left

while inserting the filament, in such a scenario, please load filament again.

Push down on the Extruder Arm, Continue to hold it down as you insert the free

end of the filament into the hole in the top of the extruder. Push the filament in as

far as it will go. You will see plastic start to emerge from the extruder nozzle.

Release the extruder arm.

Feeding pipe

Filament out device knob

Feed port

Feed port

Extruder button /arm

4. Leveling the Build Platform

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

9

principle:rotate the below four nuts, the spring shrink or spread, and further control the

platform down or up.

method:move the extruder to anywhere on the platform, make sure the nozzle is close to the

platform, move normal and do not scratch the masking paper(the preminum distance

is 0.1-0.2mm)

○

1

click<Home>——<Home>

○

2

click<Set>——<Motor off>

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

10

D.MAKING AN OBJECT WITH 3D printer

1.Making a Test Object from the SD Card

The Firepen 3D printer package includes an SD card pre-loaded with a file for

making a test object.

The SD Card is located in the accessory box. Insert the SD card into the SD

card slot. Go to the Touch screen panel and select Print and choose

“whistle.g” to start printing.

Tips: Stl is a widely used file format for 3D models. (Others: obj,amf,dae)

Thingiverse is a website where 3D printer users can share design files and

download it for free.

For printing it is very important that the first layer is nicely squished into the build

plate and sticks well to it.

1. If the distance between the nozzle and build plate is too big, your print won’t

stick properly to the glass plate.

Please loose the knobs [turn them to the left] moves the build plate closer to the

extruder nozzle

2. If the nozzle is too close to the build plate it can prevent the filament

from extruding from the nozzle. This can also scratch the build plate.

Please tighten the knobs [turn them to the right] moves the build plate away from

the extruder nozzle.

3. The 3rd image below, shows the Perfect first layer, with correct setting of the

extruder nozzle distance from the build plate.

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

11

1

2

3

Appendix

Using Slicer Software Cura(一)

1. Installing Software

Insert the SD card reader with SD card on your computer, copy the Cura

installer to your computer.

Open the installer and run

the installation wizard to

complete the installation.

Select Next and tick all the

options.

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

12

Install > Next > Finish

Select your language > English >

Next

Select your machine > Other > Next

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

13

Other machine information >

Custom > Next

Finish the blank with the specs of

your 3D printer in Custom RepRap

information > Finish

ET-K1

200

200

200

0.4

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

14

2. Software Settings

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

15

3. Tutorial of parameter setting

1. The layer height of general settings for the 0.1,0.2,0.3mm.if 0.3 mm, the model has

obvious sense of hierarchy, but it can reduce the time of printing;0.2mm,it is usually

be used; the fine print is set to 0.1mm, the printing surface is smooth, the print time

will be longer

2. The shell thickness is set to a multiple of 0.4mm, such as 0.8, 1.2, 1.6., and so on.

3. Enable retraction, it can avoid printing residue silk filament, the detail is in advanced

settings.

4. For the general model. The bottom / top thickness is set to 1mm. If you print a

thinner object, the upper surface has an unfilled surface. This value can be increased

appropriately.

5. The fill density is generally set to 5%--20%, and smaller objects or single wall models

can be set to 100% fill, and larger seal models can also be set to 0 fill.

6. Print speed is set to 30mm/s--80mm/s range

7. The print temperature is only the nozzle temperature of the extruder, the PLA print is

set to 200-210 centigrade, and the ABS is set to 240 centigrade.

8. The heating bed temperature for PLA is usually set to 45-50 centigrade, and ABS need

more then 80 .

9. Support is divided into: no support for the None, Touching buildplate, everywhere,

full support for Everywhere. Print model has vacated part or larger slope need to

open the support function, Touching buildplate refers to the generation of support

between the platform and the supporting model. everywhere refers to in addition to

support generation between the platform and the model can also generate support in

the inner of the hang model, the specific choice depends on the display of model.

10.The platform adhesion type is generally selected as None, the contact surface

between print model and platform is smaller, and when the printing model height is

higher, the adhesion can be opened, and the attachment type is divided into two

kinds, brim and raft ,and the specific difference reference software is introduced.

11.filament diameter defaults to 1.75mm

12. flow default 100%, if diameter less than 1.75mm and lead to print model surface

filling unevenly, can increase this value appropriately, but seldom happened.

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

16

Save the model in

SD card

Load a 3D model

save the file

Choose your desired settings and wait for Cura to

slice the model.

When Cura has converted the file you can save the

print file

(G code) via the “Save” button. Save the file to the

SD card.

1. Software operation

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

17

Display and Controller(二)

Main menu

Set

Preheat

1. E1 Change the display from

nozzle temp

into heated bed

2. 1℃Choose the increase rate

1/5/10℃of

the nozzle or heated bed.

3. OFF Turn off nozzle or heated

bed.

Extrude

1. E1 Change the display from

nozzle 1

into nozzle 2.(only works on

dual nozzle)

2. 1mm Choose the length of

extruded

filament 1/5/10mm

3. Slow Choose the speed of

load or unload filament.

Move

Move the extruder

1. 0.1mm Choose extruder move

distance

0.1/0.5/1mm

File Sys

Fan

Printing

1. model file will display in the print

options interface, when models

files too much,

click<Page Up>,<Page Down>to

search the file you need

Home

1. <Home> X/Y/Z axis move

towards to limit switch

direction.

2. <X> X axis moves left

3. <Y> Y axis moves back

4. <Z> Z axis moves up

Evobi Automations Pvt Ltd www.firepen3d.bibox.in

18

Any further Questions / support related queries

Contact:-

Mobile:- +917760676606 / +919008333233

Tel:- +91-80-25743579

Evobi Automations Pvt Ltd

1st Floor, Pixel Park ‘A’,

PESIT South Campus,

Electronics City, Hosur Road,

Bangalore - 560100

www.firepen3d.bibox.in

www.bibox.in

Table of contents