2 2023-05-02

Click to go to Top of Document

Copyright © 2023 Cold Jet, LLC

All rights reserved. Printed in the USA.

Due to continued product development this information may change without notice. The information and

intellectual property contained herein is confidential between Cold Jet and the client and remains the

exclusive property of Cold Jet. If you find any problems in the documentation, please report them to us in

writing. Cold Jet does not warrant that this document is error-free.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written

permission of Cold Jet.

This manual reflects the product configuration as was current at the time of its writing. An item’s display in

this manual does not guarantee the item’s availability at any time in the future. Images shown are for

representation purposes only. Products may vary from the images displayed. Cold Jet is not liable for

typographical errors or changes to specifications presented.

Contents

System Identification____________________________________________________________________________________3

Introduction _____________________________________________________________________________________________4

Safety ____________________________________________________________________________________________________5

General Safety Guidelines ____________________________________________________________________________5

CO2Safety _____________________________________________________________________________________________6

Electrostatic Discharge _______________________________________________________________________________6

Electrical Grounding __________________________________________________________________________________7

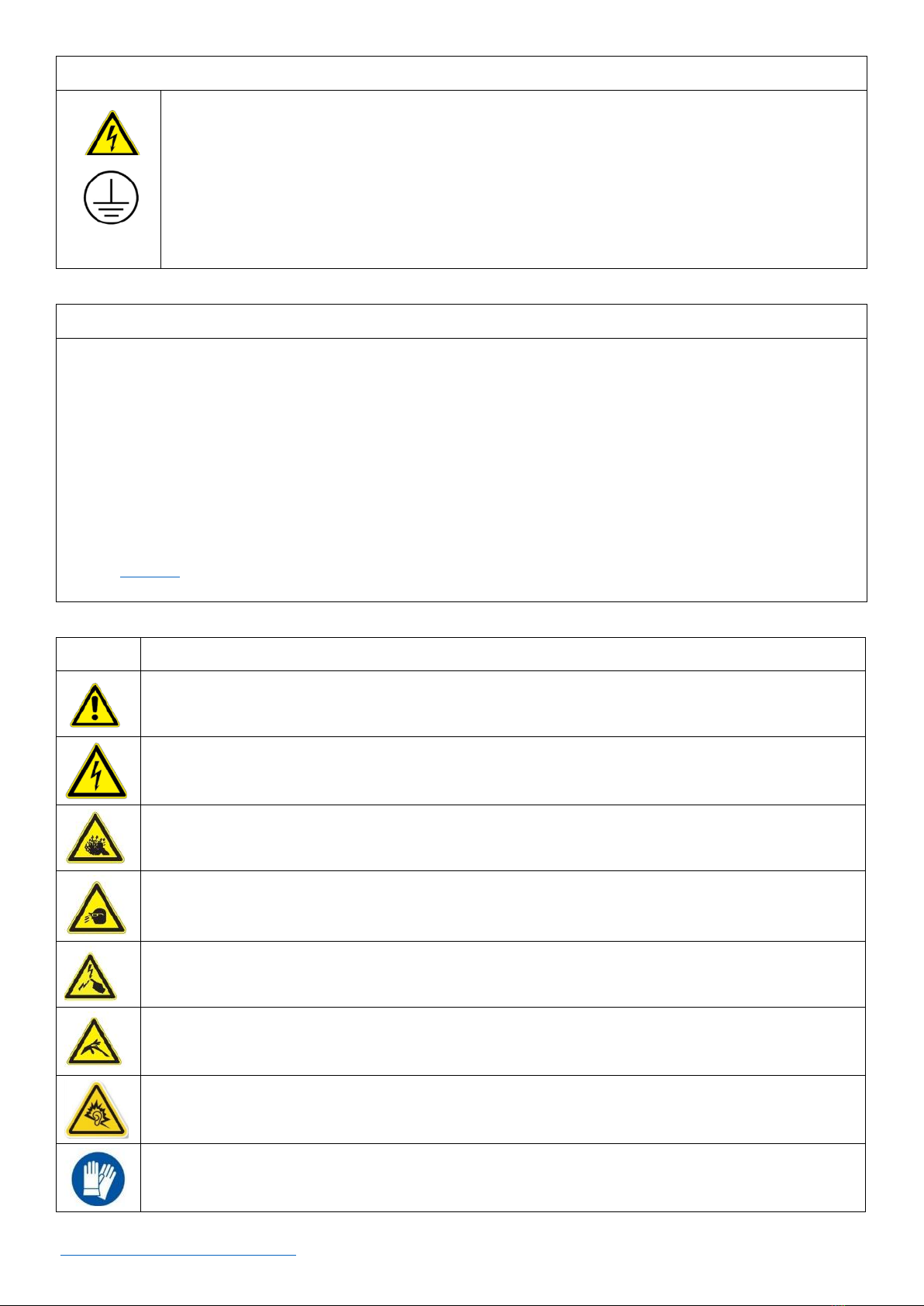

Safety Labels __________________________________________________________________________________________7

Cautions and Warnings _______________________________________________________________________________9

Steps for conducting a Lockout Tagout ____________________________________________________________ 10

System Description____________________________________________________________________________________ 12

Machine Data _______________________________________________________________________________________ 12

Machine Components_______________________________________________________________________________ 12

Applicators __________________________________________________________________________________________ 13

Control Panel________________________________________________________________________________________ 15

Nozzles ______________________________________________________________________________________________ 16

Operation______________________________________________________________________________________________ 18

Unpacking the Machine_____________________________________________________________________________ 18

Transport, Storage, and Disposal___________________________________________________________________ 19

Machine Setup ______________________________________________________________________________________ 20

The Compressed Air Supply_________________________________________________________________________ 22

Starting the Machine________________________________________________________________________________ 26