TECAi venet User manual

venetvenet

Electric brushing unit with built-in vacuum cleaner

user manual EN

original manual

Electric brushing unit with built-in vacuum cleaner 2-29

venetvenet

©

introduction

Training service

Technical service

Thank you very much for placing your trust in a quality product from TEINNOVA.

This product is manufactured using modern production processes and extensive

quality assurance measures.

We try to do everything possible to ensure that you are satisfied with this product and

can work with it without any problems.

If you have any questions about this product, please contact your dealer or our

company directly.

Before operating the machine, carefully read the operating instructions for your

equipment.

Please consider this manual as part of the machine and keep it handy for future

reference.

We offer the option of providing companies with specific training in the use of our

equipment and training their operators to provide the best service and thus contribute

to the success of their end customers.

Aspects such as knowing how to draw up a good quotation objectively, how to respond

to specific problems that may arise, or how to offer a more professional and efficient

service.

Thanks to our own manufacturing of cleaning equipment, we can control at all times

the quality and performance of each machine we manufacture, and this has allowed

us to have very low repair ratios which have always been solved with our own Tech-

nical Support Service managed by the same team that manufactures it, and in very

short periods of time.

We have all kinds of spare parts for your equipment, as well as related accessories.

This instruction manual is protected by copyright. We reserve all rights, especially the right to production,

translation and processing with electronic systems.

Dear customer:

Electric brushing unit with built-in vacuum cleaner 3-29

venetvenet

5-29

6-29

7-29

8-29

9-29

11-29

14-29

10-29

symbology

safety warnings

envisaged conditions of use

know your machine

control panel

accessories and related equipment

operating instructions

remote control

index

Electric brushing unit with built-in vacuum cleaner 4-29

venetvenet

24-29

25-29

26-29

27-29

29-29

28-29

transport

maintenance and care

waste management

technical specifications

“EC” declaration of conformity

guarantee conditions

index

Electric brushing unit with built-in vacuum cleaner 5-29

venetvenet

symbology

DANGER!

WARNING!

CAUTION!

IMPORTANT NOTE!

All the existing graphic symbols in this manual as well as those indicated on the equipment itself are explained

in this section, it is important to read with special attention the text related to this symbology as it is related to

personal and equipment safety.

This symbol alerts you to a potentially hazardous situation which can result in

death or serious injury if t h e instructions are not followed properly. Be sure to

read all instructions described in the “Safety Information” section.

This symbol alerts you to a potentially hazardous situation which may result in

minor or moderate injury, or property damage resulting in personal injury if the

indicated instructions are not followed properly.

This symbol alerts you to a situation that may result in property damage without

personal injury if you do not follow the instructions properly.

This symbol alerts you to information regarding the optimal use of the equipment

to avoid possible misuse.

Electric brushing unit with built-in vacuum cleaner 6-29

venetvenet

VENET equipment must NOT be used for purposes other than those described in t h i s instruction manual.

Before starting up the equipment, make sure that all electrical connections are correct.

Before starting the equipment, make sure that the brush is inside the duct to be cleaned.

Be careful to place your VENET on a smooth and stable surface. Lock the wheel brakes to keep the

machine stable while working.

Hold the hose firmly before operating the brush motor. Keep a f i rm grip on the hose at all times while

operating the brush.

Do not use the equipment without filters

In case of obstruction in the suction hose or any part of the equipment, disconnect it immediately.

Do not suck up explosive mixtures, easily flammable dusts or gases, aggressive or organic substances.

Do not use the equipment in explosive atmospheres.

Do not suck up liquids or watery matter with the machine, only dusty dirt may be sucked up..

The machine has an air outlet on the turbine, leave enough space for the correct air evacuation.

It is mandatory to wear safety goggles to prevent possible dust projections from reaching the operator’s

eyes.

Persons operating VENET equipment must be sufficiently trained.

Properly secure VENET equipment in an upright position during transport in a vehicle.

Do not open or tamper with any of the internal elements of the equipment. In the event of a fault, contact

TEINNOVA’s Technical Assistance Service on +34 941 44 50 56.

safety warnings

Electric brushing unit with built-in vacuum cleaner 7-29

venetvenet

Any other use is strictly prohibited

without the written permission of

the manufacturer

Do not place the device in a horizon-

tal position under any circumstances,

as this could lead to malfunctions.

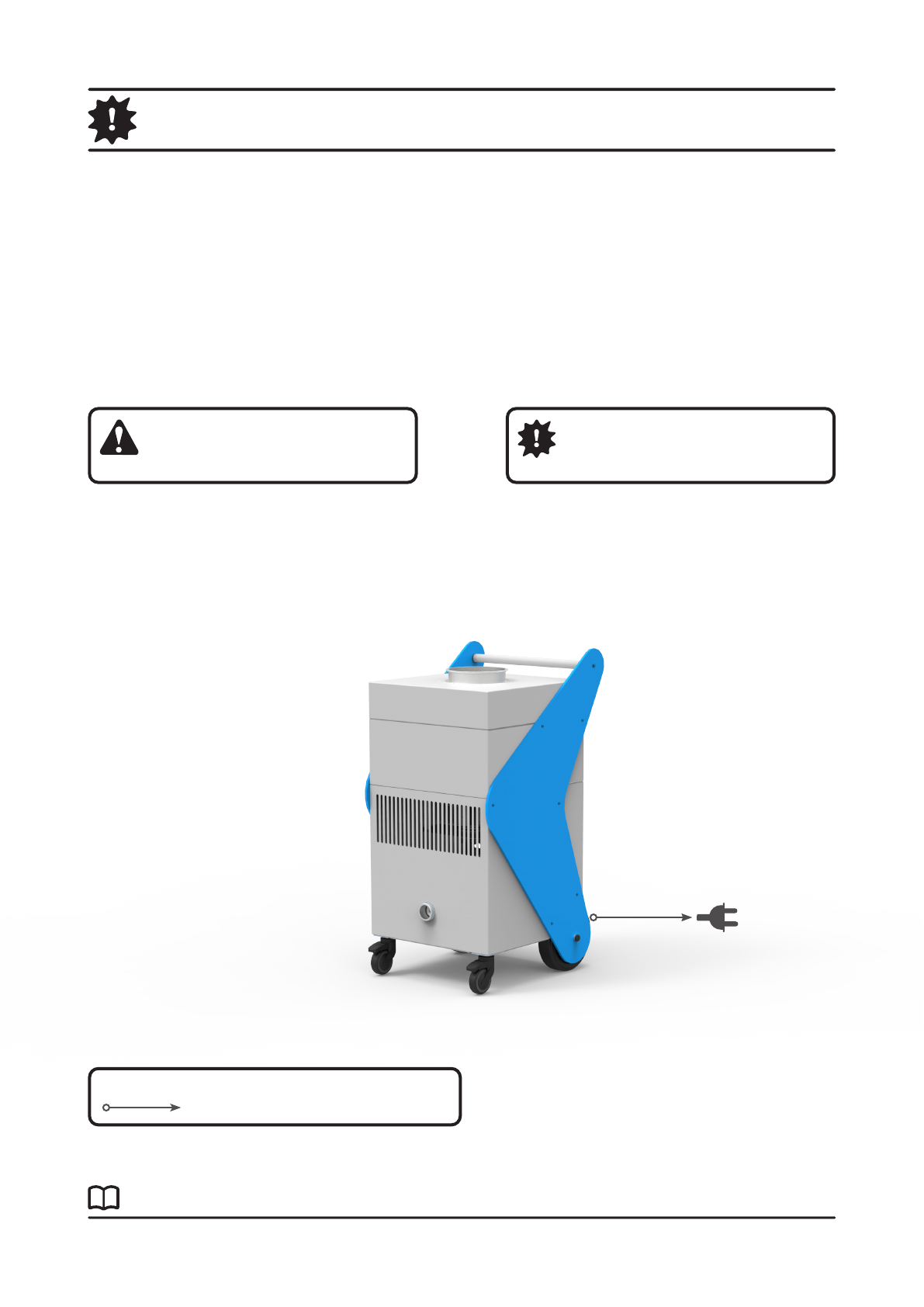

LEGEND

VENET is an equipment for cleaning ventilation and/or air conditioning ducts of small dimensions, up to 400mm.

Suitable accessories must be provided for each duct.

It includes a 10 metre hose so that 20 metres of pipe can be cleaned from a single point on the pipe.

In addition, the equipment has a suction system to work in a complementary way to brushing. It has a 3m hose

which, by means of a telescopic adapter, is attached to the access point of t h e installation.

It has two filtration stages, FILTER F7- MAIN HEPA FILTER H13.

power supply

envisaged conditions of use

venetvenet

Electric brushing robot with built-

in suction, for duct cleaning.

Electric brushing unit with built-in vacuum cleaner 8-29

venetvenet

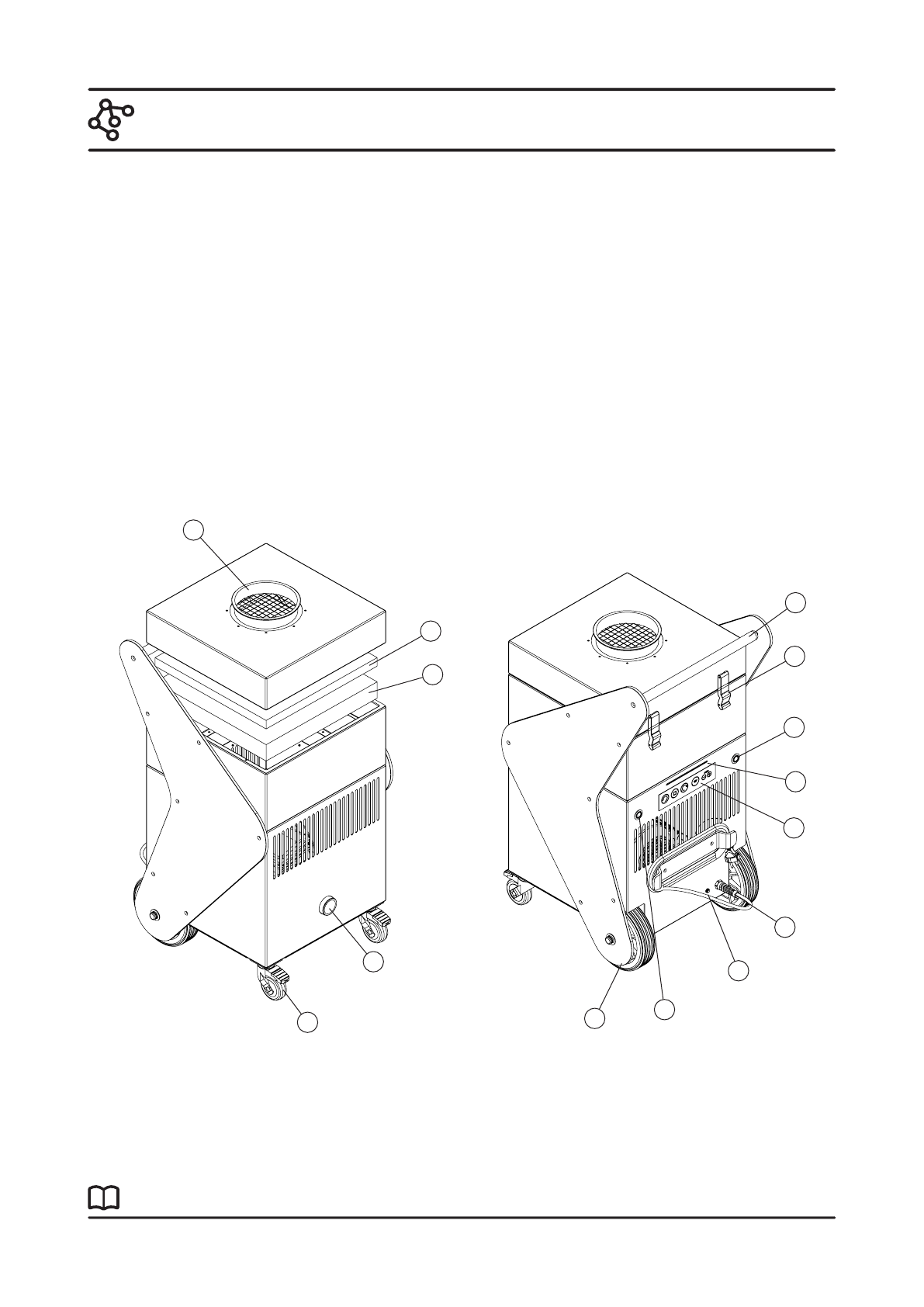

1

2

3

4

567

8

9

10

12

11

14

13

Components:

1- Connection for suction hose

2- Filter F7

3- Filter H13

4- Shaft connection

5- Braked wheel

6- Rear wheel

7- Turbine ignition switch

8- Resettable fuse

9- Electrical connection

10- Control panel

11- Led indicator

12- ON/OFF switch

13- Filter cover fastening tab

14- Carrying hand

know your machine

Electric brushing unit with built-in vacuum cleaner 9-29

venetvenet

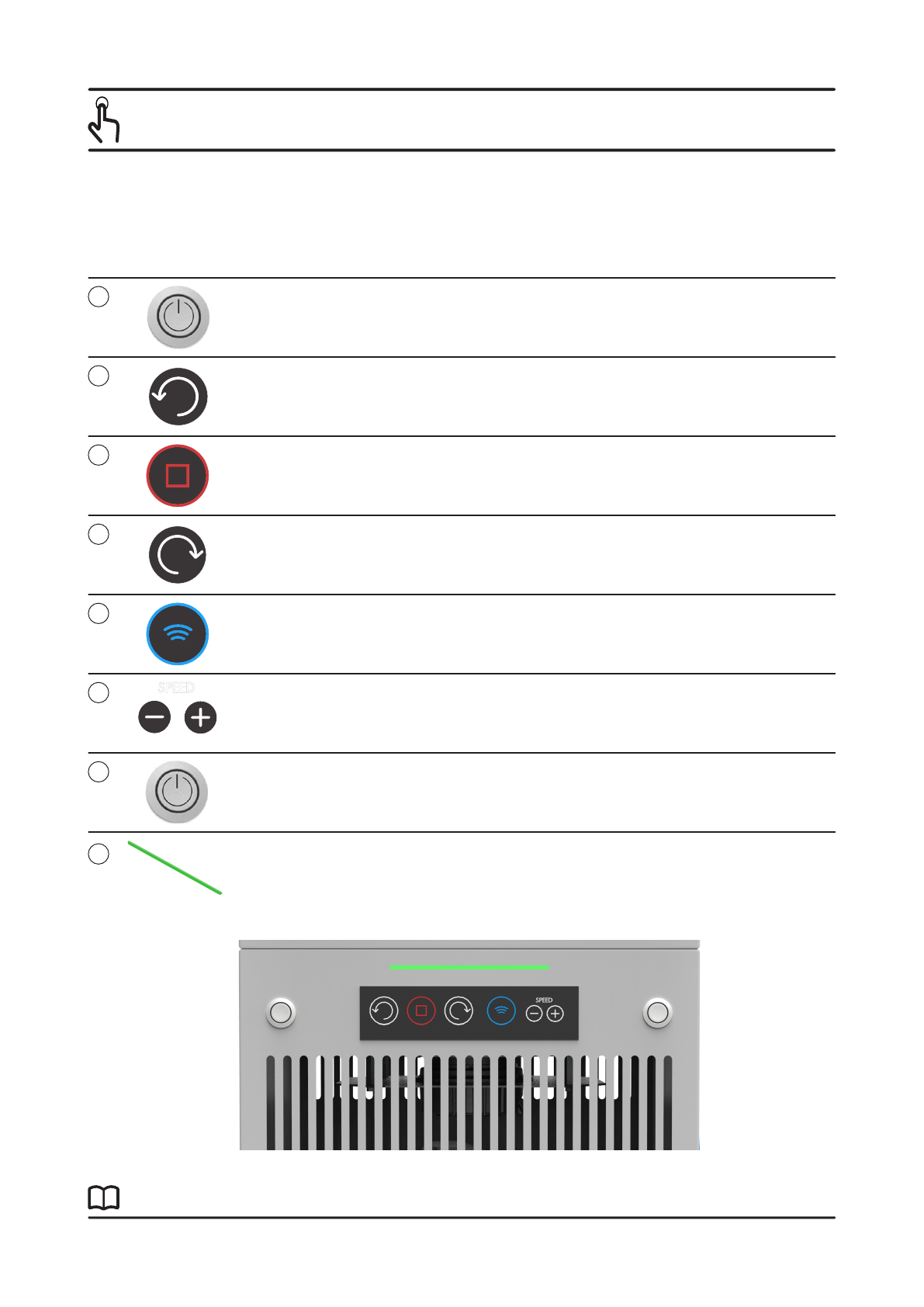

6

1

2

3

4

5

7

8

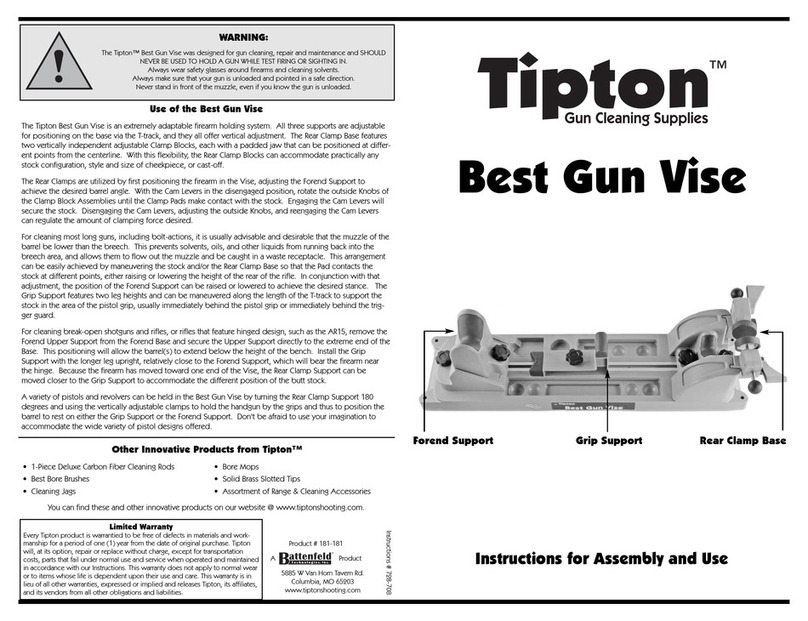

Main control panel:

control panel

Potentiometer

General Switch

Left Turn

Stop

Right Turn

Remote control

Turbine switch

Increases or decreases the speed of the brushing function

Switching the equipment on and off

Operate the motor of the planing machine so that its rotational

movement is counterclockwise.

General shutdown of any system in operation.

Actuates the motor of the planing machine so that its rotational

movement is clockwise.

Activates the remote control, leaving the equipment control

panel deactivated..

Activates the suction of the equipment by turning on the turbine.

LED Strip Indicates the status of the machine

Electric brushing unit with built-in vacuum cleaner 10-29

venetvenet

1

2

3

5

4

5

1

3

2

A

4

remote control

Remote control panel:

Unlock button

Right Turn

STOP

Automatic mode

Left Turn

Button for activating the above functions. In order to start a

function, both buttons must always be pressed at the same

time.

Actuates the motor of the planing machine so that its rotational

movement is counterclockwise.

General shutdown of any system in operation

Operate the timer on the brushing machine, so that the brushes

rotate for 10 seconds for each side. It will automatically start to

rotate to the right.

Actuates the motor of the planing machine so that its rotational

movement is clockwise.

1 Battery 12V.

Alkaline 23A

Electric brushing unit with built-in vacuum cleaner 11-29

venetvenet

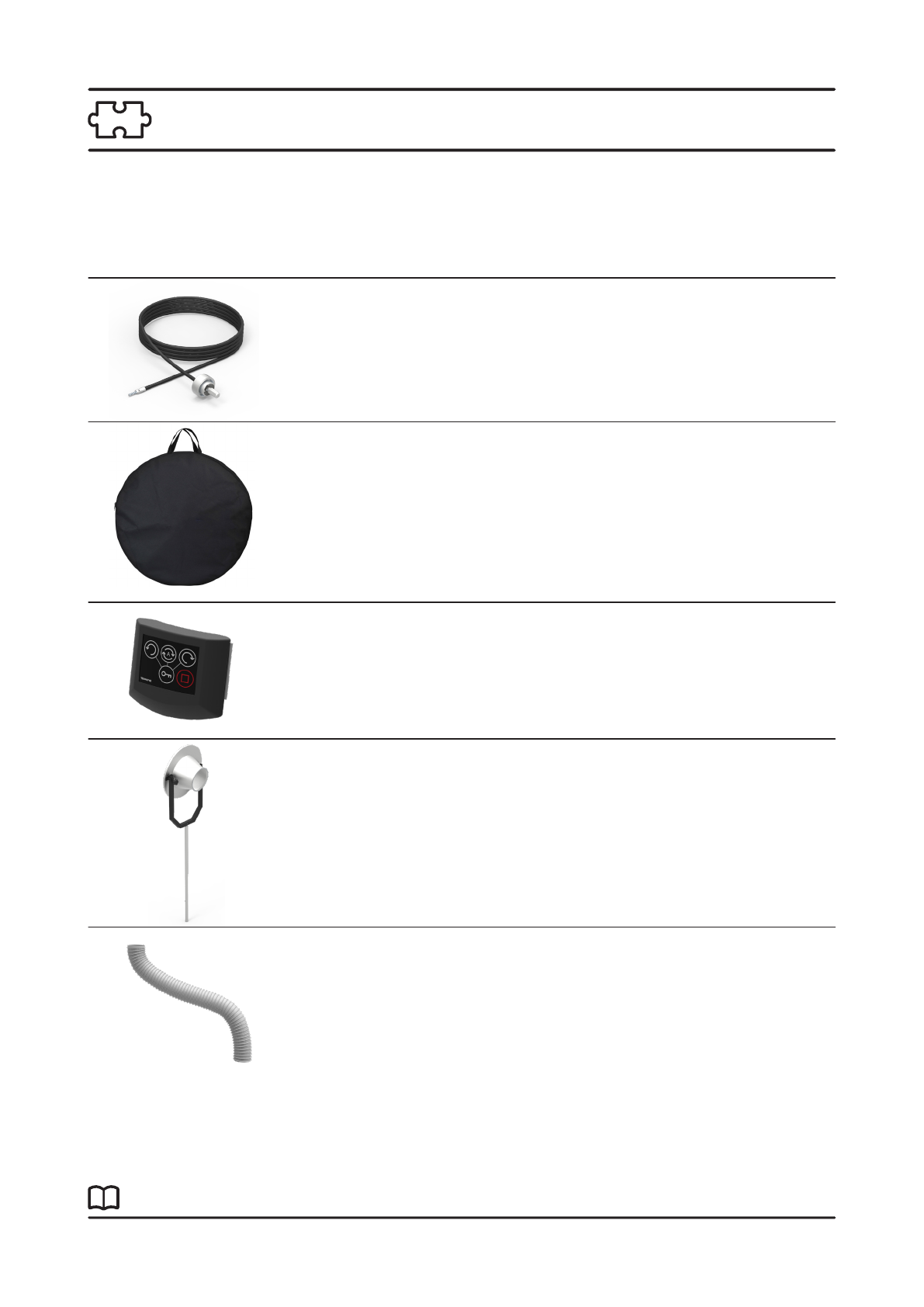

Accessories included:

accessories and related equipment

Flexible shaft Ø6 of 10 metres for the brushing function of your VENET.

Cod. AC3303614

Fabric bag for protection and transport of the flexible shaft.

Cod. AC3101210

Flexible shaft Ø6

Flexible shaft transport bag

Remote control unit with which you can operate your VENET equipment.

Cod. AC3303605

Remote control

Swivel adapter to fit the sleeve in both vertical and horizontal ducts.

Cod. AC3101404

Flexible pipe made of plasticised PVC with self-extinguishing textile PVC

reinforcement and galvanised steel reinforcement spiral. It incorporates the

quick connectors between the hoover and the duct adaptation module.

Cod. AC3101319

Duct adapter for hose Ø160mm

Sleeve Ø160mm 3m

Electric brushing unit with built-in vacuum cleaner 12-29

venetvenet

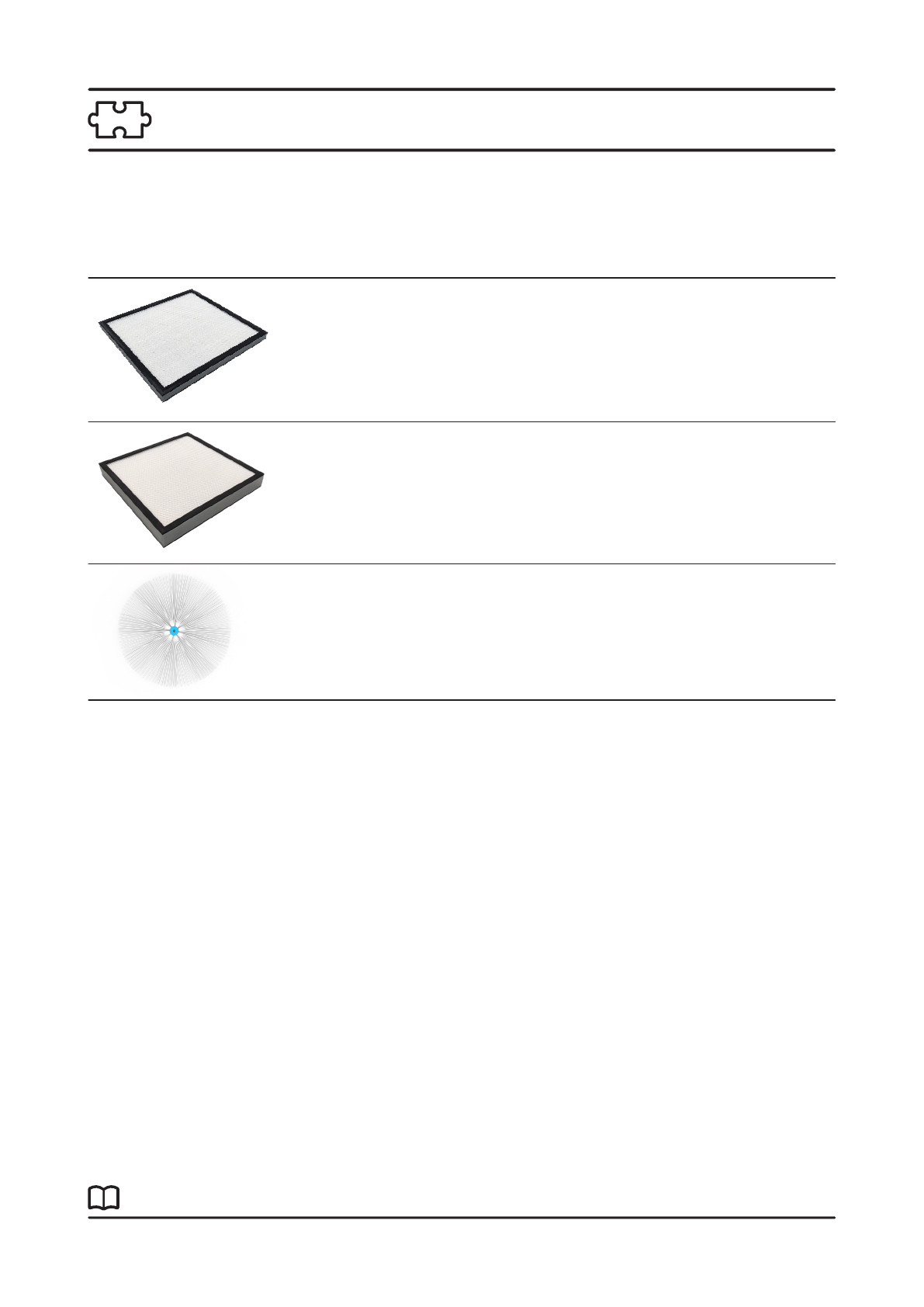

accessories and related equipment

High capacity filter with F7 classification. Frame made of galvanised steel.

Cod. AC1300007

High capacity filter with HEPA H13 classification. Frame made of galvanised

steel.

Cod. AC1300013

Filter F7

Filter H13

Nylon brush recommended for cleaning ventilation ducts

Cod. CP4000250

Nylon brush Ø250

Electric brushing unit with built-in vacuum cleaner 13-29

venetvenet

accessories and related equipment

Flexible shaft Ø10 of 15 metres for the brushing function of your VENET.

Cod. AC3303615

Anti-breakage protector for the shaft and hose of your VENET equipment.

Cod. AC3303112

5 metre protective weatherstrip for manhole.

Cod. AC6134102

Flexible shaft Ø10

Anti-breakage protector

Protective weatherstripping

Optional accessories:

Electric brushing unit with built-in vacuum cleaner 14-29

venetvenet

300

350

400

Cod.mm in

11,81

13,78

15,75

CP2010530

CP2010535

CP2010540

300

350

400

Cod.mm in

11,81

13,78

15,75

CP2010530

CP2010535

CP2010540

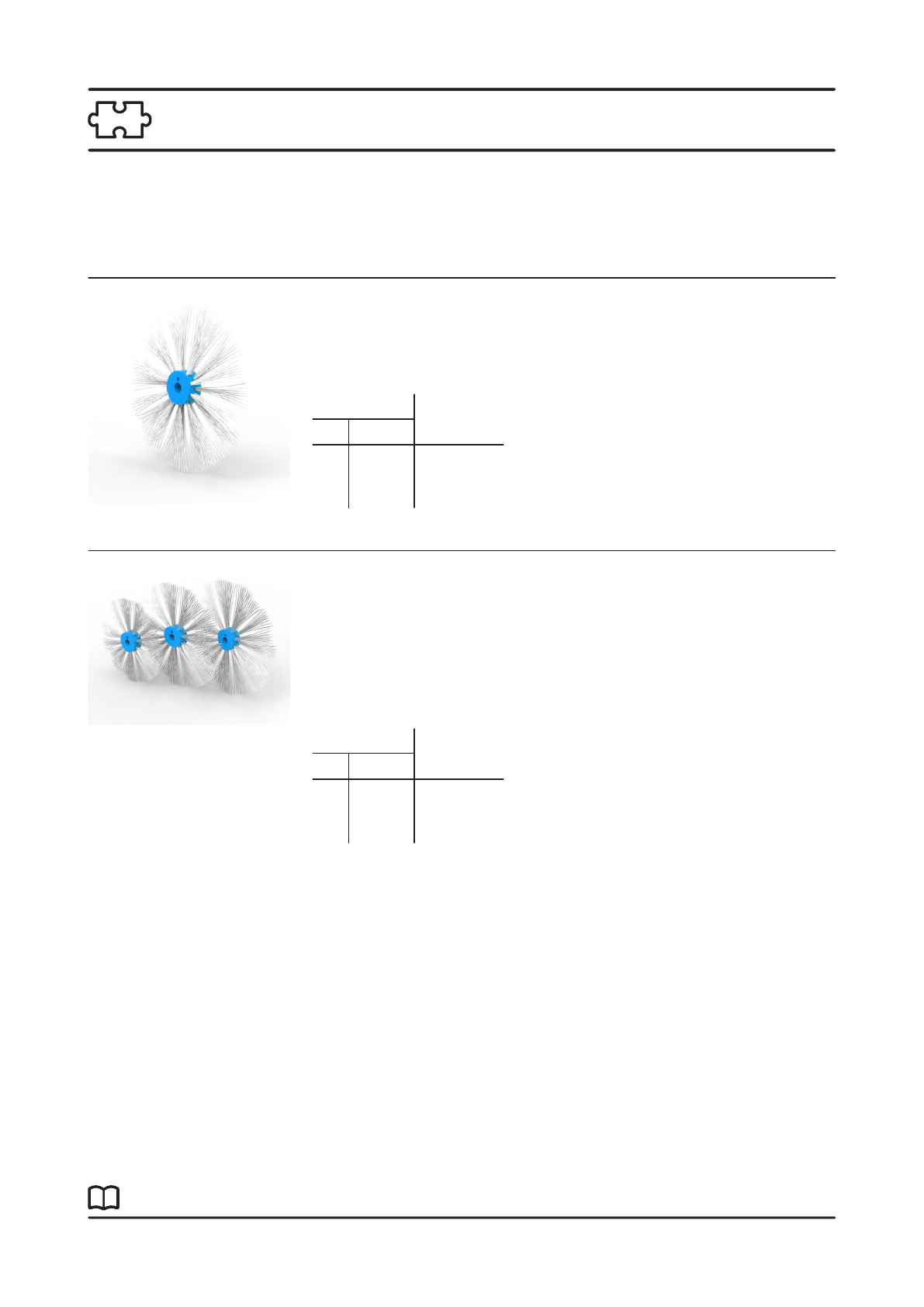

Fine nylon brushes recommended for cleaning ducts with grade 1 dust (low

soiling).

Fine Nylon Brushes

Dimensions

Pack of 3 fine nylon brushes recommended for cleaning circular ducts, with

grade 1 dust (low dirt). The brushes range in size from 300mm to 400mm

diameter.

Cod. CP2103040

Fine Nylon Brushes Pack

Dimensions

accessories and related equipment

Electric brushing unit with built-in vacuum cleaner 15-29

venetvenet

300

350

400

Cod.mm in

11,81

13,78

15,75

CP2033040

CP2033550

CP2034055

300

350

400

Cod.mm in

11,81

13,78

15,75

CP2033040

CP2033550

CP2034055

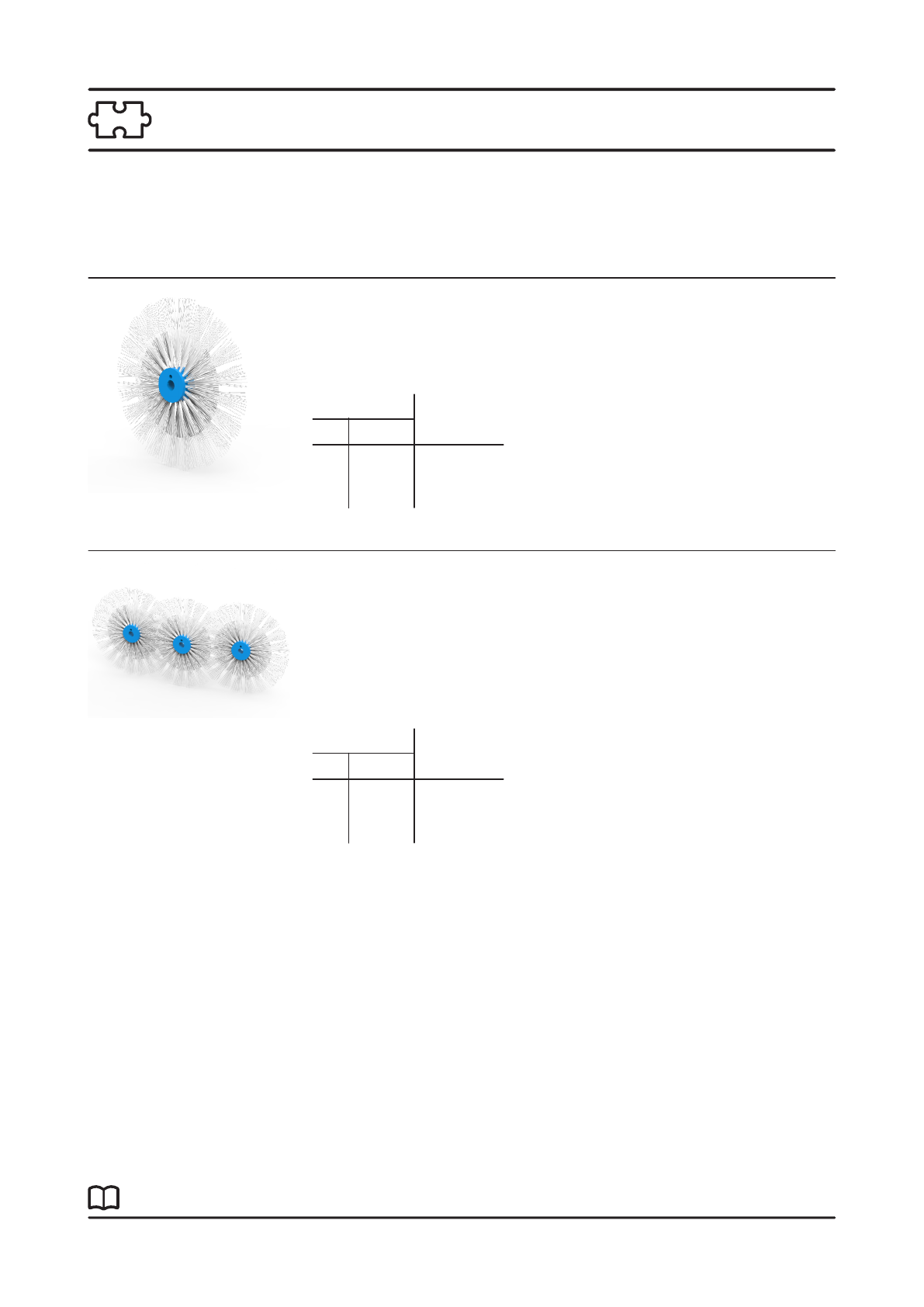

Double row nylon brushes. One row is the same size as the duct height, while

the other requires a specific dimension to achieve effective brushing in the

corner.

Nylon square duct brushes

Dimensions

Pack of 3 double row nylon brushes recommended for cleaning square and

rectangular ducts. The brushes range in size from 300mm to 400mm diameter..

Cod. CP2104055

Square Pack

Dimensions

accessories and related equipment

Electric brushing unit with built-in vacuum cleaner 16-29

venetvenet

1

2

3

Placement of your VENET:

Place your VENET on a smooth, stable surface and apply the wheel

brakes..

The connection is made by means of the electrical connection cable

supplied with the equipment. This cable consists of a standard

connection to the mains. Connect the cable to the ma i n s.

The connection is made by means of a quick connector at one end

of the hose.

Connection to the mains:

It is recommended to keep the axle stretched, avoiding

excessive bends, to prevent rubbing and premature

wear on the axle.

Steps for a correct installation of your VENET:

operating instructions

Connection of the brushing hose:

Electric brushing unit with built-in vacuum cleaner 17-29

venetvenet

4

5

6

operating instructions

Assembly of the brush:

At the other end of the shaft, fit the brush by means of a nut

Place one end of the suction hose over the inlet of your equipment.

Position the quick clamp and tighten it so that the suction hose and

the hoover are firmly connected.

Place the other end of the suction hose over the mouth of the

adapter.

Position the quick release flange and tighten it so that the suction

hose and adapter are firmly connected

Suction hose connection to the adapter:

Suction hose connection to the equipment:

Electric brushing unit with built-in vacuum cleanervenetvenet

7

8

operating instructions

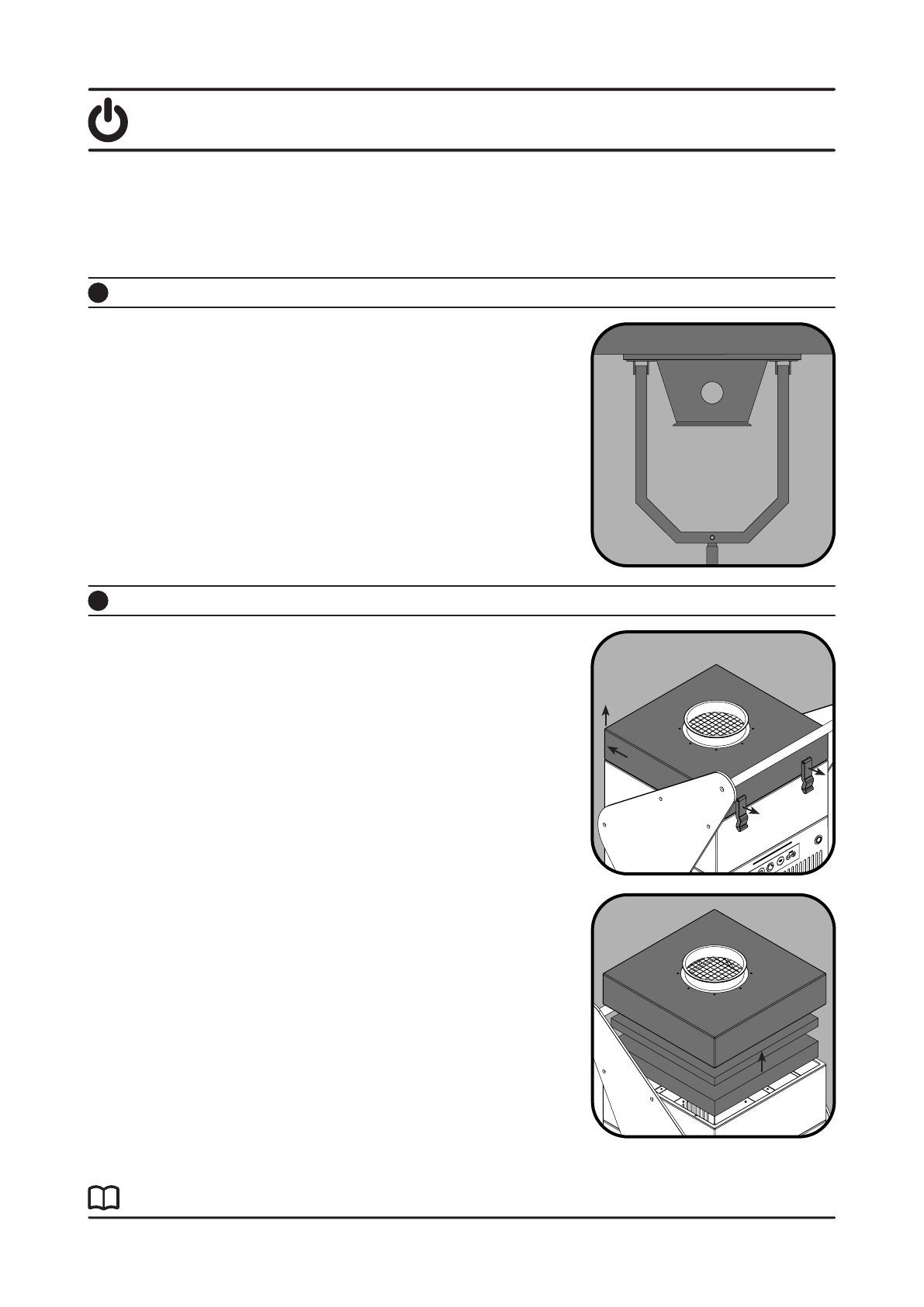

Fitting the adapter into the duct:

Place the adapter in the duct as shown in the picture. Adjust the

height by raising and turning the strut.

Change the filters if they are saturated or need to be replaced. To

do this, open the rear latches of the unit and push the cover forward.

Then pull the cover upwards and remove the filters.

Insert the filters and close the lid again.

Change of filters:

Electric brushing unit with built-in vacuum cleaner 19-29

venetvenet

1

2

operating instructions

Selection of the function to be performed:

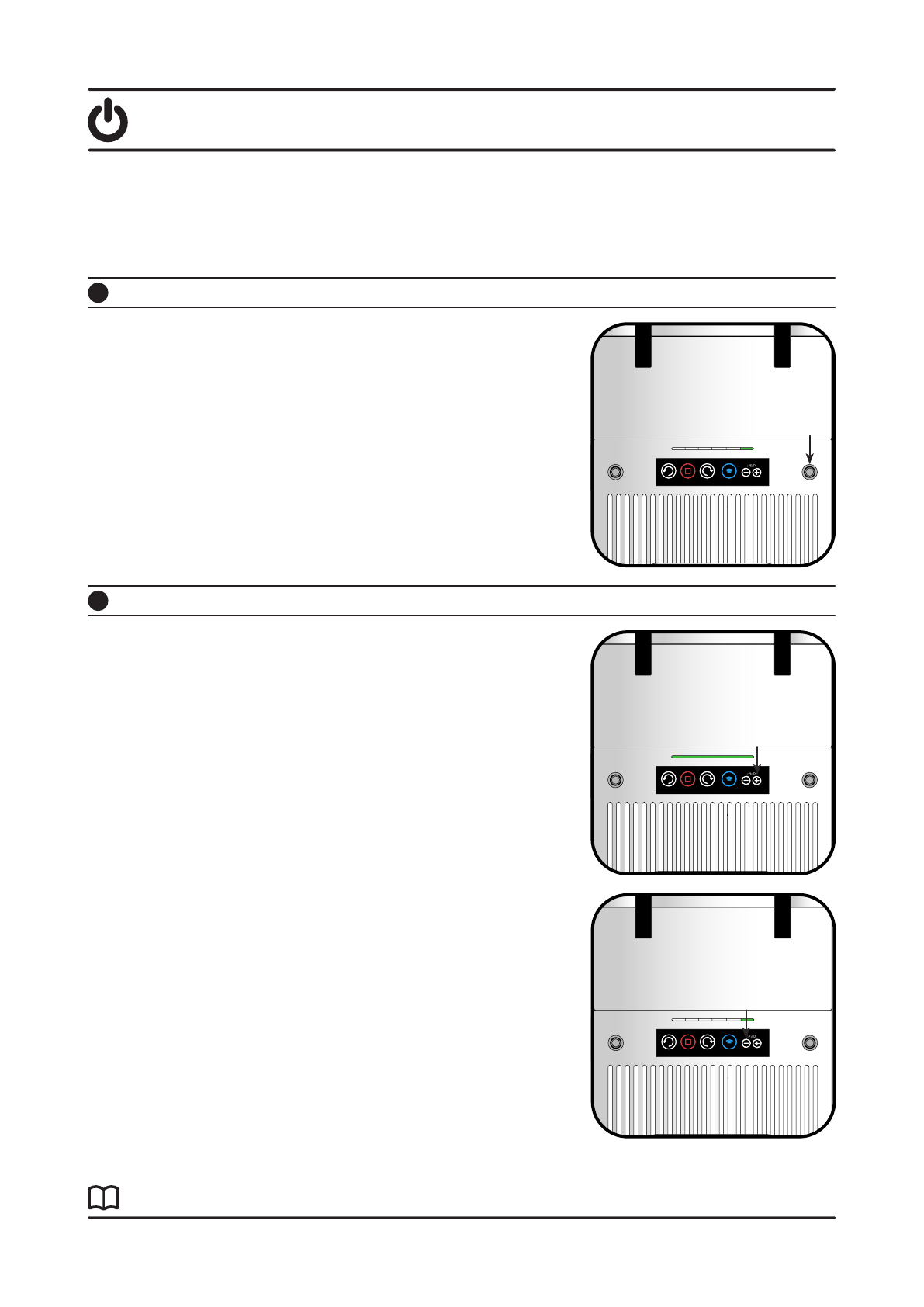

Switching on the equipment:

Switch on your VENET by pressing the on/off button. The LED strip

will turn green up to the section that corresponds t o t h e

minimum speed of the brush rotation, with intensity increases and

decreases.

The equipment is ready for use.

The equipment has 5 brush rotation speeds.

With the + button, you increase the speed, illuminating, in green,

each of the 5 sections into which the LED strip is divided, until all

five sections are illuminated, corresponding to the maximum

speed of rotation of the brush.

With the - button, you reduce the speed, turning off each section

of the LED strip, until you are left with an illuminated section

corresponding to the minimum speed of the brush rotation.

Brush rotation speed:

Electric brushing unit with built-in vacuum cleaner 20-29

venetvenet

3

4

5

operating instructions

Brush rotation to the left:

Pressing this button activates the counterclockwise rotation of the

brush.

The LED strip will light up progressively from right to left, going up to

the selected speed and back, remaining in continuous movement.

Pressing this button activates the clockwise rotation of the brush.

The LED strip will light up progressively from left to right, going up to

the selected speed and back, remaining in continuous movement.

Pressing the button activates the remote control, leaving the

equipment control panel deactivated.

The LED strip will turn blue up to the section proportional to the

selected rotational speed.

Right-hand rotation of the brush:

Remote control:

Table of contents

Other TECAi Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Clas Ohlson

Clas Ohlson TC-168 Guide

Bissell

Bissell CrossWave X7 Cordless Pet Pro 3011 Series user guide

Almeco

Almeco JetBlack Safety Cleaning Booth Installation, operation and maintenance instructions

Ultrasonic

Ultrasonic BT H Series System manual

Tineco

Tineco PURE ONE STATION FURFREE Series instruction manual

RIDGID

RIDGID 0095691386786 manual

Gardena

Gardena AquaBrush Compact 02/18V P4A Operator's manual

IPC

IPC 146743 manual

Streamline

Streamline STREAMVAC 70ltr instruction manual

Tacony

Tacony Powr-Flite NEBULA MISTER Operator's manual

MSW

MSW MSW-DRAIN CLEAN 7.5E user manual

Battenfeld

Battenfeld Tipton Best Gun Vise Instructions for assembly and use