4

1. Safety Information

1.1 General Instructions

• There are care/precautions that should be observed when assembling, use, maintenance and

discontinue using this device;

• Before performing any operation (installation, use, maintenance and reuse after prolonged

interruption in the use of the device), read the manual;

• The device must be used by people trained and knowledgeable in use and safety requirements

described in this manual;

• This device is not intended for use by persons (including children) with physical, sensory or mental

capacities reduced, or people with lack of experience and knowledge, unless they have received

instructions regarding the use of the device or under the supervision of a person responsible for their

safety;

• It is recommended that children be supervised to ensure that they are not playing with the device;

• In case of alternation of staff to work with the device, the new operator must be instructed on the

rules and the operation of the device;

• The operator must use the appropriate PPE (personal protective equipment). For example: use cap

in hair preventing it from locking up in moving parts;

• The operator must always be alert to situations that can cause risks of accidents and avoid them.

For example: avoid working with loose sleeves uniforms, where they can lock in the moving parts,

causing accidents;

• After being held reading and clarified all doubts, this manual should be stored carefully in an easily

accessible place, known to all people who will operate the unit and placed the willingness of people to

carry out maintenance, for any queries. Whenever there is any doubt, be sure to consult the manual.

Do not operate in any way with any questions;

• Upon installation, it is essential to put this manual available for the professionals who will do the

same;

• Before you start cleaning and any maintenance, it is essential to disconnect the device from the

power network;

• Periodically check the condition of cables and electrical parts;

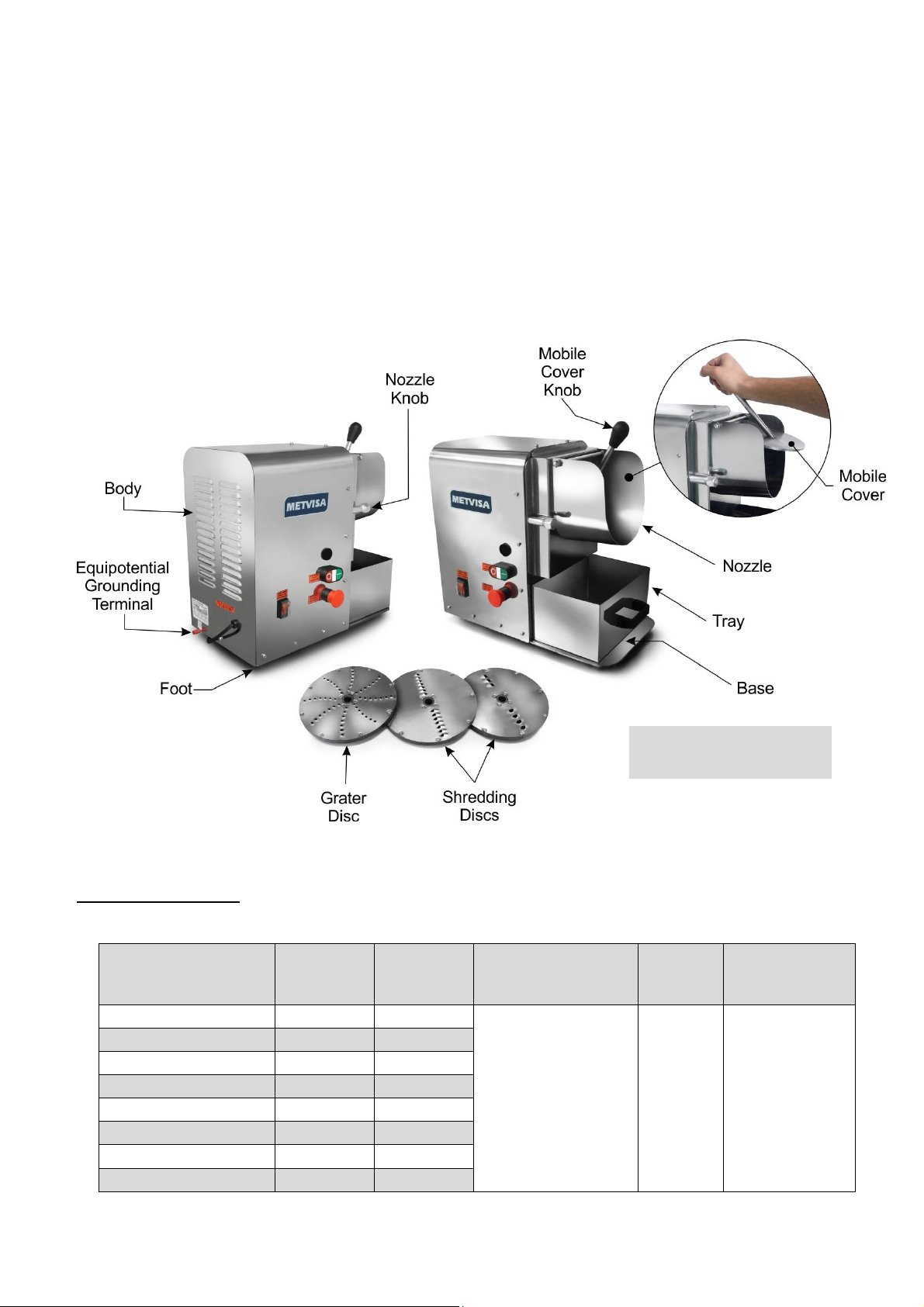

• Do not turn the device on without locking the Disc or Nozzle. Insert only specific products to what the

device was made for, and never place your hands, fingers or objects on the Nozzle or mobile parts

with the power on, it might cause an accident;

• Do not leave the device switched on without supervision.

WARNING!

Do not make repairs yourself. Go to technical assistance authorized by the manufacturer.

Use only original parts in your device.