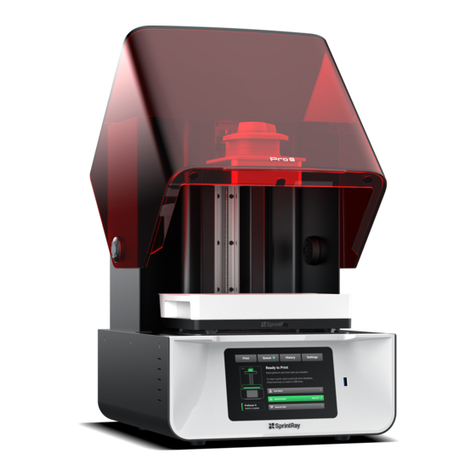

SprintRay Pro S User manual

Desktop 3D Printer Designed for Digital Dentistry

Quick Start Guide

Hello...

Resin Wiper

Print Platform

Pre-installed

Resin Tank and Cover

Pre-installed

Pro S 3D Printer

Pro 55S / Pro 95S

Power Cable

Print Removal Tool Support Snipper Cleaning Cloth

The print platform and resin tank are pre-installed and have a protective film

that must be removed prior to first use.

The print platform and resin tank will be a different

size depending on the model of your printer.

Situate your Pro 3D printer in a

well-ventilated area on a flat and

level surface.

Keep it away from extreme

temperatures, windows, bright UV

light sources, and direct sunlight.

Where to Set Up

Level Surface

In the Box

Congratulations!

In this brief guide, we’re going to show you how to set up

and make your first model on the new SprintRay® Pro S

Desktop 3D Printer.

Please follow the instructions carefully and visit our

website fpr tips & tricks.

We’re so excited to see what you make!

Training and Support

Contact our team of support technicians

with questions.

Visit

Call

Email

support.sprintray.com

(0) 800-70708000

Uneven Surface / Warm Environment

Recommended

Operating Temperature

Min 21 °C

70 °F

Max 29 °C

85 °F

Onboarding Card

2

1

Smart Life Tracking

Your SprintRay Pro S is equipped with

advanced electronics that allow the printer

to track the lifetime and health of each tank.

Follow onscreen instructions to properly set

up new resin tanks to ensure longevity and

proper tracking.

Resin Tanks Are Consumable

Resin tanks are consumable products that have an expected

lifetime. Follow the onscreen instructions to understand the

remaining life of your resin tank.

Resin Tank Fill Lines

When starting a print, the desktop software or touchscreen of

your Pro S 3D printer will display the resin level necessary for

the planned job.

Fill the tank to the suggested level, ensuring even distribution

of the resin across the tank. Pay attention to the Min and

Max indications in the tank to ensure that the correct amount

of resin is present. Before printing, double check resin levels

against the value needed which is displayed on the screen.

The Min/Max indicators on the Pro 55S and Pro 95S resin

tank are in different locations and indicate different amounts.

Resin Tank Best Practices

For best results, use a dedicated resin tank for each different

material you use. Keep a backup tank on hand in case of an

emergency to avoid ordering downtime.

Backup Resin Tank: Keep a backup resin tank on

hand to avoid downtime due to tank life.

Use the provided power cable to plug your printer into

a surge protector or uninterrupted power supply.

When not in use, the printer automatically goes into

lower power mode, and does not need to be turned

off.

Use the power switch if you need to perform a hard

reset or disconnect your Pro S from its power source.

Plug in Pro S

UV Lid

USB Port

Touchscreen

Power

Switch

Power Port

Prepare Resin Tank

(Pre-installed)

Lock: Place the tank in its

cradle, then push away from

you. You will hear a ‘click’ when

the tank is properly locked.

Unlock: Gently pull toward

you until you hear a ‘click’ to

unlock. Lift up to remove the

tank from its cradle.

After powering-up your Pro S, you will be presented with onboarding

instructions on the screen which will help you connect to the internet.

Set up Pro S

Hello...

Let’s get started.

Pro 55S Min 150mL

Max 400mL

Pro 95S Min 200mL

Max 500mL

Cover Resin Tank After Print

If you’re done printing for the day,

secure the tank cover to help extend

the life of resin in tank.

Stir Resin Before Print

If you keep resin in the tank

between jobs, use the resin wiper to

mix the tank before every print.

RFID

MAX

MIN

WARNING!

Over pouring resin will cause spillage that is not

covered by the limited warranty offered by SprintRay.

Make Printer Discoverable

Ensure that your printer and computer are both

connected to the same wireless network.

3

4

5

3D Printing

Get Software Download RayWare Software from sprintray.com/software

Prepare Print Platform

(Pre-installed)

Unlock and pull to remove.

A

B

Insert and lock.

A

B

Turn to lock/unlock.

Prepare a Print Job in RayWare

After launching RayWare, select your printing material and

the desired layer thickness. Import your STL model, orient

the model, and add supports if necessary.

The model is now ready for printing. Click on the green

printer icon, select your 3D printer from the list of available

printer(s) and click Print.

The software will process the job and send it to your

printer.

Printing

The print platform should now slowly descend into the resin

tank. Once this has happened, the print process has begun.

Depending on the type of resin you are printing with, the printer

may have to go through a warming resin process.

Warming resin may take up to 15 minutes.

Your printer runs independently once it begins a print job.

Any changes to your network or computer will not affect print

progress as long as the printer maintains power.

Preparing the Pro S 3D Printer

Install resin tank and print platform. It is extremely important to make sure both the

print platform and resin tank are fully secured and locked before you start a print.

Compatible with

Mac and Windows

Gently Shake Resin Bottle to Mix

Before you pour resin into your Pro’s tank,

it is important to shake the bottle until it is

thoroughly mixed.

Wear Gloves

We strongly recommend wearing

gloves while handling printer and resin.

Inspect and Stir Gently

Inspect resin tank and mix

resin with resin wiper before

every print.

Keep the UV lid

closed during the

entire print cycle.

Platform Heating

SprintRay Pro S is equipped with a heated build platform

to improve printing reliability. The platform may be warm

to the touch when this feature is enabled.

Built-in Heater

Locking/Unlocking the Print Platform

The SprintRay Pro S print platform uses magnetic

locking. When the platform is seated on the

Z-axis arm, activate the magnetic lock by turning

the red knob clockwise. Turn the knob counter-

clockwise to unlock the platform before removal.

Make Printer Discoverable

Ensure that your printer and computer are both

connected to the same wireless network.

Firewall/Antivirus May Block Connection

Keep in mind that firewall or antivirus software may prevent

your computer from finding the printer. Consult SprintRay

customer support if you need help with connection issues.

1

2

4

3

5

Select printer/resin type

Import Model(s)

Orient Model(s)

Add supports (if needed)

Send to printer

7

6

8

Software Updates

SprintRay will periodically publishes software updates for

the Pro S 3D printer. Ensure your printer is connected to

internet to receive software updates.

Backup Resin Tank

Resin tanks are consumable products that have an

expected lifetime. Keep a backup resin tank on hand

to avoid downtime due to tank life.

Maintenance

Finishing a Print Job

Cleaning the Printer Chassis

Clean the printer chassis with a soft,

damp cloth. If resin is spilled on the

printer, clean up immediately and wipe

clean with a paper towel and IPA.

Resin Care

Cured resin can be discarded as regular trash. Never dispose of

liquid resin in your sink or other plumbing.

Removing Prints from Print Platform

When the print job is complete and the build arm has fully raised, remove

the platform and place it on a flat surface.

Using the provided print removal tool, detach the part from print platform.

Using the support snipper, remove the supports from your part.

ABC

Washing Models with SprintRay Pro Wash/Dry™

Use IPA 99% to wash the 3D printed models prior to post curing. To ensure

complete cleanliness, the washing process can be repeated. We recommend using

SprintRay Pro Wash/Dry to perform a fully-automated, two-stage wash and dry.

Start washing models by simply placing the print platform in the Pro Wash/Dry to

wash models and the platform simultaneously.

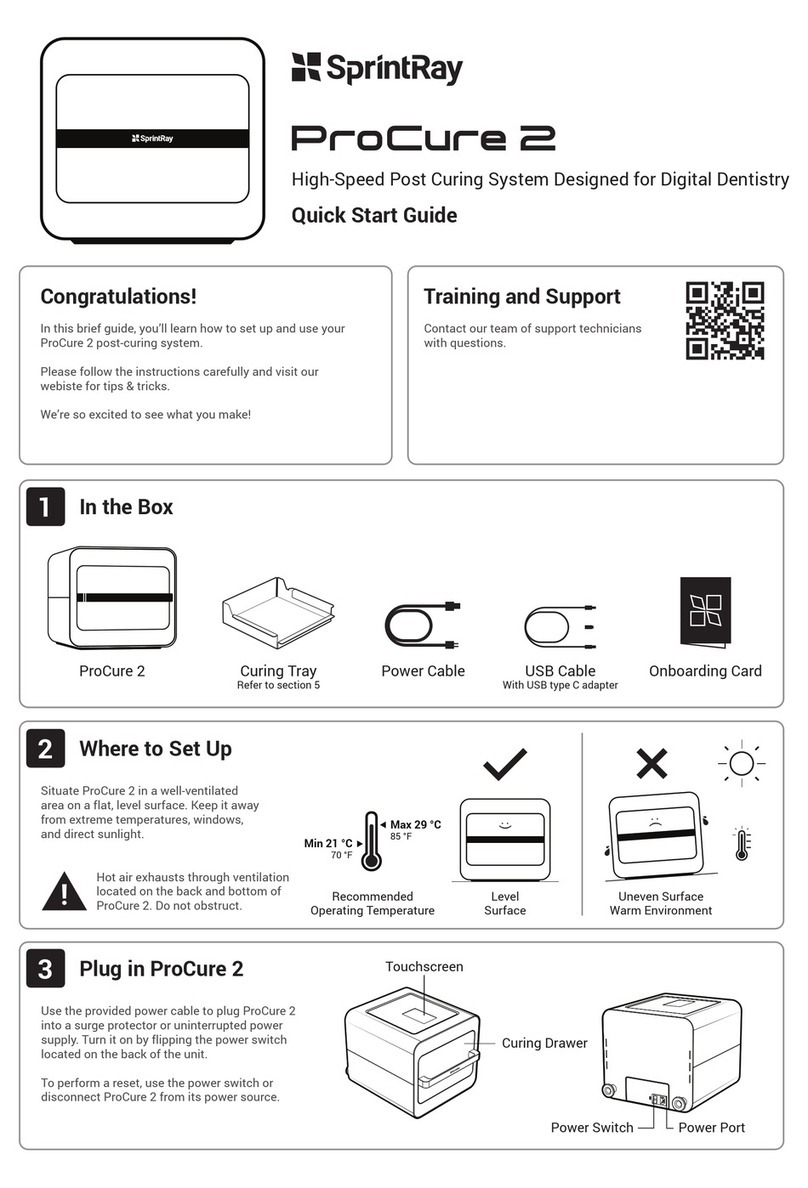

Post Curing Models with SprintRay ProCure 2™

Depending on the material specifications and regional regulatory requirements,

you may need to post-cure the printed part after wash. You can use presets on

SprintRay ProCure 2 to complete the post-curing in a few minutes.

SprintRay Pro Wash/Dry and ProCure 2 are sold separately.

Minimize Clean Up

To minimize cleanup, always

remove the platform before

removing your resin tank.

Wear Gloves

We strongly recommend

wearing gloves while

handling printer and resin.

Clean 3D Printer Optical Glass Regularly

If resin cures onto the optical window, spray the

glass with IPA and wipe with a soft cloth. Repeat if

needed. Spray with glass cleaner and use a soft

cloth to clean away fingerprints or other smudges.

2 3

IPA

99 %

Glass

Cleaner

1

Cover Resin Tank After Print

If you’re done printing for the day,

secure the tank cover to help extend

the life of resin in tank.

Clean Underside Tank Glass Regularly

Avoid touching the glass on the underside of the

resin tank. To clean, spray with IPA to remove

resin and then use glass cleaner to finish.

Reorder Consumables

To reorder consumables, including materials and resin tanks,

contact your equipment dealer representative.

9

10

Other SprintRay 3D Printer manuals