BILOXXI RHP25 User manual

Instruction manual

Hand pallet truck

RHP25

t

Original instructions

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 1 7/3/15 17:09

-2-

Dear Customer,

Congratulations on your purchase of this BILOXXI product.

Please take a few minutes before starting operation of the appliance and read the

following operating instructions.

Many thanks.

MCC Trading International GmbH

Schlüterstr. 5

40235 Düsseldorf

METRO-Habib Cash & Carry Pakistan (Pvt) Limited

Thokar Niaz Baig, Multan Road

Lahore 53700, Pakistan.

For Customer Feedback:

Call: 111-786-622

E-mail: feedback@metro.pk

Visit us: www.metro.pk

Made in Vietnam

Net weight: 64 kg

METRO Cash & Carry India Private Limited,

No. 26/3, Industrial Suburbs, Ward No. 9

A Block, Subramanyanagar,

BANGALORE - 560 055

D&D Technologies Co.,Ltd

Lot 105-106 Linh Trung III IP & EPZ, Trang Bang

Tay Ninh, Vietnam

Net weight: 64 kg

For Feedback / Suggestion & Complaints:

Customer Care Executive,

P.O. Box No. 5600, Bangalore 560 055,

Customer Care NO.: 18602662010 (Toll Free)

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 2 7/3/15 17:09

-3-

Contents

1. Intended use ......................................................................................................................3

2. Technical data ...................................................................................................................3

3. Symbols and abbreviations ...........................................................................................4

4. Safety warnings ................................................................................................................6

5. Parts description ...............................................................................................................8

6. Scope of delivery ........................................................................................................... 10

7. Before use ....................................................................................................................... 10

8. Operation ........................................................................................................................ 12

9. Troubleshooting ............................................................................................................. 13

10. Cleaning, maintenance and repair ............................................................................ 15

11. Storage and transportation ......................................................................................... 17

12. Hydraulic diagram ......................................................................................................... 18

13. Disposal ........................................................................................................................... 18

14. Warranty .......................................................................................................................... 19

1. Intended use

This pallet hand truck is designed for lifting and transporting heavy objects up to

the rated load on a suitable carrier such as industrial pallets.

It is not intended for any commercial or industrial use.

Do not use it for other purposes. Any other use might lead to damage or personal

injury.

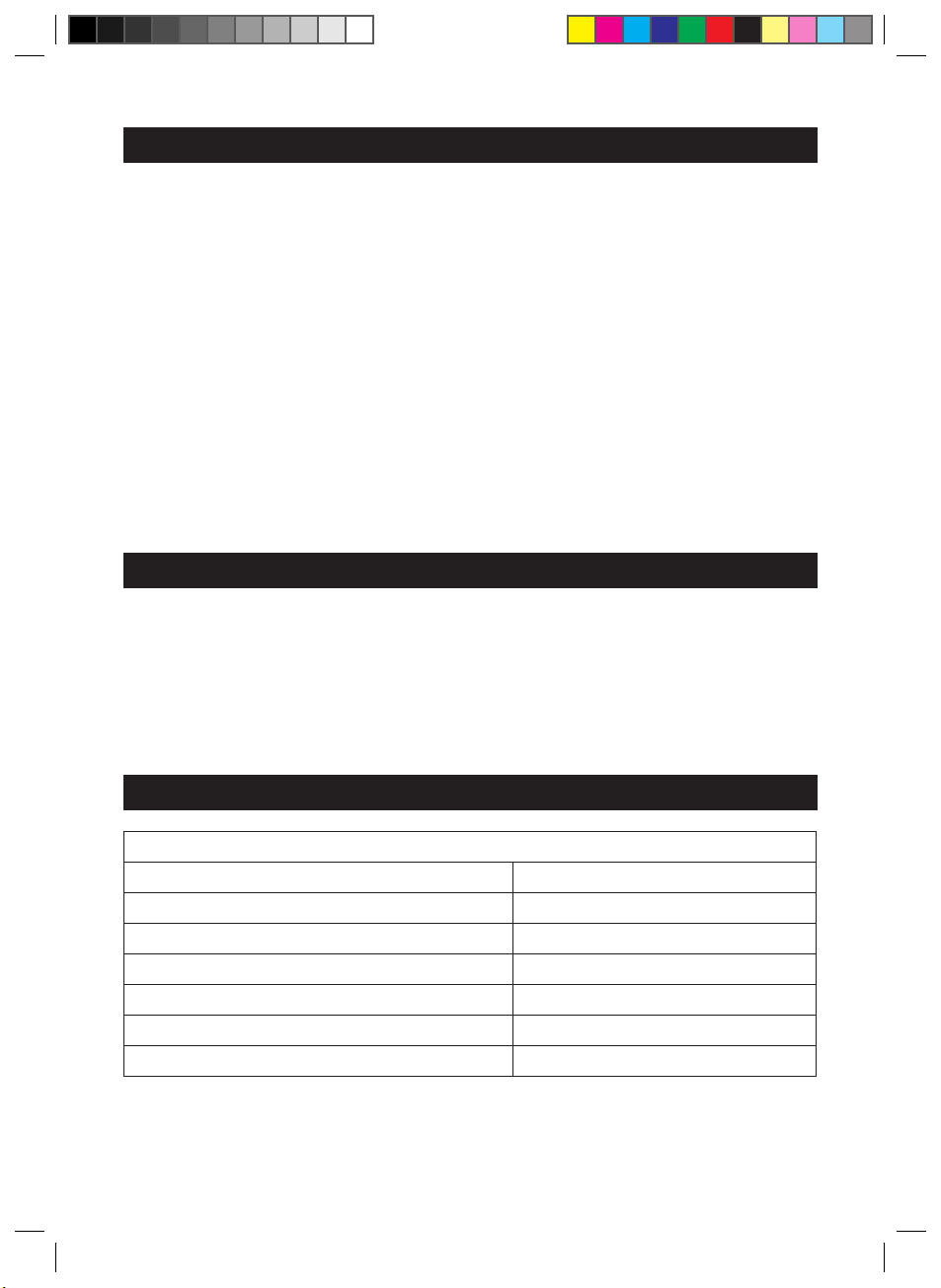

2. Technical data

General

Load capacity 2500 kg

Net weight 64 kg

Max. lifting height 200 mm

Min. lifting height 85 mm

Till height 1210 mm

Overall length 1480 mm

Fork dimensions 160 x 50 x 1150 mm

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 3 7/3/15 17:09

-4-

2. Technical data

Wheel type and size (front) Ø 180 x 50 mm / Polyurethane

Wheel type and size (rear) Ø 80 x 70 mm / Polyurethane

Operating temperatures 5°C to 40°C

Minimum operating lighting 50 lx

3. Symbols and abbreviations

On the product, the rating label and within these instructions you will find among

others the following symbols and abbreviations. Familiarise yourself with them to

reduce hazards like personal injuries and damage to property.

kg kilogram

mm millimetre

°C temperature in celsius

lx illuminance in lux

cSt viscosity in centistokes

Lot. no. batch number

Warning symbol.

This symbol indicates additional information and explanations about

the product and its use.

Read the instruction manual before operation.

Wear protective gloves. Wear sturdy footwear.

Do not place load only partially on the forks. Always use the entire

loading area.

Do not place loads transversely.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 4 7/3/15 17:09

-5-

3. Symbols and abbreviations

Do not place loads unilateral.

Do not place your feet under the forks, especially when lowering the

forks.

Do not put your foot in front of rolling wheel, as you could suffer

injury.

Do not lift or carry persons, as they could fall down and suffer severe

injuries.

Do not use the product on a slope or inclined surface, as it may

become uncontrollable and create danger.

Do not overhang the product at loading docks. Use extreme caution

when approaching loading docks.

Do not allow another person than the operator to stand in front of or

behind the product, when it is moving or lifting/lowering.

Warning! Danger of crushing of fingers or hands!

Indoor use only.

CE stands for “Conformité Européenne” which means “Conformity

with EU directives”. With the CE marking the manufacturer confirms

that this product corresponds to the applicable European directives.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 5 7/3/15 17:09

-6-

4. Safety warnings

1. The operator / the operating company has to ensure the correct usage and has

to ensure that this product is used only by staff, who is trained and authorised

to use this product.

2. The product must be only used by one person at a time and he has to ensure

the necessary clearance to manoeuvre the product safely.

3. Keep the operating area clear from all by-standers, when moving, lifting and

lowering the product.

4. The product must not be used to transport humans or live animals.

5. The product must not be used by children.

6. The product must not be overloaded. The maximum load is 2500 kg.

7. The product must not be used in applications, where the danger exists the

maximum load is exceeded.

8. Distribute the load as evenly as possible.

9. Do not pull the product with vehicles.

10. Keep the centre of gravity as low as possible.

11. Stack loads from bottom to top, heaviest to lightest.

12. Always observe the load and watch out for goods about to drop. In this case,

stop immediately and rearrange the load.

13. Reduce the load correspondingly if the product is to be used on angled surfaces

e.g. ramps.

14. When moving the product over a slightly inclined surface (< 2°), the forks must

be empty.

15. The product must not be used on inclining paths (> 2°), as the danger of loss

of control exists.

16. Use both hands to push the product loaded and unloaded and move it slow

and evenly.

17. The required force needed to handle the product is varying with weight of the

load, the conditions of flooring and the product itself. Consider the frequency

of use under load.

18. Use only spare parts or accessories recommended by the manufacturer.

19. Do not modify the product or install accessory equipment.

20. Do not use the product in wet or extremely humid environments.

21. Do not use the product in explosive atmospheres.

22. Always wear personal protective equipment.

23. Never reach inside the lifting mechanism or below the forks.

24. Be aware that wind can affect the stability and handling of the product,

particularly when transporting loads with large surface areas.

25. Never leave the loaded product unattended.

26. The product must be used on substantially firm, smooth, level and prepared

surfaces.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 6 7/3/15 17:09

-7-

4. Safety warnings

27. Regularly check the product according to the instructions given within this

manual.

28. The product must be used, maintained and repaired in accordance with

manufacturer’s recommendations given within this manual.

NOTE: No modifications or alterations to this product which may

affect, for example, capacity, stability or safety requirements of the

product, shall be made without the prior written approval of the

original manufacturer, its authorized representative, or a successor

thereof. This includes changes affecting, for example braking,

steering, visibility and the addition of removable attachments.

When the manufacturer or its successor approve a modification or

alteration, they shall also make and approve appropriate changes

to capacity plate, decals, tags and operation and maintenance

handbooks. By not observing these instructions, the warranty

becomes void.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 7 7/3/15 17:09

-8-

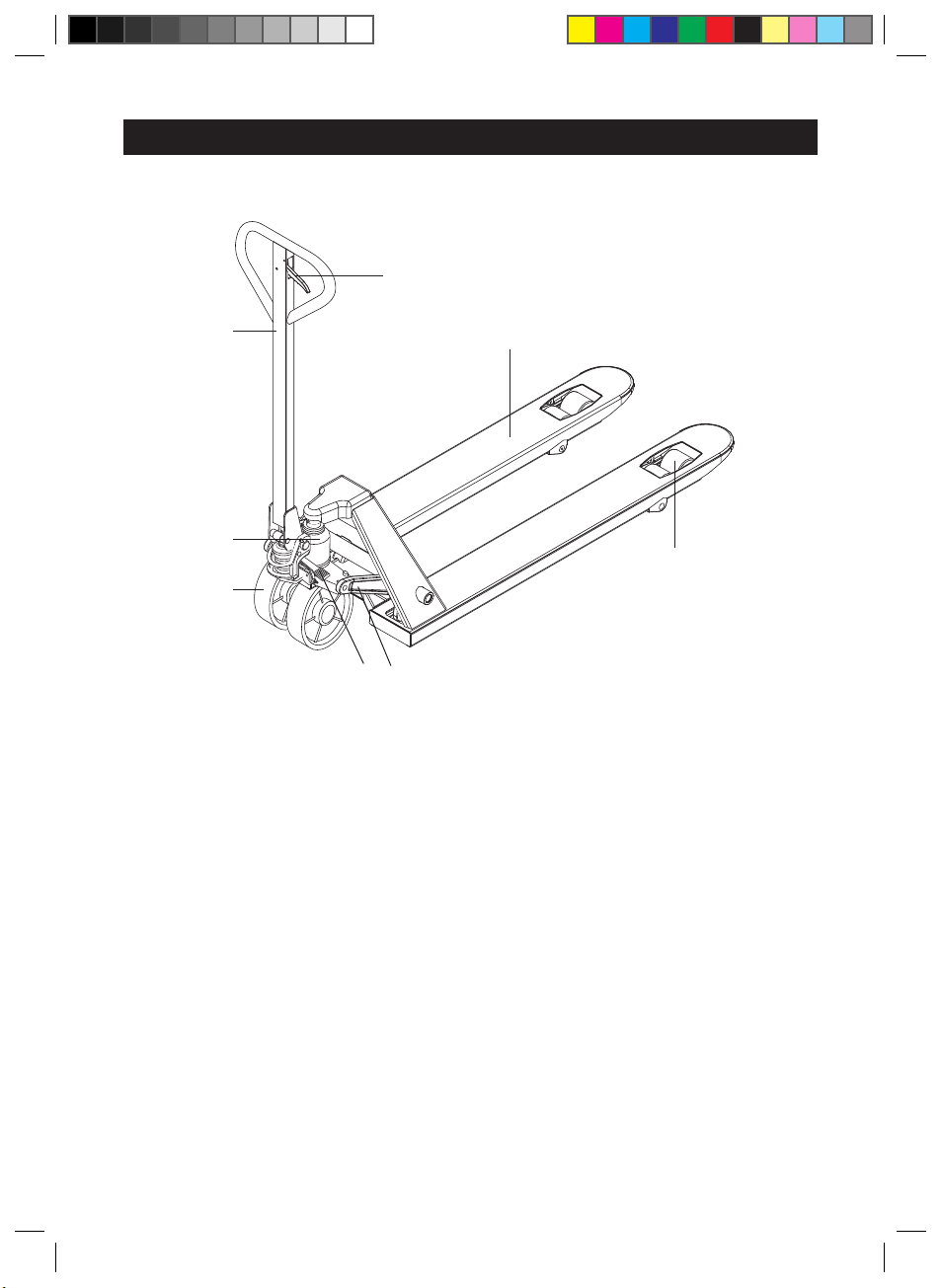

5. Parts description

4

5

6

3

2

1

78

1. Steering wheels

2. Pump unit

3. Tiller arm

4. Control lever

5. Forks

6. Load wheels

7. Lifting mechanism

8. Swing rod

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 8 7/3/15 17:09

-9-

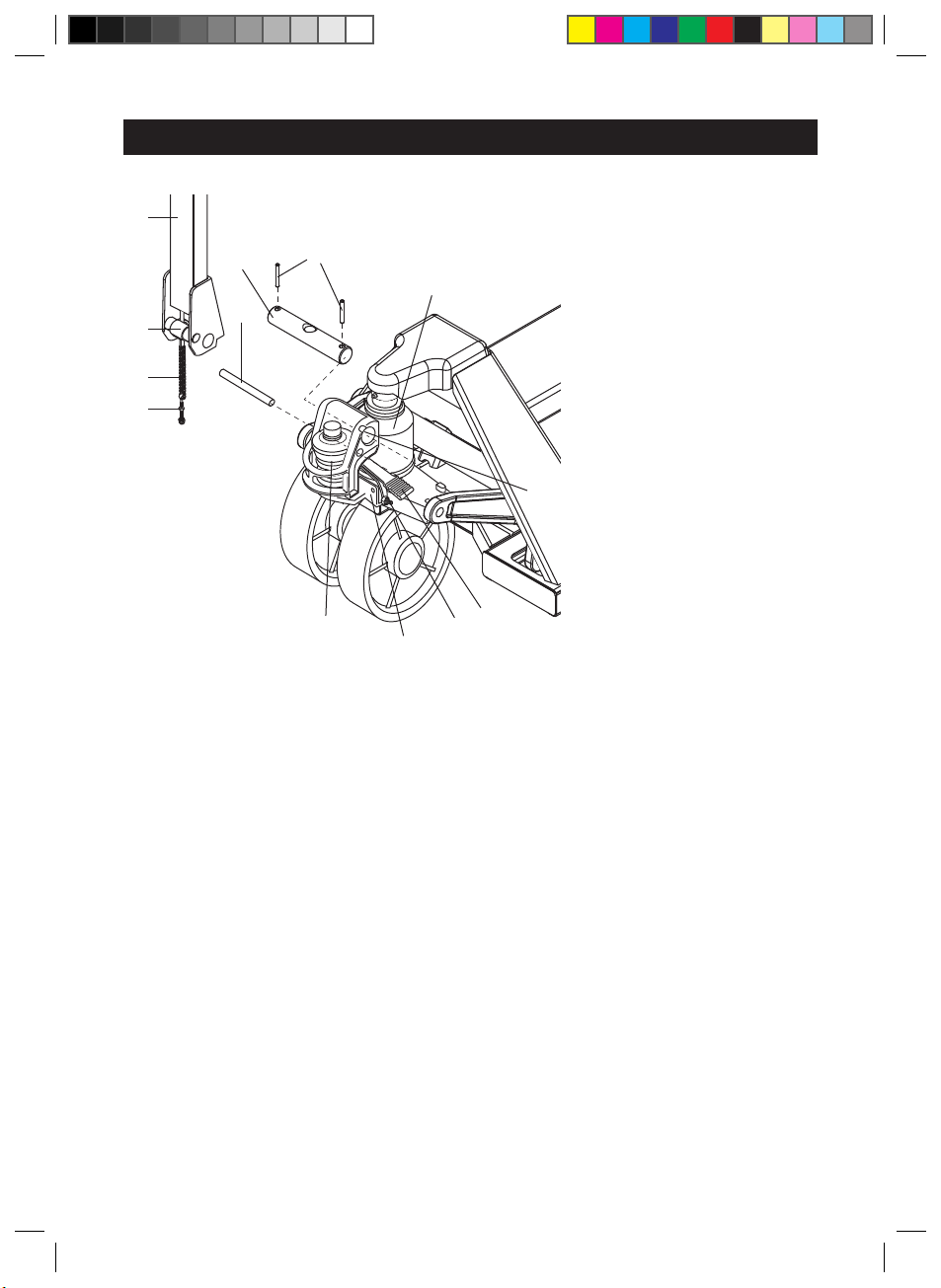

5. Parts description

3

i

j

h

a

bc

2

d

8e

f

g

a) Safety pin

b) Axle

c) Roll pin (x2)

d) Hinge

e) Adjusting screw

f) Hydraulic valve unit

g) Small piston rod

h) Roller

i) Adjusting bolt

j) Chain

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 9 7/3/15 17:09

-10-

6. Scope of delivery

1 pre-assembled chassis with pump unit

1 pre-assembled tiller arm

1 axle

2 roll pins

Please check the completeness of the delivery and ensure that all parts are free

from any transport-related damage or any damage in general. Please contact the

seller from whom you purchased the product should there be any parts missing

or damaged.

7. Before use

7.1 Unpacking

1. Unpack all parts and lay them on a flat, stable surface.

2. Remove all packing materials and shipping devices if applicable.

3. Make sure the delivery contents are complete and free of any damage. If you

find that parts are missing or show damage do not use the product but contact

your dealer. Using an incomplete or damaged product represents a hazard to

people and property.

4. Ensure that you have all the accessories and tools needed for assembly and

operation. This also includes suitable personal protective equipment.

WARNING!

The product and the packaging are not children’s toys! Children

must not play with plastic bags, sheets and small parts! There

is a danger of choking and suffocation!

7.2 Assembly

1. Insert the tiller arm (3) with the roller (h) facing the small piston rod (g) into

the hinge (d). Use a hammer to insert the axle (b) through the hinge (d) and

the tiller arm (3). Make sure the holes for the roll pins (c) are aligned with the

respective slots on the hinge (d).

2. Set the control lever (4) to the “lower” position. Pass the chain (j) and the

adjusting bolt (i) through the centre hole of the axle (b).

3. Use a hammer to insert the two roll pins (c) into the two outer holes of the axle

(b) aligned to the slots in the hinge (d).

4. Press the tiller arm (3) all the way down and hold it in position with one hand,

while removing the safety pin (a) from the hinge (d). Move the tiller arm (3)

back to the upright position.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 10 7/3/15 17:09

-11-

7. Before use

5. Set the control lever (4) to the “lift” position. Raise the swing rod (8) and insert

the adjusting bolt (i) into the slot, with one nut each underneath and above the

swing rod (8).

6. Move the nuts on the adjusting bolt (i) close to the swing rod (8) so that it

cannot fall out of the slot. Do not tighten against each other!

7. Adjust the swing rod (8) (→ 7.3 Swing rod adjustment).

7.3 Swing rod adjustment

The control lever (4) on the tiller (3) and the swing rod (8) are linked to each other

and move respectively in the following three positions:

Control lever Swing rod Action Position

Lower

(pull and hold)

Neutral

(set before moving)

Lift

(set before pumping)

Adjust the swing rod according to following steps if necessary:

1. Set the control lever (4) to the “lift” position.

2. Turn the adjusting screw (e) on the swing rod (8) clockwise until it has contact

with the hydraulic valve unit (f) on the pump unit (2). Do not apply pressure!

3. Check if all three positions of the control lever (4) and the swing rod (8) are

working properly.

4. If the forks (5) elevate while pumping in the “neutral” position, turn the adjusting

screw (e) on the swing rod (8) clockwise until pumping action does not raise

the forks (5) and the “neutral” position works properly.

5. If the forks (5) descend while pumping in the “neutral” position, turn the

adjusting screw (e) on the swing rod (8) counter-clockwise until the forks (5)

do not lower.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 11 7/3/15 17:09

-12-

7. Before use

6. If the forks (5) do not descend when the control lever (4) is in the “lower”

position, turn the adjusting screw (e) on the swing rod (8) clockwise until

pulling the control lever (4) lowers the forks (5). Check the “neutral” position

afterwards.

7. lf the forks (5) do not elevate while pumping in the “lift” position, turn the

adjusting screw (e) on the swing rod (8) counter-clockwise until the forks (5)

elevate while pumping in the “lift” position. Check the “lower” and “lift” position

afterwards.

8. Check again if all three positions of the control lever (4) and the swing rod (8)

are working properly and adjust again if not.

9. Tighten the nut on the adjusting screw (e) in swing rod (8).

8. Operation

NOTE: Always perform the “daily inspection” (→ 10.3 Daily

inspection) before putting the product into operation.

8.1 Parking

1. Lower the forks to the lowest position and park the product on a smooth and

even level ground where it will not disturb any other operations.

8.2 Lifting

1. Ensure that the load does not exceed the loading capacity.

2. Roll the product with its forks slowly under the goods until the back end of the

fork resists against the load.

3. The load must be evenly distributed across both forks.

4. Shift the control lever down to the “lift” position.

5. Lift the load by up and down movements of the tiller arm.

8.3 Moving

1. Always lower the forks as far as possible, while maintaining sufficient height

to manoeuvre.

2. Move the product by pushing or pulling the tiller arm.

3. The tiller arm is connected to the steering wheels. The wheels are steered

automatically by moving or steering the tiller arm.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 12 7/3/15 17:09

-13-

8. Operation

8.4 Lowering

1. Lower the load by carefully shifting the control lever up to the “lower” position.

Ensure there are no obstacles below the load.

2. By releasing the control lever, the lowering movement will stop.

3. Be sure there is adequate clearance behind to remove the product from the

lowered goods.

9. Troubleshooting

Suspected malfunctions are often due to causes that the users can fix themselves.

Therefore check the product using this section. In most cases the problem can be

solved quickly.

WARNING!

Only perform the steps described within these instructions!

All further inspection, maintenance and repair work must

be performed by an authorised service centre or a similarly

qualified specialist if you cannot solve the problem yourself!

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 13 7/3/15 17:09

-14-

9. Troubleshooting

Problem Possible cause Solution

1. Forks do not

elevate, do not

elevate fully or

elevate slowly

1.1 Low hydraulic fluid

leveI or impurities in

oil

1.2 Swing rod is out of

adjustment

1.3 Load is too heavy.

Overload release

valve is being

activated

1.4 Temperature is

too low and the

hydraulic oil has

become too thick

1.5 Air in the hydraulic

oil

1. Add approved hydraulic

fluid or change the oil

(→ 10.7 Adding

hydraulic oil to the

pump reservoir)

2. Follow the procedure

for adjusting the swing

rod (→ 7.3 Swing rod

adjustment)

3. Reduce load

4. Move product to a

warmer location

5. Bleed the pump unit

(→ 10.6 Bleeding the

hydraulic system)

2. Forks do not

descend or do not

descend fully

2.1 Obstacle located

under the forks or in

lifting mechanism

2.2 Swing rod is out of

adjustment

2.3 Forks were left in an

elevated position for

an extended time

causing the exposed

big piston rod to rust

2.4 The big piston rod or

pump is deformed

due to over-loading

or uneven loading

1. Use caution removing

the obstacle

2. Follow the procedure

for adjusting the swing

rod (→ 7.3 Swing rod

adjustment)

3. Keep fork in the lowest

position when not

in use and keep the

big piston rod well

lubricated

4. Have the big piston rod

or pump unit replaced

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 14 7/3/15 17:09

-15-

9. Troubleshooting

Problem Possible cause Solution

3. Forks descend

without putting

the control lever

in the „lower“

position

3.1 Oil impurities are

preventing the

release valve from

fully closing

3.2 Some hydraulic

components or seals

are cracked or worn

3.3 Control lever is out

of adjustment

1. Drain and replace

hydraulic fluid with

approved fluid

2. Inspect and have

components replaced

as needed

3. Follow the procedure

for adjusting the swing

rod (→ 7.3 Swing rod

adjustment)

4. Oil leakage 4.1 Worn or damaged

seals

4.2 Other cracked or

worn parts

1. Have the seals replaced

2. Have the damaged

parts replaced

10. Cleaning, maintenance and repair

10.1 Cleaning

1. Clean the product after each use with a slightly damp cloth and a little soap.

Use brushes for hard to reach places.

2. Remove stubborn dirt with high pressure air (max. 3 bar).

3. Clean off dirt and debris every six month.

NOTE: Do not use chemical, alkaline, abrasive or other aggressive

detergents or disinfectants to clean this product as they might be

harmful to its surfaces.

10.2 Maintenance

1. Only qualified and trained personnel are allowed to do service on this product.

2. Before servicing the product, remove the load and lower the forks to the lowest

position. Completely immobilise the product before working on components

that might pinch fingers or hands if movement was allowed.

3. Spare parts are available from your seller or contact the manufacturer.

4. Consider that oil leakage of hydraulic fluid can cause failures and accidents.

5. It is allowed to adjust the pressure valve only from trained service technicians.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 15 7/3/15 17:09

-16-

10. Cleaning, maintenance and repair

6. Waste material like oil, or others must be probably disposed of and recycled

according to the national regulation; if necessary, bring it to a recycling

company.

7. All bushings and bearings have been lubricated at factory. To increase their life

expectancy, regular maintenance is recommended.

8. Harsh environments may require more frequent maintenance.

10.3 Daily inspection

Visually check for structural deformation or cracks of arms, forks, or any other

component and unusual noise or binding of the lifting mechanism. Do not use the

product if any malfunction or fault is detected.

1. Check if there is any oil leakage.

2. Check the vertical movement of the lifting mechanism.

3. Check the smooth movement of the wheels.

4. Check if there are any particles or damages on the wheels.

5. Check if all the bolts and nuts are tightened firmly.

6. Verify that all labels are in place, undamaged and readable.

7. Check if all parts are functional as described within these instructions.

10.4 Monthly inspection

1. Check hydraulic oil level (more frequently for high use applications).

2. All bearings and shafts are provided with long-life grease at factory. Long-life

grease should be applied to the lubrication points at monthly intervals or after

each time the product is cleaned.

3. Change oil (more frequently if colour has substantially darkened or feels gritty)

(→ 10.7 Adding hydraulic oil to the pump reservoir).

NOTE: lf hydraulic oil is milky white in colour and water is in the

hydraulic system, change the hydraulic oil immediately.

10.5 Repair

This product does not contain any parts that can be repaired by the consumer.

Contact a qualified specialist to have it checked and repaired.

WARNING!

Always make sure all guards, if available, have been reinstalled

safely and correctly after each cleaning or maintenance

operation! Never use the product without its guards!

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 16 7/3/15 17:09

-17-

10. Cleaning, maintenance and repair

10.6 Bleeding the hydraulic system

Air may find its way into the pump during transportation, tilting or usage on uneven

ground. It can result in not elevating forks while pumping in the “lift” position. The

air can be removed in the following way:

1. Move the control handle to the “lower” position, and then move the tiller down

several times. Thereafter normal operation can be resumed.

10.7 Adding hydraulic oil to the pump reservoir

1. Make sure forks are in lowered position.

2. Lay the product on either side. Position the drain plug of hydraulic cylinder up.

3. Remove the screw plug.

4. Add hydraulic oil until level of oil is at bottom of the hole.

5. Change oil (more frequently if colour has substantially darkened or feels gritty).

The required hydraulic fluid type is ISO VG32, its viscosity should be 30 cSt at

400°C, total volume is about 0.3 I.

6. Replace drain plug, upright the product.

11. Storage and transportation

11.1 Storage

1. Clean the product as described above.

2. Remove the load and lower the product to its lowest position.

3. Store the product in a dry, frost-free place. Protect it from any kind of moisture.

4. Always store the product in a place that is inaccessible to children. The ideal

storage temperature is between 10°C and 30°C.

5. We recommend using the original package for storage or covering the product

with a suitable cloth to protect it against dust.

NOTE: Before using it again, use this instruction manual to check

the product for possible wear and damage.

11.2 Transportation

1. Remove the load and lower the product to its lowest position.

2. Lash it safe with dedicated lashing straps.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 17 7/3/15 17:09

-18-

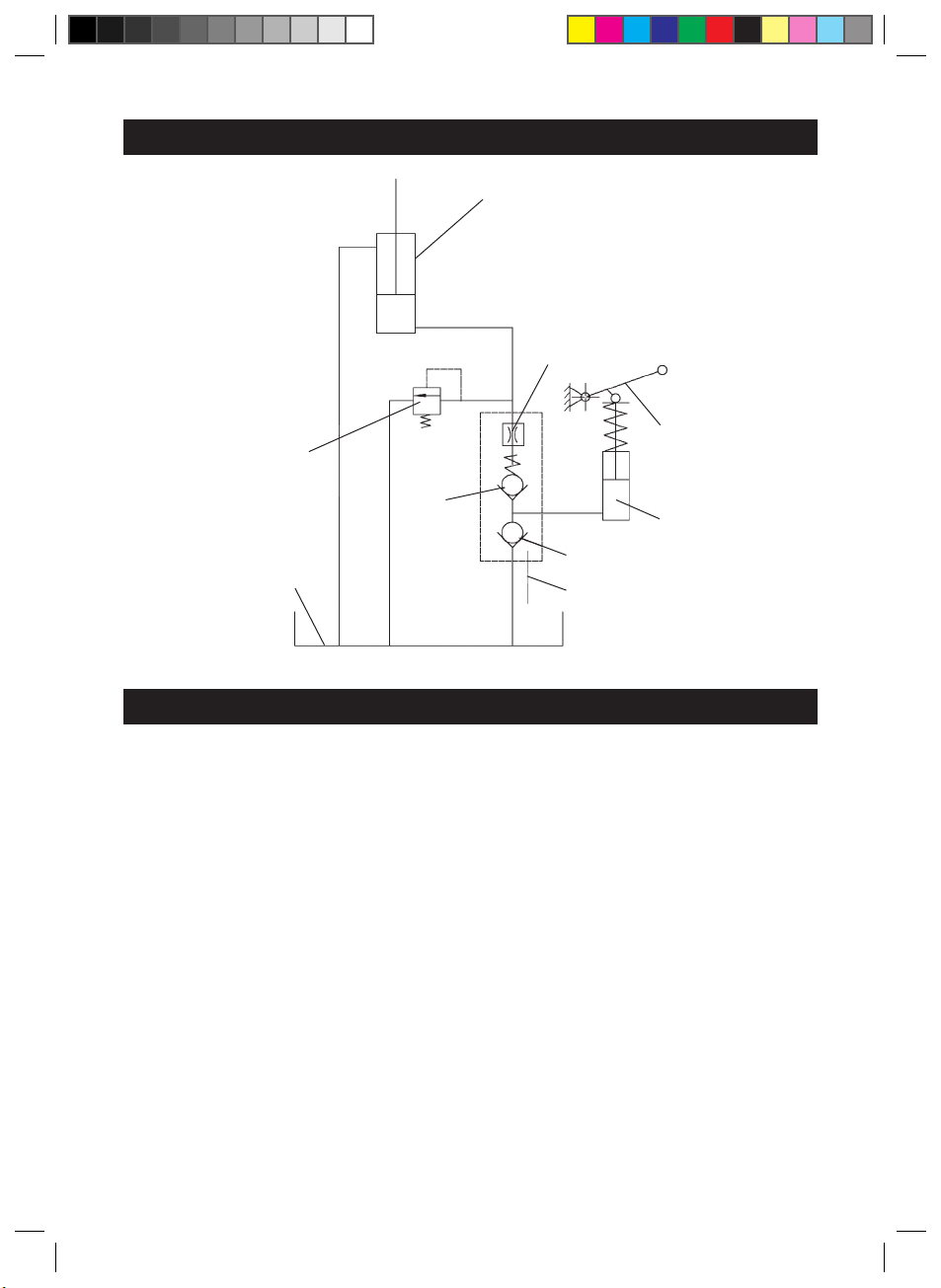

12. Hydraulic diagram

Cylinder

Valve

Valve

Valve

Lever

Oil tank

Tiller

Pump

Safety

valve

13. Disposal

Used products are recyclable materials and therefore do not belong in ordinary

household waste! We would therefore like to ask you to support us in the

conservation of resources and the protection of the environment, and hand this

product to return sites – where available.

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 18 7/3/15 17:09

-19-

14. Warranty

A statutory warranty applies for this product.

Damages caused by wrong treatment or operation, by false placement or storage,

improper connection or installation, as well as force or other external influences

are not covered by this warranty. We recommend careful reading of the operating

instructions as it contains important information.

Note:

1. In case this product does not function correctly, please firstly check if there are

other reasons, e.g. for electrical appliances interruption of the power supply, or

generally incorrect handling are the cause.

2. Please note that, where possible, the following documents or rather information

should be provided together with your faulty product:

– Purchase receipt

– Model description/Type/Brand

– Describe the fault and problem as detailed as possible

In the case of a claim for guarantee or defects, please contact the seller.

GWL 8/14 EN

RHP25 ENGLISH 150626

(IM)237‐000413_RHP25_GB-IM_V4_150626.indd 19 7/3/15 17:09

Table of contents

Popular Truck manuals by other brands

CUSTOM TRUCK

CUSTOM TRUCK LOAD KING 10 FT. DUMP BODY Operator's manual

Baxtran

Baxtran ARN manual

Still

Still ECH 12C Original instructions

Big Joe

Big Joe PDSR 30 Installation, operation, maintenance & repair parts

Still

Still EXH-SF 20 Original instructions

EP Equipment

EP Equipment CQD15S-E Operation manual