Problem Cause Solution

The forks cannot be raised to their maxi-

mum height,

- Their is insufcient oil in the reservoir. - Replenish the oil to the correct level.

The forks cannot be raised. - No hydraulic oil or impurities or air in the oil.

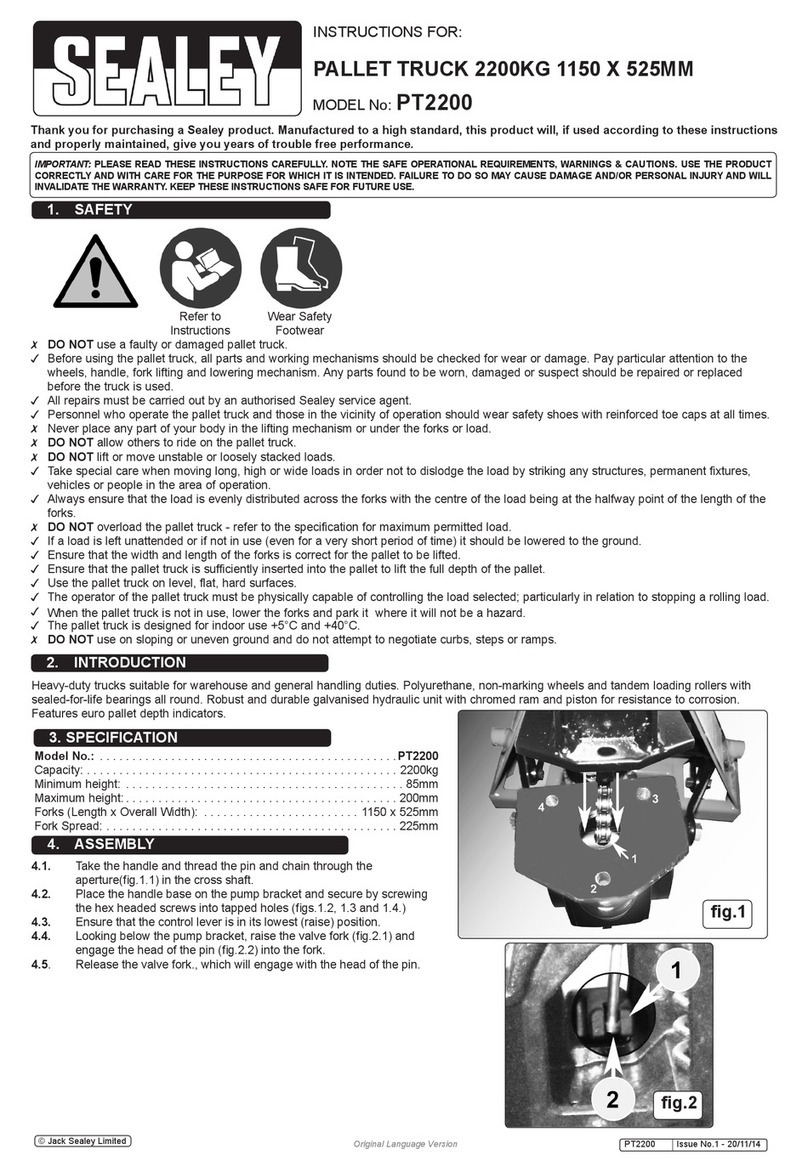

- The adjusting nut (g.2D) is too high keeping the

pumping valve open.

- Air has entered the hydraulic system.

- Replenish or change the oil.

- Reset the adjusting nut or bolt (g.2E).

- Purge the air from the hydraulic system.

The forks cannot be lowered - The piston rod (g.2A) or the pump is

deformed.

- Forks have been kept in the rise position

resulting in the rod jamming.

- The adjusting nut or bolt is incorrectly positioned.

- Replace the piston rod or pump.

- Keep the forks in the lowest position when

not in use.

- Adjust the nut or bolt.

The forks lower without the release valve

operating.

- Impurities, or air, has got into the release valve

oil.

- Parts of the hydraulic system have been

damaged.

- Adjusting nut (fig.2D) or bolt (fig.3F) incorrectly

positioned.

- Replace the oil and/or purge the air from

valve.

- Inspect and replace the damaged parts.

- Adjust the nut (fig.2D) or screw (fig.3F).

7.1. Daily Maintenance Check

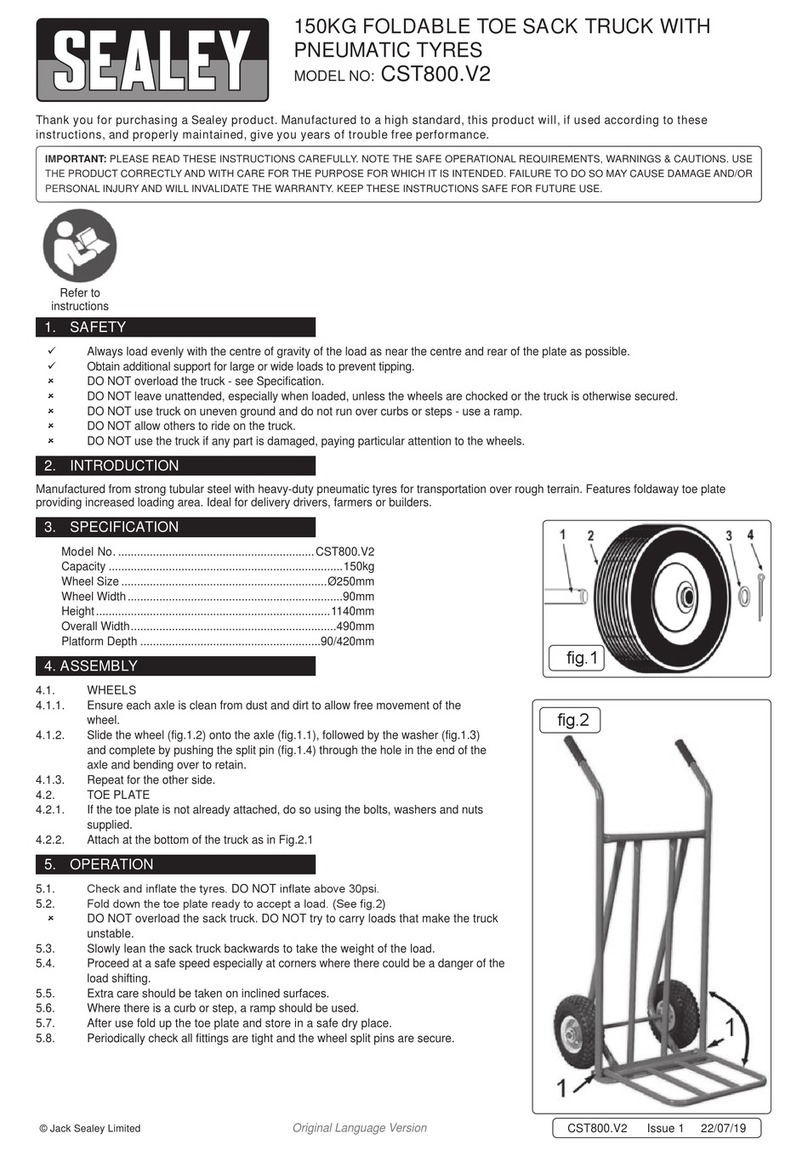

7.1.1. Check the state of the wheels and the axles since thread, rags and other foreign objects can jam the wheels making safe, effective

operation difficult.

7.1.2. On completion of each task, unload the forks and return them to the lowest position.

7.2. Oil Check

7.2.1. Check the oil level at six monthly intervals. Sealey hydraulic jack oil is used with the pallet truck. The viscosity of the oil should be

30cSt at 40°C. The amount used in the pallet truck is approximately 0.4 litres.

7.3 Lubrication

7.3.1. The bearings and shafts of the pallet truck have long-life grease applied to them during manufacture. The bearings will only require

.greasing at monthly intervals or after the pallet truck had been serviced down to the lubrication points.

7.4. Purging Air from the Hydraulics

7.4.1. Air can get into the hydraulic oil through transportation, or the pump becoming misaligned. As a result, the forks will not elevate.

7.4.2. The air can be purged by setting the control level to the LOWER position and pumping the operating handle up and down for 30 - 40

seconds.

7.4.3. When the pallet truck is not in use, lower the forks and park the truck where it will not be a hazard.

8. TROUBLESHOOTING

8.1. Troubleshooting on the pallet truck.

8.2. Fault-finding on the weighing unit.

Problem Cause Solution

HELP1 on display - The load is too heavy for the scale. - Remove the load immediately

Scale is not accurate - The fork shoe is touching the bottom part of the

scale.

- Cable in junction box is loose.

- One of the load cells is broken.

- Remove anything that restricts movement

of the scale.

- Check the connection in the junction box

and conrm it is secure.

- Apply weight to all four corners of the

scale and the load cell with the different

weight should be replaced.

Display won't turn on. - Battery voltage is too low.

- Battery life is complete.

- Change the batteries.

- Change the batteries.

7.5. Battery Replacement

7.5.1. To insert batteries, first remove the back cover at the rear of the console display unit.

7.5.2. Insert 4XAA cells making sure that they are correctly placed in the display unit.

7.5.3. Replace the cover on the display unit

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

7. MAINTENANCE

Original Language Version PT1150SC.V2 Issue:3(SP)-26/04/13

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to www.sealey.co.uk, email

sales@sealey.co.uk or phone 01284 757500.

© Jack Sealey Limited