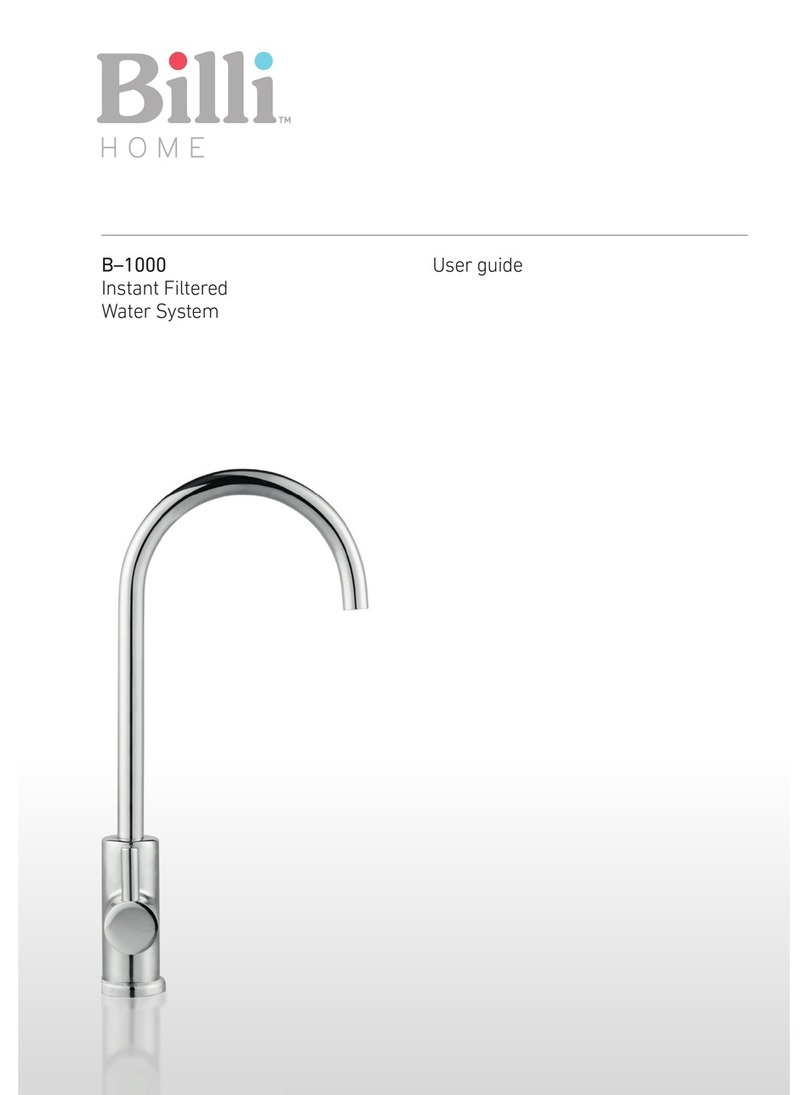

4

—Turn On Water Supply

Turn on the water supply tap and

check there are no leaks.

—Turn On Electricity

Turn on power switch. Check normal

time display is showing. Status line

should display ‘INITIAL FILL’. Boiling

and chilled water tanks are now filling.

Dispenser icons flash orange slowly.

—Cold Water

During the initial fill, cold water valve

automatically opens to fill the cold tank.

After approximately 1 minute, cold water

will begin to flow from the dispenser outlet.

Water will continue to run for a further minute

to flush and condition the filters.

—Hot Water (Auto Boiling Calibration)

Auto Boiling Point Calibration:

The hot tank will first fill to the height

of the low level sensor. The water is then

heated until it reaches boiling point. The unit

will continue to boil for up to 30 seconds while

the temperature sensor calibrates.

WARNING: Steam and small amount of hot

water may be discharged from the taps and

vent during this period. While calibration is

underway the hot water indicator (red) will

double blink rapidly. The hot water set point is

calibrated 1.5°C below the boiling point. Once

calibrated, the unit will resume normal

operation and the calibration data will be saved.

The unit will not re-calibrate under normal

circumstances.

—Setting the programs

The B-6000 operational settings have been

factory set for a typical installation. Clock is

set to Eastern Standard Time (EST). Refer to

B-6000 User Guide for setting instructions.

In some installations, boiling water delivery

settings may need to be changed as

outlined below.

—Setting the programs

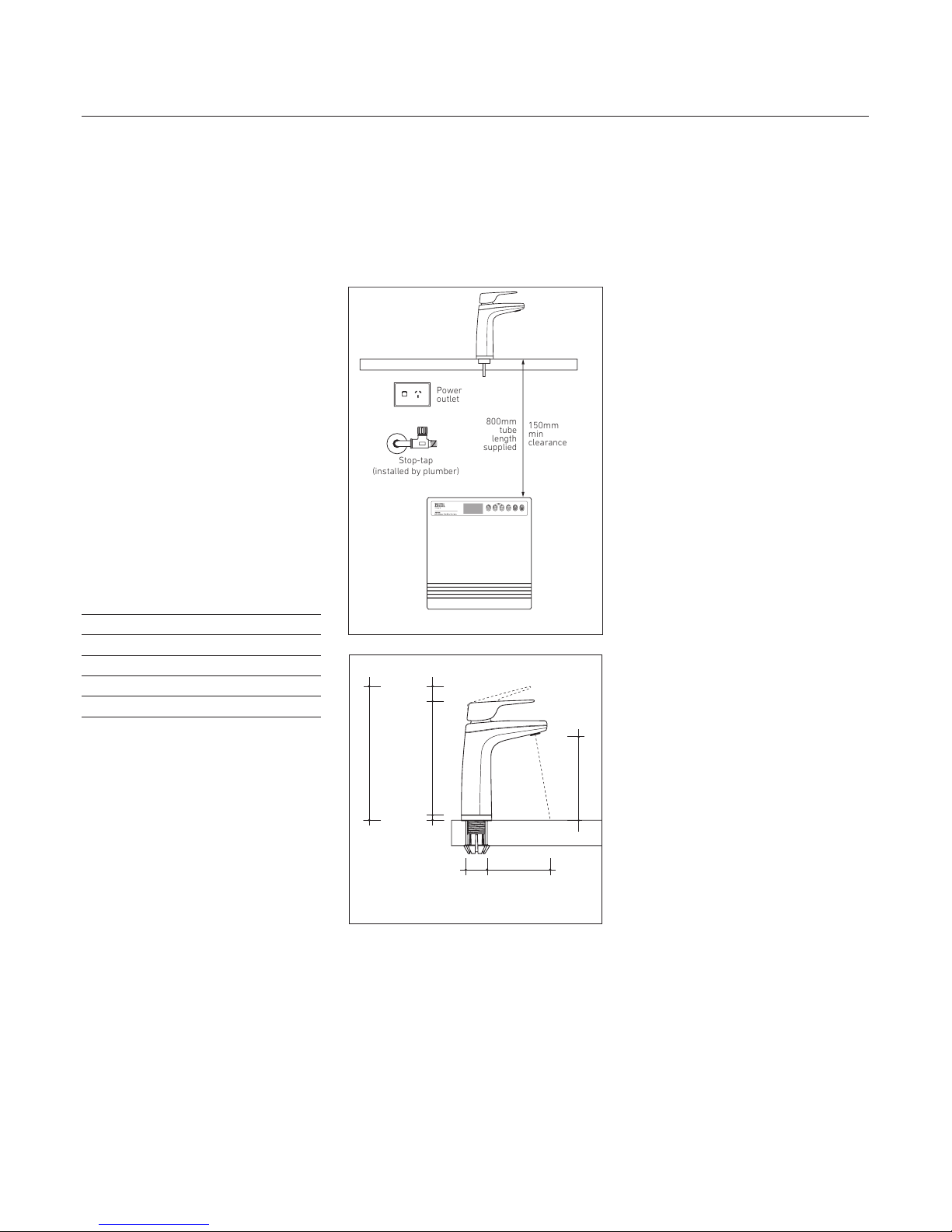

The B-6000’s boiling water flow rate

slows briefly as water first enters the

cup to prevent splashing. Correct timing

of the moment of reduced flow is dependent

on the length of the tube between the B-6000

module and the dispenser. The standard

timing is set for a tube length of 500mm but

this setting can be simply altered to suit the

installation. After installation, measure the

length of the red tube from the underside

of the dispenser to the boiling water outlet

fitting. If the measured length is less than

450mm or greater than 550mm, the

correct value should be set in as follows:

1. Press SELECT. Display changes

to menu selection mode.

2. Press 4 times. Shaded cursor

shows ‘INITIAL SETUP’.

3. Press SELECT. Display shows:

4. Press SELECT. ‘0500 mm’ flashes.

5. Press or buttons to enter the

correct tube length.

6. Press SELECT.

7. Press BACK twice to return

to normal display.

—Boiling water flow rate

The boiling water flow rate can be adjusted

to suit the installation or user preference.

Extended tube lengths will require the

pump speed to be increased.

1. To adjust, use the selection procedure

as described above in Steps 1, 2 and 3.

2. Press SELECT. Shaded cursor

shows ‘Pump Speed 015’.

3. Press SELECT. ‘015’ flashes.

4. Press or buttons to increase or

decrease. Range is between 10 and 20.

5. Press SELECT.

6. Press BACK twice to return to

normal display.

—Calibrating boiling water temperature

(Manually)

The boiling water temperature has been factory

calibrated. Because water boils at a slightly

lower temperature at elevated altitudes, the

factory-set temperature may be too high for

units installed at certain

inland locations. If the local altitude is greater

than 500 metres above sea level,

a calibration cycle should be performed.

The procedure is as follows;

1. Use the selection procedure as

described above, in Steps 1, 2 and 3.

2. Press SELECT twice to select

‘Calibrate Boiling Water’.

3. Press SELECT twice to begin cycle.

4. The unit will fill and heat (if not yet

up to operating temperature before

cycle begins).

—CAUTION

Steam will discharge from the vent

outlet located between the hot and

cold water outlets.

Once correct boiling temperature is

established, the B-6000 recalibrates

its internal settings and the display

panel returns to normal.

Commissioning.

Billi Pty Ltd

42 Lucknow Crescent, Thomastown

Victoria 3074 Australia

Telephone +61 3 9469 0400

Facsimile +61 3 9469 0499

www.billi.com.au

Designed and manufactured in Australia.

As Billi Pty Ltd has a policy of continual

improvement, all details are subject

to change without notice. All goods

are sold subject to our published terms

and conditions. Billi is a registered

trademark. 1012

WARNINGS.

For continued safety of this appliance

it must be installed, operated and

maintained in accordance with the

manufacturer’s instructions.

—Your appliance should be installed by

a suitably qualified tradesperson.

—For correct operation of this appliance

it is essential to observe the instructions

as outlined in this booklet.

—Do not use this appliance with water

that is microbiologically unsafe or with

water of unknown quality without adequate

disinfection before or after the system.

Systems certified for cyst reduction may

be used on disinfected water that may

contain filterable cysts.

—Filter replacement must be performed

at intervals of not more than 6 months.

—Use this appliance only as directed in

these instructions and only for its designed

purpose.

—This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety.

—Children should be supervised to ensure

that they do not play with the appliance.

—DANGER: The operation of the thermal

cut-out indicates a possibly dangerous

situation. Do not reset the thermal cut-out

until the water heater has been serviced

by a qualified person.

—WARNING: Do not connect any restrictor

or pressure relief device to the vent pipe

of this water heater if installed.

—If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualified persons in

order to avoid a hazard.

—New hose-sets supplied with the appliance

are to be used and old hose-sets should

not be re-used.