Big Joe PDSR 30 Use and care manual

Big Lift LLC MANUAL NO. BL-PDSR 30-0319 - 03-07-2019

www.bigjoeforklifts.com

PDSR 30

POWER DRIVE REACH

LIFT TRUCK

Operation

Maintenance

Repair Parts List

TABLE OF CONTENTS

BL-PDSR 30-0319 - 03-07-2019 1

Section Page Section Page

1 DESCRIPTION ............................................................1-1

1-1 INTRODUCTION ................................................1-1

1-2 GENERAL DESCRIPTION .................................1-1

1-3 SAFETY FEATURES..........................................1-2

2 OPERATION ...............................................................2-1

2-1 GENERAL...........................................................2-1

2-2 OPERATING PRECAUTIONS............................2-1

2-3 BEFORE OPERATION.......................................2-2

2-4 GENERAL CONTROL OPERATION..................2-4

2-5 DRIVING AND

STOPPING PROCEDURES...............................2-4

2-5.1 STOPPING ................................................2-4

2-6 BELLY-BUTTON SWITCH .................................2-5

2-7 STEERING ARM GAS SPRING ........................2-5

2-8 LIFT AND LOWER CONTROLS........................2-5

2-9 LOADING AND UNLOADING.............................2-5

2-10 PARKING............................................................2-5

3 PLANNED MAINTENANCE ........................................3-1

3-1 GENERAL...........................................................3-1

3-2 MONTHLY AND QUARTERLY CHECKS..........3-1

3-3 BATTERY CARE ................................................3-1

3-3.1 GENERAL..................................................3-1

3-3.2 SAFETY RULES ........................................3-2

3-3.3 BATTERY CARE AND CHARGING...........3-2

3-3.4 BATTERY CLEANING ...............................3-2

3-4 CHARGING BATTERIES ..................................3-3

3-5 LUBRICATION...................................................3-3

3-6 LIFT CHAIN MAINTENANCE ............................3-3

4 TROUBLESHOOTING ................................................4-1

4-1 GENERAL...........................................................4-1

4-2 CONTROLLER TROUBLESHOOTING ..............4-4

4-2.1 ZAPI HANDSET (OPTIONAL) ...................4-4

4-2.2 FAULT DETECTION..................................4-4

4-2.2.1 GENERAL ............................................4-4

4-2.2.2 LOGBOOK ACCESS............................4-4

4-2.3 TESTING TRUCK OPERATION................4-4

4-2.4 SETTINGS AND ADJUSTMENTS.............4-5

4-2.4.1 SET OPTIONS .....................................4-5

5 OPERATING CONTROL SYSTEM .............................5-1

5-1 CONTROL HEAD ...............................................5-1

5-1.1 CAP ASSEMBLY REMOVAL.....................5-1

5-1.2 CAP ASSEMBLY INSTALLATION.............5-1

5-1.3 CONTROL HEAD REMOVAL....................5-1

5-1.4 CONTROL HEAD INSTALLATION............5-1

5-1.5 POTENTIOMETER REPLACEMENT ........5-1

5.1.6 BELLY-BUTTON

SWITCH REPLACEMENT.........................5-1

5-1.7 HORN SWITCH REPLACEMENT .............5-4

5-1.8 LIFT AND LOWER

SWITCH REPLACEMENT.........................5-4

5-2 COMPARTMENT COVERS ...............................5-4

5-2.1 REMOVAL .................................................5-4

5-2.2 INSTALLATION..........................................5-4

5-3 STEERING ARM................................................ 5-4

5-3.1 RETURN SPRING REPLACEMENT......... 5-4

5-3.2 STEERING ARM REMOVAL..................... 5-4

5-3.3 STEERING ARM INSTALLATION............. 5-4

6 BRAKE SERVICING ................................................... 6-1

6-1 BRAKES............................................................. 6-1

6-1.1 AIR GAP ADJUSTMENT........................... 6-1

6-1.2 STOPPING DISTANCE ADJUSTMENT.... 6-2

6-1.3 BRAKE ASSEMBLY REPLACEMENT...... 6-2

7 DRIVING SYSTEM ..................................................... 7-1

7-1 DRIVE WHEEL .................................................. 7-1

7-2 TRANSMISSION................................................ 7-1

7-3 STEERING MOTOR .......................................... 7-1

7-4 LOAD WHEEL.................................................... 7-1

7-4.1 REMOVAL................................................. 7-1

7-4.2 REPAIR ..................................................... 7-1

7-4.3 LOAD WHEEL INSTALLATION ................ 7-2

8 ELEVATION SYSTEM SERVICING ........................... 8-1

8-1 GENERAL .......................................................... 8-1

8-2 LIFT CHAIN LENGTH ADJUSTMENT............... 8-1

8-3 LIFT CHAIN WEAR INSPECTION..................... 8-2

8-4 LIFT CHAIN REPLACEMENT............................ 8-2

8-4.1 TELESCOPIC............................................ 8-2

8-4.2 TRIMAST FREE LIFT CHAIN.................... 8-4

8-4.3 TRIMAST SECONDARY LIFT CHAIN ...... 8-4

8-5 LIFT CYLINDERS .............................................. 8-4

9 HYDRAULIC SYSTEM SERVICING........................... 9-1

9-1 LINES AND FITTINGS....................................... 9-1

9-2 HYDRAULIC PUMP,

MOTOR AND RESERVOIR ............................... 9-6

9-2.1 REMOVAL................................................. 9-6

9-2.2 DISASSEMBLY AND REASSEMBLY ....... 9-6

9-2.3 INSTALLATION......................................... 9-6

9-2.4 LIFT CYLINDER (TELESCOPIC).............. 9-7

9-2.4.1 REMOVAL ........................................... 9-7

9-2.4.2 REPAIR ............................................... 9-7

9-2.4.3 INSTALLATION ................................... 9-7

9-2.5 LIFT CYLINDER (TRIMAST FREE LIFT).. 9-8

9-2.5.1 REMOVAL ........................................... 9-8

9-2.5.2 REPAIR ............................................... 9-8

9-2.5.3 INSTALLATION ................................... 9-9

9-2.6 LIFT CYLINDER

(TRIMAST SECONDARY)......................... 9-9

9-2.6.1 REMOVAL ........................................... 9-9

9-2.6.2 REPAIR ............................................... 9-9

9-2.6.3 INSTALLATION ................................. 9-10

9-2.7 REACH CYLINDER................................. 9-10

9-2.7.1 REMOVAL ......................................... 9-10

9-2.7.2 REPAIR ............................................. 9-10

9-2.7.3 INSTALLATION ................................. 9-15

9-2.8 TILT CYLINDER...................................... 9-15

9-2.8.1 REMOVAL ......................................... 9-15

9-2.8.2 REPAIR ............................................. 9-15

TABLE OF CONTENTS - CONTINUED

1-2 BL-PDSR 30-0319 - 03-07-2019

9-2.8.3 INSTALLATION ................................. 9-18

Section Page Section Page

10 ELECTRICAL COMPONENTS ................................. 10-1

10-1 ELECTRICAL CONTROL PANEL.................... 10-1

10-1.1 MAINTENANCE ...................................... 10-1

10-1.2 CLEANING .............................................. 10-1

10-1.3 PANEL REMOVAL .................................. 10-1

10-1.4 PANEL DISASSEMBLY .......................... 10-1

10-1.5 PANEL INSTALLATION .......................... 10-1

10-2 HORN REPLACEMENT................................... 10-1

10-3 PUMP MOTOR.................................................10-5

10-4 DRIVE MOTOR ................................................10-5

10-5 DEADMAN SWITCH ........................................10-5

11 OPTIONAL EQUIPMENT..........................................11-1

11-1 LOAD BACKREST ...........................................11-1

12 ILLUSTRATED PARTS BREAKDOWN ....................12-1

BL-PDSR 30-0319 - 03-07-2019 1-1

SECTION 1

DESCRIPTION

1-1. INTRODUCTION.

.This publication describes the 24 volt lift truck distrib-

uted by Big Lift LLC. Included are operating instruc-

tions, planned maintenance instructions, lubrication

procedures, corrective maintenance procedures and a

complete parts list with part location illustrations.

Users shall comply with all requirements indicated in

applicable OSHA standards and current edition of

A.N.S.I. B56.1 Part II.By following these requirements

and the recommendations contained in this manual,

you will receive many years of dependable service

from your PDSR lift truck

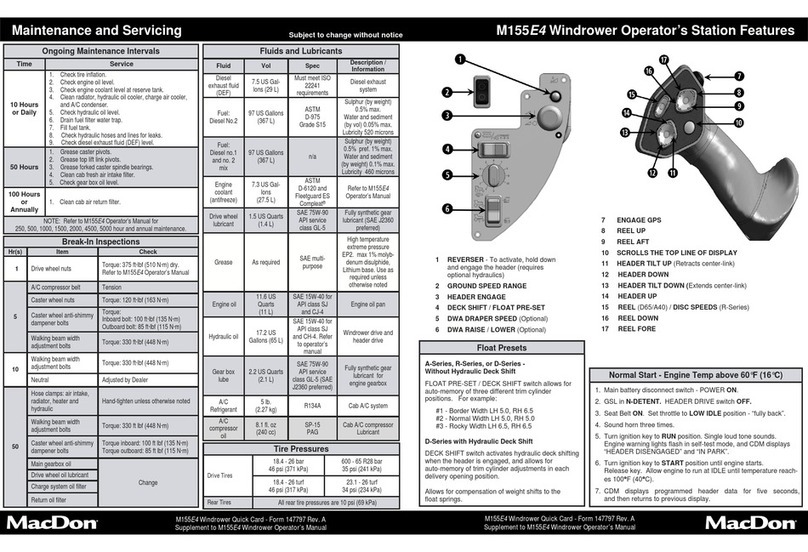

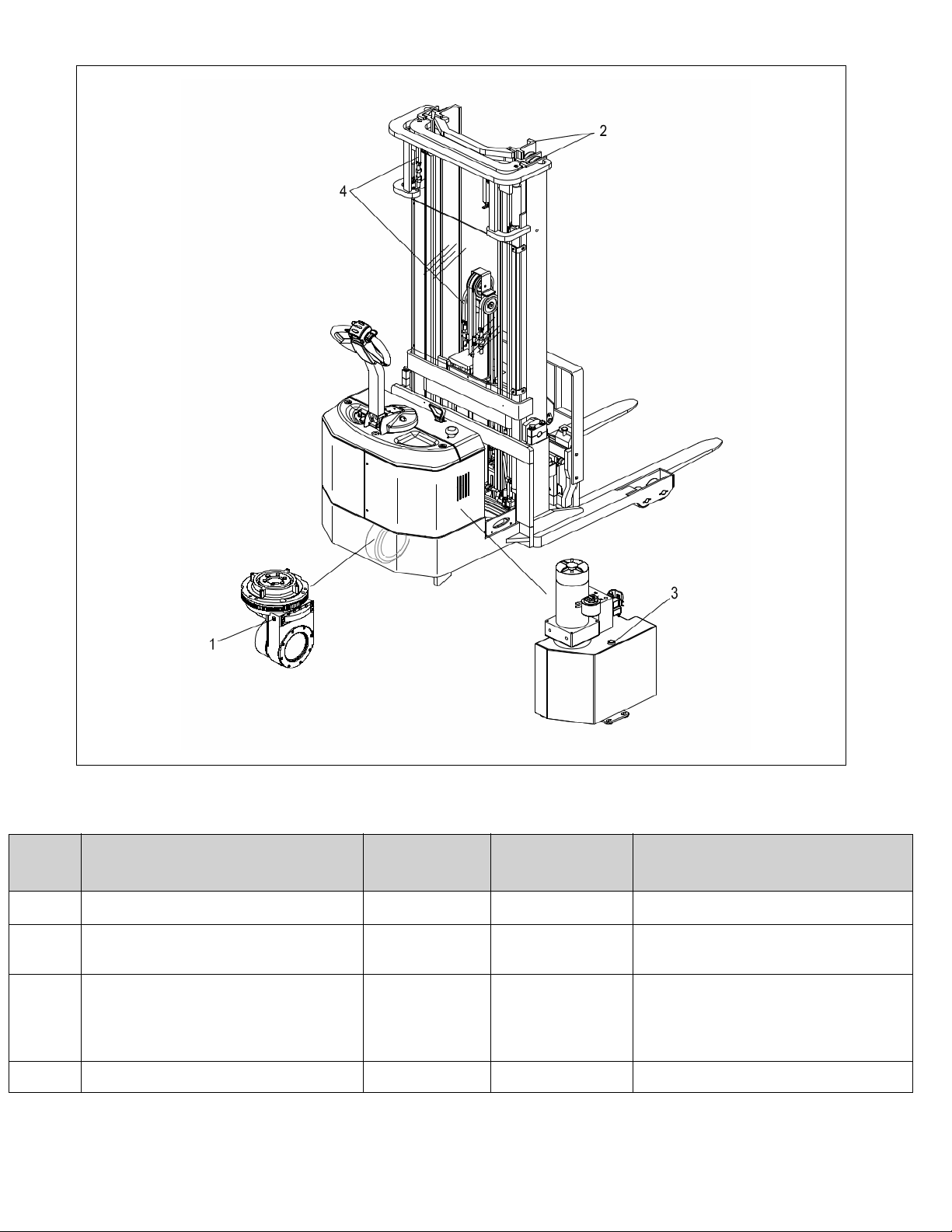

The model number will be found on the name plate

(Figure 1-1) along with the serial number, lifting capac-

ity, and load center. Figure 1-2 shows the locations of

the trucks main components and controls.

1-2. GENERAL DESCRIPTION.

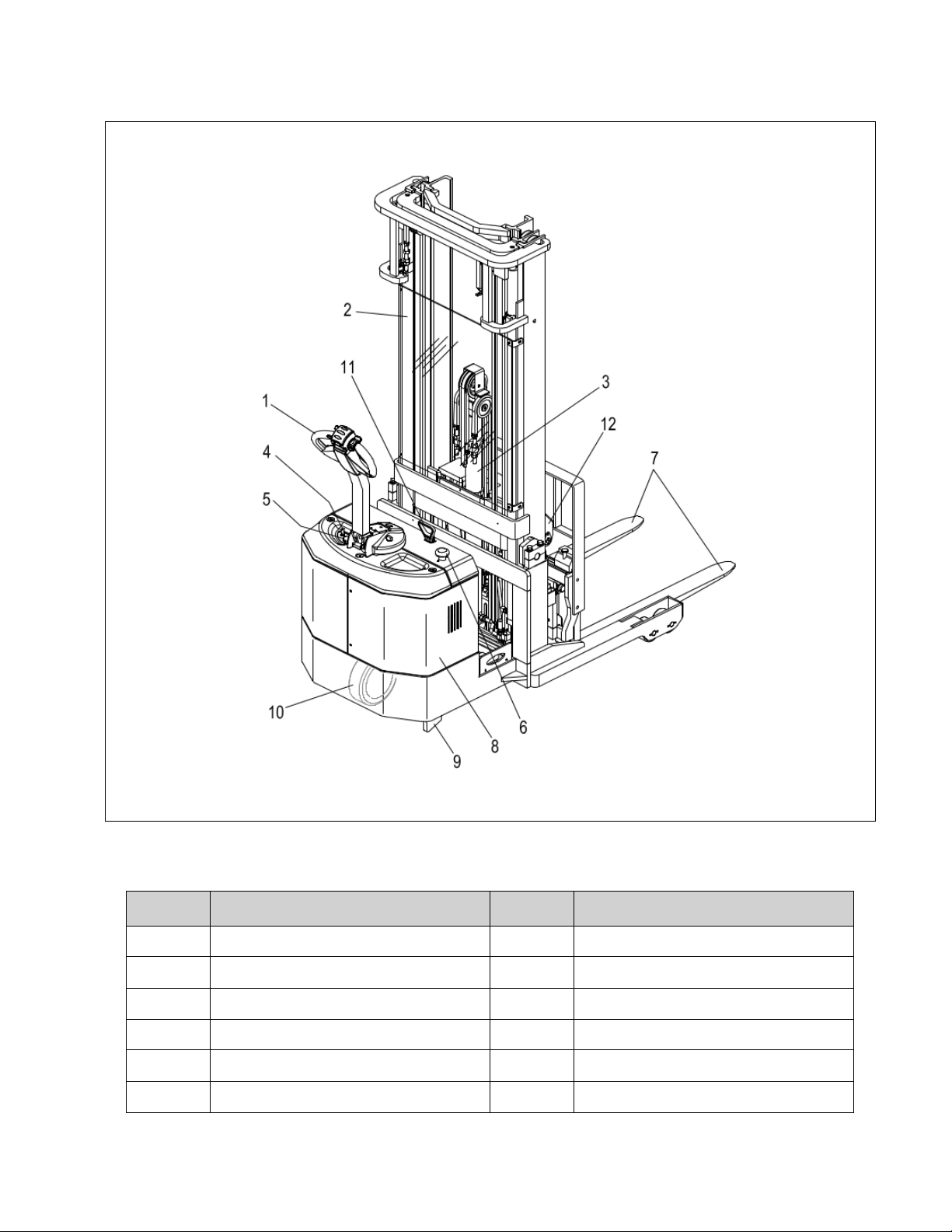

The self-propelled truck, (Figure 1-2), lifts and transp-

orts payloads up to 3000 pounds on rigid forks.

4 feet without changing the overall lift height. Then the

mast will start to rise. However, if the truck has an

optional load backrest, the backrest will raise above

the mast before the end of the full free lift.

The forward and reverse motion is controlled by either

of two controller levers mounted on the control

head.Stopping and turning is controlled by the steering

arm.Lift and Lower is controlled by pushbuttons on the

control head. The battery powered lift truck is quiet

and without exhaust fumes.

The reversible AC motor propels the lift truck in for-

ward or reverse direction throughout the available

speed range. The PDSR lift truck can be driven with

forks raised or lowered; however, the speed is restri-

cted when the platform is raised above a preset limit.

The model number will be found on the name plate

(Figure 1-1) along with the serial number, lifting capac-

ity, and load center. Figure 1-2 shows the locations of

the truck's main components and controls.

Figure 1-1 Name Plate

R6209

1-2 BL-PDSR 30-0319 - 03-07-2019

1-3. SAFETY FEATURES.

The PDSR is designed engineered to provide maxi-

mum safety for operator and payload. Some of the

safety features incorporated into the design are:

• Dead-man brake to apply the brake and cut off drive

power when the steering arm is released.

• Belly-button switch to reverse truck should the oper-

ator accidentally pin himself against a wall or

obstruction when backing up in slow speed.

• High speed limit switch to restrict speed when lift

carriage is raised above the preset limit.

• All control functions automatically return to "OFF"

when released.

• Externally accessible battery disconnect within oper-

ator's reach.

• Separately fused control circuits and power circuits.

• Readily accessible horn button.

• Lift carriage backrest to help stabilize the load.

• Handle to provide a firm hand hold for operator.

• Flow control valve regulates maximum lowering

speed within prescribed limits.

• Relief valve maintains hydraulic pressure within pre-

scribed limits.

• High visibility color scheme of truck provides visual

alert of truck's presence.

• Battery Indicator.

• Stabilizers.

BL-PDSR 30-0319 - 03-07-2019 1-3

Figure 1-2 PDSR Lift Truck

Pos. Component Pos. Component

1 CONTROL HANDLE 7 FORKS

2 WINDSHIELD 8 COVER

3 LIFT CYLINDER 9 STABILIZERS

4 KEY SWITCH 10 DRIVE WHEEL

5 BATTERY INDICATOR 11 BATTERY PLUG

6 EMERGENCY DISCONNECT 12 REACH ASSEMBLY

R3930

1-4 BL-PDSR 30-0319 - 03-07-2019

NOTES

BL-PDSR 30-0319 - 03-07-2019 2-1

SECTION 2

OPERATION

2-1. GENERAL.

This section gives detailed operating instructions for

the lift truck. The instructions are divided into the vari-

ous phases of operations, such as operating lift, driv-

ing, and stopping. Routine precautions are included

for safe operation

2-2. OPERATING PRECAUTIONS.

WARNING: Improper operation of the lift truck may

result in operator injury, or load and/or lift

truck damage. Observe the following

precautions when operating the lift truck.

The following safety precautions must be adhered to

at all times.

• Do not operate this truck unless you have been

trained and authorized to do so.

• All warnings and instructions must be read and

understood before using the equipment.

• Equipment must not be altered in any way.

• Equipment must be inspected by a qualified person

on a regular basis.

• Do not exceed the rated capacity. Overloading may

result in damage to the hydraulic system and struc-

tural components.

• Be certain that the lifting mechanism is operating

smoothly throughout its entire height, both empty

and loaded.

• Be sure that mast is vertical - do not operate on a

side slope.

• Be sure the truck has a firm and level footing.

• Avoid overhead wires and obstructions.

• Check for obstructions when raising or lowering the

lift carriage.

• Do not handle unstable or loosely stacked loads.

Use special care when handling long, high, or wide

loads to avoid tipping, loss of load, or striking bysta-

nders.

• Center and carry the load as far back as possible

toward the lift carriage back rest. The center-of-

gravity of the load must not exceed the load center

listed on the nameplate. See Figure 2-1 for load cen-

ter limitations.

• Pick up loads on both forks. Do not pick up on only

one fork.

• When traveling, always lower the load as far as pos-

sible.

• When stacking pallets in racks and it is necessary to

move the load in a raised position, use caution.

Operate truck smoothly.

• Observe applicable traffic regulations. Yield right of

way to pedestrians. Slow down and sound horn at

cross aisles and wherever vision is obstructed.

• Operate truck only from designated operation posi-

tion.Never place any part of your body between the

mast uprights. Do not carry passengers.

• Do not allow anyone to stand or pass under load or

lifting mechanism.

• When leaving truck, neutralize travel control. Fully

lower lifting mechanism and set brake. When leaving

truck unattended, turn off key switch, remove key

and disengage the emergency stop switch.

Figure 2-1 Load Center

R3814

2-2 BL-PDSR 30-0319 - 03-07-2019

2-3. BEFORE OPERATION

Table 2-1 covers important inspection points on the

PDSR lift truck which should be checked prior to oper-

ation.Depending on use, some trucks may require

additional checks.

Figure 2-2 shows a sample format for an Operator

Checklist, which can be modified as necessary to fit

your operation.

WARNING: Periodic maintenance of this truck by a

UALIFIED TECHNICIAN is required.

CAUTION: A QUALIFIED SERVICE TECHNICIAN

should check the truck monthly for

proper lubrication, proper fluid levels,

brake maintenance, motor maintenance

and other areas specified in the SEC-

TION 3.

WARNING: If the truck is found to be unsafe and in

need of repair, or contributes to an

unsafe condition, report it immediately to

the designated authority. Do not operate

it until it has been restored to a safe

operating condition. Do not make any

unauthorized repairs or adjustments. All

service must be performed by a qualified

maintenance technician.

Table 2-1 Operator Checks

ITEM PROCEDURE

Transmission and

hydraulic systems.

Check for signs of fluid leak-

age.

Forks

Check for cracks and dam-

age; and, that they are prop-

erly secured.

Chains, cables and

hoses

Check that they are in place,

secured correctly,functioning

properly and free of binding or

damage.

Guards and load

backrest

Check that safety guards are in

place, properly secured and

not damaged.

Safety signs

Check that warning labels,

nameplate, etc., are in good

condition and legible

Horn Check that horn sounds when

operated

Steering Check for binding or looseness

in steering arm when steering.

Travel controls

Check that speed controls on

control head operate in all

speed ranges in forward and

reverse and that belly button

switch functions.

Wheels

Check drive wheel for cracks

or damage. Move truck to

check load for freedom of rota-

tion.

Hydraulic controls

Check operation of lift and

lower to their maximum posi-

tions.

Brakes

Check that brakes actuate

when steering arm is raised to

upright position, and when low-

ered to horizontal position.

Deadman/ Parking

brake

Check that steering arm raises

to upright position when

released and brake applies.

Emergency Stop

Switch

Check that emergency stop

switch can be disengaged and

reengaged.

Battery charge Check the battery indicator.

High speed limit

switch

Allow for enough space to

operate truck in high speed.

Elevate forks approximately

two feet, then test drive truck

to check if high speed is cut

out

ITEM PROCEDURE

BL-PDSR 30-0319 - 03-07-2019 2-3

Figure 2-2 Sample of Operator Check List

R3815

2-4 BL-PDSR 30-0319 - 03-07-2019

2-4. GENERAL CONTROL OPERATION.

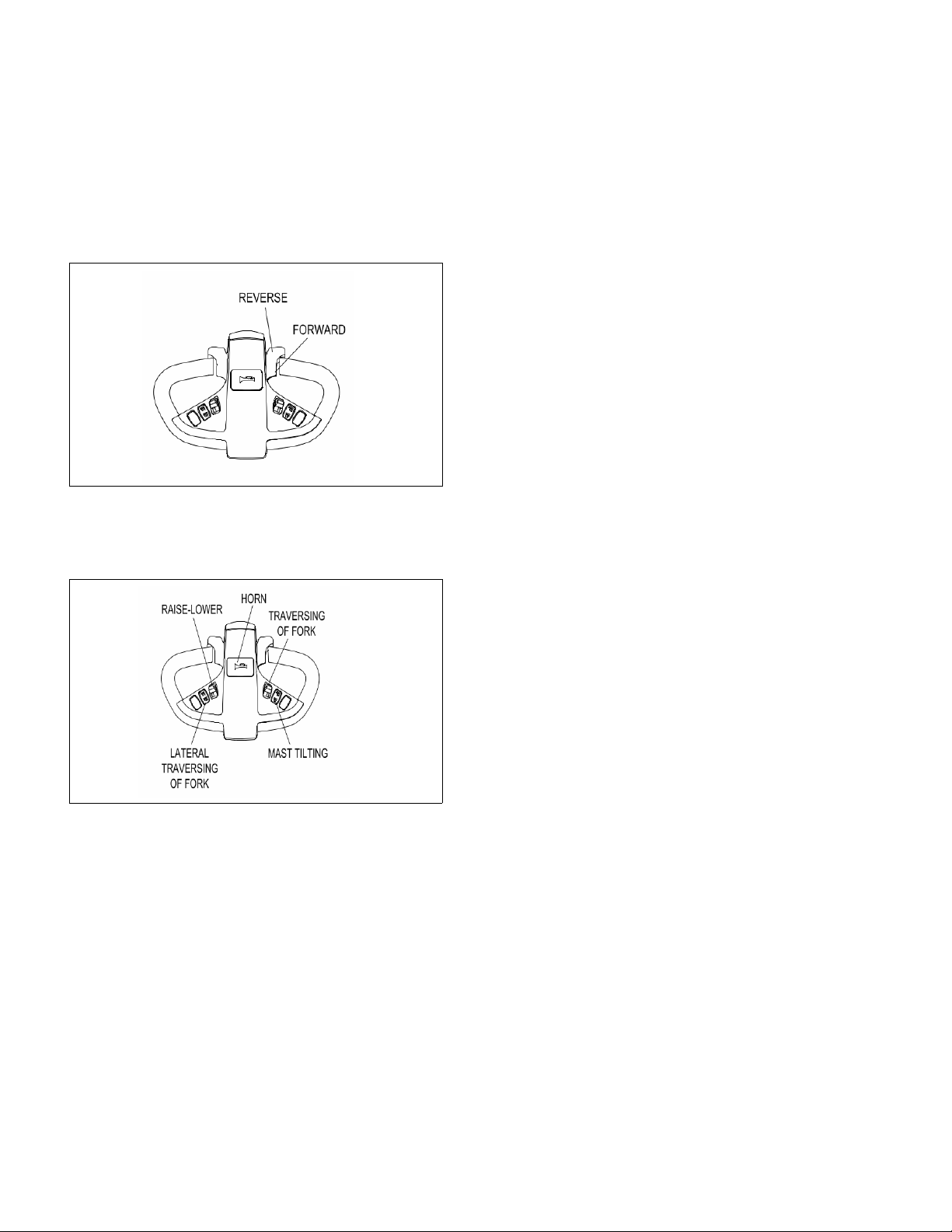

The speed control (See Figure 2-3) located on each

side of the control head provides fingertip control for

driving the truck. Rotate the control in the direction

you want to travel. The farther you rotate the control

from the neutral position,the faster the truck will

travel.

Figure 2-3 Forward / Reverse Control

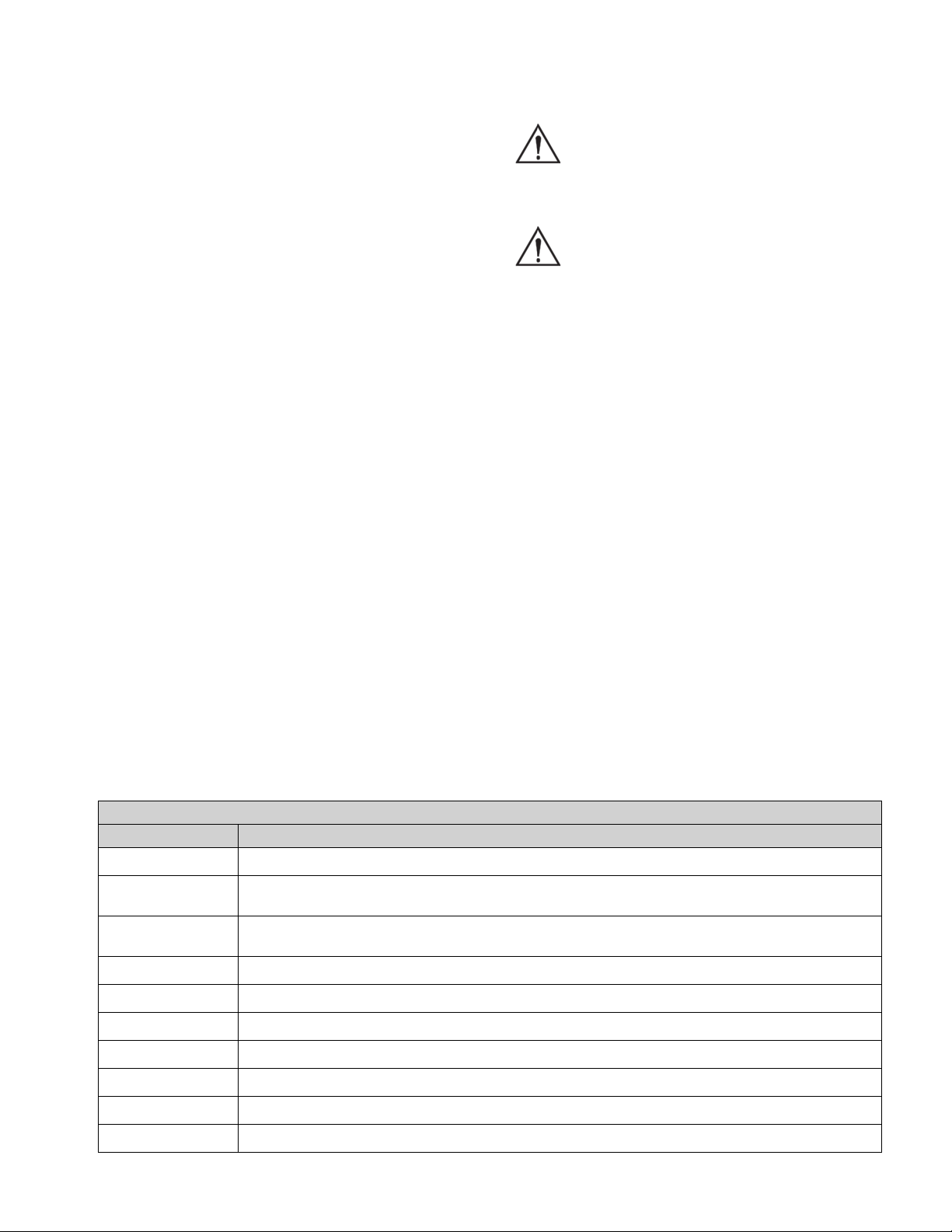

The pushbutton switches (See Figure 2-4), located on

the front of the control head activate the lift-lower con-

trols and the horn.

Figure 2-4 Pushbutton Switches

2-5. DRIVING AND STOPPING PROCEDURES

1. Connect the battery and turn on the key switch.

Grasp the grips of the steering head so that the

speed control can be comfortably operated by

either thumb.

2. Lower the steering arm to a comfortable position

above horizontal to disengage the brake and to

energize the electrical circuits.If the truck is not

moved, the electrical circuits will time out and will

deenergize. See.

3. To move forward (with load in back), slowly press

the speed control forward. See Figure 2-3. Press

the forward speed control farther to increase

speed.

4. To slow down or stop, release the speed control

and lower or raise the steering arm to the horizon-

tal or vertical position. In those positions, the

brake engages, slowing or stopping the truck.

5. Procedures for movement in reverse are the

same as in the forward direction except slowly

press the speed control backward.

2-5.1. Stopping

The stopping distance of the truck depends on the

ground conditions.The driver must take this into

account when operating the truck.

The driver must be looking ahead when traveling.

If there is no hazard,brake moderately to avoid

moving the load.

There are four different ways to stop the truck:

1. Plugging: This electrical braking function con-

sists of rotating the speed control lever in the

opposite direction of travel and then releasing it

when the truck stops. Plugging is a convenient

way to slow down the truck during normal

operation.If the control is not released, the truck

will accelerate in the opposite direction.

2. Steering arm (See Figure 2-5): The brake is fully

applied by lowering or raising the steering arm.

(See Figure 2-5) All traction control power is shut

off when the brake is engaged. When the steering

arm is in the upright position, the brake acts as a

parking brake. Deadman braking occurs when the

handle is released and spring action raises steer-

ing arm to the upright position.

3. Emergency braking: Press the emergency

brake switch, all electrical functions are cut out

and the truck automatically brakes.

4. Regenerative braking: If the speed control lever

is released, the truck automatically brakes regen-

eratively.When the speed is below.5 MPH, the

brake applies.

R8120

R8121

BL-PDSR 30-0319 - 03-07-2019 2-5

Figure 2-5 Brake Actuation

2-6. BELLY-BUTTON SWITCH

The belly-button switch (Figure 2-6) minimizes the

possibility of the driver being pinned by the steering

arm while driving the lift truck in slow speed.If the

switch presses against the operator while the lift

truck is being driven toward the operator,the switch

changes the direction of the lift truck.

Figure 2-6 Belly Button Switch

2-7. STEERING ARM GAS SPRING

The steering arm gas spring automatically raises the

steering arm to the upright position when the

steering arm is released.If the steering arm does not

return fully, the steering arm gas spring requires

replacement.Return truck to maintenance for repair.

2-8. LIFT AND LOWER CONTROLS

Lift/Lower Control buttons are located on the steering

control head. (Figure 2-4)

To lift forks, push in either LIFT button and hold until

forks reach desired height.To lower forks, push in

either LOWER button and hold until forks descend to

desired height.

2-9. LOADING AND UNLOADING

1. Move truck to location where load is to be picked

up.

2. Move the truck into position so forks are within

pallet or skid, and the load is centered over the

forks and as far back as possible.

3. Raise forks to lift load.

4. Drive to area where load is to be placed.

5. Move truck to align load with its new position.

6. Lower the load until it rests squarely in place and

the forks are free.

7. Slowly move the truck out from under the load.

2-10. PARKING

When finished with moving loads,return the truck

to its maintenance or storage area. Turn off the key

switch and disconnect the battery. Charge battery as

necessary.Refer to battery care instructions, SEC-

TION 3.

R8122

R8123

2-6 BL-PDSR 30-0319 - 03-07-2019

NOTES

BL-PDSR 30-0319 - 03-01-2019 3-1

SECTION 3

PLANNED MAINTENANCE

3-1. GENERAL.

Planned maintenance consists of periodic visual and

operational checks, parts inspection, lubrication, and

scheduled maintenance designed to prevent or

discover malfunctions and defective parts. The

operator performs the checks in SECTION 2,and

refers any required servicing to a qualified mainte-

nance technician who performs the scheduled mainte-

nance and any required servicing.

3-2. MONTHLY AND QUARTERLY CHECKS

Table 3-1 is a monthly and quarterly inspection and

service chart based on normal usage of equipment

eight hours per day,five days per week.If the lift

truck is used in excess of forty hours per week,

the frequency of inspection and service should be

increased accordingly.These procedures must be

performed by a qualified service technician or your

EP Service Representative.

3-3. BATTERY CARE

3-3.1. General

The PDSR may be equipped with maintenance free

or industrial wet cell batteries.

The care and maintenance of the battery is very

important to obtain efficient truck operation and

maximum battery life.

CAUTION: Gases produced by a battery can be

explosive. Do not smoke, use an open

flame, create an arc or sparks in the

vicinity of the battery. Ventilate an

enclosed area well when charging.

CAUTION: Batteries contain sulfuric acid which may

cause severe burns. Avoid contact with

eyes, skin or clothing. In case of contact,

flush immediately and thoroughly with

clean water. Obtain medical attention

when eyes are affected. A baking soda

solution (one pound to one gallon of wat-

er) applied to spilled acid until bubbling

stops, neutralizes the acid for safe hand-

ing and disposal.

Leakage voltage from battery terminals to battery

case can cause misleading trouble symptoms with

the truck electrical system.Since components of

the truck electrical system are insulated from truck

frame, leakage voltage will not normally affect truck

operation unless a short circuit or breakdown of

circuit wire insulation to truck frame occurs.

A voltage check from battery connector terminal

to battery case should indicate near zero volts.

Typically, however,the sum of the voltages at both

terminals will equal battery volts. This leakage

voltage will discharge the battery. As battery

cleanliness deteriorates,the usable charge of the

battery decreases due to this self discharge.

Although a leakage voltage reading of zero volts

may not be possible, a cleaner battery will have

more usable charge for truck operation and not affect

operation of electronic devices on the unit.

Table 3-1 Monthly and Quarterly Inspection and Service Chart

VISUAL CHECKS

INTERVAL INSPECTION OR SERVICE

Monthly Check electrical brake for proper operation.

Monthly Check load wheels for wear.A poly load wheel must be replaced if worn to within 1/16 inch

of hub. Check for separation from hub.

Monthly Check drive wheel for wear.A poly drive wheel must be replaced if worn to within 3/4 inch

of hub. Check for separation from hub.

Monthly Inspect wiring for loose connections and damaged insulation.

Monthly Inspect contractors for proper operation.

Monthly Check deadman brake switch for proper operation.

Monthly Check lift chain tension, lubrication & operation (see paragraph 3-6.)

Quarterly Check lift cylinder for leakage.

Quarterly Check for excessive jerking of steering arm when stopping or starting.

Semi-annually Inspect for chain wear (See SECTION 8)

3-2 BL-PDSR 30-0319 - 03-01-2019

3-3.2. Safety Rules

•Wear protective clothing, such as rubber apron,

gloves, boots and goggles when performing any

maintenance on batteries. Do not allow electrolyte

to come in contact with eyes, skin, clothing or floor

.

If

electrolyte comes in contact with eyes,flush

immediately and thoroughly with clean water.

Obtain medical attention immediately. Should

electrolyte be spilled on skin, rinse promptly with

clean water and wash with soap.A baking soda

solution (one pound to one gallon of water) will

neutralize acid spilled on clothing, floor or any

other surface. Apply solution until bubbing stops

and rinse with clean water.

• If truck is equipped with wet cell batteries,keep vent

plugs firmly in place at all times except when adding

water or taking hydrometer readings. Do not allow

dirt, cleaning solution or other foreign material to

enter cells. Impurities in electrolyte has a neutraliz-

ing effect reducing available charge.

•Do not bring any type of flame, spark, etc., near the

battery.Gas formed while the battery is charging, is

highly explosive. This gas remains in cell long after

charging has stopped.

• Do not lay metallic or conductive objects on battery.

Arcing will result.

•Do not touch non-insulated parts of DC output

connector or battery terminals to avoid possible

electrical shock.

• De-energize all AC and DC power connections

before servicing battery.

• Do not charge a frozen battery.

• Do not use charger if it has been dropped or other-

wise damaged.

3-3.3. Battery Care and Charging

CAUTION: Never smoke or bring open flame near

the battery.Gas formed during charging

is highly explosive and can cause seri-

ous injury.

1. Charge the battery only in areas designated for

that use.

2. Make certain the charger being used matches the

voltage and amperage of the truck battery.

3. Before disconnecting or connecting batteries to a

charger,make sure the charger is “OFF”. If an

attempt is made to do this while the charger is

“ON”, serious injury to you,the battery and the

charger could result.

4. Before connecting the battery cable to the trucks

receptacle,make sure the key switch is off. The

battery cable must be fully connected before the

truck is used. If the plug is not making good con-

tact, heat will weld the two parts of the battery

connector together,making it difficult to remove

and necessary to replace.

5. Battery terminals should be checked and cleaned

of corrosion regularly.Good battery terminal con-

tact is essential not only for operation, but also for

proper charging of the battery.

6. The charging requirements will vary depending on

the use of the truck. The battery should be given

as equalizing charge on a weekly basis.This

charge should normally be an additional three

hours at the finish rate.

7. Make certain battery used meets weight and size

requirements of truck. NEVER operate truck with

an undersized battery.

3-3.4. Battery Cleaning

Always keep vent plugs tightly in place when

cleaning battery. When properly watered and

charged,the battery will remain clean and dry. All

that is necessary is to brush or blow off any dust

or dirt that may accumulate on them.However,

if electrolyte is spilled or overflows from a cell, it

should be neutralized with a solution of baking soda

and water, brushing the soda solution beneath the

connectors and removing grime from the covers.

Then rinse the battery with cool water from a low

pressure supply to remove the soda and loosen dirt. If

batteries stay wet consistently,they may be either

overcharged or over filled. This condition should be

investigated and corrected.

BL-PDSR 30-0319 - 03-01-2019 3-3

3-4. CHARGING BATTERIES

Charging requirements will vary depending on depth

of discharge and temperature. Follow safety rules

when placing a battery on charge.

Proceed as follows:

1. Park truck at charging station with carriage low-

ered and turn the key switch off.

2. Check the condition of the AC cord and battery

cables.If there are any cuts in the cable,any

exposed wires, loose plugs or connectors, DO

NOT attempt to charge the batteries.Contact

appropriate personnel for repairs to be made.

3. Disconnect the batteries from the truck and con-

nect the batteries to the charger.Make sure

connectors are mated properly.

4. Connect the charger to the appropriate power

supply.

5. Follow the instructions for the charger being used.

3-5. LUBRICATION

Refer to Table 3-2 for the recommended types of

grease and oil. Table 3-3 in conjunction withFigure

3-1 identifies the items requiring lubrication.

3-6. LIFT CHAIN MAINTENANCE

Fully raise and lower lift carriage while observing

chains as they move over chain sheaves. Ensure

chain is aligned and tracking properly and all links

are pivoting freely. With lift carriage fully lowered,

spray or brush on a film of SAE 30 or 40 engine oil

Table 3-2 Recommended Lubricants (See Table 3-3 for Application)

No. 1 Transmission oil- 85W-90

Transmission oil-10W-30 (NOTE)

No. 2 Grease-Lithium base, general purpose.

No. 3 Hydraulic oil-Heavy duty with a viscosity of 150 SUS foam suppressing agent and rust and

oxidation inhibitors

Hydraulic oil-Heavy duty with a viscosity of 100 SUS foam suppressing agent and rust and

oxidation inhibitors (NOTE)

No. 4 SAE 30 or 40 Engine lubricating oil.

NOTE: USED ON COLD CONDITIONED TRUCKS

3-4 BL-PDSR 30-0319 - 03-01-2019

Figure 3-1 Lubrication Diagram

Table 3-3 Lubrication Chart

Pos. Location Method of

Application

TYPE

(Table3-2) APPLICATION OF LUBRICANT

1Transmission Capacity - 1.75 Liters Can No. 1 Fill to level plug opening.

2 Inner & Outer Mast Brush No.2 Full length of channel where rollers

operate.

3

Hydraulic Reservoir:

Capacity - 13.78 Liters (L.H. 2600mm)

Capacity - 14.91 Liters (L.H. 3200mm)

Capacity - 16.86 Liters (L.H.4000mm)

Can No. 3

With lift carriage fully lowered, fill res-

ervoir with hydraulic oil to 1 inch

below opening.

4Lift Chain Brush or Spray No. 4 See Paragraph 3-6

R8124

BL-PDSR 30-0319 - 03-07-2019 4-1

SECTION 4

TROUBLESHOOTING

4-1. GENERAL

Use Table 4-1. as a guide to determine possible

causes of trouble. The table is divided into five main

categories: Truck and Hydraulic System Will Not

Operate:

Truck Does Not Operate Forward or Reverse: Trouble

With Braking: Trouble With Lifting Or Lowering, and

Miscellaneous malfunctions.

Table 4-1. Troubleshooting Chart

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

TRUCK AND HYDRAULIC

SYSTEM WILL NOT OPERATE

Truck will not travel not will lift sys-

tem operate.

a. Fuse blown. Check fuse and replace if neces-

sary.

b.

Fuse blown. Check fuse and replace if neces-

sary.

c. Battery dead or disconnected. Check battery connections and

check battery voltage.

d. Key switch defective Bypass key switch to determine if

it is malfunctioning.

e. Emergency brake switch defective. Bypass the switch to determine if it

is malfunctioning.

f. Defective wiring. Check for open circuit. Repair as

required

TRUCK DOES NOT OPERATE

FORWARD OR REVERSE

Truck does not travel forward or

reverse. All other functions operate

normally.

a. Check all wiring. A loose connec-

tion may be the cause of mal-

function.

Tighten all loose connections

before further troubleshooting.

b. Defective deadman switch. Check and replace switch if defec-

tive.

c. Defective main controller. Check for proper operation and

replace if necessary.

d. Defective potentiometer in control

head.

Check and replace potentiometer

if defective.

Truck travels forward but not in

reverse.

Defective potentiometer in control

head.

Check and replace potentiometer

if defective.

Truck travels reverse but not in

forward.

Defective potentiometer in control

head.

Check and replace potentiometer

if defective.

4-2 BL-PDSR 30-0319 - 03-07-2019

Truck travels forward and in reverse

at lower speeds; will not travel at

high speed.

Defective potentiometer in control

head.

Check and replace potentiometer

if defective.

TROUBLE WITH BRAKING

Truck does not slow with brake, or

brake does not engage.

a. Defective deadman switch.

Check deadman switch for conti-

nuity.If none found when the con-

trol arm is in the brake position,

replace switch.

b. Defective electric brake. Adjust or replace brake.

Brake will not release.

a. Defective electric brake. Replace.

b. Brake temperature above 281° F Allow to cool and check air gap.

c. Open brake circuitry or wiring. Make voltage checks.

Brake drags. Defective electric brake Replace.

Brake grabs.

a. Incorrect stopping distance adjust-

ment Adjust.

b. Defective electric brake. Replace.

Abnormal noise and chatter when

brake is applied. Defective electric brake Replace.

TROUBLE WITH LIFTING OR

LOWERING

Oil sprays or flows from the top of

the lift cylinder.Defective packing in lift cylinder. Repair lift cylinder.

Squealing sounds when lifting forks. a. Oil level too low.Identify oil leak and fill reservoir.

b. Lift linkage binding. Apply grease.

Forks do not lift to top. a. Oil level too low.Add oil to reservoir.

b. Load larger than capacity.Refer to I.D.plate for capacity.

Weak, slow or uneven action of

hydraulic system.

a. Defective pump or relief valve Check pressure. Adjust as neces-

sary.

b. Worn lift cylinder.Replace cylinder.

c. Load larger than capacity.Refer to I.D.platefor capacity.

d. Defective lift motor solenoid. Replace solenoid on pump motor.

e. Battery charge low.Charge battery.

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

Table of contents

Other Big Joe Truck manuals