BLX-600-GEN2 User Manual Page 15 of 19 Updated: 09/02/22

USER MANUAL: BLX-600-GEN2

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

General

Installaon

OperaonAppendix Maintenance ConguraonTroubleshoong

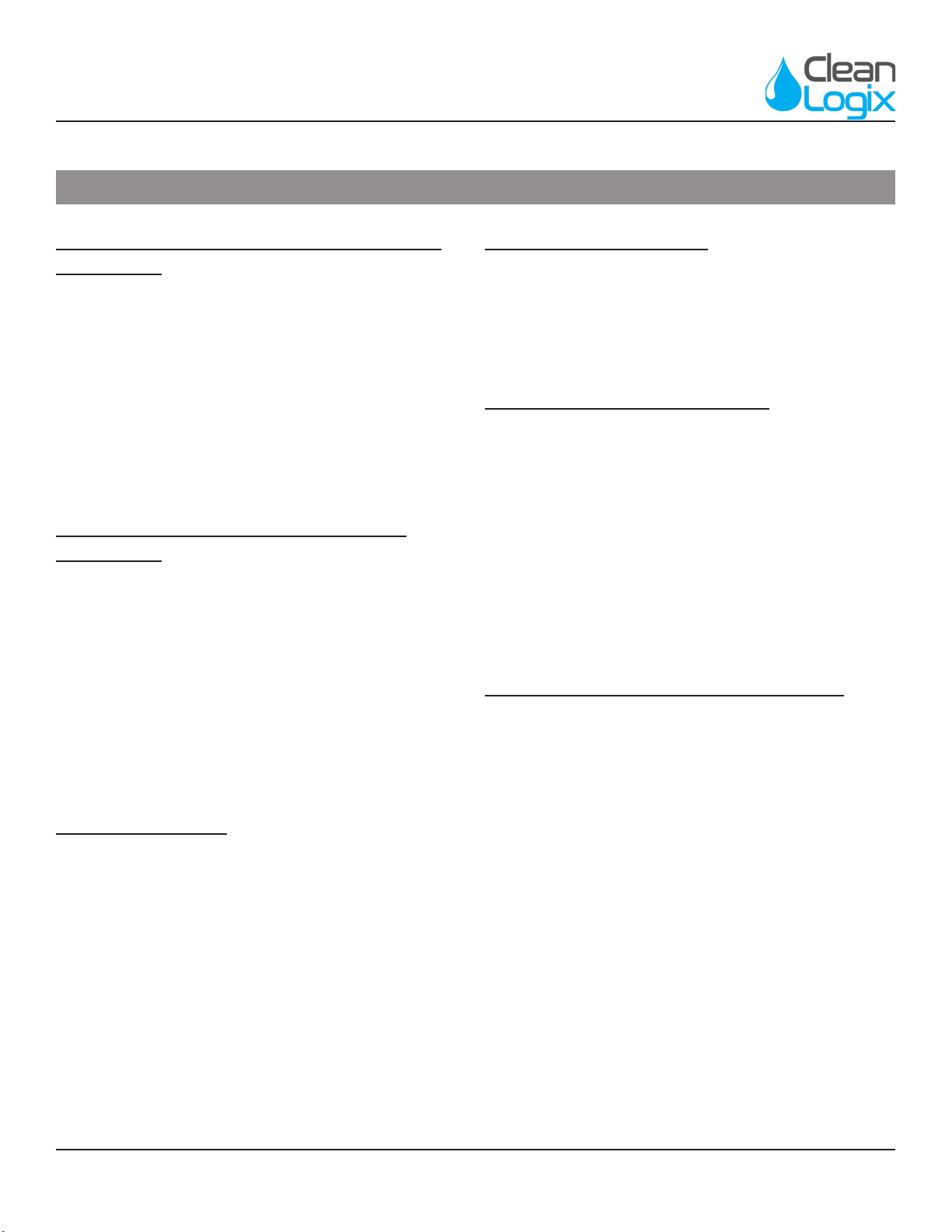

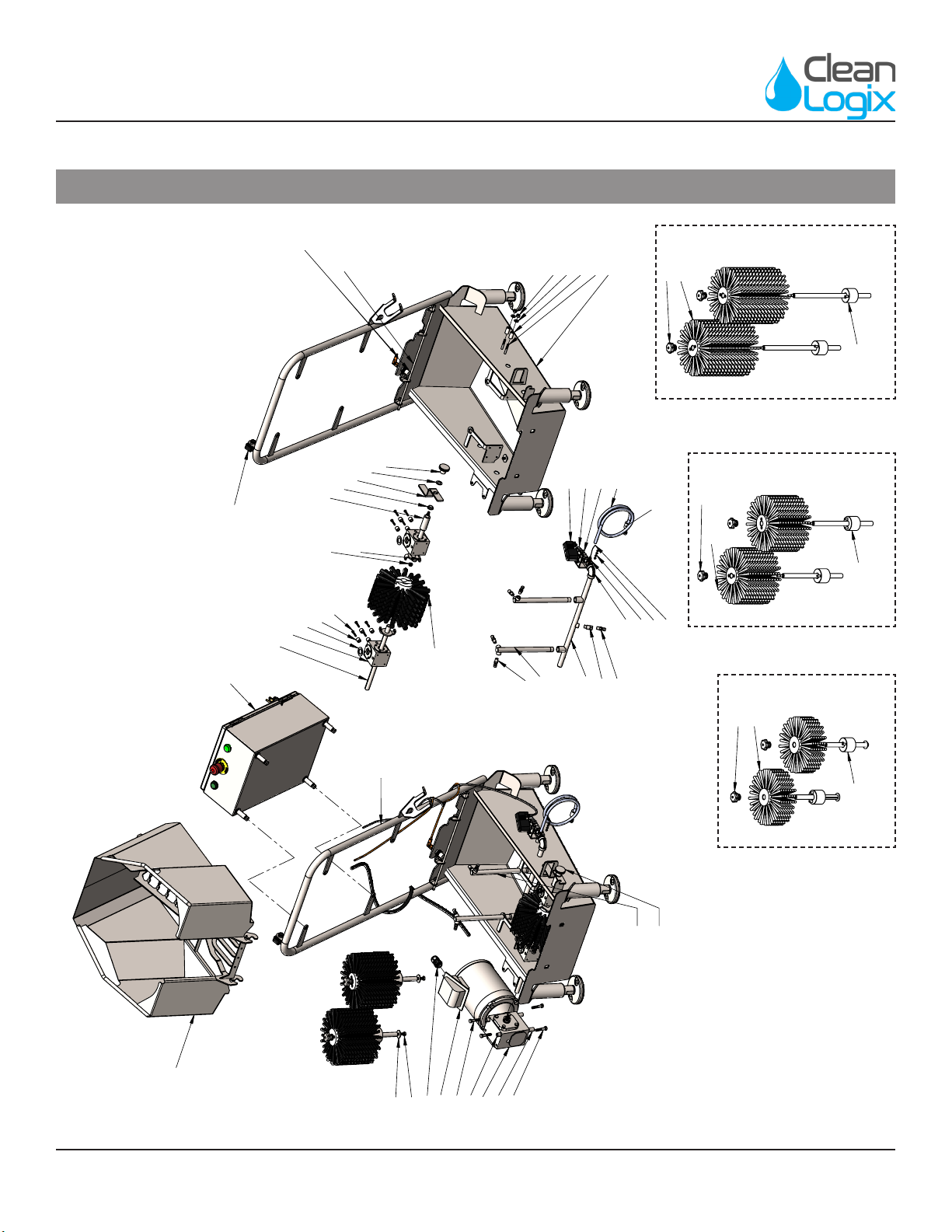

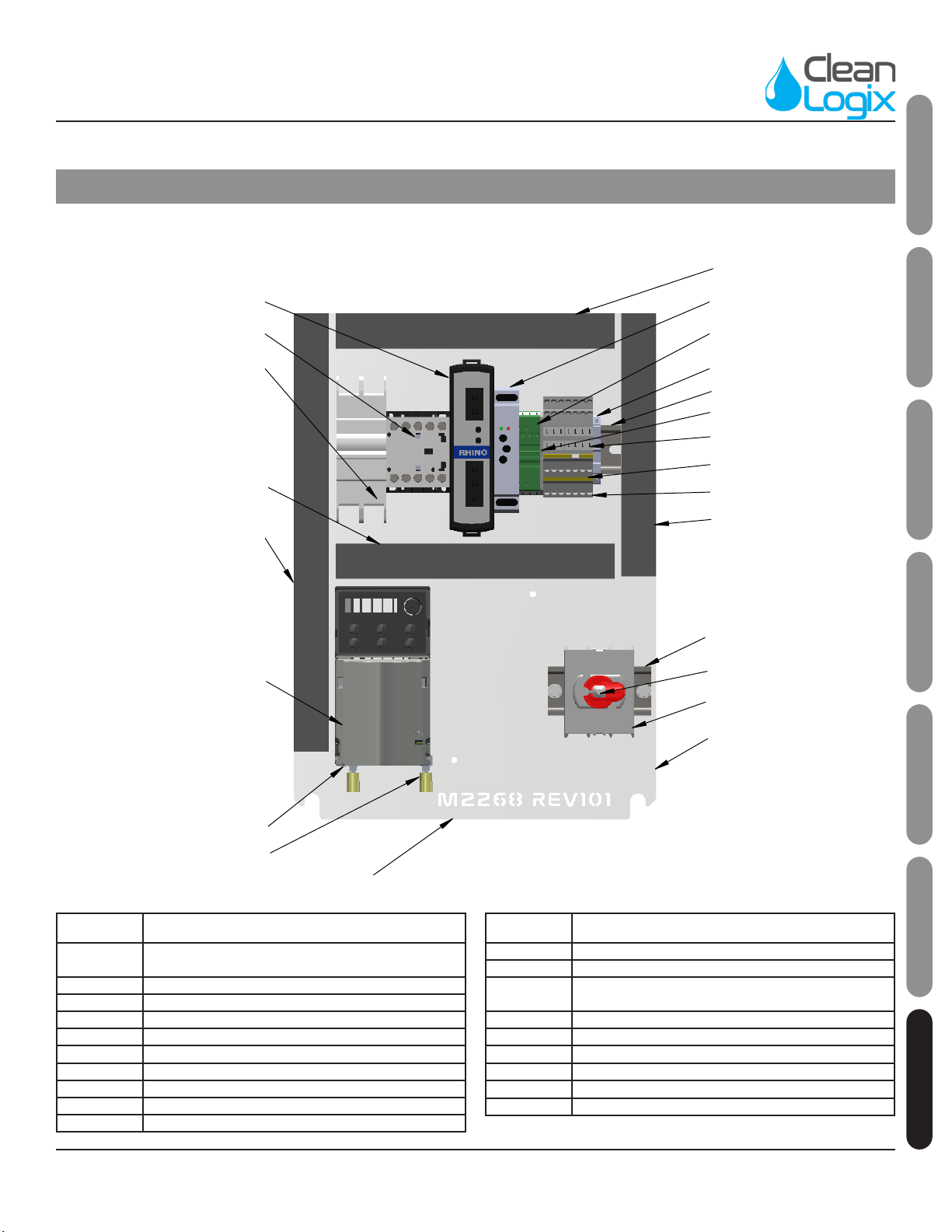

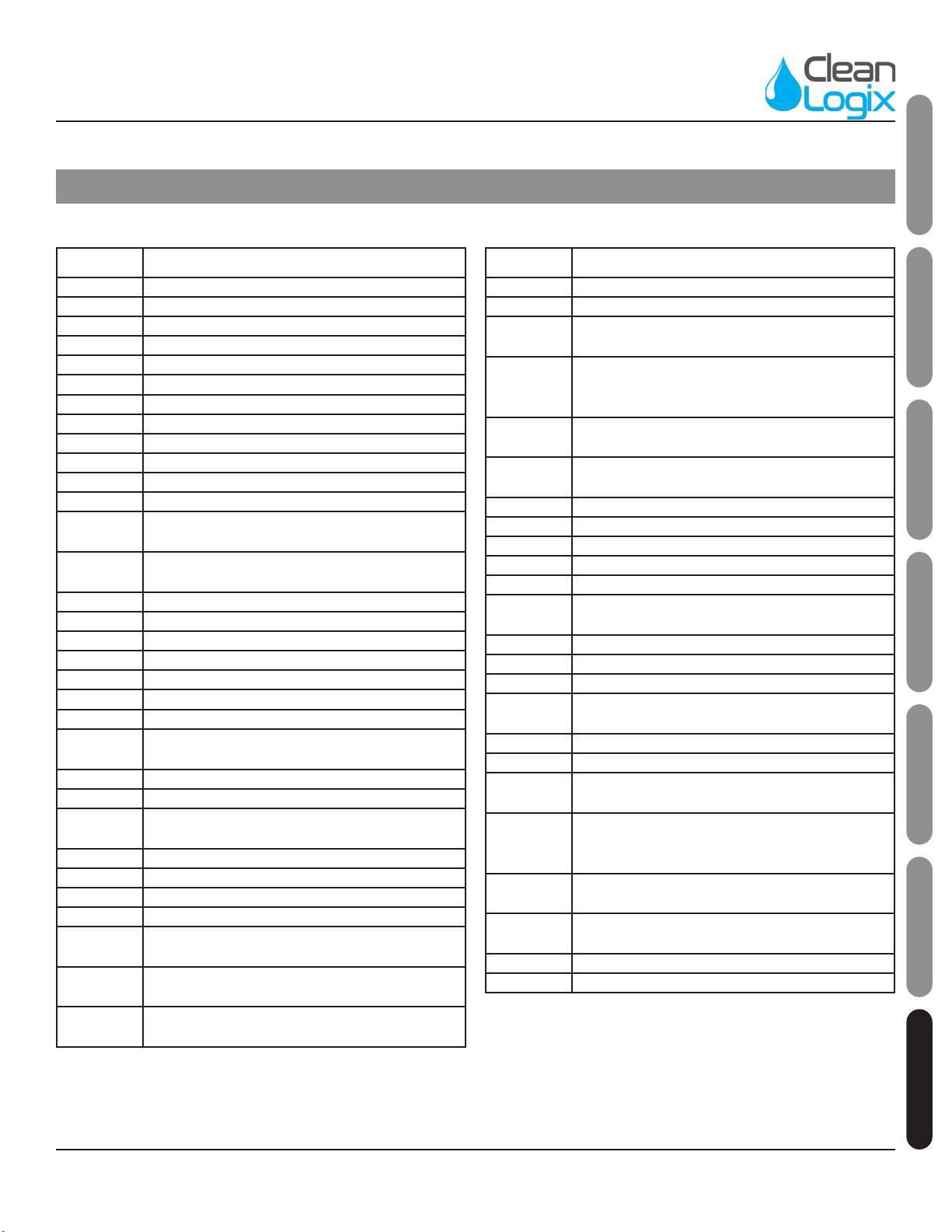

Appendix A - Parts Callout : BLX-600

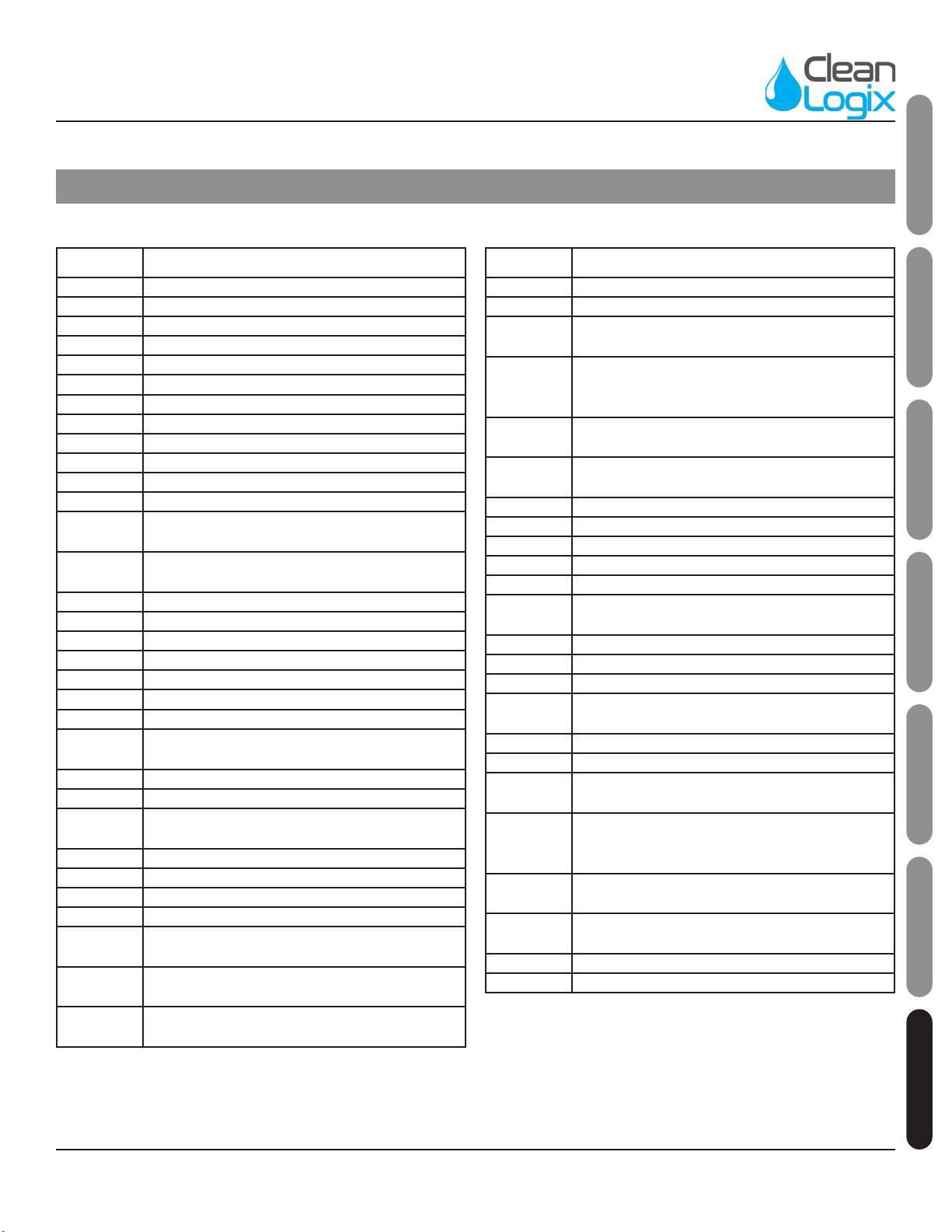

Part No. Descripon

F1000 STANDOFF 1/4 x 1/2 x 1/2 SS

F1001 Washer 3/4" X 1-1/4" X 1/16" PTFE

F1002 BEARING FLANGED 1/2' X 5/8' X 1/4' PTFE

F1046 NUT HEX FLANGED 1/4-20 SS

F1047 NUT NYLOCK 1/4-20 SS

F1056 WASHER 1/4 SS TYPE A

F1078 WASHER .5 X .88 X .06 UHMW

F1088 BOLT HHC 1/4-20 X 1-3/4 SS

F1126 BOLT HHC 10-32 X 1 SS

F1129 BOLT HHC 5/16-18 X 1-1/2 SS

F1136 STANDOFF 1/4 X 1/2 X 1 SS

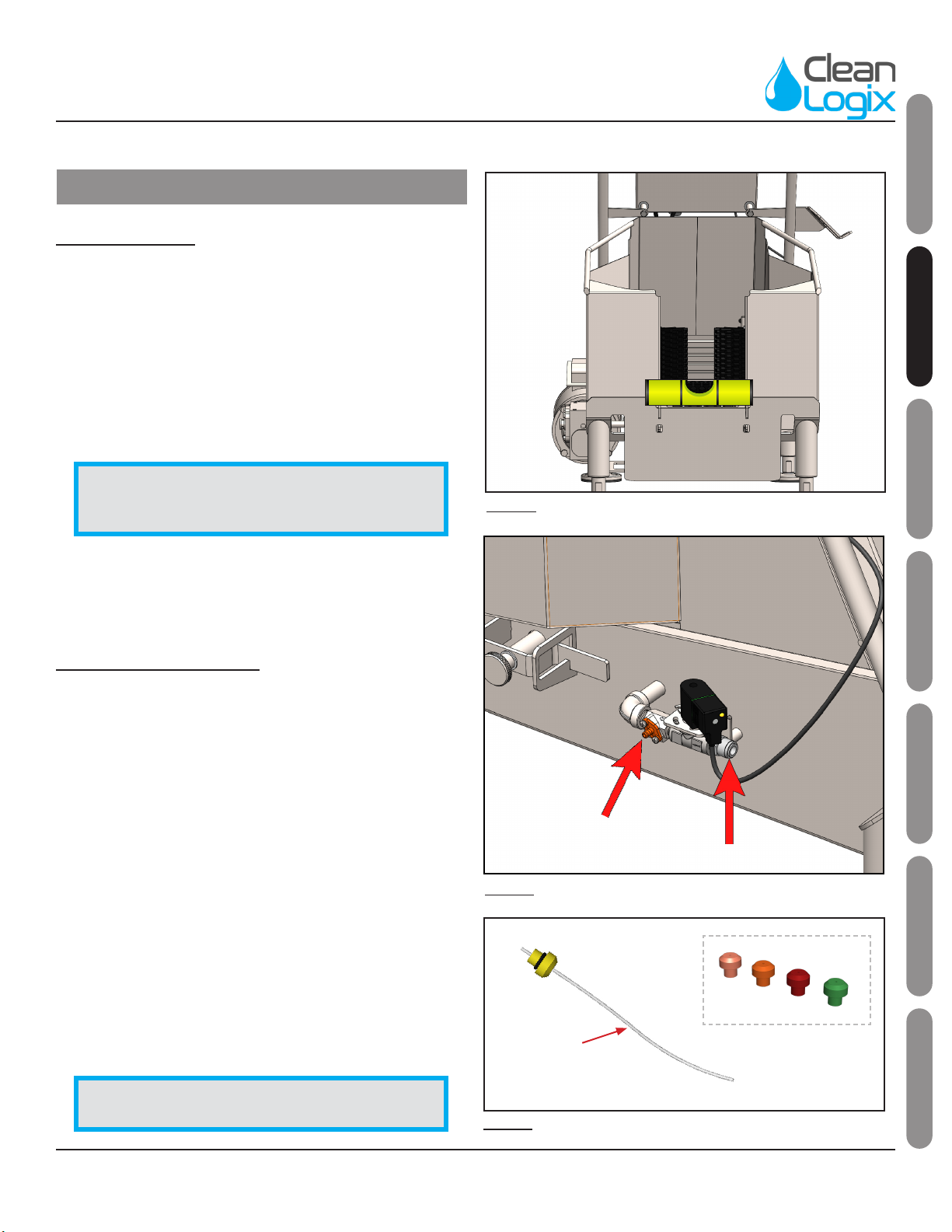

M1021 BRUSH SHAFT WELDMENT BLX-600

M1025 BRUSH, CYLINDER, 8" DIA. X 3" LONG, BLACK

PP FILAMENT

M1026 HORIZONTAL BRUSH BLX-600/800/1000 8"

DIAMETER, 6" WIDE

M1027 DRIVE SHAFT 1 WELDMENT BLX-600

M1030 Brush Coupler BLX-600

M1057 BRUSH KNOB WELDMENT FEMALE

M1134 SOLENOID BRACKET

M1570 SPACER 5/16 X 1/2 X 1 SS

M1618 BRUSH VERTICAL CYL 8 X 6

M1623 BRUSH SHAFT WLDMNT V-6

M1928 BRUSH, CYLINDER, 8" DIA. X 9" LONG, BLACK

PP FILAMENT

M1932 BRUSH SHAFT WLDMNT V9

M2212 BLX-600 GEN2 V9 SPRAY BAR

M2213 BLX-600 GEN2 SPRAY BAR WELDMENT SOLE

V3

M2214 BLX-600 GEN2 TUB WELDMENT

M2311 BLX-600V GEN2 GRATE WELDMENT

M2363 BLX-V SHAFT LATCH V2

M2366 BLX-600 GEN2 SPRING BAR WELDMENT

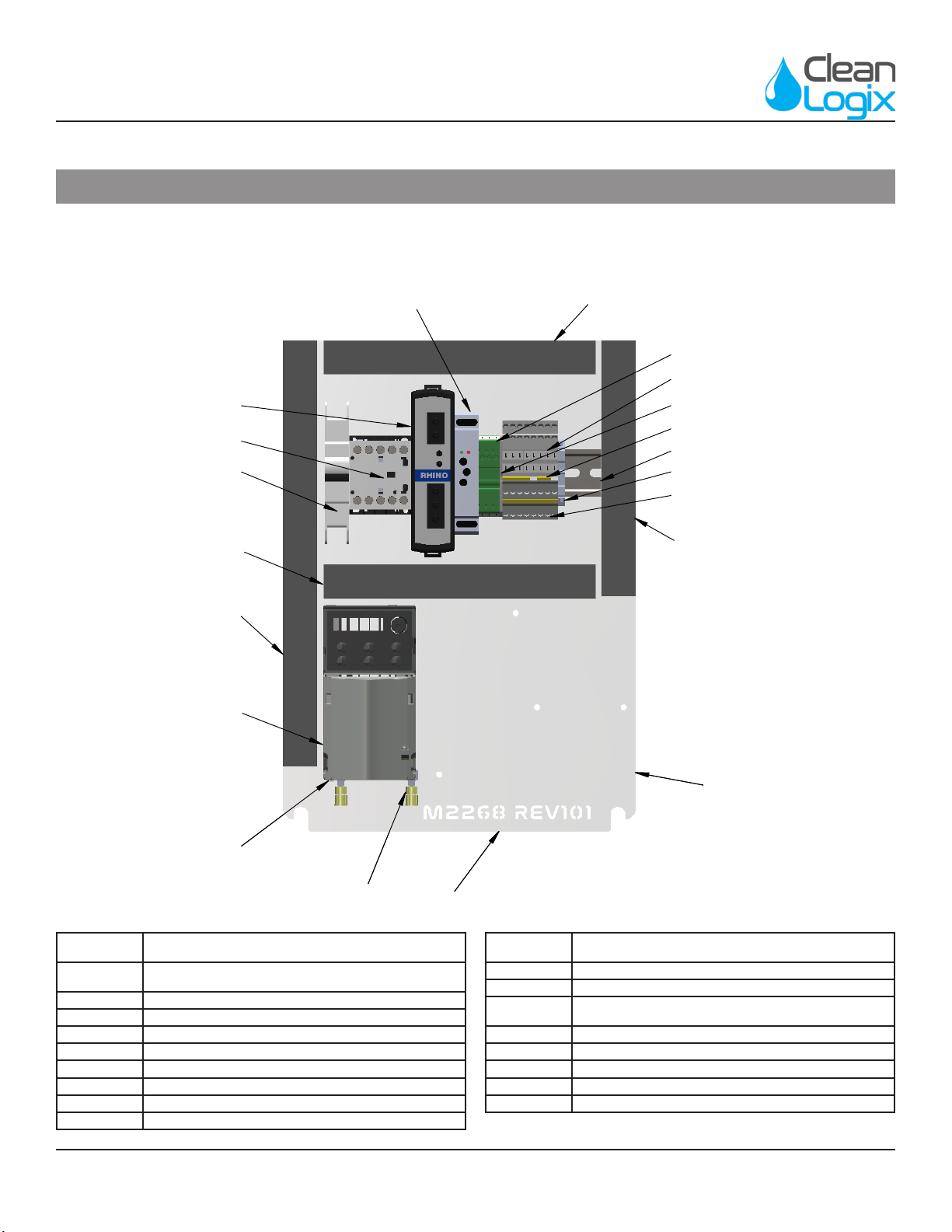

M2382 BLX-400-600 GEN2 ELECTRICAL ASSEMBLY -

230V-1PH

M2386 BLX-400-600 GEN2 ELECTRICAL ASSEMBLY -

115V-1PH

P1005 STERLING SS MOTOR 1/2HP, 1800 RPM,

230/460/3/60, TENV, 56C FOOTLESS

Part No. Descripon

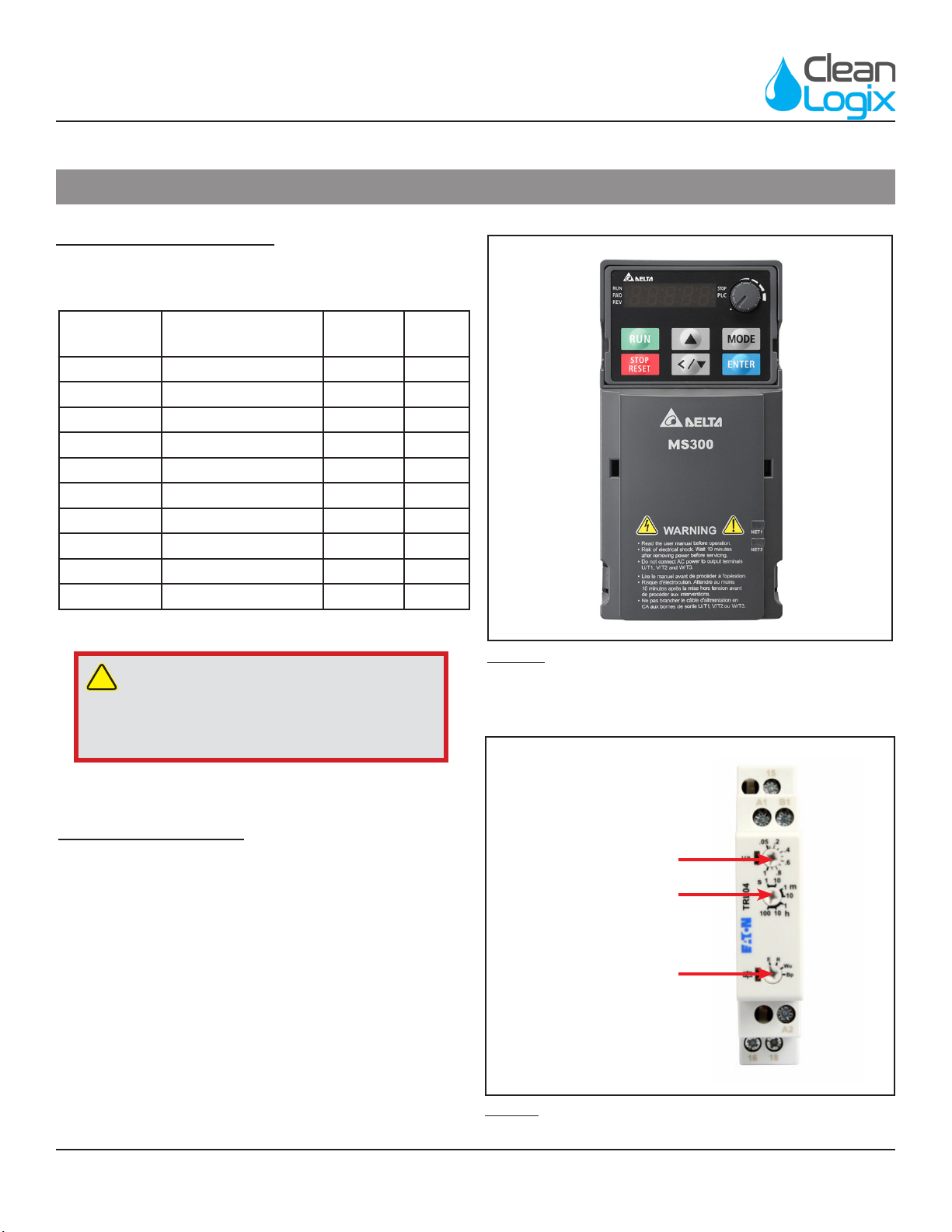

P1006 STERLING GEAR REDUCER 20:1

P1041 Photo Eye, Allen-Bradley 42EF, 24VDC

P1046 VALVE, SOLENOID, 3/8" SS 24VDC DIN COIL,

DEMA 463PS.4D

P1121

SENSOR, INDUCTIVE PROXIMITY, 18mm PP

8mm RN 4-Wire DC N.E./M.C. M12 IQ/D

Shielded

P1186 KNOB 1-1/2 x 5/16-18 THREADED HOLE SS

60205K68

P1187 SOLENOID CABLE 18MM DIN 24V LED 3M

SC18-LS24-3

P1219 QUICK FIT ADAPTER 3/8" NPT x 3/8" TUBE

P1244 LABEL PINCH POINT HAZARD

P1245 LABEL MOVING PARTS

P1247 LABEL BLX NOTICE

P1248 LABEL SLIP HAZARD

P1400 CABLE, M12, 4 POLE, 5m (16.48 ), RT-ANG

FEMALE/AXIAL MALE

P1515 CORD GRIP PG16 X .260-.545 GREY W/NUT

P1599 METERING TIP, CAPILLARY TUBE

P1677 SPLICE TERMINAL 10-16 AWG NATURAL

P1753 Branham SSIAS1101 : 1LHA.625B.625 Right

Angle Gear Box

P1769 METERING TIPS, ULTRA LEAN 100-15KU

P1830 PIPE ELBOW 3/8" x 90 304SS

P1903 VENTURI INJECTOR DEMA ROCKET, ORANGE,

.070", 1.3GPM@100PSI, SINGLE BARB

P1944

NOZZLE, FAN SPRAY, 110 DEGREE, 1/8 MNPT,

304SS, FLOODJET TYPE K, 0.2 GPM @ 10 PSI

(1/8KSS-2)

P1945 VENTURI INJECTOR 1/4" SUCTION LINE AND

STRAINER

P1946 VENTURI INJECTOR SUCTION WEIGHT

CERAMIC FOR 1/4" TUBE

P2199 CHECK VALVE 1/8"F X 1/8"M 1# SS

P2542 PIPE NIPPLE 3/8" X 3.5" L 304SS