BIC 980 User manual

0O0

Multiple

Play

Manual

Turntables

Features

of

Models

980

and

960

BTC

Multiple

Play

Manual

Turntables

1.

Cycle

button—feather

touch

control

activates

all

turntable

functions.

2.

Tone

arm

finger

lift—human-

engineered

for

positive,

secure

manual

handling

of

tonearm.

3.

Programmer

selector—selects

manual

or

automatic

operation,

shut-off

and

number

of

plays.

4.

Initial

15

degree

tracking

angle

adjustment—permits

pivoting

of

entire

shell

for

parallel

alignment

and

15

degree

tracking

angle

of

stylus

assembly,

regardless

of

shape

or

depth

of

cartridge.

5.

Knurled

cartridge

shell

retaining

nut—locks

shell

firmly

in

proper

alignment.

6.

Cartridge

shell

connector—male

female

connection

for

positive

electrical

contact.

7.

Tonearm

rest—extended

for

stylus

and

cartridge

protection.

8.

Tonearm

lock—prevents

damage

during

transport

or

accidental

jarring.

9.

Speed

selector—shifts

drive

belt

for

33V3

rpm

or

45

rpm

rotation.

10.

Tonearm

set-down

adjustment—

adjusts

set-down

position

of

stylus

at

edge

of

record.

11.

Cueing

rate

adjustment—varies

cueing

speed

in

accordance

with

user

preference

or

to

suit

climatic

conditions.

12.

Force

calibration

scale—expanded

scale

for

precision

setting

of

stylus

tracking

and

anti-skate

forces.

13.

Tracking

force

adjustment

lever—

sets

desired

tracking

force

from

0

to

4

grams.

14.

Anti-skate

force

adjustment

lever

—sets

corresponding

anti-skate

force—may

be

set

in

tandem

with

tracking

force

adjustment

or

independently.

15.

Cueing

lever—initiates

safe,

damped

lowering

or

raising

of

tone

arm

or

can

be

used

as

pause

control.

16.

Stylus

mode

selector—selects

proper

skating

force

reference

for

elliptical

or

conical

styli;

elimin¬

ates

the

need

for

two

calibration

scales.

17.

Isolated

tonearm

counterweight

permits

dynamic

zero

balancing

of

entire

tonearm,

while

insuring

maximum

damping.

18.

Precision

gimbal

bearings—for

minimal

horizontal

and

vertical

pivotal

friction.

19.

12"

diecast

platter—solid,

one-

piece

precision

casting

has

computer

optimized

mass.

20.

Manual

spindle—rotates

with

platter

during

single-play

operation.

21.

Automatic

spindle—supports

records

during

automatic

record

play.

22.

Record

support—platform

stabilizes

records

placed

on

spindle

for

safe

two-point

support

during

automatic

play.

23.

Solid

state

electronic

pitch

control

(Model

980

only)—

sets

precise,

unvarying

turntable

speed

and

permits

±3%

variation

from

nominal

speed.

24.

Illuminated

stroboscope

(Model

980

only)—used

in

con¬

junction

with

electronic

pitch

control.

Visible

during

record

play.

25.

Auto/Manual

cartridge

angle

selector—permits

proper

15

degree

compensation.

26.

Elastomer

suspension

mounts

—correlated

to

the

mass

of

the

turntable

assembly

for

maximum

isolation

from

external

shock

in

all

planes.

27.

All

electronic

drive

signal

generator

(Model

980

only)—

modular

etched

circuit

generates

stable

60

Hz.

signal

to

drive

synchronous

motor.

28.

Synchronous

24

pole

motor—oper¬

ates

at

slow,

vibration-free

300

rpm.

Index

PAGE

Set-Up

Procedures

Operating

Procedures

There

are

many

playing

and

operating

options

built

into

your

B-l-C

Multiple

Play

Manual

Turntable,

plus

a

number

of

unique

control

features.

These

are

sum¬

marized

on

this

page

—and

specific

operating

instruc¬

tions

for

the

various

playing

options

are

detailed

on

the

pages

indicated.

Normal

maintenance

procedures

are

also

described

and

listed,

along

with

a

set

of

specifications

which

will

be

of

interest

to

the

audio

enthusiast.

4

How

to

properly

unpack

the

unit

5

Note

the

accessories

supplied

5

Installing

the

turntable

on

the

base

5

Proper

mounting

of

the

cartridge

in

the

tonearm

shell

6

How

to

properly

orient

and

position

the

cartridge

6

Connecting

the

shell

with

the

tonearm

7

Installing

the

counterweight

7

Selecting

proper

stylus

setting

7

Adjusting

proper

tracking

and

anti-skate

forces

7

Leveling

the

cartridge

shell

7

Installation

of

audio

cable

and

ground

connection

'

8

.

Connecting

to

AC

power

8

Manual

play

of

a

single

record

9

Programmed

repeat

play

of

a

single

record

10

Automatic

play

of

a

single

record

10

Automatic

play

of

multiple

records

10

Multiple

play

of

records

plus

repeat

of

last

record

11

Use

of

cueing

and

pause

control

11

Adjusting

the

cueing

rate

11

Adjustment

of

stylus

set-down

point

11

Turntable

removal

12

Drive

belt

installation

12

Lubrication

instructions

13

Tips

on

record

care

13

Spare

parts

list

13

Accessories

13

General

specifications

14

Trouble-shooting

hints

15

Set-Up

Procedure

■

*©f

Unpacking

the

Unit

Remove

the

unit

from

the

bottom

styrofoam

filler

by

grasping

the

unit

plate

at

the

points

indicated

on

the

top

cardboard

packing

piece.

DO

NOT

lift

the

unit

by

grasping

the

tonearm.

Whenever

possible,

the

packing

material

should

be

retained

in

the

event

re¬

shipment

is

necessary.

In

any

event,

do

not

discard

the

packing

material

until

all

of

the

accessories

described

below

are

accounted

for.

The

top

styrofoam

filler

contains

the

following:

1.

A

short

manual

spindle

for

playing

single

records.

2.

A

long

automatic

spindle

for

playing

up

to

six

records

automatic¬

ally.

3.

Tonearm

counterbalance

weight.

4.

A

manual

45

rpm

adaptor

for

playing

large

hole

records,

one

at

a

time.

5.

Cartridge

mounting

hardware;

this

contains

the

various

screws

that

are

needed

for

mounting

the

cartridge

in

the

pickup

head.

6.

A

combination

gauge

for

setting

stylus

overhang

and

paralleling

the

stylus.

7.

Transit

wing

nuts

(2).

8.

Extra

lock

nut.

9.

Pick-up

head.

10.

S

crewdriver

A

small

cardboard

packing

piece

is

installed

in

the

right-hand

pivot

of

the

tonearm

gimbal.

MAKE

CERTAIN

THIS

IS

REMOVED,

or

the

unit

will

not

perform

properly.

Also,

make

certain

that

all

rubber

bands

securing

the

line

cord,

audio

cables,

the

tonearm

tie,

etc.,

are

removed

along

with

all

other

packing

pieces.

Packing

pieces

are

installed

between

the

unit

plate

and

turntable.

They

must

also

be

removed

and,

if

possible,

should

be

retained

as

they

are

a

very

important

part

of

the

packing

if

the

unit

is

ever

shipped.

The

audio

cable

is

packed

in

a

wedge

on

the

right

side

of

the

unit.

Installing

the

Unit

on

the

Base

Both

the

B-20

Base

and

WB-20

Base

are

supplied

with

a

bottom

safety

cover

which

eliminates

any

possibility

of

mechanical,

hazard.

Comprehensive

installation

instructions

are

included

with

each

base.

Prior

to

mounting

upon

a

base,

the

audio

cable

must

be

installed

on

your

BTC

unit

as

per

page

8

of

this

booklet.

PROPER

INSTALLATION

IS

EXTREMELY

IMPORTANT.

DO

NOT

INSTALL

THIS

UNIT

ON

ANY

DEVICE

OTHER

THAN

THE

OFFICIAL

B-20

OR

WB-20

BASES.

5

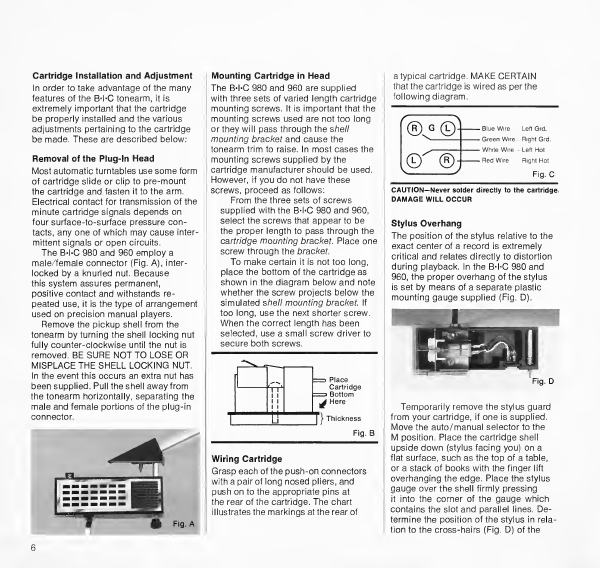

Cartridge

Installation

and

Adjustment

In

order

to

take

advantage

of

the

many

features

of

the

B-l-C

tonearm,

it

is

extremely

important

that

the

cartridge

be

properly

installed

and

the

various

adjustments

pertaining

to

the

cartridge

be

made.

These

are

described

below:

Removal

of

the

Plug-In

Head

Most

automatic

turntables

use

some

form

of

cartridge

slide

or

clip

to

pre-mount

the

cartridge

and

fasten

it

to

the

arm.

Electrical

contact

for

transmission

of

the

minute

cartridge

signals

depends

on

four

surface-to-surface

pressure

con¬

tacts,

any

one

of

which

may

cause

inter¬

mittent

signals

or

open

circuits.

The

B-l-C

980

and

960

employ

a

male/female

connector

(Fig.

A),

inter¬

locked

by

a

knurled

nut.

Because

this

system

assures

permanent,

positive

contact

and

withstands

re¬

peated

use,

it

is

the

type

of

arrangement

used

on

precision

manual

players.

Remove

the

pickup

shell

from

the

tonearm

by

turning

the

shell

locking

nut

fully

counter-clockwise

until

the

nut

is

removed.

BE

SURE

NOT

TO

LOSE

OR

MISPLACE

THE

SHELL

LOCKING

NUT.

In

the

event

this

occurs

an

extra

nut

has

been

supplied.

Pull

the

shell

away

from

the

tonearm

horizontally,

separating

the

male

and

female

portions

of

the

plug-in

connector.

6

Mounting

Cartridge

in

Head

The

B-l-C

980

and

960

are

supplied

with

three

sets

of

varied

length

cartridge

mounting

screws.

It

is

important

that

the

mounting

screws

used

are

not

too

long

or

they

will

pass

through

the

shell

mounting

bracket

and

cause

the

tonearm

trim

to

raise.

In

most

cases

the

mounting

screws

supplied

by

the

cartridge

manufacturer

should

be

used.

However,

if

you

do

not

have

these

screws,

proceed

as

follows:

From

the

three

sets

of

screws

supplied

with

the

B-l-C

980

and

960,

select

the

screws

that

appear

to

be

the

proper

length

to

pass

through

the

cartridge

mounting

brackef.

Place

one

screw

through

the

bracket.

To

make

certain

it

is

not

too

long,

place

the

bottom

of

the

cartridge

as

shown

in

the

diagram

below

and

note

whether

the

screw

projects

below

the

simulated

shell

mounting

bracket.

If

too

long,

use

the

next

shorter

screw.

When

the

correct

length

has

been

selected,

use

a

small

screw

driver

to

secure

both

screws.

Cartridge

=

Bottom

^

Here

Wiring

Cartridge

Grasp

each

of

the

push-on

connectors

with

a

pair

of

long

nosed

pliers,

and

push

on

to

the

appropriate

pins

at

the

rear

of

the

cartridge.

The

chart

illustrates

the

markings

at

the

rear

of

atypical

cartridge.

MAKE

CERTAIN

that

the

cartridge

is

wired

as

per

the

following

diagram.

®

G

©1

-

B

,ueWire

LeftGrd

-Green

Wire=-

Right

Grd.

©

®

I

—

Red

Wire

=

R

ght

Hot

^-

'

Fig.

C

CAUTION—Never

solder

directly

to

the

cartridge.

DAMAGE

WILL

OCCUR

Stylus

Overhang

The

position

of

the

stylus

relative

to

the

exact

center

of

a

record

is

extremely

critical

and

relates

directly

to

distortion

during

playback.

In

the

B-l-C

980

and

960,

the

proper

overhang

of

the

stylus

is

set

by

means

of

a

separate

plastic

mounting

gauge

supplied

(Fig.

D).

Fig.

D

Temporarily

remove

the

stylus

guard

from

your

cartridge,

if

one

is

supplied.

Move

the

auto/manual

selector

to

the

M

position.

Place

the

cartridge

shell

upside

down

(stylus

facing

you)

on

a

flat

surface,

such

as

the

top

of

a

table,

or

a

stack

of

books

with

the

finger

lift

overhanging

the

edge.

Place

the

stylus

gauge

over

the

shell

firmly

pressing

it

into

the

corner

of

the

gauge

which

contains

the

slot

and

parallel

lines.

De¬

termine

the

position

of

the

stylus

in

rela¬

tion

to

the

cross-hairs

(Fig.

D)

of

the

gauge.

Loosen

the

cartridge

mounting

screws

and

move

the

cartridge

until

the

stylus

tip

lies

directly

under

the

center

of

the

cross-hairs.

Remove

the

gauge

from

the

shell

and

re-tighten

the

mounting

screws.

Re-check

alignment,

using

the

gauge,

to

make

sure

the

cartridge

has

not

shifted

during

the

tightening

process.

Attach

Shell

to

Tonearm

Line

up

the

hole

in

the

rear

of

the

shell

with

the

pivot

pin

on

the

tonearm

and

engage

the

plug-in

socket

of

the

pickup

head

with

the

pickup

arm

(Fig.

A,

Pg.

6).

(The

connector

in

the

tonearm

is

a

floating,

self-aligning

connector.)

Press

the

pickup

head

into

the

tonearm.

Re-install

the

head

locking

nut

but

do

not

fully

tighten.

Counterweight

Installation

The

counterweight

should

be

installed

on

the

tonearm

in

the

following

manner:

Place

the

counterweight

at

the

end

of

the

tonearm,

with

the

knurl

facing

the

rear,

and

rotate

it

in

a

counter-clock¬

wise

direction

(Fig.

A).

The

counter¬

weight

must

be

assembled

and

taken

off

the

tonearm

only

by

a

winding

action

—not

by

directly

pushing

or

pull¬

ing.

Rotate

the

platter

in

a

clockwise

direction

approximately

5

turns

to

make

certain

that

the

mechanism

is

free

and

the

unit

is

not

in

cycle.

Also,

make

cer¬

tain

that

the

cueing

lever

is

in

the

play

position.

With

the

tonearm

released

from

its

locked

position

and

both

anti¬

skate

and

tracking

force

levers

set

to

0

(zero),

continue

to

rotate

the

counter¬

weight

until

the

tonearm

is

perfectly

balanced,

floating

parallel

to

the

turn¬

table.

When

this

is

accomplished,

the

tonearm

will

be

at

the

approximate

level

of

the

extension

on

the

tonearm

pickup

rest.

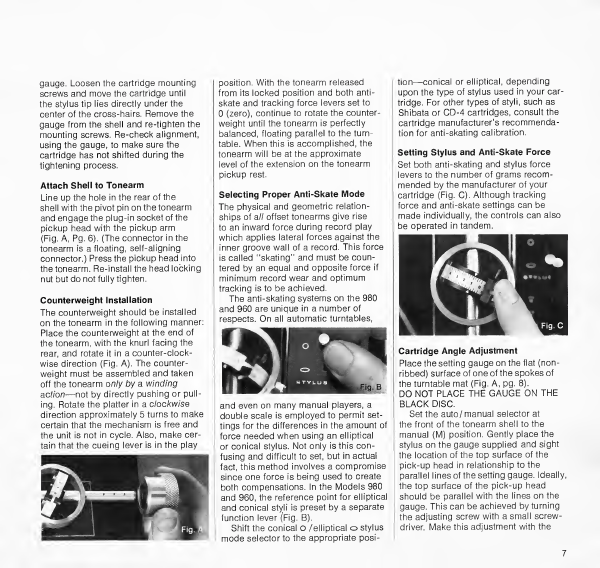

Selecting

Proper

Anti-Skate

Mode

The

physical

and

geometric

relation¬

ships

of

all

offset

tonearms

give

rise

to

an

inward

force

during

record

play

which

applies

lateral

forces

against

the

inner

groove

wall

of

a

record.

This

force

is

called

“skating”

and

must

be

coun¬

tered

by

an

equal

and

opposite

force

if

minimum

record

wear

and

optimum

tracking

is

to

be

achieved.

The

anti-skating

systems

on

the

980

and

960

are

unique

in

a

number

of

respects.

On

all

automatic

turntables,

and

even

on

many

manual

players,

a

double

scale

is

employed

to

permit

set¬

tings

for

the

differences

in

the

amount

of

force

needed

when

using

an

elliptical

or

conical

stylus.

Not

only

is

this

con¬

fusing

and

difficult

to

set,

but

in

actual

fact,

this

method

involves

a

compromise

since

one

force

is

being

used

to

create

both

compensations.

In

the

Models

980

and

960,

the

reference

point

for

elliptical

and

conical

styli

is

preset

by

a

separate

function

lever

(Fig.

B).

Shift

the

conical

o

/elliptical

o

stylus

mode

selector

to

the

appropriate

posi¬

tion—conical

or

elliptical,

depending

upon

the

type

of

stylus

used

in

your

car¬

tridge.

For

other

types

of

styli,

such

as

Shibata

or

CD-4

cartridges,

consult

the

cartridge

manufacturer’s

recommenda¬

tion

for

anti-skating

calibration.

Setting

Stylus

and

Anti-Skate

Force

Set

both

anti-skating

and

stylus

force

levers

to

the

number

of

grams

recom¬

mended

by

the

manufacturer

of

your

cartridge

(Fig.

C).

Although

tracking

force

and

anti-skate

settings

can

be

made

individually,

the

controls

can

also

be

operated

in

tandem.

Cartridge

Angle

Adjustment

Place

the

setting

gauge

on

the

flat

(non-

ribbed)

surface

of

one

of

the

spokes

of

the

turntable

mat

(Fig.

A,

pg.

8).

DO

NOT

PLACE

THE

GAUGE

ON

THE

BLACK

DISC.

Set

the

auto/

manual

selector

at

the

front

of

the

tonearm

shell

to

the

manual

(M)

position.

Gently

place

the

stylus

on

the

gauge

supplied

and

sight

the

location

of

the

top

surface

of

the

pick-up

head

in

relationship

to

the

parallel

lines

of

the

setting

gauge.

Ideally,

the

top

surface

of

the

pick-up

head

should

be

parallel

with

the

lines

on

the

gauge.

This

can

be

achieved

by

turning

the

adjusting

screw

with

a

small

screw¬

driver.

Make

this

adjustment

with

the

tonearm

elevated

over

the

gauge

to

avoid

any

damage

to

your

stylus

(Fig.

A).

Lower

to

gauge

and

re-check.

Once

the

correct

position

is

achieved,

fully

tighten

the

pick-up

head

locking

nut.

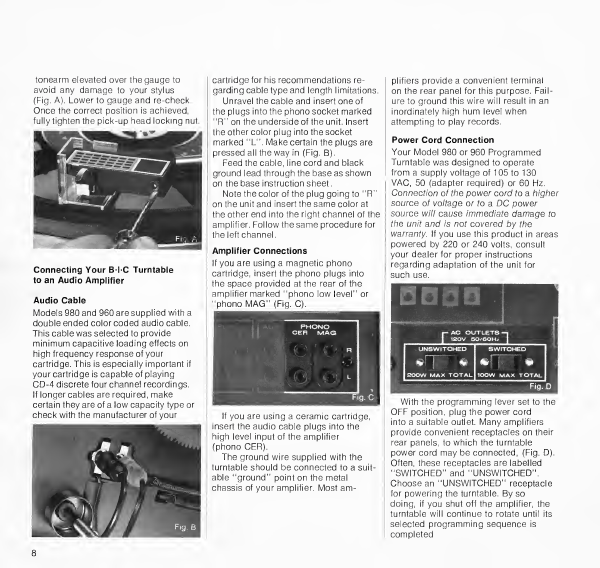

Connecting

Your

B

I

C

Turntable

to

an

Audio

Amplifier

Audio

Cable

Models

980

and

960

are

supplied

with

a

double

ended

color

coded

audio

cable.

This

cable

was

selected

to

provide

minimum

capacitive

loading

effects

on

high

frequency

response

of

your

cartridge.

This

is

especially

important

if

your

cartridge

is

capable

of

playing

CD-4

discrete

four

channel

recordings.

If

longer

cables

are

required,

make

certain

they

are

of

a

low

capacity

type

or

check

with

the

manufacturer

of

your

cartridge

for

his

recommendations

re¬

garding

cable

type

and

length

limitations.

Unravel

the

cable

and

insert

one

of

the

plugs

into

the

phono

socket

marked

“R"

on

the

underside

of

the

unit.

Insert

the

other

color

plug

into

the

socket

marked

“L”.

Make

certain

the

plugs

are

pressed

all

the

way

in

(Fig.

B).

Feed

the

cable,

line

cord

and

black

ground

lead

through

the

base

as

shown

on

the

base

instruction

sheet.

Note

the

color

of

the

plug

going

to

"R"

on

the

unit

and

insert

the

same

color

at

the

other

end

into

the

right

channel

of

the

amplifier.

Follow

the

same

procedure

for

the

left

channel.

Amplifier

Connections

If

you

are

using

a

magnetic

phono

cartridge,

insert

the

phono

plugs

into

the

space

provided

at

the

rear

of

the

amplifier

marked

“phono

low

level"

or

“phono

MAG”

(Fig.

C).

If

you

are

using

a

ceramic

cartridge,

insert

the

audio

cable

plugs

into

the

high

level

input

of

the

amplifier

(phono

CER).

The

ground

wire

supplied

with

the

turntable

should

be

connected

to

a

suit¬

able

“ground”

point

on

the

metal

chassis

of

your

amplifier.

Most

am¬

plifiers

provide

a

convenient

terminal

on

the

rear

panel

for

this

purpose.

Fail¬

ure

to

ground

this

wire

will

result

in

an

inordinately

high

hum

level

when

attempting

to

play

records.

Power

Cord

Connection

Your

Model

980

or

960

Programmed

Turntable

was

designed

to

operate

from

a

supply

voltage

of

105

to

130

VAC,

50

(adapter

required)

or

60

Hz.

Connection

of

the

power

cord

to

a

higher

source

of

voltage

or

to

a

DC

power

source

will

cause

immediate

damage

to

the

unit

and

is

not

covered

by

the

warranty.

If

you

use

this

product

in

areas

powered

by

220

or

240

volts,

consult

your

dealer

for

proper

instructions

regarding

adaptation

of

the

unit

for

such

use.

With

the

programming

lever

set

to

the

OFF

position,

plug

the

power

cord

into

a

suitable

outlet.

Many

amplifiers

provide

convenient

receptacles

on

their

rear

panels,

to

which

the

turntable

power

cord

may

be

connected,

(Fig.

D).

Often,

these

receptacles

are

labelled

“SWITCHED”

and

“UNSWITCHED”.

Choose

an

“UNSWITCHED”

receptacle

for

powering

the

turntable.

By

so

doing,

if

you

shut

off

the

amplifier,

the

turntable

will

continue

to

rotate

until

its

selected

programming

sequence

is

completed,

Operating

Procedure

Before

attempting

to

play

records

on

your

B-l-C

Belt

Drive

Programmed

Turn¬

table,

make

certain

that

the

tonearm

retaining

lock

(Fig.

A)

bn

the

tonearm

rest

is

loosened

by

moving

it

to

the

right

with

forefinger.

Most

cartridges

are

fit¬

ted

with

a

stylus

guard

or

protective

cover.

Make

certain

this

cover

is

re¬

moved

or

pivoted

so

as

to

expose

the

stylus

tip.

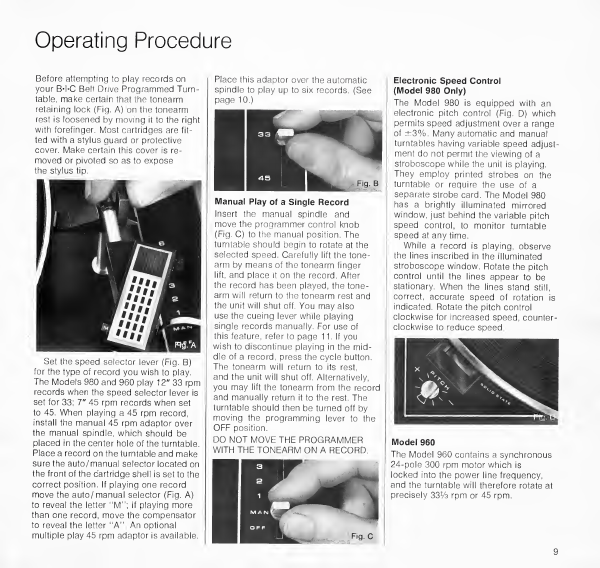

Set

the

speed

selector

lever

(Fig.

B)

for

the

type

of

record

you

wish

to

play.

The

Models

980

and

960

play

12"

33

rpm

records

when

the

speed

selector

lever

is

set

for

33;

7"

45

rpm

records

when

set

to

45.

When

playing

a

45

rpm

record,

install

the

manual

45

rpm

adaptor

over

the

manual

spindle,

which

should

be

placed

in

the

center

hole

of

the

turntable.

Place

a

record

on

the

turntable

and

make

sure

the

auto/manual

selector

located

on

the

front

of

the

cartridge

shell

is

set

to

the

correct

position.

If

playing

one

record

move

the

auto/

manual

selector

(Fig.

A)

to

reveal

the

letter

“M”;

if

playing

more

than

one

record,

move

the

compensator

to

reveal

the

letter

“A”.

An

optional

multiple

play

45

rpm

adaptor

is

available.

Place

this

adaptor

over

the

automatic

spindle

to

play

up

to

six

records-.

(See

page

10.)

Manual

Play

of

a

Single

Record

Insert

the

manual

spindle

and

move

the

programmer

control

knob

(Fig.

C)

to

the

manual

position.

The

turntable

should

begin

to

rotate

at

the

selected

speed.

Carefully

lift

the

tone¬

arm

by

means

of

the

tonearm

finger

lift,

and

place

it

on

the

record.

After

the

record

has

been

played,

the

tone¬

arm

will

return

to

the

tonearm

rest

and

the

unit

will

shut

off.

You

may

also

use

the

cueing

lever

while

playing

single

records

manually.

For

use

of

this

feature,

refer

to

page

11.

If

you

wish

to

discontinue

playing

in

the

mid¬

dle

of

a

record,

press

the

cycle

button.

The

tonearm

will

return

to

its

rest,

and

the

unit

will

shut

off.

Alternatively,

you

may

lift

the

tonearm

from

the

record

and

manually

return

it

to

the

rest.

The

turntable

should

then

be

turned

off

by

moving

the

programming

lever

to

the

OFF

position.

DO

NOT

MOVE

THE

PROGRAMMER

WITH

THE

TONEARM

ON

A

RECORD.

Electronic

Speed

Control

(Model

980

Only)

The

Model

980

is

equipped

with

an

electronic

pitch

control

(Fig.

D)

which

permits

speed

adjustment

over

a

range

of

±3%.

Many

automatic

and

manual

turntables

having

variable

speed

adjust¬

ment

do

not

permit

the

viewing

of

a

stroboscope

while

the

unit

is

playing.

They

employ

printed

strobes

on

the

turntable

or

require

the

use

of

a

separate

strobe

card.

The

Model

980

has

a

brightly

illuminated

mirrored

window,

just

behind

the

variable

pitch

speed

control,

to

monitor

turntable

speed

at

any

time.

While

a

record

is

playing,

observe

the

lines

inscribed

in

the

illuminated

stroboscope

window.

Rotate

the

pitch

control

until

the

lines

appear

to

be

stationary.

When

the

lines

stand

still,

correct,

accurate

speed

of

rotation

is

indicated.

Rotate

the

pitch

control

clockwise

for

increased

speed,

counter¬

clockwise

to

reduce

speed.

Model

960

The

Model

960

contains

a

synchronous

24-pole

300

rpm

motor

which

is

locked

into

the

power

line

frequency,

and

the

turntable

will

therefore

rotate

at

precisely

331/3

rpm

or

45

rpm.

9

Repeat

Play

of

a

Single

Record

Here

is

another

BTC

feature:

If

you

would

like

to

hear

one

twelve-inch

record

played

three

times,

simply

advance

the

.

programmer

to

the

number

3.

With

the

tonearm

on

the

pickup

rest,

depress

the

cycle

button

and

the

unit

will

play

the

record

three

times

and

shut

off.

Automatic

Play

of

a

Single

Record

To

play

a

single

record

automatically,

advance

the

programmer

to

the

number

1

setting

and

depress

the

cycle

button.

This

cycle

button

initiates

totally

auto¬

matic

operation.

The

arm

rises,

comes

to

the

edge

of

the

record,

and

is

gently

lowered.

At

the

end

of

record

play,

the

tonearm

returns

to

the-rest

and

the

machine

automatically

shuts

off.

If

you

move

the

programmer

to

the

number

1

setting

and

place

the

tonearm

on

the

record,

the

unit

will

not

shut

off

at

the

end

of

the

record,

but

will

continue

to

play

the

record

one

more

time.

Turning

Off

the

Unit

The

unit

can

be

turned

off

at

any

time

in

one

of

two

ways:

The

cycle

button

can

be

depressed

fb

advance

the

programming

cycle

to

ttfe

next

lower

program

number

until

the

“MAN"

position

is

reached.

Depressing

the

cycle

button

once

again

will

cause

the

tonearm

to

return

to

the

tonearm

rest

and

complete

shut

off

of

the

turntable.

Alternatively,

the

tonearm

can

be

lifted

manually

by

means

of

the

tonearm

finger

lift

and

returned

to

the

tonearm

rest.

The

programming

lever

should

then

be

moved

to

the

OFF

position

to

turn

off

the

unit

(Fig.

A).

Automatic

Multiple

Record

Play

Your

Model

980

or

960

can

be

used

to

play

multiple

records

automatically,

but

with

important

differences

when

com¬

pared

with

units

which

are

commonly

categorized

as

“automatic

turntables”.

The

B-l-C

mechanism

is

exceptionally

simple,

with

a

minimum

number

of

moving

parts.

Records

are

handled

with

two-point

support,

as

opposed

to

the

umbrella-

type

single-support

system

commonly

used.

The

BTC

system

stabilizes

the

records

and

insures

reliable

dropping.

There

are

other

automatic

turntables

that

use

a

two-point

record

support

system,

but

the

980

and

960

differ

in

that

automatic

shut-off

is

completely

independent

of

the

center

automatic

spindle.

This

eliminates

the

critical

sensing

nature

of

the

spindle

and

is

one

of

the

reasons

for

the

reliable

changing

capabilities

of

the

B-l-C

unit.

This

design

also

makes

it

much

simpler

to

accommodate

records

with

variations

in

the

center

hole

diameter

or

thickness.

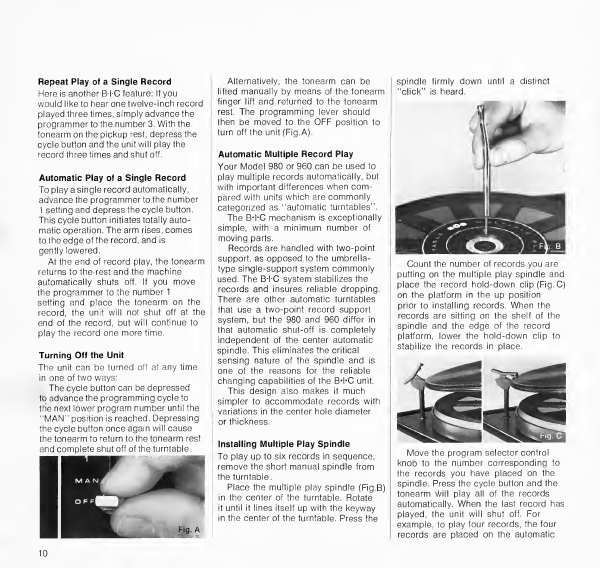

Installing

Multiple

Play

Spindle

To

play

up

to

six

records

in

sequence,

remove

the

short

manual

spindle

from

the

turntable.

Place

the

multiple

play

spindle

(Fig.B)

in

the

center

of

the

turntable.

Rotate

it

until

it

lines

itself

up

with

the

keyway

in

the

center

of

the

turntable.

Press

the

spindle

firmly

down

until

a

distinct

“click”

is

heard.

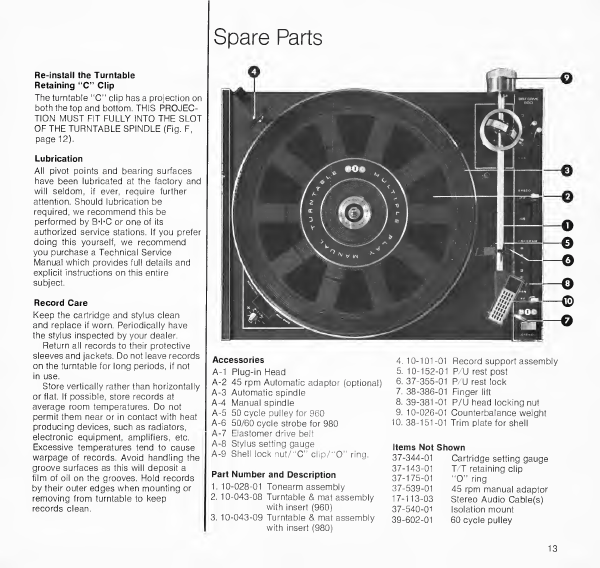

Count

the

number

of

records

you

are

putting

on

the

multiple

play

spindle

and

place

the

record

hold-down

clip

(Fig.

C)

on

the

platform

in

the

up

position

prior

to

installing

records.

When

the

records

are

sitting

on

the

shelf

of

the

spindle

and

the

edge

of

the

record

platform,

lower

the

hold-down

clip

to

stabilize

the

records

in

place.

Move

the

program

selector

control

knob

to

the

number

corresponding

to

the

records

you

have

placed

on

the

spindle.

Press

the

cycle

button

and

the

tonearm

Will

play

all

of

the

records

automatically.

When

the

last

record

has

played,

the

unit

will

shut

off.

For

example,

to

play

four

records,

the

four

records

are

placed

on

the

automatic

10

spindle

and

the

programmer

is

advanced

to

4.

The

cycle

button

is

depressed,

the

four

records

play

and

the

programmer

determines

when

it

is

to

shut

off.

Multiple

Play

Plus

Repeat

of

the

Last

Record

If

you

wish

to

play

less

than

six

records

and

would

like

the

last

record

to

be

repeated

one

or

more

times,

simply

move

the

program

selector

knob

to

the

number

of

records

plus

the

number

of

additional

plays

desired.

For

example,

if

three

records

are

on

the

spindle

and

you

wish

the

last

record

to

play

once

and

repeat

three

times,

simply

set

the

program

control

to

the

number

6.

(Fig.

A).

Removing

Multiple

Play

Spindle

All

records

must

first

be

removed.

To

remove

the

records,

tilt

the

stack

down

and

away

from

the

record

platform

and

lift

up.

The

automatic

spindle

can

then

be

removed

by

grasping

and

lifting

straight

up.

Cueing

and

Pause

Control

The

cueing

lever

(Fig.

B)

is

used

to

raise

or

lower

the

tonearm

during

automatic

or

manual

play.

Moving

the

control

forward

raises

the

tonearm,

pushing

it

back

lowers

the

tonearm.

Cueing

Rate

Adjustment

Today,

most

manual

and

automatic

turntables

have

a

cueing

device,

and

many

are

damped

in

both

upward

and

downward

motions.

Flowever,

whether

damping

is

accomplished

by

dashpots,

springs,

or

other

devices,

they

are

all

pre-set

at

the

factory.

This

poses

two

problems:

First,

temperature

can

affect

the

rate

of

cueing

so

that

in

hot

climates

the

rate

of

drop

is

fast

(frequently

too

fast)

and

in

cold

weather,

may

be

too

slow.

Second,

the

user

normally

has

his

own

preferences

as

to

the

speed

at

which

he

wants

the

cueing

to

operate,

and

has

been

powerless

to

control

it.

The

Models

980

and

960

incorporate,

for

the

first

time

in

any

tonearm,

a

variable

control

with

which

the

owner

can

set

the

rate

of

cueing

to

his

preference

or

compensate

for

tempera¬

ture

variations.

The

cueing

rate

can

be

increased

or

decreased

by

a

knurled

control

knob,

easily

accessible

from

the

top

surface

of

the

unit.

(Fig.

C).

Turning

the

knob

in

a

clockwise

dir¬

ection

will

decrease

the

rate

of

cueing;

counter-clockwise

rotation

will

increase

the

cueing

rate.

When

turning

the

knob

to'its

maximum

up

or

down

position,

do

not

force

it

beyond

the

stop

point.

Stylus

Set-Down

Adjustment

and

Tonearm

Height

Your

Model

980

or

960

was

carefully

assembled

and

all

necessary

adjust¬

ments

were

performed

at

the

factory.

There

are,

however,

two

minor

adjust¬

ments

that

may

have

to

be

made

to

suit

your

particular

cartridge.

One

adjust¬

ment

controls

the

point

at

which

the

sty¬

lus

lands

upon

the

record’s

surface.

All

records

contain

a

groove

guard

(Fig.'D)

Ideally,

the

stylus

should

land

inside

the

groove

guard

just

before

the

recorded

portion

of

the

record

(Fig.

D).

The

tone¬

arm

set-down

adjusting

screw

controls

the

exact

point

of

set-down.

To

re¬

position

the

tonearm

to

land

inside

the

groove

guard,

turn

the

adjusting

INCORRECT

CORRECT

A\\W\WW\\$S)

Fig.

D

CROSS

SECTION

RECORD

11

Maintenance

and

Record

Care

Belt

Installation

When

the

turntable

is

removed,

the

drive

belt

will

come

off

the

rim

of

the

turntable.

To

re-install

the

belt

onto

the

platter,

place

the

belt

on

the

drive

rim

of

the

turntable

(Fig.

E).

Grasp

the

belt

and

engage

either

one

of

the

two

belt

.

retaining

studs

projecting

from

the

turntable.

Do

not

twist

belt.

On

the

top

surface

of

the

platter

there

are

two

indi¬

cators

(Fig.

F.

These

indicators

line

up

with

the

two

studs.

When

re-installing

the

platter,

locate

the

turntable

so

that

the

indicator

for

the

stud

retaining

the

belt

is

facing

your

left

(parallel

to

front

of

machine—Fig.

F).

Make

certain

the

speed

control

is

set

at

the

33

position.

Place

the

turntable

on

the

spindle

and

rotate

the

turntable

clockwise

one

full

turn.

The

belt

will

automatically

engage

the

motor

pulley.

Turntable

Removal

It

is

not

necessary

to

remove

the

turntable

mat

in

order

to

remove

the

turntable.

The

turntable

assembly

is

held

in

place

by

a

nylon

retaining

clip

located

in

the

center.

Remove

the

spindle

and

lift

one

edge

of

the

retaining

clip

with

a

screwdriver

until

the

edge

of

the

clip

is

lifted

free

(Fig.

C).

Once

this

has

been

done

proceed

in

p

“0”

ring

and

washer

onto

the

turntable

spindle.

Be

sure

the

“O”

ring

is

atop

the

washer.

Do

not

lose

these

parts!

When

the

turntable

is

re-installed,

the

rubber

"0”

ring

and

washer

(already

on

the

spindle)

will

automatically

align

with

the

bottom

of

the

turntable

hub

B

(Fig..D).

screw

(Fig.

A)

until

tonearm

is

at

the

correct

position.

In

rare

instances,

when

very

deep

or

very

shallow

cartridges

are

used,

adjustment

may

have

to

be

performed

to

the

pickup

height.

This

adjustment

controls

the

amount

of

lift

to

the

tonearm

in

both

automatic

play

and

manual

cueing.

The

stylus

should

lift

high

enough

to

clear

six

records

and

the

tonearm

extension.

If

adjusted

too

high,

the

top

of

the

shell

will

touch

the

bottom

record

on

the

stack.

Turning

the

adjusting

screw

(Fig.

B)

counter¬

clockwise

will

raise

the

tonearm;

clockwise

rotation

will

lower

the

tonearm.

the

same

manner

with

the

other

edge

of

the

clip,

remove,

and

lift

off

the

turntable

(Fig.

D).

A

rubber

“O"

ring

and

washer

may

come

off

with

the

turntable.

Re-insert

the

12

Spare

Parts

Re-install

the

Turntable

Retaining

“C”

Clip

The

turntable

"C"

clip

has

a

projection

on

both

the

top

and

botfom.

THIS

PROJEC¬

TION

MUST

FIT

FULLY

INTO

THE

SLOT

OF

THE

TURNTABLE

SPINDLE

(Fig.

F,

page

12).

Lubrication

All

pivot

points

and

bearing

surfaces

have

been

lubricated

at

the

factory

and

will

seldom,

if

ever,

require

further

attention.

Should

lubrication

be

required,

we

recommend

this

be

performed

by

B-l-C

or

one

of

its

authorized

service

stations.

If

you

prefer

doing

this

yourself,

we

recommend

you

purchase

a

Technical

Service

Manual

which

provides

full

details

and

explicit

instructions

on

this

entire

subject.

Record

Care

Keep

the

cartridge

and

stylus

clean

and

replace

if

worn.

Periodically

have

the

stylus

inspected

by

your

dealer.

Return

all

records

to

their

protective

sleeves

and

jackets.

Do

not

leave

records

on

the

turntable

for

long

periods,

if

not

in

use.

Store

vertically

rather

than

horizontally

or

flat.

If

possible,

store

records

at

average

room

temperatures.

Do

not

permit

them

near

or

in

contact

with

heat

producing

devices,

such

as

radiators,

electronic

equipment,

amplifiers,

etc.

Excessive

temperatures

tend

to

cause

warpage

of

records.

Avoid

handling

the

groove

surfaces

as

this

will

deposit

a

film

of

oil

on

the

grooves.

Hold

records

by

their

outer

edges

when

mounting

or

removing

from

turntable

to

keep

records

clean.

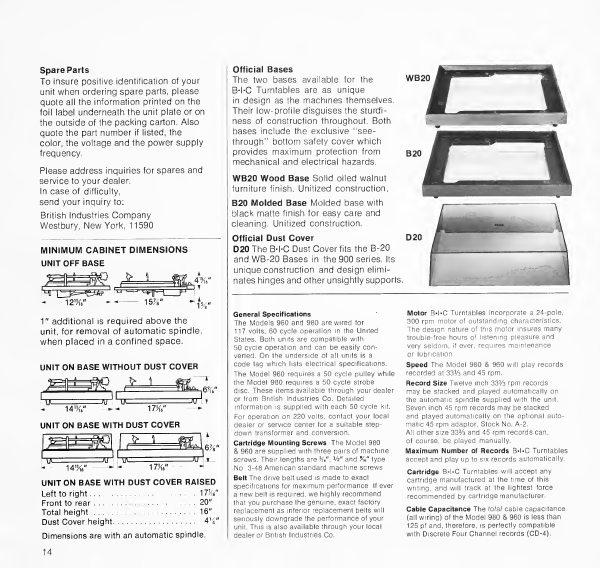

Accessories

A-1

Plug-in

Head

A-2

45

rpm

Automatic

adaptor

(optional)

A-3

Automatic

spindle

A-4

Manual

spindle

A-5

50

cycle

pul

ley

for

960

A-6

50/60

cycle

strobe

for

980

A-7

Elastomer

drive

belt

A-8

Stylus

setting

gauge

A-9

Shell

lock

nut/"C"

clip/'‘0"

ring.

Part

Number

and

Description

1.

10-028-01

Tonearm

assembly

2.

10-043-08

Turntable

&

mat

assembly

with

insert

(960)

3.

10-043-09

Turntable

&

mat

assembly

with

insert

(980)

4.10-101

-01

Record

support

assembly

5.

10-152-01

P/U

rest

post

6.

37-355-01

P/U

rest

lock

7.

38-386-01

Finger

lift

8.39-381-01

P/U

head

locking

nut

9.

10-026-01

Counterbalance

weight

10.

38-151-01

Trim

plate

for

shell

Items

Not

Shown

37-344-01

Cartridge

setting

gauge

37-143-01

T/T

retaining

clip

37-175-01

"O"

ring

37-539-01

45

rpm

manual

adaptor

17-113-03

Stereo

Audio

Cable(s)

37-540-01

Isolation

mount

39-602-01

60

cycle

pulley

13

Spare

Parts

To

insure

positive

identification

of

your

unit

when

ordering

spare

parts,

please

quote

all

the

information

printed

on

the

foil

label

underneath

the

unit

plate

or

on

the

outside

of

the

packing

carton.

Also

quote

the

part

number

if

listed,

the

color,

the

voltage

and

the

power

supply

frequency.

Please

address

inquiries

for

spares

and

service

to

your

dealer.

In

case

of

difficulty,

send

your

inquiry

to:

British

Industries

Company

Westbury,

New

York,

11590

MINIMUM

CABINET

DIMENSIONS

UNITOFF

BASE

1"

additional

is

required

above

the

unit,

for

removal

of

automatic

spindle,

when

placed

in

a

confined

space.

UNIT

ON

BASE

WITHOUT

DUST

COVER

'

|

,

*

1

■

Ut

-iu

m

[

J-

-

14%"

17%"

UNIT

ON

BASE

WITH

DUST

COVER

UNIT

ON

BASE

WITH

DUST

COVER

RAISED

Left

to

right.17%"

Front

to

rear.20"

Total

height

.16"

Dust

Cover

height.

4

Dimensions

are

with

an

automatic

spindle.

14

Official

Bases

The

two

bases

available

for

the

B-l-C

Turntables

are

as

unique

in

design

as

the

machines

themselves.

Their

low-profile

disguises

the

sturdi¬

ness

of

construction

throughout.

Both

bases

include

the

exclusive

“see-

through’

1

bottom

safety

cover

which

provides

maximum

protection

from

mechanical

and

electrical

hazards.

WB20

Wood

Base

Solid

oiled

walnut

furniture

finish.

Unitized

construction.

B20

Molded

Base

Molded

base

with

black

matte

finish

for

easy

care

and

cleaning.

Unitized

construction.

Motor

B-l-C

Turntables

incorporate

a

24-pole,

300

rpm

motor

of

outstanding

characteristics.

The

design

nature

of

this

motor

insures

many

trouble-free

hours

of

listening

pleasure

and

very

seldom,

if

ever,

requires

maintenance

or

lubrication.

Speed

The

Model

980

&

960

will

play

records

recorded

at

3316

and

45

rpm.

Record

Size

Twelve

inch

3316

rpm

records

may

be

stacked

and

played

automatically

on

the

automatic

spindle

supplied

with

the

unit.

Seven

inch

45

rpm

records

may

be

stacked

and

played

automatically

on

the

optional

auto¬

matic

45

rpm

adaptor,

Stock

No.

A-2.

All

other

size

3316

and

45

rpm

records

can,

of

course,

be

played

manually.

Maximum

Number

of

Records

B-l-C

Turntables

accept

and

play

up

to

six

records

automatically.

Cartridge

B-l-C

Turntables

will

accept

any

cartridge

manufactured

at

the

time

of

this

writing,

and

will

track

at

the

lightest

force

recommended

by

cartridge

manufacturer.

Cable

Capacitance

The

total

cable

capacitance

(all

wiring)

of

the

Model

980

&

960

is

less

than

125

pf

and,

therefore,

is

perfectly

compatible

with

Discrete

Four

Channel

records

(CD-4).

Official

Dust

Cover

D20

The

B-l-C

Dust

Cover

fits

the

B-20

and

WB-20

Bases

in

the

900

series.

Its

unique

construction

and

design

elimi¬

nates

hinges

and

other

unsightly

supports.

General

Specifications

The

Models

960

and

980

are

wired

for

117

volts,

60

cycle

operation

in

the

United

States.

Both

units

are

compatible

with

50

cycle

operation

and

can

be

easily

con¬

verted.

On

the

underside

of

all

units

is

a

code

tag

which

lists

electrical

specifications.

The

Model

960

requires

a

50

cycle

pulley

while

the

Model

980

requires

a

50

cycle

strobe

disc.

These

items

available

through

your

dealer

or

from

British

Industries

Co.

Detailed

information

is

supplied

with

each

50

cycle

kit.

For

operation

on

220

volts,

contact

your

local

dealer

or

service

center

for

a

suitable

step-

down

transformer

and

conversion.

Cartridge

Mounting

Screws

The

Model

980

&

960

are

supplied

with

three

pairs

of

machine

screws.

Their

lengths

are

W,

16"

and

%"

type

No.

3-48

American

standard

machine

screws.

Belt

The

drive

belt

used

is

made

to

exact

specifications

for

maximum

performance.

If

ever

a

new

belt

is

required,

we

highly

recommend

that

you

purchase

the

genuine,

exact

factory

replacement

as

inferior

replacement

belts

will

seriously

downgrade

the

performance

of

your

unit.

This

is

also

available

through

your

local

dealer

or

British

Industries

Co.

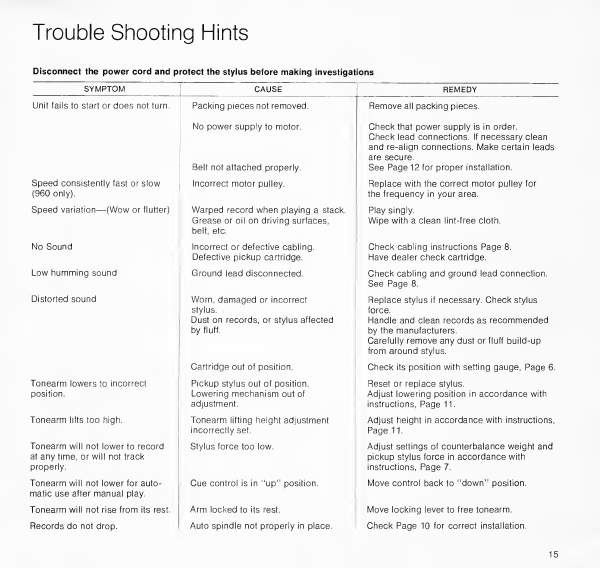

Trouble

Shooting

Hints

Disconnect

the

power

cord

and

protect

the

stylus

before

making

investigations

SYMPTOM

CAUSE

REMEDY

Unit

fails

to

start

or

does

not

turn.

Packing

pieces

not

removed.

Remove

all

packing

pieces.

No

power

supply

to

motor.

Belt

not

attached

properly.

Check

that

power

supply

is

in

order.

Check

lead

connections.

If

necessary

clean

and

re-align

connections.

Make

certain

leads

are

secure.

See

Page

12

for

proper

installation.

Speed

consistently

fast

or

slow

(960

only).

Incorrect

motor

pulley.

Replace

with

the

correct

motor

pulley

for

the

frequency

in

your

area.

Speed

variation—(Wow

or

flutter)

Warped

record

when

playing

a

stack.

Grease

or

oil

on

driving

surfaces,

belt,

etc.

Play

singly.

Wipe

with

a

clean

lint-free

cloth.

No

Sound

Incorrect

or

defective

cabling.

Defective

pickup

cartridge.

Check

cabling

instructions

Page

8.

Have

dealer

check

cartridge.

Low

humming

sound

Ground

lead

disconnected.

Check

cabling

and

ground

lead

connection.

See

Page

8.

Distorted

sound

Worn,

damaged

or

incorrect

stylus.

.

Dust

on

records,

or

stylus

affected

by

fluff.

Replace

stylus

if

necessary.

Check

stylus

force.

Handle

and

clean

records

as

recommended

by

the

manufacturers.

Carefully

remove

any

dust

or

fluff

build-up

from

around

stylus.

Cartridge

out

of

position.

Check

its

position

with

setting

gauge,

Page

6.

Tonearm

lowers

to

incorrect

position.

Pickup

stylus

out

of

position.

Lowering

mechanism

out

of

adjustment.

Reset

or

replace

stylus.

Adjust

lowering

position

in

accordance

with

instructions,

Page

11.

Tonearm

lifts

too

high.

Tonearm

lifting

height

adjustment

incorrectly

set.

Adjust

height

in

accordance

with

instructions,

Page

11.

Tonearm

will

not

lower

to

record

at

any

time,

or

will

not

track

properly.

Stylus

force

too

low.

Adjust

settings

of

counterbalance

weight

and

pickup

stylus

force

in

accordance

with

instructions,

Page

7.

Tonearm

will

not

lower

for

auto¬

matic

use

after

manual

play.

Cue

control

is

in

"up”

position.

Move

control

back

to

"down"

position.

Tonearm

will

not

rise

from

its

rest.

Arm

locked

to

its

rest.

Move

locking

lever

to

free

tonearm.

Records

do

not

drop.

Auto

spindle

not

properly

in

place.

Check

Page

10

for

correct

installation.

15

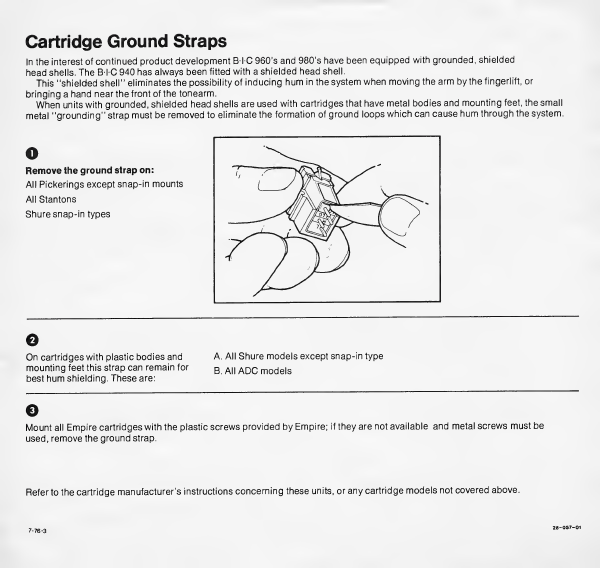

©o©

BRITISH

INDUSTRIES

COMPANY,

Westbury,

N.Y.

11590

U.S.A.

|

Division

of

Avnet,

Inc.

IMPORTANT!

©O©

Amendment

to

all

BIC

Owner’s

Manuals

This

unit

is

supplied

with

four

pairs

of

nylon

screws

which

are

—

W"

—

Vi

"

—

in

length.

Use

only

the

nylon

screws

supplied

when

mounting

the

cartridge

and

choose

the

correct

length

as

per

the

owner’s

manual.

Packed

with

the

screws

is

a

special

insulator.

The

insulator

must

be

installed

beneath

the

cartridge

as

per

the

illustration.

Both

the

nylon

screws

and

insulator

are

non-conductive.

If

this

insulator

is

not

used,

or

if

the

metal

cartridge

mounting

screws

are

used,

hum

will

exist.

DISREGARD

ANY

INFORMATION

IN

THE

OWNER’S

MANUAL

CONCERNING

“REMOVAL

OF

THE

GROUND

STRAP

FROM

THE

CARTRIDGE”.

Illustration

shows

pickup

head

used

in

Models

1000,

980

and

960.

On

the

920

and

940,

mount

in

the

same

manner.

Due

to

their

extreme

length,

certain

Ortofon

cartridges