Version: QLA QLR QLAT QLRT EN V.7.04i

Date: 20/09/2021

4 (106)

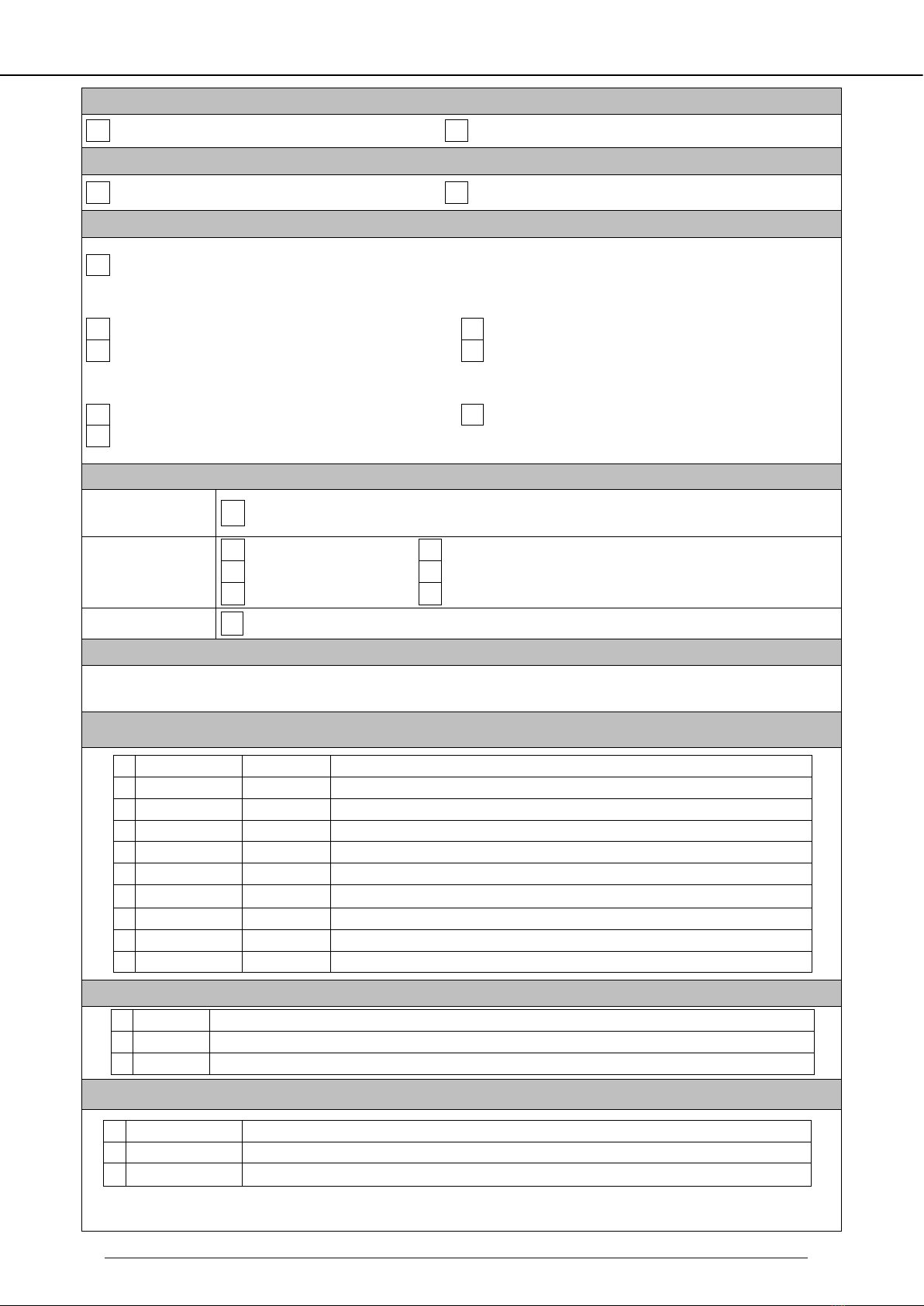

Table of Contents

1. DELIVERY SPECIFICATION ...................................................................................................8

2. WARRANTY ........................................................................................................................12

3. GENERAL SAFETY INSTRUCTIONS........................................................................................13

3.1Safety features –lifting device ..................................................................................... 13

4. OPERATING DESCRIPTION ..................................................................................................15

4.1 Control handle/External handle ................................................................................... 15

4.2 Emergency stop ............................................................................................................ 15

4.3 Function in handle mode.............................................................................................. 15

4.4 Function in full auto-balance mode.............................................................................. 16

4.5 Function –lifting device in limited auto-balance mode ............................................... 16

4.6 Before start................................................................................................................... 16

4.7 When starting............................................................................................................... 17

4.8 Performing a lift operation........................................................................................... 17

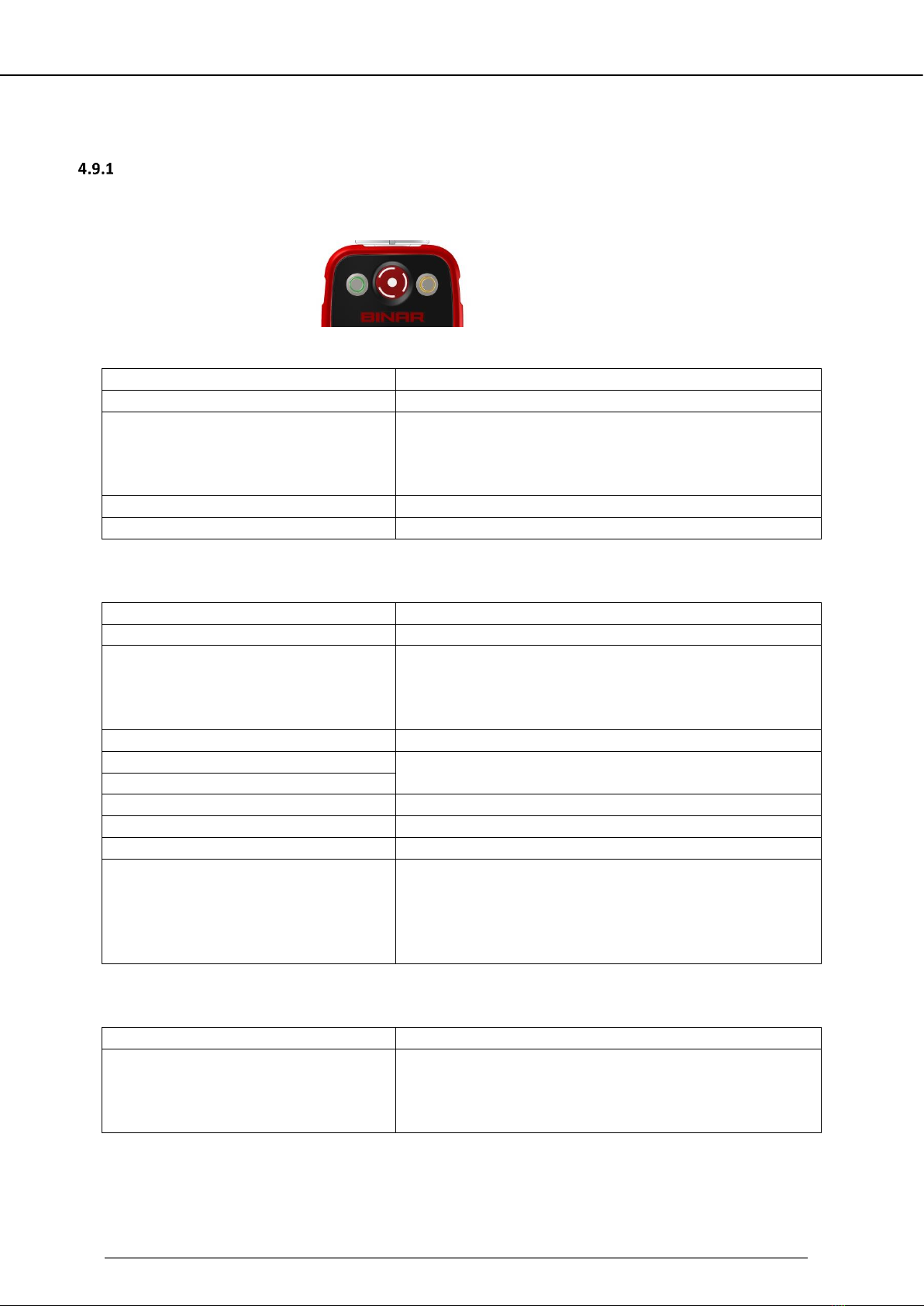

4.9 The LEDs functions on different types of control handles/external handles ............... 18

4.10 The buttons' functions on different types of control handles/external handles ......... 20

4.11 Other functions............................................................................................................. 23

4.12 Installation instructions when replacing the gripper.................................................... 24

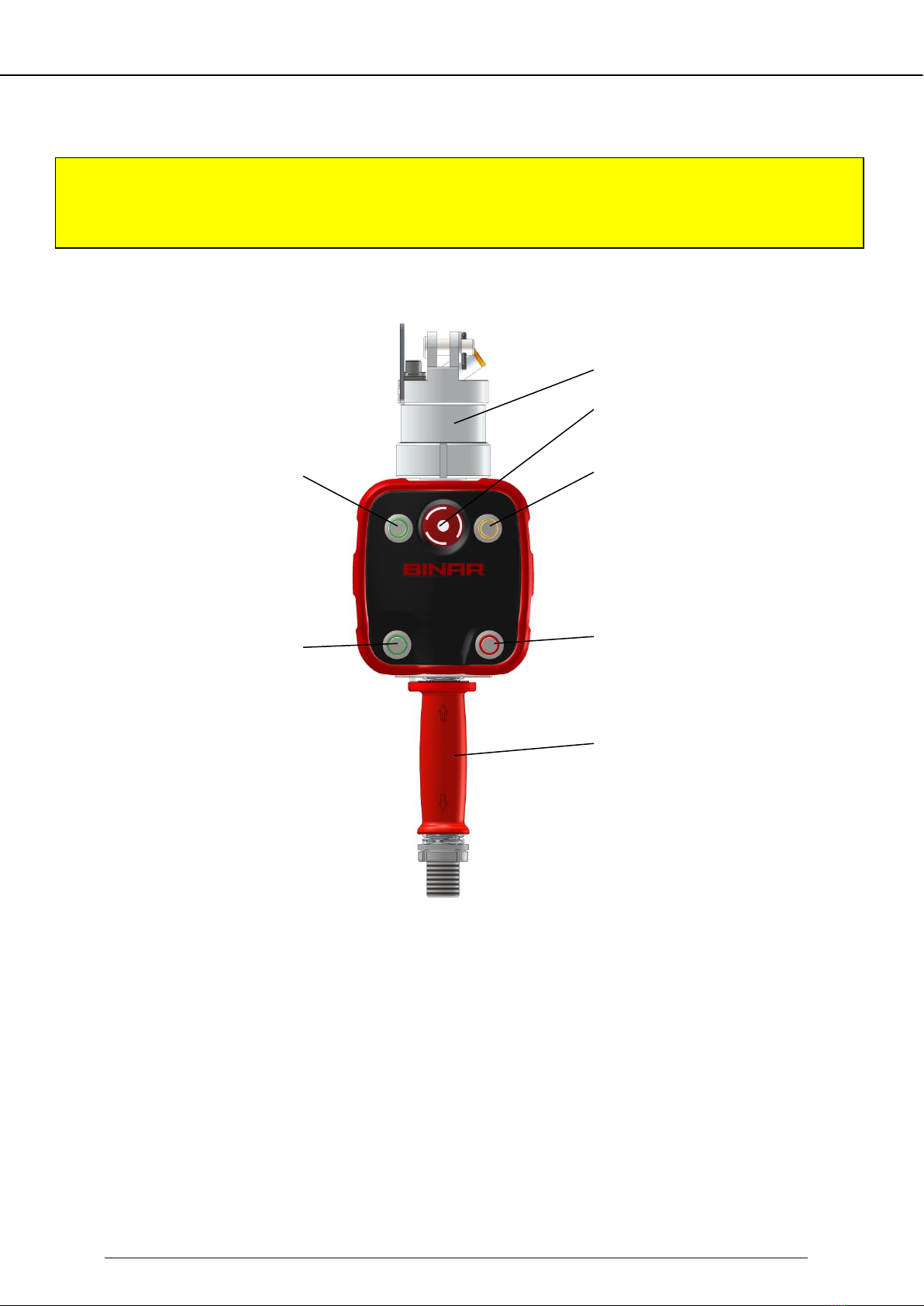

5. LIFTING DEVICE, GENERAL DESCRIPTION ............................................................................28

6. VARIANTS OF QUICK-LIFT ARM/QUICK-LIFT RAIL/QUICK-LIFT ARM TORQUE .....................29

6.1 QLA ............................................................................................................................... 29

6.2 QLR ............................................................................................................................... 29

7. ADVANCED USE / ILAB 3 PROGRAM ...................................................................................30

7.1 General ......................................................................................................................... 30

7.2 Program window .......................................................................................................... 31

7.3 Menu bar ...................................................................................................................... 32

7.4 Parameter window, “SETTINGS” .................................................................................. 36

7.5 Parameter window, “STATUS”...................................................................................... 38

7.6 Parameter window, “IN/OUT”...................................................................................... 39

7.7 Parameter window “ADVANCED”................................................................................. 39

7.8 I/O board, connection principle.................................................................................... 42

8. SPARE PARTS......................................................................................................................47

8.1 Spare parts, lifting device ............................................................................................. 47

8.2Spare parts, control handle/external handle/control box............................................ 48

8.3 Exploded view –Spare parts......................................................................................... 49

9. INSTRUCTIONS FOR INSTALLING SPARE PARTS...................................................................50

9.1 Safety instructions when working on the lifting device ............................................... 50

9.2 Installation of the cable drum guard ............................................................................ 50

9.3 Cutting the wire rope ................................................................................................... 50

9.4 Replacement of the spiral cable ................................................................................... 50

9.5 Replacement of the wire rope...................................................................................... 51

10. MAINTENANCE OF THE LIFTING DEVICE..............................................................................53

10.1 Safety instructions when working on the lifting device ............................................... 53

10.2 Skills requirements for maintenance personnel........................................................... 53

10.3 Daily inspection ............................................................................................................ 53

10.4 One month after installation ........................................................................................ 53

10.5 Quarterly maintenance ................................................................................................ 54

10.6 Maintenance every twelve months.............................................................................. 54

10.7 Replacement of the wire rope...................................................................................... 55

10.8 End effectors and adaptors .......................................................................................... 55

11.TROUBLESHOOTING ...........................................................................................................56

11.1 Troubleshooting –for operators .................................................................................. 56

11.2 Troubleshooting - Via iLab 3 and the control handle’s/external handle’s LEDs........... 56

11.3 The wire rope guide has run against the mechanical stop and has jammed. .............. 59

11.4 Wire rope drum is jammed........................................................................................... 60