CUTTING OPERATION

The unit performs best when the ground is wet. If possible

sprinkle the work area several hours before starting.

CAUTION: Shut off the blades when crossing gravel drives, walks or

roads and under all conditions where thrown objects might be a hazard.

CLEARING DEBRIS FROM UNDERSIDE OF MACHINE: Turn

engine off and wait for blade to stop completely. Disconnect spark plug

wire and place the unit in gear to prevent the unit from rolling.

Wearing durable gloves, remove debris. Danger, the debris may

contain sharp materials. Reconnect spark plug wire.

CAUTION: Use extreme care when operating the blade. Inspect the

work area for foreign objects that could cause damage to the unit or

injure the operator if struck by the blade. Never operate the blade with

bystanders in the work area.

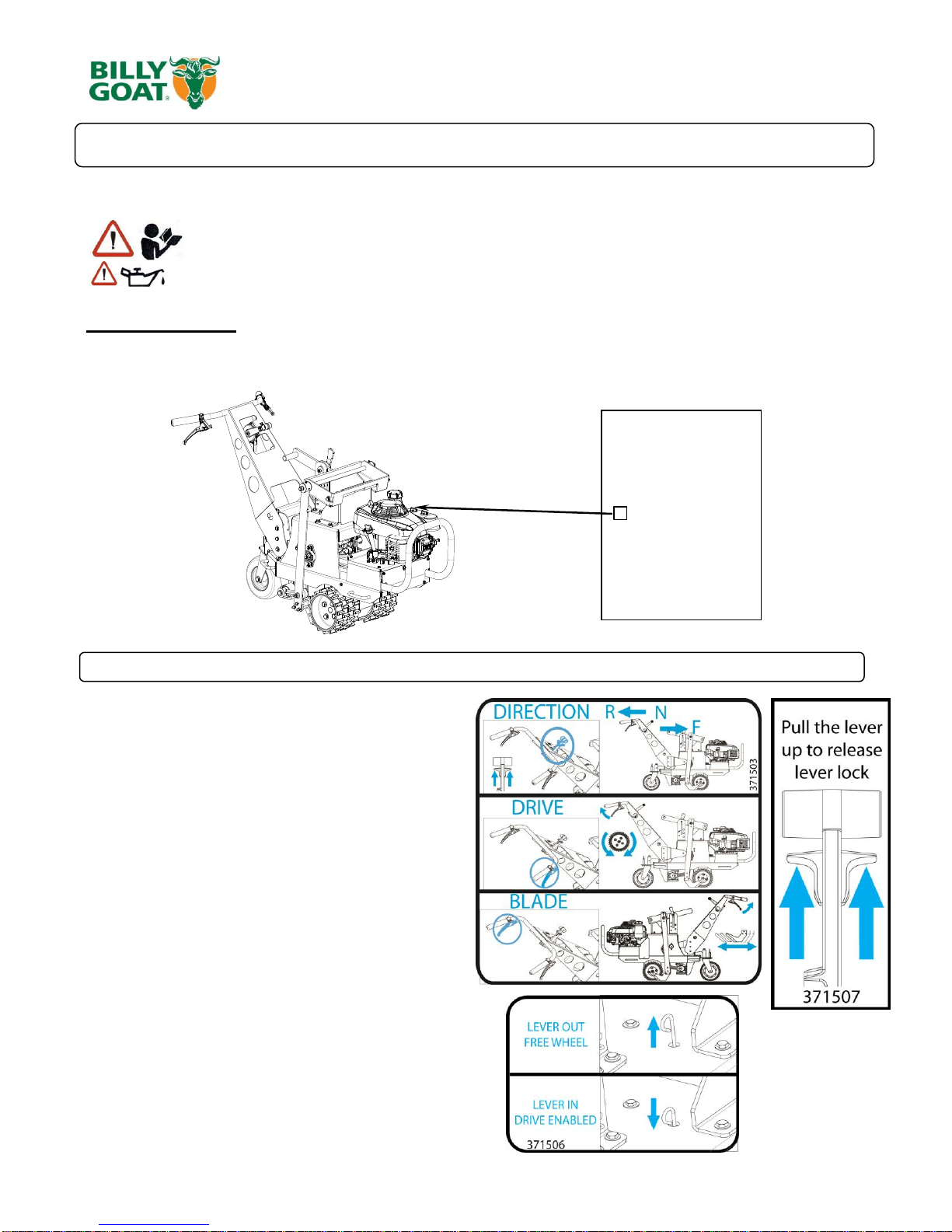

GENERAL OPERATION:

Position the turf cutter outdoors on sufficiently firm, flat soil. Read the

instructions provided by the engine manufacturer in the relative manual

and follow them carefully to prevent situations arising which may

endanger either persons or the machine.

WARNING: When using the machine for the first time it is

advisable to get the feel of it by executing maneuvers on flat

ground free of foreign objects.

After switching on the engine following the instructions given in the

previous paragraph:

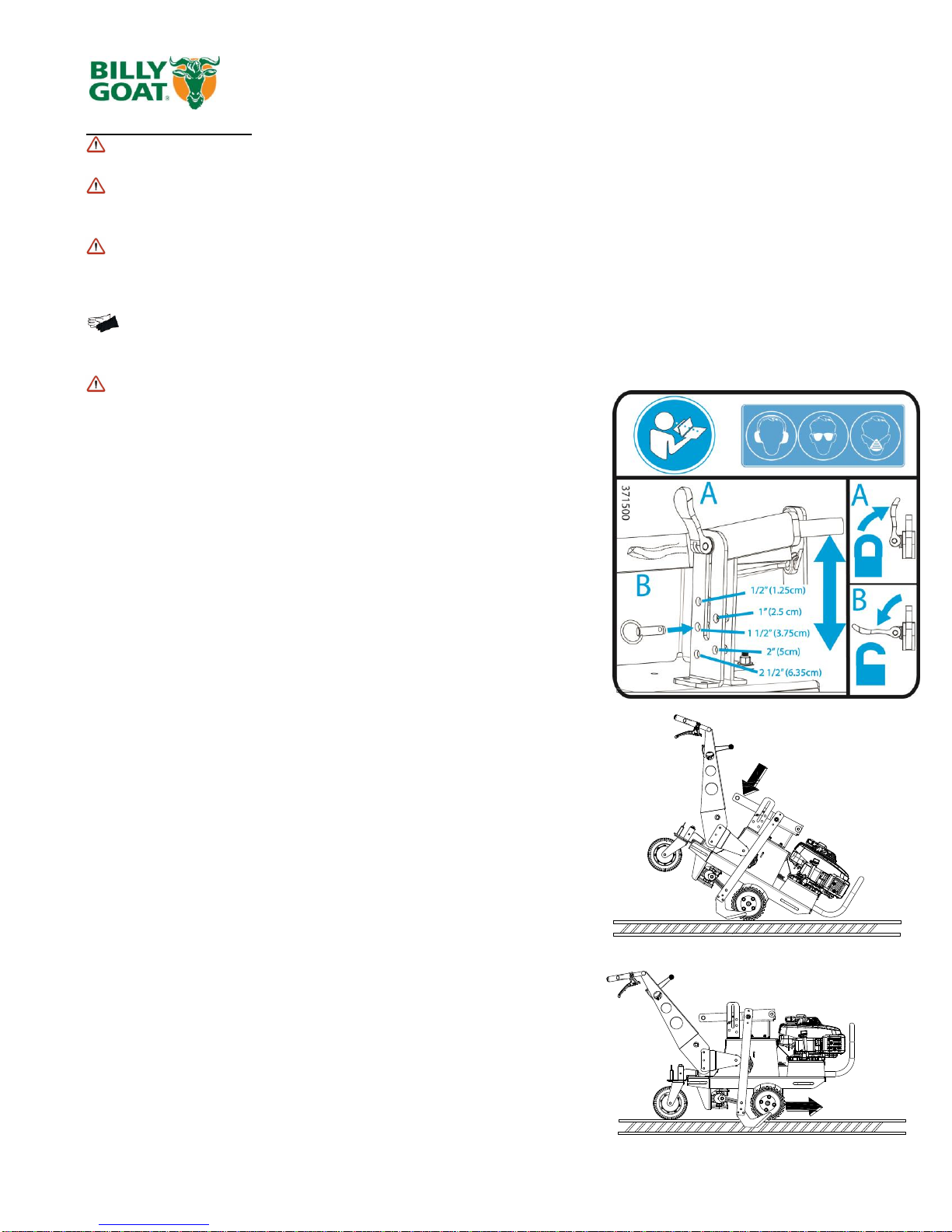

WARNING: DO NOT adjust cutting depth while machine is in

motion. Choose a cutting depth suitable for the type of terrain the

machine is to be used on. Cutting height is set using the removable

pin and placing it into the desired slot for depth. Then loosening the

locking lever to allow the arm to be raised or lowered. The arm should

be resting against the pin for the desired cutting height. Make sure to

engage the locking lever before blade operation.

1. Tilt the machine forward and select the proper cutting depth, make

sure to lock the blade height in place before cutting.

2. Engage the blade and engage the drive. This should pull the blade

into the ground.

3. To remove the blade from the ground make sure the machine and

blade are not in motion, then tilt forward and raise the height arm. Then,

engage the drive and blade again, this will allow the blade to cut out of

the sod.

CUTTING TIPS

1) Before commencing cutting operations, read the safety instructions

given in the previous sections.

2) At first the setting of a relatively shallow cutting depth is

recommended and then lowering it gradually according to working

conditions.

3) Engage the blade clutch only after having carried out the machine

switch on and gear engagement operations.