Bike Friday Ever-E-Day 2021 User manual

Using Your Bike Friday®

Ever-E-Day

Green Gear Cycling, Inc.

3364 W 11th Ave. Eugene, OR 97402

800-777-0258 USA & Canada

+1-541-687-0487 Int’l • +1-541-687-0403 Fax

www.bikefriday.com • [email protected]

version 4/30/20

800-777-0258 •+1-541-687-0487 www.bikefriday.com

Table of Contents

Congratulations / If You Need Help

3

A Word on Safety / Your Tools

4

Unpacking your Ever-E-Day

5

Assembly: Install seatmast and seatpost

6-10

Assembling Riser, Stem, and Handlebars

7

Connect OSATA Frame

8

Installing wiring, housing, and cabling

9

Install and connect battery

10

Using a Quick Release

11-12

Assembly: Install Front Wheel, Disc Brake

12

Adding Brake Cable Slack

13

Double Check Steering

14

Install Pedals

15

Double Check Your Bike Friday

16

Adjusting your Ever-E-Day

17-18

Saddle Height

17

Handlebar Height

18

Bike Friday Service Overhauls

19

Bike Friday Service

20

More Maintenance Tips and Information

21-23

Airport and Travel Tips

24

Warranty Information

25

2www.bikefriday.com 800-777-0258 •+1-541-687-0487

Welcome to the Community

Congratulations!

You have just purchased the most versatile Electric Cargo

Bike available today. Your bike has been carefully

designed and constructed for your personal needs. All of

our bikes are manufactured in our Eugene, Oregon factory

by real cyclists who care about our customers and our

products.

Please take your time reviewing this manual before you

assemble your new Bike Friday. You will find your new

bicycle to be simple and reliable anywhere you go!

If You Need Help . . .

If you need technical assistance with any Green Gear® Cycling

product, or are unclear on the proper operation of your Bike

call and a Service Technician will help you get back on the

road. Our toll-free number in the US and Canada is

800-777-0258; international is +1-541-687-0487. Normal

business hours are 9 a.m. to 5 p.m. Monday through Friday

Pacific Time.. Because we understand the needs of world

travelers, we offer 24-hour technical support in emergencies.

If necessary, please call our regular number and our

answering service can forward you to a Service Technician on

call.

Extra Accessories

We also sell an extensive line of bicycle and travel

accessories. Whether you are riding the local back roads or

venturing into foreign lands we have the gear you need. Call

us for information on spare tires, tubes, replacement parts,

fenders, racks, bags, or other items to complete your Travel

System. You can purchase these products from our online

store: www.store.bikefriday.com

More Information

To check out our products, find other useful information,

discover Bike Friday events and Yak with other Bike Friday

owners on the bulletin board, go to our main website at:

www.bikefriday.com

Blue skies and happy trails from Green Gear Cycling

3www.bikefriday.com 800-777-0258 •+1-541-687-0487

A Word on Safety

Bicycles are a lot of fun, but improper use can result in

harm. Please, always ride safely!

• Always have all passengers wear a helmet.

• Follow the rules of the road, and be courteous.

• Use front and rear lights after dark.

• Dress appropriately for the weather, the season, and

lighting conditions. Be seen!

• Always carry a spare tube, patch kit, pump and a tool

kit.

• Keep your bicycle in good shape.

• Check your tire pressure before every ride.

• Make sure all quick releases are secure.

• Have your bicycle routinely serviced for trouble-free

travels.

Bicycle Assembly and Maintenance

Correct assembly is essential to ensuring your comfort,

performance and safety while riding the Ever-E-Day. Even if

you have the experience and tools to complete these

essential assembly steps before your first ride, Bike Friday

recommends having a reputable bike mechanic check your

work.

If you feel you do not have the experience and tools to

complete assembly and fit, Bike Friday strongly

recommends having the bike assembled by a reputable bike

mechanic for best results.

Your Ever-E-Day uses industry standard components and

most bike shops should be able to service your bicycle.

They are welcome to call or email us with questions. We

also encourage you to learn how to work on your own bike.

If you are not familiar with bicycle maintenance, consider

taking a local class. It will improve your confidence and

self-sufficiency as you venture across the globe or explore

your own hometown.

4www.bikefriday.com 800-777-0258 •

+1-541-687-0487

Unpacking your Ever-E-Day

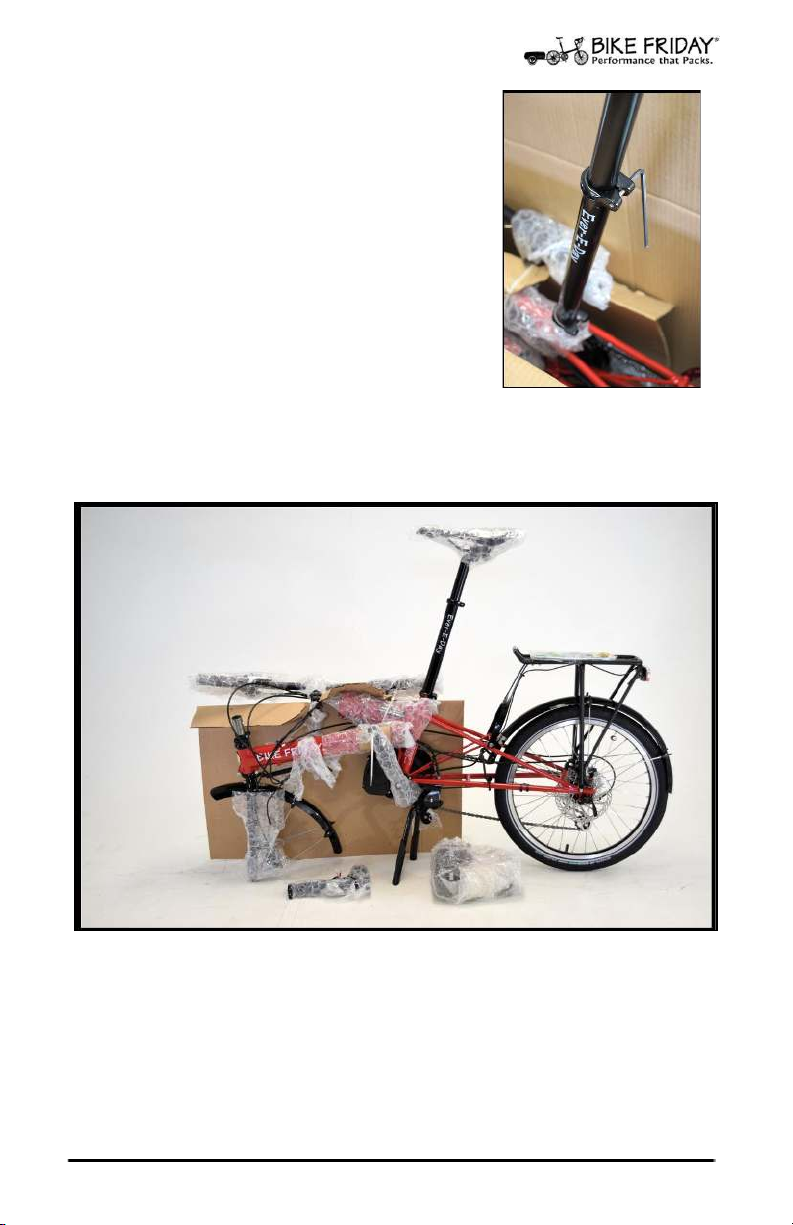

Unpacking Your Ever-E-Day From a Box

Opening your box may present an intimidating

sight, particularly if you ordered many accessories.

Do not worry; we work hard to keep our products as

simple as possible. We recommend finding a quiet

area and some room to spread out.

This manual will address the fundamentals of unpacking,

assembly and adjusting techniques. However, because

your bicycle was built for you, you might discover that

your bike was packed at the factory slightly different

than the one in this manual.

Your Ever-E-Day should only require minimal assembly. It

will take approximately 40-60 minutes and require a

basic level of technical skill.

You will need a safety knife for

cutting the box open, 4, 5 and

6mm Hex/Allen wrenches, a

15mm open/pedal wrench and

a pair of scissors (or better yet

wire cutters, snips or diagonal

cutters) to cut zip ties.

Fig. 1 Tools Required for Ever-E-Day assembly.

[Note: Depending on the components and accessories you

have purchased with your Bike Friday, your specific model

may require additional tools.]

Fig. 2 Open the shipping box and remove this manual,

packing material, and various bicycle parts at the top of

the box. Take care not to damage the frame while cutting

zip ties.

5www.bikefriday.com 800-777-0258 •+1-541-687-0487

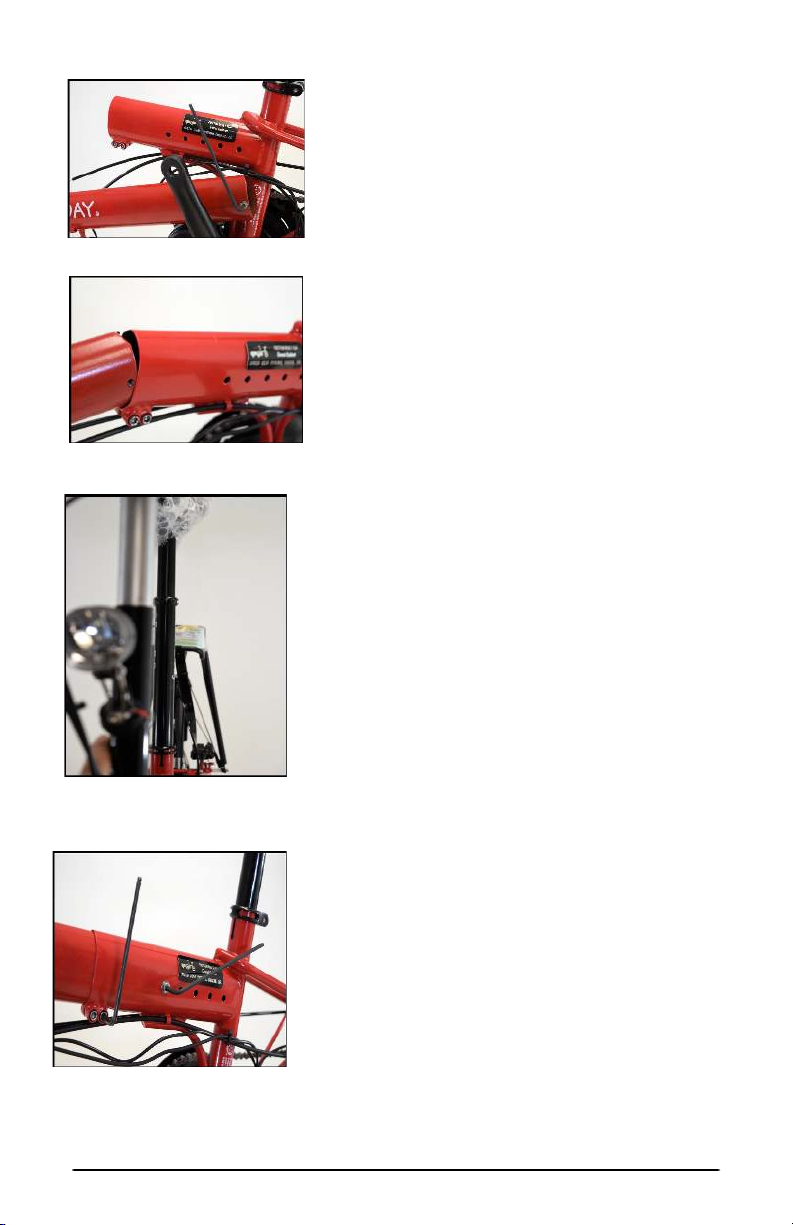

Unpacking your Ever-E-Day

Remove the bubble wrap and zip ties

to expose your seatmast, seatpost, and

saddle. Minding the minimum insertion

marks, install these components using

the 5mm Allen as shown to the right in

Fig 3.

Note: The minimum insertion mark is

etched at 4” from the bottom on the

mast. This is the minimum amount of

the mast that must be inserted

(overlapped) in the frame.

Now the bike is ready to be lifted and clamped in a repair

stand if desired. The instructions for assembly will

proceed as if you do not have a repair stand available.

Fig. 4. Either cut the front panel of the box and fold it

down, or lift the bike out of the box so it is set up as

shown. Accessories and components will differ for your

specific Ever-E-Day ensemble.

6www.bikefriday.com 800-777-0258 •+1-541-687-0487

Assembling your Ever-E-Day

Assembling Riser, Stem, and Handlebars

Locate riser clamp [Fig.5] Push down the button on the steerer

tube, slide riser clamp over steerer tube until button pops into

place. [Fig. 6] Tighten riser clamp. [Fig. 7]

Check that this system is secure by holding the front wheel

between your legs and attempt to turn the handlebars. If

properly adjusted you should be unable to turn the handlebars

while the wheel is held in place.

Fig. 5 Riser Clamp Fig. 6 Push Button Fig. 7 Tighten Riser Clamp

Cut zip ties over the front wheel and handlebars [Fig.8]

Check that all cables and housing are not kinked or twisted

around before installing [Fig.9] . Also note minimum insertion

mark on aluminum riser. This mark must be covered by the top

of the riser clamp for safe riding. Use 5mm allen to tighten.

Fig. 8 Cut zip ties over the

front wheel and

handlebars

Fig. 9 Ensure housing is untwisted

7www.bikefriday.com 800-777-0258 •+1-541-687-0487

Assembling your Ever-E-Day

Fig. 10 Remove sizing bolt

Fig. 11 Insert front section

Fig. 12 OSATA frame aligned

properly

Fig. 13 Tighten pinch bolts and

sizing bolt.

Attaching front section to

mid section (One Size

Adjusts To All (OSATA))

Cut zip ties and remove packing

material on the front frame

section. Remove the sizing bolt

from the front frame section.

[Fig.10]

Insert the front frame section

(male) into the frame mid

section (female) opening.This

connection should be greased

and slide easily when aligned.

[Fig. 11] Align threaded hole at

end of front section to

preferred OSATA sizing hole.

50-60cm range. Reinsert sizing

bolt.[Fig. 13]

Before tightening the OSATA

pinch bolts, align the frame by

sighting along the riser and seat

mast. Riser and mast should be

parallel.[Fig.12]

Tighten the sizing bolt. Tighten

the main frame pinch bolts with

a 5mm hex wrench. [Fig. 13]

Alternate tightening OSATA

pinch bolts until 8-10 Nm

torque is reached. This is

important for handling and

safety!

8www.bikefriday.com 800-777-0258 •+1-541-687-0487

Assembling your Ever-E-Day

Installing wiring, housing, and cabling

Seat cable housing for rear brake

into rear cable stop and pull

front section of housing into front

cable stop. Repeat this process

for the rear derailleur.

[Fig. 14]

Fig. 14 Seat housing in stops

Integrated front and rear LED lights come

standard on the Ever-E-Day. Connect red to

red, black to black for the front light. If you

get the order incorrect don’t worry, the light

just won’t turn on. Flip the order and try

again. [Fig. 15] The rear light wiring

connects red to “+” and black to “-” [Fig. 16]

Fig. 15 Front Light

Fig. 16 Rear Light

Fig. 17 Wiring Detail Fig. 18 Speed Sensor

Wiring connections behind the bottom bracket shell are tested at the

factory. [Fig. 17] Small arrow/triangle on speed sensor should align

with magnet on rear wheel. [Fig. 18]

9www.bikefriday.com 800-777-0258 •+1-541-687-0487

Assembling your Ever-E-Day

Install, connect and charge battery

Locate Separately wrapped battery and battery bag. Bag can be

attached to saddle rails and seatpost. [Fig. 20] Bag and battery can also

be attached to seat stays between seatmast and rear rack. Battery,

battery cable, and charger use Anderson quick-connectors. Connect Red

to Red, Black to Black. [Fig. 20]

Batteries have built in protection against misuse, but it is still

important to prevent damage, including water penetration from

harming the Battery. We recommend fully closing the battery bag with

the wiring exiting the bag from the lowest point. [Fig. 21] To recharge

the battery use the barrel plug connector or Anderson connector

depending on the type of battery and charger you have.

Fig. 20 Battery in bag Fig. 21 Ready to connect or charge

Electrical wiring is secured with a combination of zipties, spiral wrap,

and velcro straps for ease of customization, maintenance, and

upgrading.

The battery charger works like a standard laptop battery charger.

Several hours may be required for charging, depending on battery size

and level of charge.

If you’re not using your electric bike for a while, it is best to remove it

from the bike and store it in a warm area at least 40 degrees

Fahrenheit or more It’s best to keep it around 40 to 90 percent charged

during this storage. Do not leave the battery on the charger during

storage, but charge it every month or so to keep the levels in check.

Batteries that are not cared for can deplete beyond the point of

recharge and become unusable or have a shortened lifespan.

10 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Using a Quick Release

Using Those Nifty Quick Releases

The quick release is one of those simple but great inventions that really

makes life better. However, if used incorrectly, it can be potentially

dangerous. Although a reliable and safe product when used properly,

people have been injured or killed due to improper use.

If you are not familiar with their operation,PLEASE study these

directions carefully. If you are still unclear on their operation, call

us or contact your local bike shop before you ride!

Quick Release Operation

A quick release has a simple cam with a lever that swings through an

arc that is square to the axle. As the lever moves, the cam clamps the

wheel to the frame, or secures the frame joint. It is not a wing nut to

be rotated around the axle.

The tension on the quick release is controlled by how tight the knurled

nut on the other end is set. Only wheel quick releases have the small

cone-shaped springs. Note that the small ends of the springs face

toward the center of the hub.

Quick Release Maintenance

We recommend adding a few drops of light oil to the lever where it

enters the cap several times per year. This will keep your quick release

working smoothly for years.

11 www.bikefriday.com 800-777-0258 •+1-541-687-0487

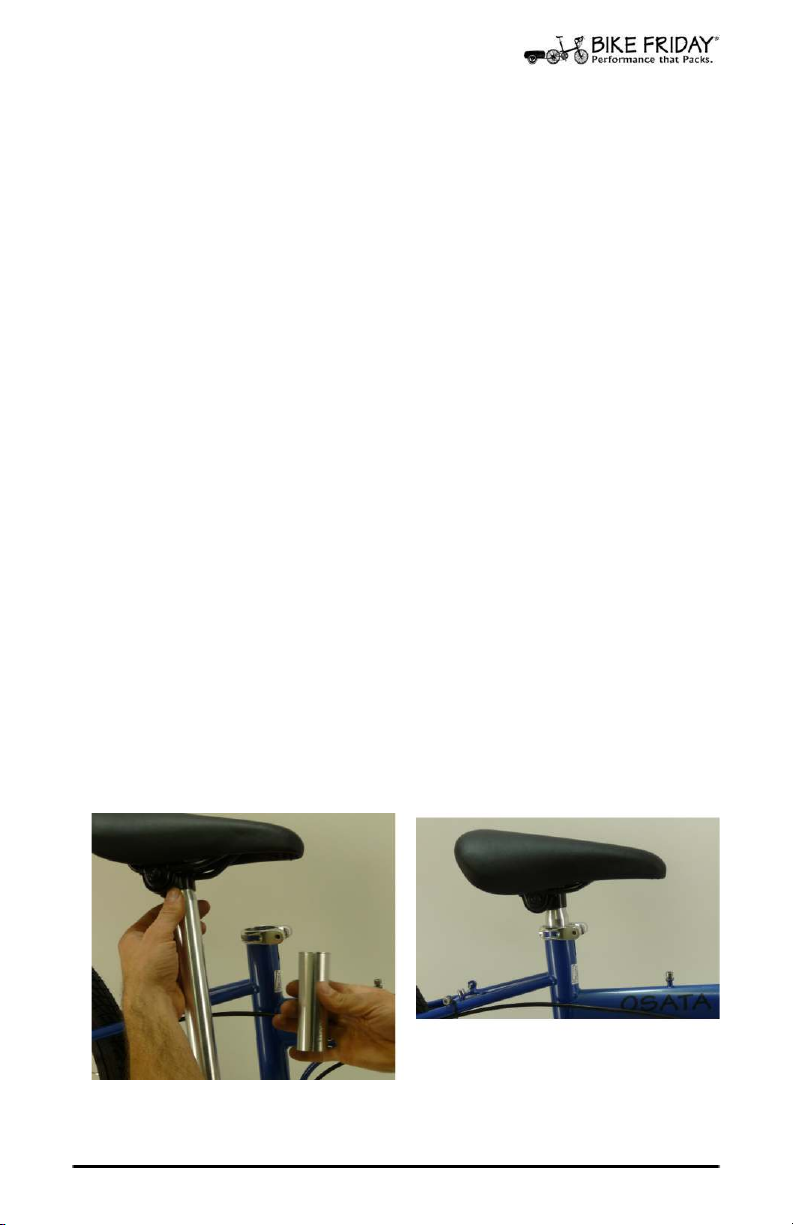

Assembling your Ever-E-Day

Install the Front Wheel

Make certain the wheel is fully

seated in the fork drop-outs,

with the disc brake rotor

properly aligned, you can now

securely close the quick release

lever. [Fig 20.] The quick release

levers (front and rear) are to be

placed on the non-drive side of

the bicycle. When the quick

release is properly adjusted, you

should be able to freely swing

the quick release lever for the

first half of its arc, at which

point the lever should offer

resistance but still allow for the

lever to be fully closed.

Fig. 20 Secured quick release.

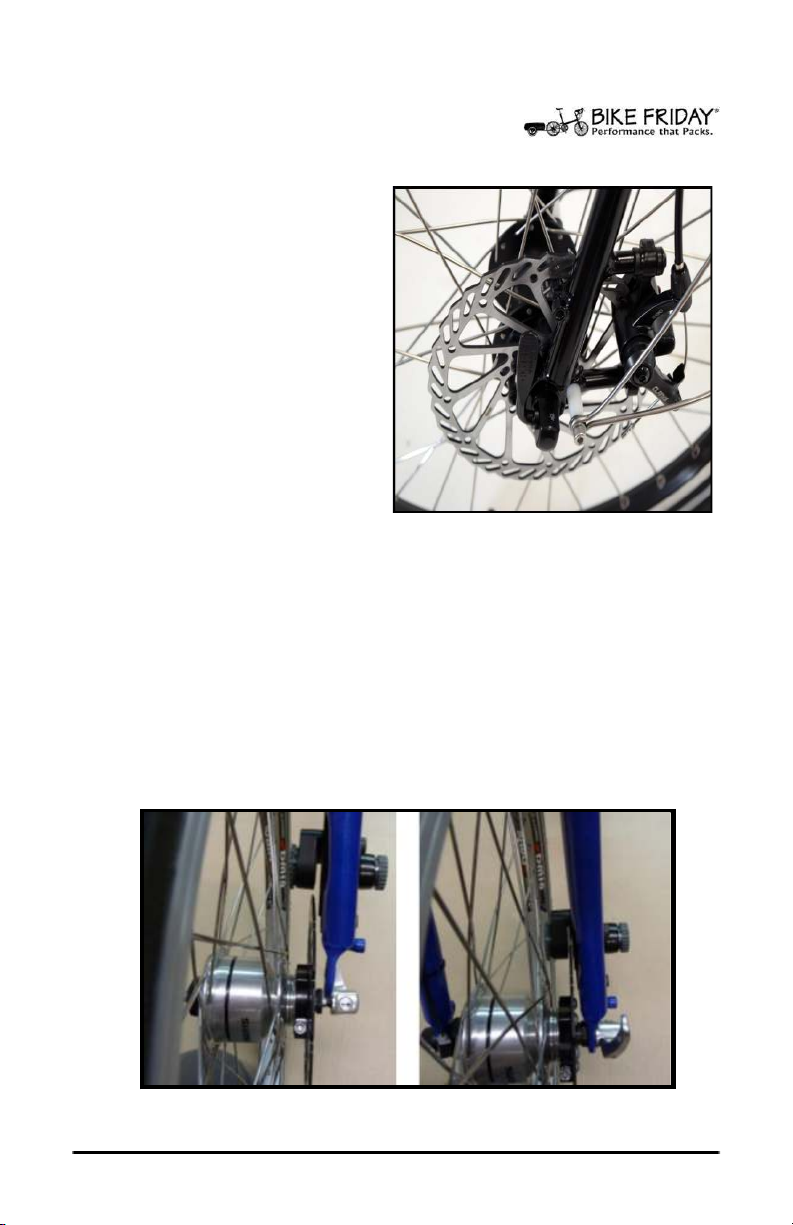

Disc Brakes

When inserting the front wheel into the fork, ensure the disc

rotor (on wheel) fits nicely into the slot on the caliper (installed

on the fork leg). You will want to avoid the rotor getting hung

up or caught on some part of the caliper as you are installing

the wheel into the fork to prevent rotor damage. Also avoid

touching the disc brake rotor as oil can make your brakes squeal

and degrade brake performance.

12 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Assembling your Ever-E-Day

Fine Tuning the Brakes

For quick minor adjustments to

the brake tension in the brake

cable, you can turn the barrel

adjuster on the brake lever. Turn

this adjuster clockwise to loosen

the cable or counter clockwise to

add tension to the cable. Ensure

that you don’t thread the barrel

adjuster out too far and always

tighten the lock nut to the lever

after making an adjustment.

More major adjustments can be performed at the brake caliper. Some

brake calipers feature both individual pad and cable adjustment while

others only off cable adjustment and control over the fixed pad. Since

these adjustments can, please consult with the manufacturer's

instructions or contact us and we can provide you with the necessary

information.

ALWAYS DOUBLE CHECK YOUR BRAKES BEFORE RIDING!

Improperly adjusted brakes can be a recipe for disaster.

If you are not confident in your brakes, please have them inspected by

a local bike shop.

Assembly: Pedals

Pedal Thread Directions

Bike pedals have two different thread directions. The right pedal has a

right-hand (clockwise) thread, and the left pedal has a left-hand

(counter-clockwise) thread. Pedals are often stamped with an R or L on

the pedal axle near the threads. Always grease your pedal threads on

new pedals before their first installation. We recommend starting

thread engagement with your hands instead of a wrench. If something

doesn’t feel right STOP. It is very easy to trip the thread of an

aluminum crank arm if pedals are installed incorrectly.

Mechanic’s Tip: You can put a wrench on the pedal’s wrench flats,

and use a back pedaling motion to screw the pedals on. This is a

quick and easy way to remember which way to thread your pedals

on and is applicable to either side of the bike.

13 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Double Check Your Friday

Double Check Your Bike Friday!

At this point your bike should be ready to ride. However,

before you ride away, be sure to double-check your assembly.

• Are the handlebars tight?

• How about the stem and pedals?

• Are the quick releases all secure?

• Is the saddle secure and at a reasonable angle?

• Are the handlebar and control levers in a proper place

and clamped tight?

• Do the electronics power on?

Although we always inflate the tires at the factory, check

your tire pressure for proper inflation. Under-inflated tires

not only wear faster and are more prone to flats, but they

also add rolling resistance.

Be sure to have at least the 5/6mm wrenches with you for

quick roadside adjustments. You will probably want to stop

and adjust saddle height and the angle, as well as perhaps

adjust a few other items during your first ride or two.

Mechanic’s Tip: Grease is your friend. Be sure to keep a

light film of grease on any intersecting bike parts. This

will help to prevent corrosion, facilitate disassembly, and

eliminate annoying noises. Areas include: Ever-E-Day frame

coupling joint, seatposts, saddle rails, handlebars, stems,

pedal threads and seatmast. Doing this a couple of times

per year during routine maintenance should be enough.

Wipe off any excess or visible grease. Also be sure to

lightly grease all bolt threads on your bicycle as you repair

or upgrade com-ponents. Lubricating your bolts will allow

you to adequately tighten the fasteners and keep them

from seizing in the future.

14 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Adjusting your Ever-E-Day

How to Adjust Your Ever-E-Day to Fit Each Individual Rider

The Ever-E-Day is adjustable to a wide range of riders.

Adjustments can be made to the main frame (frame size) as well

as the seatmast / saddle height and stem / handlebar height.

Frame Size: The Ever-E-Day frame can be adjusted between a

50 cm and 60 cm in 2 cm increments.

If you are comfortable with your current bike, you can use that

measurement as a guideline for your frame adjustment.

If you experience pain in your neck, shoulders, back or knees

from your current bike, you might want to go to a bike shop that

offers fitting. They can find the correct size to set your

Ever-E-Day to for a perfect fit.

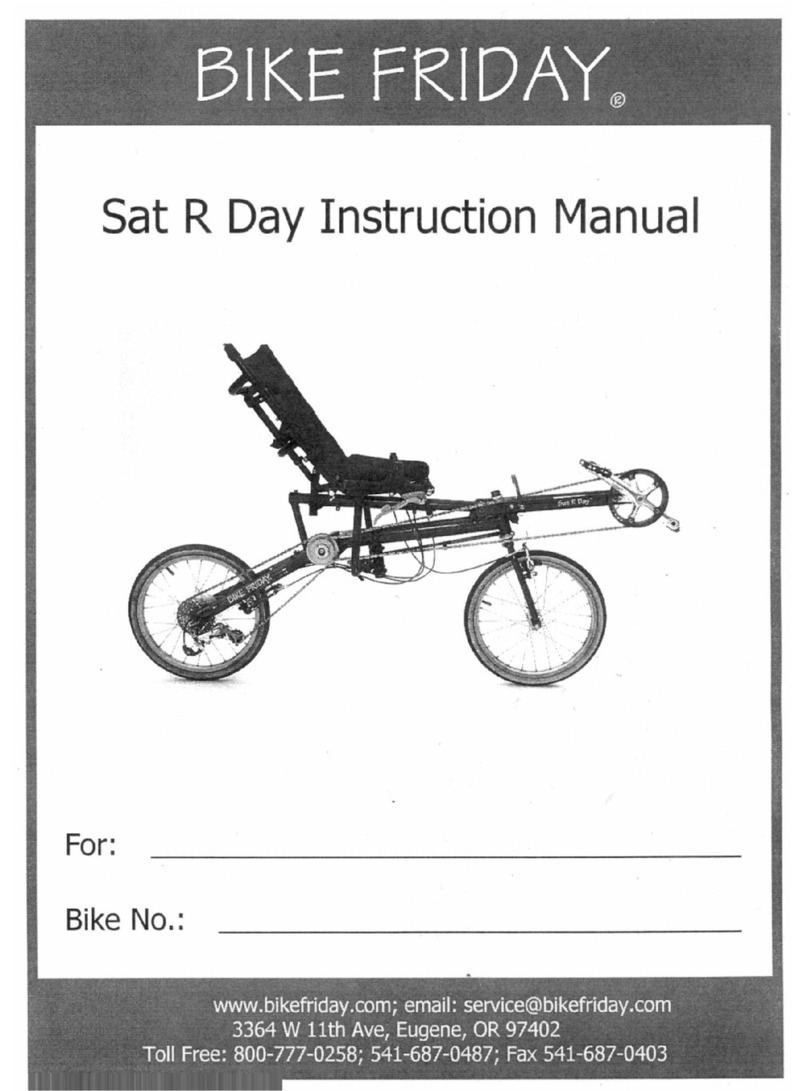

Saddle Height: Proper saddle height is important in

prevent-ing injuries as well as increasing riding efficiency and

com-fort. A rough rule of thumb method for determining

proper saddle height is when the pedal is in the 6 o’clock

position, your leg should have a slight bend in it with the ball

of your foot centered on the pedal, your knee almost fully

extended (but not quite). A quick way of achieving this is to

raise your saddle in small increments until you notice your leg

is fully extended in the 6 o’clock position and then lower the

saddle slightly. Rocking your hips to be able to reach the

pedals during the pedal stroke is to be avoided.

Special Feature: If you require the saddle to be lower than

the current lowest setting, you can purchase a shim and

seatpost from Bike Friday so the seat post is usable directly

inserted into the mainframe without the use of the seatmast.

Fig. 27 Lower Seatmast

no seatpost.

Fig. 26 Lower Seatmast, shim.

15 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Adjusting: Handlebar

Handlebar Height: This is a subjective preference. Handle-

bar height can be classified into three general categories:

1) bars below saddle; 2) bars level with saddle; 3) bars

higher than saddle.

For reference you can use an existing comfortable bike or

you can try out the three settings and see which one works

best for you.

Do note that humans tend to acclimate to whatever position

we are given to the point that we may subsequently be set up

with a properly sized bike and it will feel improper.

You may find it quite constructive to try a few positions,

just be sure to try them out for more than a few minutes

because that initial period may feel awkward, but possibly

because you have acclimated to incorrect sizing.

The beauty of the Ever-E-Day is the ability to try and use a

wide range of positions on the bike.

16 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Bike Friday Service

Bike Friday Service Overhauls

All of this, and the health of other components, can be checked

by our mechanics during your optional yearly overhaul.

A Bike Friday Overhaul includes:

• Check all components for wear and recommendations

on replacements

• Strip frame and clean components (optional solvent tank

option)

• Clean and optional alignment of the frame

• Replace stickers

• New cables and housing

• New bar tape, where applicable

• Test ride and packing

Don’t hesitate to call Bike Friday’s Customer Service

Depart-ment for help: 1-800-777-0258 (U.S.) or 1-541-687-0487

(world), or email [email protected]

17 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Bike Friday Service

New Bike Maintenance

Like all bikes, your Bike Friday travel bike will go through a break-in

period. After the first few weeks of riding you might find that your

drive train doesn’t shift as crisply as it did when new, or perhaps the

brakes are slightly loose. This happens as new cables stretch, housing

compresses and parts wear in.

After the initial break-in period, but before a significant tour, it is

important to have your Bike Friday bicycle professionally serviced at

your local favorite bike shop. A new bike tune-up takes very little time

and the small cost for the work is minor considering the improved

performance and reliability it provides. Then, at least once a year and

before any major tour, take your bike back to your local shop for

another tune-up to be sure that it runs smoothly.

After a few years of use and a few thousand miles of riding, you might

notice that the decals on your bike are starting to look worn and the

paint has some scratches. Perhaps your bike doesn’t ride as smoothly as

it used to, and the local bike shop can’t get it to function as well as

you would like. We offer factory service programs including tune-ups,

overhauls, and other repair work by our expert mechanics. A month or

two before your next big ride, you may wish to send the bike back for a

complete overhaul.

Visit our website for repair packages, costs, and details at

www.bikefriday.com/Service/. For those who plan ahead, we can

gen-erally offer the quickest repair turn-around during the winter

months.

18 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Bike Friday Maintenance

New Bicycle Tips and Maintenance Recommendations

Unlike other new bicycles purchased from a shop, your Bike

Friday Ever-E-Day has been disassembled partly and placed in a

suitcase or box. Then it was shipped across town, the country

or the world.

As with any new bicycle, your Bike Friday will need several

minor adjustments as it “settles in.” Knowing how to use barrel

adjusters on brakes and derailleurs and adjust spring tension on

brakes will help you through this settling in period. These skills

are also handy for when you travel with your bike.

Your local bike shop can help, or, check out the excellent

adjustment and repair guides at Park Tool Company’s

website: http://www.parktool.com/repair.

The Initial Break-in Period

It is reasonable to expect that a new bicycle will have an initial

break-in period where adjustments will need to be made after

a hundred-ish miles. The following items may occur or need

at-tention during this break in period:

• Brake and derailleur cables may stretch. You can perceive

this as you squeeze the brake lever and you have to

squeeze farther than previously OR you have to squeeze so

far before the pads contact the rims that there is not

sufficient braking force.

• Some bearing surfaces, notably some headsets, might

settle in after some use. If they are properly adjusted after

this initial break in period, they tend to then hold that

adjust-ment for a much longer period of time.

• For square taper bottom brackets (and the

corresponding crankset), it is a good idea to use an 8mm

hex / Allen wrench to ensure the crank bolt is tight.

19 www.bikefriday.com 800-777-0258 •+1-541-687-0487

Table of contents

Other Bike Friday Bicycle manuals

Bike Friday

Bike Friday Family Tandem Traveler User manual

Bike Friday

Bike Friday SAT R DAY User manual

Bike Friday

Bike Friday All-Packa Guide

Bike Friday

Bike Friday Hub Motor E-assist User manual

Bike Friday

Bike Friday Pocket Rocket User manual

Bike Friday

Bike Friday Pocket Rocket User manual

Bike Friday

Bike Friday pakiT User manual

Bike Friday

Bike Friday tikit User manual

Bike Friday

Bike Friday tikit User manual

Bike Friday

Bike Friday tikit User manual