Clean Logix EPX-TM User manual

USER

MANUAL

MODEL NUMBER:

Tote Mixer Delivery System

English (Original Instrucons)

Updated: 07/18/2018

EPX-TM

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 2 of 25 Last Update: 07/18/2018

General

Specicaons

Requirements

Installaon Instrucons

Conguraon

User Management

Scale Calibraon

Chemical Conguraon

Pump Priming

Creang Recipes

Operaon

Dispensing a Recipe

Reporng

Advanced Funcons

Alarms

Troubleshoong

Maintenance

Appendices

Parts Callout

Electrical Schemac

03

03

04

06

07

08

09

10

12

14

16

17

18

19

20

25

!

WARNING:

1. Avoid contact of chemicals with skin and eyes. If contact

occurs, see MSDS sheet for further rst aid measures.

2. Always wear appropriate PPE

3. Follow safety instrucons of chemical manufacturer

(MSDS).

4. Always follow plant and OSHA guidelines about the use

of equipment.

5. Disconnect power and shut o compressed air and

water supply before servicing equipment.

DO NOT plumb incompable

chemistries on the same system.

If incompable chemistries are to

be used, a second system must be

installed.

DANGER:

!

Table of Contents

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 3 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Dimensions:

• Width: 48” (1,219.2 mm)

• Depth: 19” (724 mm)

• Height: 71” (1,803 mm)

• Weight: 287 lb. (130 kg)

*not including oor scale

• Floor Scale: 48" x 48" (1,219.2 x 1,219.2 mm)

Compressed Air Supply:

• 10CFM @ 80psi minimum (controls)

• 25 CFM @ 80psi minimum (1 in. pump)

• 100 psi maximum supply pressure

• 3/8” push-to-connect ng

RECOMMENDED REGULATOR SETTING 80 PSI.

Water Supply:*

• Cold Potable Water

• 7GPM @ 35 PSI minimum

• 100 psi maximum supply pressure

• ¾” hose barb ng

RECOMMENDED REGULATOR SETTING 50 PSI.

Electrical Connecon:

• 110 VAC, 5A, Single Phase, 60 Hz

• GFCI Outlet

• Surge suppression recommended

• NEMA 5-15 plug and 8 . cord supplied with unit

Weigh Scale Resoluon: 5000 lb. capacity (2,268 kg)

Accuracy, typical, tested with water at 70 degrees F,

100kg load cell, with calibrated overshoot:

• Flojet G56/P56 ¼” AODD pump @ 70 psi: +/- 4 oz

or 2% of dispense volume, whichever is greater

• Graco Husky 515 ½” AODD pump @ 70 psi: +/- 8

oz or 2% of dispense volume, whichever is greater

Materials of Construcon:

• Check valves: Glass lled polypropylene body,

Hastelloy spring, Viton seals

• Control Valves: Polypropylene body, EPDM seals

• Pump: Polypropylene body, Teon diaphragm,

Teon seals

• Fings: Glass lled Polypropylene

• Manifolds: Polypropylene

• Fluid Hoses: Reinforced PVC

• Tubing: LDPE

• Frame: HDPE

• Fasteners: 316SS / 18-8SS

• Enclosures: 316SS

• Floor Scale: Mild Steel

Specicaons Requirements

NOTE: Dispense volume accuracy for pumps

other than listed above must be determined

via tesng and is the responsibility of the end

user or system integrator.

NOTE: A backow preventer must be installed

in the water supply to this unit, per local

codes.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 4 of 25 Last Update: 07/18/2018

Installaon Instrucons

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 5 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Install Tower:

Set unit in desired locaon. Ensure the structure is

level in all direcons and is not twisng or exing. If

possible, it is recommended to aach the tower to a

wall or large shelving rack.

Connect Compressed Air:

Using 3/8" LDPE tubing or similar, connect

compressed air supply to the unit via the push-

to-connect ng as shown in [Figure 5.2] to the

Solenoid system's regulator. Connect a separate,

dedicated tube for the 1 in. Pump.

Connect Electrical Supply:

The unit is supplied with an 8' power cord and a

NEMA 5-15P grounded plug end. Connect the unit to

a GFCI protected outlet. A surge suppression device is

recommended.

Plumb Pumps:

Remove the shield to access the included pumps

[Figure 5.2].

Using 3/4" hosing or similar, connect the supply lines

for the pump to their included hose bards and secure

in place with hose clamps. [Figure 5.3].

Figure 5.1: Compressed Air Connecon

Figure 5.2: Removing shield

Installaon Instrucons (connued)

NOTE: Install the tower in a locaon where

the chances of being dripped on or sprayed by

chemicals or water is minimized. Do not install

in a locaon that will exceed 100 degrees F for

extended periods of me.

NOTE: If the system has not yet been

congured, it does not maer which pump is

plumbed to which chemical. (see page 8 for

Chemical Conguraon).

Figure 5.3: Pump hose barbs

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 6 of 25 Last Update: 07/18/2018

1. Using the HMI, login to the System using the on-

screen keyboard

2. Navigate to the MAIN MENU

3. Select USER ACCOUNTS [Figure 10.2]

4. Enter informaon as necessary for the following

procedures [Figure 6.3]:

Add User:

1. Enter USERNAME.

2. Assign to GROUP.

3. Set PASSWORD.

4. Select SAVE USER to add the user to the

system.

Change Password:

1. Enter USERNAME.

2. Enter CURRENT Password.

3. Enter NEW Password and CONFIRM.

4. Select SAVE PASSWORD to update.

Delete User:

1. Select USERNAME to be deleted from drop

down menu.

2. Select DELETE USER to conrm selecon and

delete the user from the system.

User Management

Figure 6.3: User Accounts Screen

Figure 6.2: Main menu, admin level

Figure 6.1: Login Screen Pop-Up

NOTE: Please contact your distributor for

administrave login credenals.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 7 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

1. On the HMI, log in as an administrator.

2. Click the Home icon and navigate to TANK A >

TANK A SCALE CALIBRATION [Figure 7.1].

3. Click ENABLE CALIBRATION

4. Ensure nothing is on the scale. Do not touch the

scale while calibrang!

5. Click the SET ZERO buon.

6. Place a calibrated weight of a known value onto

the oor scale. Use cauon to make sure the

weight does not shi or fall [Figure 7.2].

7. Enter the exact value of the weight into the

ENTER TEST WEIGHT box, then click SET SPAN.

8. Verify that the scale is reading the correct values

by liing the weight o of the scale and placing

it back onto the scale while watching the LIVE

WEIGHT readout.

Figure 7.1: Tank A Menu

Scale Calibraon

NOTE: Clean Logix recommends the use of a

calibrated weight between 50 - 80 lbs (22 -

37 kg). Lighter weights can cause inaccurate

dispenses!

Figure 7.2: Scale Calibraon Screen

NOTE: Other opons will remain grayed out

unl ENABLE CALIBRATION is selected.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 8 of 25 Last Update: 07/18/2018

1. On the HMI, log in as an administrator.

2. Click the Home icon and navigate to the TANK A >

CHEMICAL CONFIGURATION [Figure 8.1].

3. Click on a list item and enter a CHEMICAL NAME

and a SPECIFIC GRAVITY for each output that is

connected to a pump. [Figure 8.2]

If only pounds per gallon is known (PPG),

specic gravity can be calculated using this

formula:

Specic Gravity = PPG/8.3

Chemical Conguraon

NOTE: PREACT WT. can be le at zero for now.

It will be calibrated later in the "Calibrate

Pump Overshoot" step of this manual.

Figure 8.2: Chemical Conguraon Screen

Figure 8.1: Tank A Menu

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 9 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

1. Ensure air pressure is being supplied to the unit

and all of the Installaon Steps are completed.

2. On the HMI, log in as an administrator.

3. Click the Home icon and navigate to TANK A >

MANUAL > CHEMICAL PUMPS [Figure 9.1].

4. Make sure the ll wand's ball valve is open and

the wand is contained to catch the ow from the

pump.

5. Click MANUAL next to the chemical pump which

you would like to prime. The pump will run.

6. Once chemical begins to ow out the ll wand,

click AUTO to turn the pump o.

7. To prevent mixing of chemistry the manifold,

hose, and ll wand can be manually ushed with

water. To ush the system, select MANUAL for

TANK A WATER FILL VALVE.

8. Repeat above steps for addional chemicals, if

applicable.

Pump Priming

!

WARNING:

Pressing the MANUAL key on this screen will

cause the output to turn on and the pump to

run! Wear PPE and be ready to contain the

ow of chemical in an appropriate vessel!

Figure 9.3: Manual Chemical Pumps Screen

Figure 9.1: Manual Sub-Menu

Figure 9.2: Fill Wand ball valve (shown open)

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 10 of 25 Last Update: 07/18/2018

Recipe Structure:

A recipe is a sequence of steps to perform a delivery

procedure. There are 5 types of Steps:

1. NONE - This is a "blank" step, and will be skipped.

2. CHEMICAL - Pumps product from the specied

CHEMICAL. Requires a DISPENSE METHOD to be

chosen. Available DISPENSE METHODs are:

• VOLUME - Requires a value to be entered into

the VOLUME eld. The unit will dispense this

amount based on Calibraon sengs.

• TIME - Requires a value to be entered in the

TIME eld. The unit will dispense into the tank

for this amount of me.

3. WATER FILL - Pumps water from the specied 1

in. Pump. Requires a TIME or VOLUME value to be

specied (see above for Dispense Methods).

4. NULL - Can be used for a me delay. All elds are

ignored except the TIME eld. Specify the amount

of me to delay before the next Step.

5. ACKNOWLEDGE - Requires a user to

acknowledge a popup request on the HMI before

proceeding to the next Step. (All elds are hidden)

Recipes

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 11 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Figure 11.1: Recipe List

Figure 11.2: Recipe Edit Screen

Recipe Creaon:

1. On the HMI, log in as an administrator.

2. Click the Home icon and navigate to TANK A >

RECIPE EDITOR [Figure 11.1].

3. Use the buons and the boom of the screen to

navigate through recipes 1-60.

4. The unit can hold up to 60 recipes. Click EDIT next

to the recipe to congure it.

5. Enter the elds as necessary to create the recipe

applicaon [Figure 11.2].

• Reference the Recipe Structure (page 10) for

more informaon on eld requirements.

6. When complete exit using the back buon (top

right corner). A message will appear asking for

changes to be saved, select SAVE AND EXIT.

7. Repeat process for addional recipes, if

applicable.

Edit Exisng Recipe:

1. As an administrator, navigate to the Recipe Editor.

2. Find the recipe needing to be modied and select

EDIT.

3. Edit the elds as necessary, exit, and select SAVE

AND EXIT for the window pop-up.

Delete a Recipe:

1. As an administrator, navigate to the Recipe Editor.

2. Find the recipe and select EDIT.

3. Select DELETE RECIPE to permanently remove the

recipe.

Recipes (connued)

Figure 11.3: Recipe Save and/or Exit Pop-Up

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 12 of 25 Last Update: 07/18/2018

Recipe Queue:

1. On the HMI, log in as a user with privileges to

enqueue recipes.

2. Click the Home icon and navigate to TANK A >

TANK A OVERVIEW [Figure 12.1].

3. Click RECIPE SELECT [Figure 12.2].

4. Select a recipe in the list to add it to the QUEUE

list [Figure 12.3].

Recipe Modes:

There are two dierent modes in which the unit can

process the queue:

• The unit requires the user to press the

START buon on the overview screen in

order to run each recipe in the queue. The

start buon must be pressed by a user to

start the next recipe.

• The unit will run the recipes in sequence

one aer the other unl the queue is

empty. As soon as one nishes the next

will begin automacally.

Dispensing a Recipe

Figure 12.1: Tank A Menu

Figure 12.2: Tank A Overview Screen

Figure 12.3: Recipe Queue Screen

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 13 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Adding a Recipe to the Queue:

1. Return to the OVERVIEW page using the back

arrow or clicking RETURN TO OVERVIEW

2. The name of the recipe “on deck” will appear

under the word Recipe on the overview page

[Figure 13.1].

3. To run the recipe, click START.

4. To stop the process at any point, click STOP.

• Once stopped, the START and STOP buons

will change to RESUME and CANCEL

• To connue the process, click RESUME.

• To cancel the process completely, press

CANCEL.

Figure 13.1: Overview Screen

Figure 13.2: Overview Screen - In Process

Dispensing a Recipe (connued)

NOTE: The START buon will be grayed out if

there is no user logged in or if the currently user

does not have Privileges to dispense a recipe.

!

CAUTION:

Pressing CANCEL will end the current

process, which may cause one or more

alarms to appear if the process was

stopped with chemical in the manifold

system etc. USE WITH CARE.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 14 of 25 Last Update: 07/18/2018

There are a few opons for obtaining reports. Review

the following opons and instrucons to access them.

USB Download:

1. Open the Control Panel and insert a USB drive into

the back of the screen panel [Figure 14.1].

2. Navigate to MAIN MENU > REPORT

CONFIGURATION

3. Using the drop down menu, idenfy the USB drive

currently in use [Figure 14.2].

4. Select CREATE REPORT FOLDERS to export a new

set of reports.

USB Transfer:

1. Navigate to TANK A > REPORT CONFIGURATION

2. Two opon are available to transfer les:

• DRAG AND DROP METHOD:

1. Select BROWSE FILES and nd the report

2. Physically drag OR press and hold to

perform a "right click" on the le to

transfer it to its new folder locaon.

• SELECT SOURCE & DESTINATION:

1. Using the Folder icons, browse for the

SOURCE and DESTINATION le(s) for the

transfer

2. Select COPY FILE to transfer the report

3. The checker ag will illuminate green

and will display COPY SUCCEEDED when

complete.

Reporng

Figure 14.2: Report Conguraon screen, USB drive selecon

Figure 14.3: Report Export screen (transfer in progress)

Figure 14.1: USB port locaon on interior side of screen panel

NOTE: To idenfy USB drive, use the Browse

funcon to view system folders.

Example: "EPX USB (D:)" = D

!

WARNING:

Creang a Report Folder will cause any exisng

report folders to be deleted.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 15 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Figure 15.1: Clean Intel login screen (using Google Chrome)

Figure 15.2: Clean Intel system selecon

CleanIntel Online Reporng:

1. Using a computer, tablet, or smartphone; open an

Internet browser (i.e. Google Chrome, etc.)

2. Go to www.cleanintel.com

3. Enter login credenals [Figure 15.1]

• Contact Clean Logix for site and account login

conguraon.

4. Three system clients of Clean Intel will be available

for selecon, select EPX [Figure 15.2]

5. CSV based reports will be listed below, click the

lename to download a copy for review

[Figure 15.3]

CSV reports contain date and me stamps for all user

acvity.

Local Dispense Logs:

To view dispense logs directly from the unit itself:

1. Navigate to the MAIN MENU > DISPENSE LOGS

2. A list of all dispense acvity will be displayed

[Figure 15.4].

3. If recent dispenses are not shown, hit REFRESH to

reload the page and display more recent acvity.

Reporng (connued)

Figure 15.3: EPX Report list (zoomed in)

Figure 15.4: Dispense Logs Screen

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 16 of 25 Last Update: 07/18/2018

Manual Control:

• Allows manual control of all outputs.

• AUTO is the normal state.

• OFF means the output is disabled.

• MANUAL turns the output on.

• Reset by clicking AUTO.

• All overrides can be reset at once by clicking the

ashing icon at the boom of the screen.

I/O Overrides:

• Allows safety switches to be overridden in the

event of failure, to keep the system running while

replacement parts are on order [Figure 16.1].

• Air pressure can be disabled (blinking red).

I/O Status Screens:

• Shows the status of every PLC input and output

[Figures 16.2 & 16.3]. Green means the input or

output is ON, gray means OFF.

Weight Trend Screens:

• Shows a current and historical trend line of the

weigh system for troubleshoong purposes

[Figure 16.4]

Ops Log:

• Shows a log of all system operaons with

mestamps for troubleshoong purposes

Figure 16.1: I/O Override Screen

Figure 16.3: Output Status Screen

Figure 16.2: Input Status Screen

Advanced Funcons

Figure 16.4: Trend Screen

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 17 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

If the system detects a problem, it will stop the

process (if running) and display an alarm banner

[Figure 17.1] message at the top of the screen. The

alarm must be reset before the process can resume or

a new process can begin.

Reseng Alarms:

1. Idenfy the root cause of the alarm based on the

status message shown [Figure 14.1].

2. Once the root cause of the alarm has been xed,

the alarm can be reset either by clicking the

RESET ALARMS buon on the alarm banner or by

clicking ALARM OVERVIEW on the Tank Overview

screen [Figure 17.2].

3. Aer reseng the alarms, the process can be

resumed by pressing the RESUME buon on the

Overview screen. If you do not wish to resume

the process, press CANCEL.

Bypassing Alarms:

A user with Administrator privileges may click the

BYPASS ALARMS buon on the Alarm Overview

screen [Figure 14.3].

CAUTION: This will bypass ALL alarm condions for a

given tower! Use with cauon! Click the buon again

(now it will be ashing ALARMS BYPASSED) to undo

the bypass.

Figure 17.1: Alarm Banner

Alarms

NOTE: The alarm banner(s) can be hidden

for navigaonal purposes by clicking HIDE

ALARMS. This does not reset the alarms!

!CAUTION:

Pressing CANCEL will end the current process.

This may cause one or more alarms to appear

if the process was stopped with chemical on

the scale. USE WITH CARE.

Figure 17.3: Tank A Alarms Screen (shown with no alarms)

Figure 17.2: Tank A Menu - Alarms selecon

NOTE: See Troubleshoong secon (page 18)

for more informaon on alarm causes and

soluons.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 18 of 25 Last Update: 07/18/2018

Estop Pushed Alarm:

Controller Tags: JugA_ESTOPAlm

Criteria: The e-stop buon has been pushed

CAUSE: The e-stop buon has been pushed, to solve:

• Firmly pull the Estop buon out and make sure

the light in the center of the buon illuminates.

• Log in with administrator permissions and click

RESET ALARMS on the appropriate alarm page.

• If the process is sll in a paused state, click

RESUME on the TANK A OVERVIEW page to

connue the process.

No Flow Alarm:

Controller Tags: JugAChemNoFlowAlarm

Criteria: While the tank is lling (chemical or water

ll), the rate of change of weight is less than +20 g/s

for a period of me.

CAUSE: One of the chemical tanks is empty or its

pump has lost prime, to solve:

• Verify that the unit has air pressure.

• Check chemical tanks to make sure they are

not empty and pump sucon lines are submerged.

• Make sure foot valves on the sucon lines are

funconing.

• Log in with administrator permissions and click

RESET ALARMS on the appropriate alarm page.

• Click the RESUME buon on the Tank

Overview page to try again.

• If alarm reappears, press CANCEL on the

appropriate tank overview page and re-prime the

aected pump. (see page 9 for pump priming)

Troubleshoong

Rate of Change Alarm:

Controller Tags: JugAROCAlm

Criteria: While the tank is lling or emptying (chemical

ll, water ll, or delivery steps) the instantaneous rate

of change in weight is less than -2720 g/s. Acvates

instantaneously. NOTE: A posive spike can result in a

negave “dip” that can sasfy this criteria.

CAUSE: Someone touched or interacted with the

container and/or scale during a dispense, to solve:

• Log in with administrator permissions and click

RESET ALARMS on the appropriate alarm page.

• If the process is sll in a paused state, click

RESUME on the overview page to connue the

process.

Low Air Pressure Alarm:

Controller Tags: JugA_LowAirPressureAlm

Criteria: The air pressure switch opened while the system

was in use

CAUSE: Compressed air supply is shut o or does not

meet the minimum system requirements, to solve:

• Check the air pressure gauge on Tower A to

make sure the air pressure is set to 80 psi.

• Log in with administrator permissions and click

RESET ALARMS on the appropriate alarm page.

• If the process is sll in a paused state, click

RESUME on the appropriate jug overview page to

connue the process.

• Observe the air pressure gauge on Tower. If it

dips below 40 psi, the compressed air supply may

not be sucient.

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 19 of 25 Last Update: 07/18/2018

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

Low Air Pressure Alarm (connued):

Controller Tags: JugA_LowAirPressureAlm

Criteria: The air pressure switch opened while the system

was in use

CAUSE: Air pressure switch set point on the Tower is

too low or the switch is faulty, to solve:

• Log in with administrator permissions and click

RESET ALARMS on the appropriate alarm page.

• Go to the MAIN MENU and then SYSTEM

INPUTS to view the system input status lights.

• Use the air pressure regulator to lower the air

pressure to 20 psi an then gradually increase it

again.

• Make sure the correct input light is

illuminang when the air pressure gauge reaches

approximately 40 psi.

• Refer to the I/O pages on the wiring diagram.

• If the light illuminates at a pressure greater

than 40 psi, open the Tower A or B solenoid

enclosure and adjust the switch to a lower set

point (refer to switch manufacturer instrucons).

• If the light does not illuminate at any pressure

up to 80 psi, replace the switch.

Troubleshoong

Weekly:

• Check for leaks

• Check for corrosion

Monthly:

• Check scale calibraon and recalibrate if

necessary

• Drain water from sight bowl on air pressure

regulators

• Check air pressure sengs. Refer to beginning of

manual for recommended sengs

• Verify pumps are secure and fasteners have not

loosened over me

• Ensure hoses and clamps are maintaining proper

connecons

• Clean ll wand and mixer

Annually:

• Test funcon of air pressure switch

Maintenance Instrucons

USER MANUAL: Tote Mixer Delivery System (EPX-TM)

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Page 20 of 25 Last Update: 07/18/2018

Appendix A - Parts Callout

Table of contents

Other Clean Logix Cleaning Equipment manuals

Clean Logix

Clean Logix BLX-700-GEN2 User manual

Clean Logix

Clean Logix ALX-OMNI-LITE User manual

Clean Logix

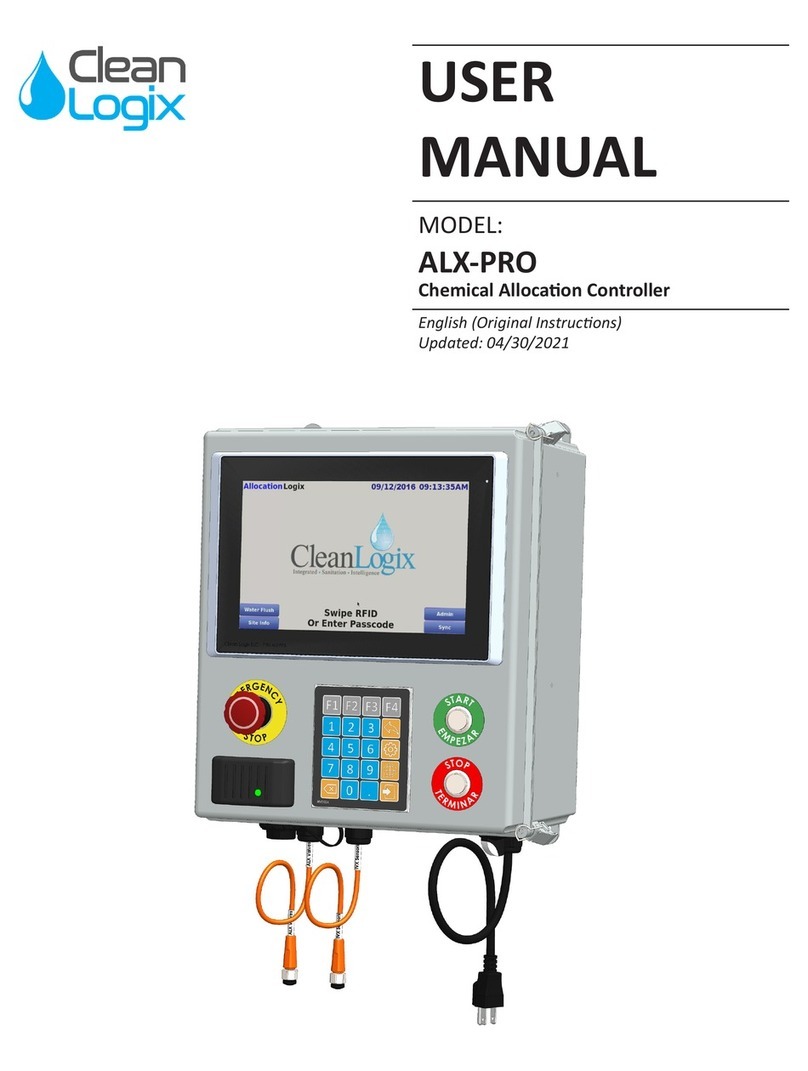

Clean Logix ALX-PRO User manual

Clean Logix

Clean Logix BLX-1000-GEN2 User manual

Clean Logix

Clean Logix BLX-800-GEN2 User manual

Clean Logix

Clean Logix BLX-400 User manual

Clean Logix

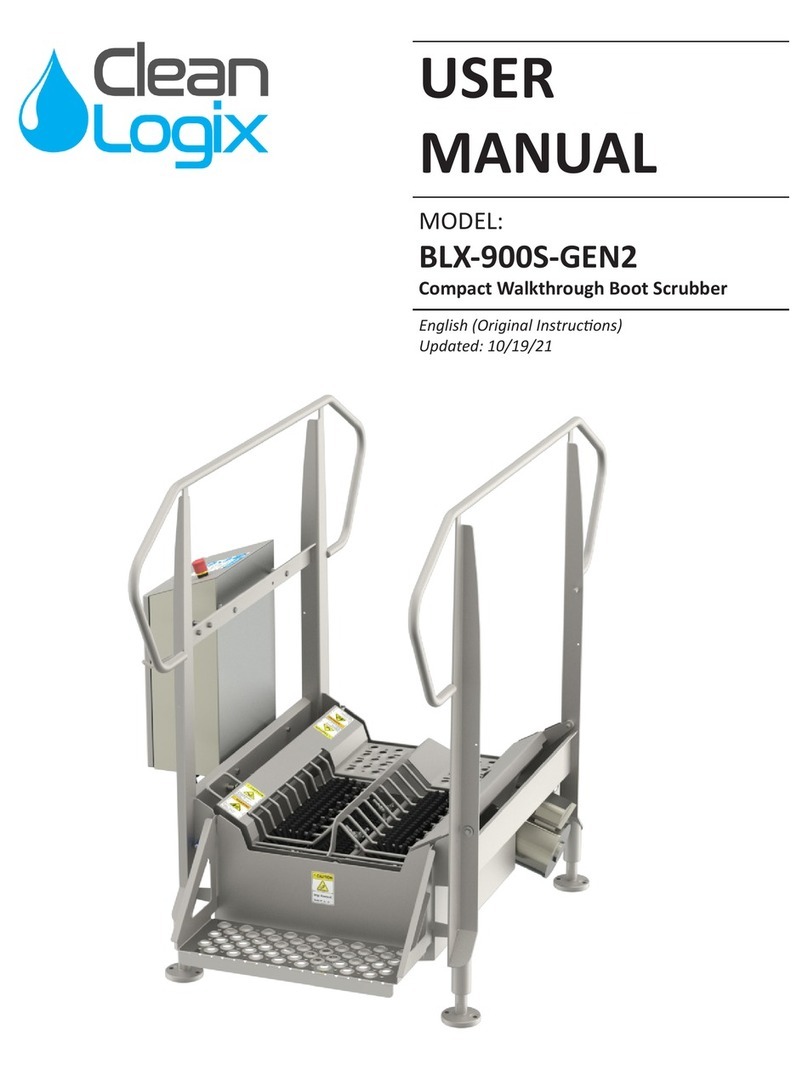

Clean Logix BLX-900S-GEN2 User manual

Clean Logix

Clean Logix BLX-600-GEN2 User manual