bierkuhl BOS Cleantec Cleaner 370e User manual

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 506

00 Mikkeli Finland

www.boscleantec

.com

BOS® Cleantec

BOS® CLEANING MACHINES

Operation and Maintenance Manual

Please read this manual carefully before using the machine –

it is essential for ensuring correct and safe operation!

READ ALL SAFETY AND OPERATING INSTRUCTIONS!

KEEP THE MANUAL FOR FUTURE REFERENCE!

Non-observance ofwarnings and instructions mayresultin electricshock,fire and/or severe injuries!

This manual only applies to BOS® Cleaner duct cleaning brushing machines. They may only be used

in dry conditions without any danger of explosion.

The machines are not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience or knowledge as to how to use the machine.

Childrenmust be kept at a distance from themachine.

Disclaimer: This manual has been reviewed, but 100 % accuracy is not guaranteed. As part of our

policyofcontinuousproductdevelopment,wereservetherighttorevisefeaturesandspecifications

of the product. Therefore, any claims based on the data, pictures, drawings or text in this manual

cannot be accepted. We cannot guarantee that there are no errors.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

2

GENERAL NOTES

The products covered by this manual have been manufactured in Finland to existing laws, decrees

and regulations as stated in the Declaration of Conformity below.

The person in charge of machine operation must be acquainted with the construction and

operation of the machine and must ensure safe operation.

The machine may only be used by people who are familiar with it.

Safety features must not be removed, nor must any alterations be made to the way they were

originally installed.

Should it be necessary to install the machine in a way that prevents the operation of any safety

features, the person in charge ofmachine operation must be informed.

The products covered by this manual are only intended for the uses for which they

have been designed and which have been stated in themanual!

The products must not be used for any other purposes!

The machine operator and the person in charge of the machine are liable for any

damage resulting from unintended use!

The manufacturer accepts no liability for any consequences of not using the machine

according to the instructions!

Always store the manual where the operator can referto it.

Read the manual carefully before machine installation and commissioning.

Observethe operatingandmaintenanceinstructions toensuretrouble-freemachine operation.

Observe the safety guidelines.

For maintenance, only use spare parts and components approved by the manufacturer.

The BOS® Cleaner duct cleaning brushes have been designed and constructed in compliance with

general safety and electrical safety guidelines. They are intended for the cleaning and disinfection

of air ducts. BOS® Cleaner BC 370e is forsmall and medium-sized ducts (100–315 mm in diameter),

and BC 750e is for ducts 250–700 mm in diameter.

Powered duct cleaning brush, available in two models: BC 370e for small ducts and BC 750e for

large ducts.

Lightweight and durable, for professional use.

Low power consumption.

Low noise level: <40 dBA.

Continuously variable brush speed 50–560 rpm.

Wide selection ofbrushes for ducts of different sizes and for different types of dirt.

Fast-response electrical pedal for changing the direction of brush rotation.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

3

TECHNICAL DATA

BOS® Cleaner 370e BOS® Cleaner 750e

Operating voltage 240 V 240 V

Frequency 50 Hz 50 Hz

Motor 0.55 kW 0.75 kW

Speed control With the drive converter With the drive converter

Power cord (rubber cable),

3G 3*1.5 mm² 5 m 5 m

Operating switch Yes Yes

Brush speed 50–560 rpm,

continuously variable 50–560 rpm,

continuously variable

Brush/direction control Electrical pedal Electrical pedal

Brush connector M12 M12

Material, housing/drum Painted steel / marine-

grade aluminium

EN AW 5754

Painted steel / marine-

grade aluminium

EN AW 5754

Dimensions (height/width/length) 925/470/690 mm 1200*500*1060

Weight 44 kg 76 kg

IP rating 54 54

Cleaning shaft length 20 m 27 m

Cleaning shaft PA MOQ 18/12 + 10 mm

flexible steel shaft

LDPE outer sheath + 11

mm glass fibre rod, 12

mm steel shaft inside

a PA tube

Shaft mounting adapter

(Easy Service System Adapter) ESSA ESSA

Casters Ø 200 mm Ø 250 mm / Ø 100 mm

locking swivel casters

Indicator Yes Yes

Emergency stop switch Yes Yes

Hour meter In the frequency

converter In the frequency

converter

Max. brush size Ø 350 mm Ø 700 mm

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

4

INTENDED USE

The BOS® Cleaner duct cleaning brushes have been designed for professional use. When working

with the machines, the following safety aspects should be considered:

Protect the machine against moisture and vibration!

ONLY USE THE MACHINE IN DRY CONDITIONS WITHOUT ANY DANGER OF EXPLOSION

or hazardous substances!

Protect the machine against moisture and vibration!

The machine must not get wet during cleaning!

Do not cover the machine during operation!

The information on the type plate must beobserved during maintenance and when

ordering spare parts!

Observe national regulations!

Make sure to use an earthed power source!

Make sure the power cord is intact!

Observe local regulations governing the use of these machines!

No-one must stay in the vicinity of the machine while it is being used for cleaning!

The machine operator shall be liable for any damage resulting from unintended use!

BOS® Cleaner duct cleaning brushes must not be altered in any way.

The manufacturer accepts no liability for any damage resulting from any alterations!

Clean the machine and the shaft carefully after use!

To achieve the best possible results, the machine should only be used with brushes

recommended by the manufacturer!

The type plate is located next to the electric box!

Observe the instructions given on the type plate and in this manual!

PLEASE NOTE THAT THE MACHINE MAY ONLY BE CONNECTED

TO A POWER SOURCE WITH A PROTECTIVE EARTH SYSTEM!

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

5

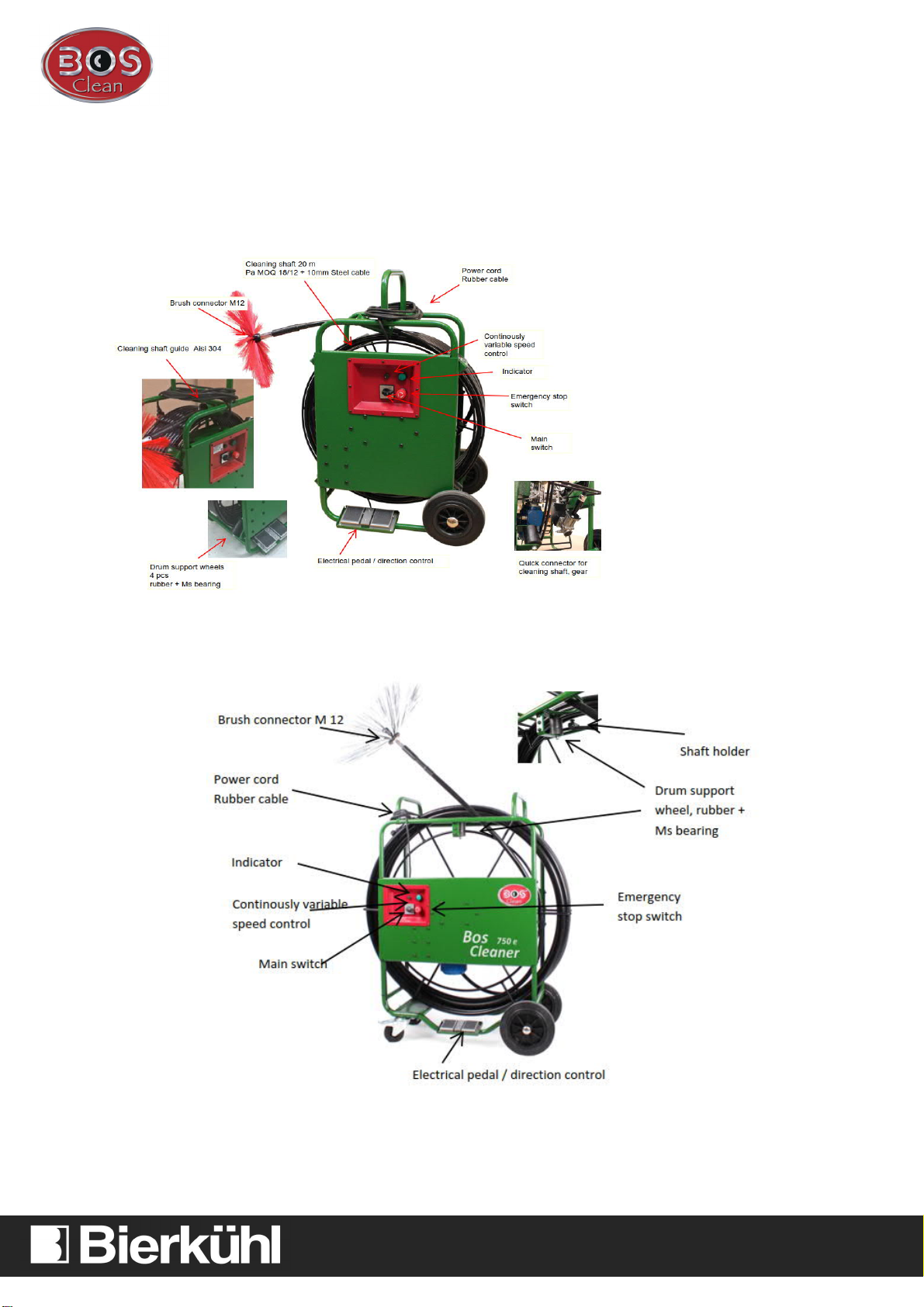

CONSTRUCTION AND CONTROLS

BOS® Cleaner 370e

BOS® Cleaner 750e

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

6

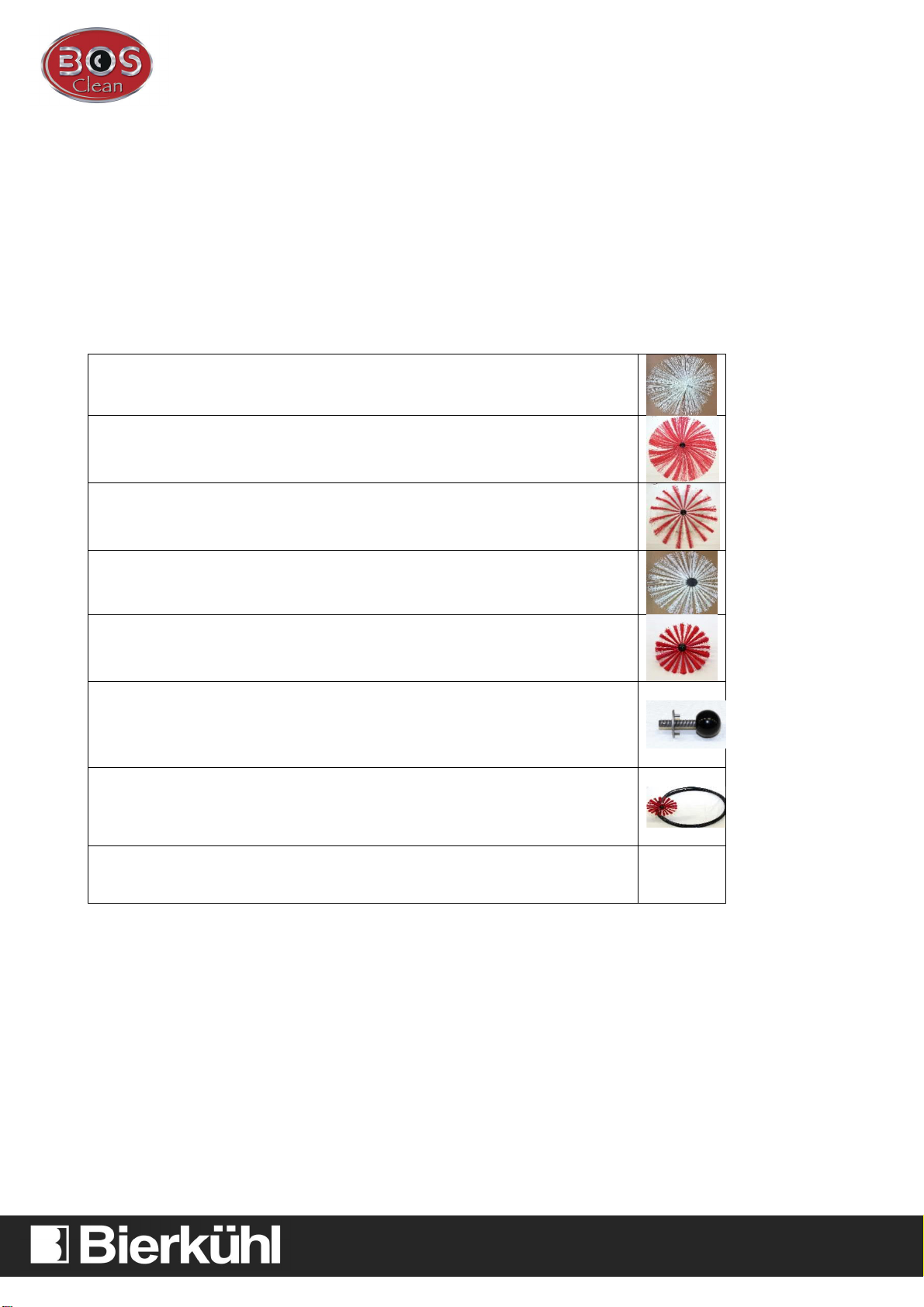

ACCESSORIES AND SPARE PARTS

When ordering spare parts, please always state the model, type and serial number of the machine.

This information can be found on the CE plate, which is located on the inside of the switch panel.

Basic brush M12 100–400 mm, soft,

PP bristle

Soft brush, 200–1000 mm,

plastic centrePEH 300, PES Ø 0.5 mm

Combination brush, disc 200/400–800/1000mm,

plastic centrePEH 300, PES Ø 0.5 mm / nylon (PA 6.6) Ø 0.75 mm

Hard brush, 300—600 mm,

plastic centrePEH 300, nylon(PA 6.6) Ø 1.0 mm

Soft brush M12for small ducts, 125–350mm,

plastic centrePEH 300, PES Ø 0.35mm

Brush adapter for brushes with nylon centre, M12

Ready-to-use shaft

Motor-end and brush-endshaft repair kits

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

7

OPERATING AND SAFETY INSTRUCTIONS

PLEASE CAREFULLY OBSERVETHE FOLLOWING BEFORE AND DURING OPERATION:

The machine operator must ensure that the machine is fit forthe intended purpose.

The machine operator must ensure that the voltage and current supplied match the ratings

on the CE plate.

All legislative requirements must be observed.

There must be no flammable particles or danger of explosion present in the operating

environment.

No flammable or explosive materials or substances must be used or stored at the location

where the machine is used.

The machine must be protected from moisture, vibration and getting wet.

Only use spare parts that are suitable for the machine (are approved by the manufacturer).

Do not cover the machine during operation.

The machine must be kept as clean as possible.

Do not stay continuously in the immediate vicinityofthe machine whenit is in operation.

The machine must not be used in the vicinity of explosive, toxic oraggressive gases.

The operating temperature must not exceed +50 °C or fall below -20 °C.

The machine must not be altered in any way.

It is recommended that these machines are used by two operators at a time, to avoid accidents

caused by the force of the rotating shaft and brush.

The shaft may only be rotated while the brush is inside a duct. Before starting the work, makesure

the brush is properly attached.

The person(s) performing the work must wear a helmet, hearing and respiratory protection, safety

goggles, clothing and footwear as well as other personal protective equipment depending on the

work performed.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

8

OPERATION

1. Transport

Themachine mustbe protected againstdirt andmoistureduring transport.The machinemust not be stored

outdoorsunprotected. Exercise extreme care and caution when moving orlifting the machine. The machine

must betransported in avertical position and securelytied down. Avoid impactsand knocks during transport

and handling.

Before commissioning, inspect the machine to make sure it is exactly as it should be (and without any

transportdamage).

2. Storage

Store the machine in a dry place, protected from weather conditions.

Avoid extreme temperatures (high andlow) during storage.

3. Commissioning

Mount the machine in a vertical position on a flat surface, and make sure to protect it from weather

conditions. Provide for lighting, ventilation and the necessary equipment (platforms, ladders). Protect the

machine against vibration and impacts. Check that all the components are in place and that the machine is

in proper working order. Ensure an adequate flow of cooling air to the motor. The maximum permitted

operatingtemperatureis50°C.Thefrequencyconverterfeaturesanoverheatingprotectionmechanismthat

is triggeredin the caseof motor overheating. The motor works when the temperature is at the correct level.

The machine mustbe powered offwhen not in use.

4. Operation

Before starting any work, make sure the workarea is clearand free ofobstacles that might be in the

way when working.

Wear personal protective equipment.

For efficient cleaning, create a negative pressureinside the ductwork to be cleaned.

Equip the machine with a brush that is suitable for the work. Check the condition of the shaft and

the attachment the brush. Adjust the brush speed to suit the job at hand.

Connect the machine to the power source, andpower it on.

Insert the shaftinto the duct, andstart cleaning.

Feed the shaftsteadily. For best results, rotate the brush both clockwise andcounter-clockwise.

It is recommended to work in pairs when cleaning ducts with a powered duct cleaning brush.

5. Electrical connection

Ensure that the current and voltage supplied are correct and match the ratings given in this manual! The

machine requires single-phase (1~) power of 230 V, 50–60 Hz. Only connect the machine to a power source

with a protective earth system.

Make sure to use an earthed power source!

Make sure the power cord is intact!

Electrical connections mustbe made by a qualified electrician!

Inspect the components of the electrical equipment at regular intervals!

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

9

MAINTENANCE

Remove all dirt and dust from the machine after every use!

Do not use running water for cleaning!

Before starting any maintenance or cleaning work on the machine,

make sure to disconnect it from the power source!

Risk of injury!

Risk of electric shock!

All maintenance and repair work that requires removal of motor guards must be performed by an

authorised service workshop. Only genuine spare parts may be used.

A machine that is in continuous, professional use must be serviced at intervals of one year.

If any electrical or mechanical faults are discovered, the machine must be taken to be serviced

withoutdelay.

During handling and transport, the machine must be protected to prevent further damage and

personal injuries.

Routinemaintenance and care covers cleaning the machineand checkingthe condition ofthe shaft

as well as tightening the steel cable if necessary. A shaft with minor damage can be repaired using

a heat-shrink tube. Any maintenance and repair work on the electrical equipment must be

performed by a professional service workshop authorised by the manufacturer.

The electric motor and the frequency converter must be carefully cleaned using a

damp cloth or low-pressure compressed air!

Any repairs must be performed by a professional service workshop approved by the

manufacturer!

Any connections and repairs of electrical equipment must only be performed by a

licensed electrician!

After every use, all dirt and grease must be removed from the shaft using a mild

detergent!

The manufacturer accepts no liability for any maintenance work performed by a third

party!

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

10

ENVIRONMENT/RECYCLING

Waste materials must be disposed of in compliance with the relevant legislative

requirements and without harming the environment.

A discarded machine or any part of it must not be disposed of together with household

waste!

Discarded machine parts and accessories must be taken to an environmentally

compatible recycling point.

It is recommended that the valuable materials and components contained in the

machine are recycled and reused.

Ifanappropriaterecyclingpointcannot befound,theproductcanalsobereturned totheseller

or manufacturer to be recycled.

Metal parts (housing and motor) can be recycled as scrap metal.

Electronic parts (frequency converter, switches and other electrical components) should be

taken to an authorised recycling facility.

Other parts can be recycled as mixed waste.

Note that the European Directive on waste electrical and electronic equipment and its

implementation in accordance with national law require that discarded electric tools are

collected separately and returned to an approved recycling facility.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

11

WARRANTY

Provided that the operating and maintenance instructions are strictly adhered to, the product is

covered by a 12-month factory warranty starting from the date of purchase.

Any defects discovered during this warranty period are rectified free of charge, provided that

the defect is in materials or components

the defect has occurred during normal use

all maintenance and repair work on the machine have been performed by the

manufactureroranauthorisedrepresentative –themanufactureraccepts noliabilityfor

any maintenance works performed by a third party

a warranty claim has been submitted in writing.

Thewarrantydoesnotcoverdefectsresultingfromnormalwearandtear,negligence,improperuse

or maintenance/repair works not performed by the manufacturer.

The product has been manufactured to existing international regulations. In case of any questions

regarding commissioning or malfunctions, please contact the manufacturer.

For maintenance or warranty repair, the machine should be sent to the following address:

Bierkühl Oy

Pellonlaita 1, 50600 Mikkeli, FINLAND

Tel.: +358 440 178 111

Bierkühl reserves therightto make changes.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and MaintenanceManual

BOS® Cleantec Duct Cleaning Brushes

SIVU

12

DECLARATION OF CONFORMITY

Manufacturer: Bierkühl Oy, Pellonlaita 1, 50600 MIKKELI, FINLAND

Tel.: +358 440 178 111

Website: www.bierkuhl.com

Product designation: Powered duct cleaning brush

Product name: BOS® Cleaner

Intended use: Cleaning of air ducts

Serial number:

Year of manufacture:

We hereby declare that the product named above has been designed to comply with the Finnish

Government Decree on the safety of machinery (400/2008) and meets the requirements of the

Machinery Directive (2006/42/EY).

We also declare that the following Directives and harmonised standards have been applied:

Essential characteristics and performance Harmonised technical specification

Safety of machinery SFS-EN ISO 12100:2010

Electrical equipment of machinery – Part 1:

General requirements SFS-EN 60204-1:2007

Decree on the safety of machinery Finnish Government Decree No. 400/2008

Machine Directive (MD) 2006/42/EY

Low Voltage Directive (LVD) 2014/35/EU

Electromagnetic Compatibility (EMC)

Directive 2004/108/EY

2014/30/EU

Restriction of Hazardous Substances

(RoHS) Directive 2011/65/EU

Waste Electrical and Electronic Equipment

(WEEE) Directive 2012/19/EU

This product conforms to the requirements to achieve CE marking.

Bierkühl Oy, 30 March 2020

Pentti Hiltunen

Managing Director

This manual suits for next models

1

Table of contents