VD (E2.1) 10/2011 page 6/83

Contents

EC – Declaration of Conformity.....................................................................................................................2

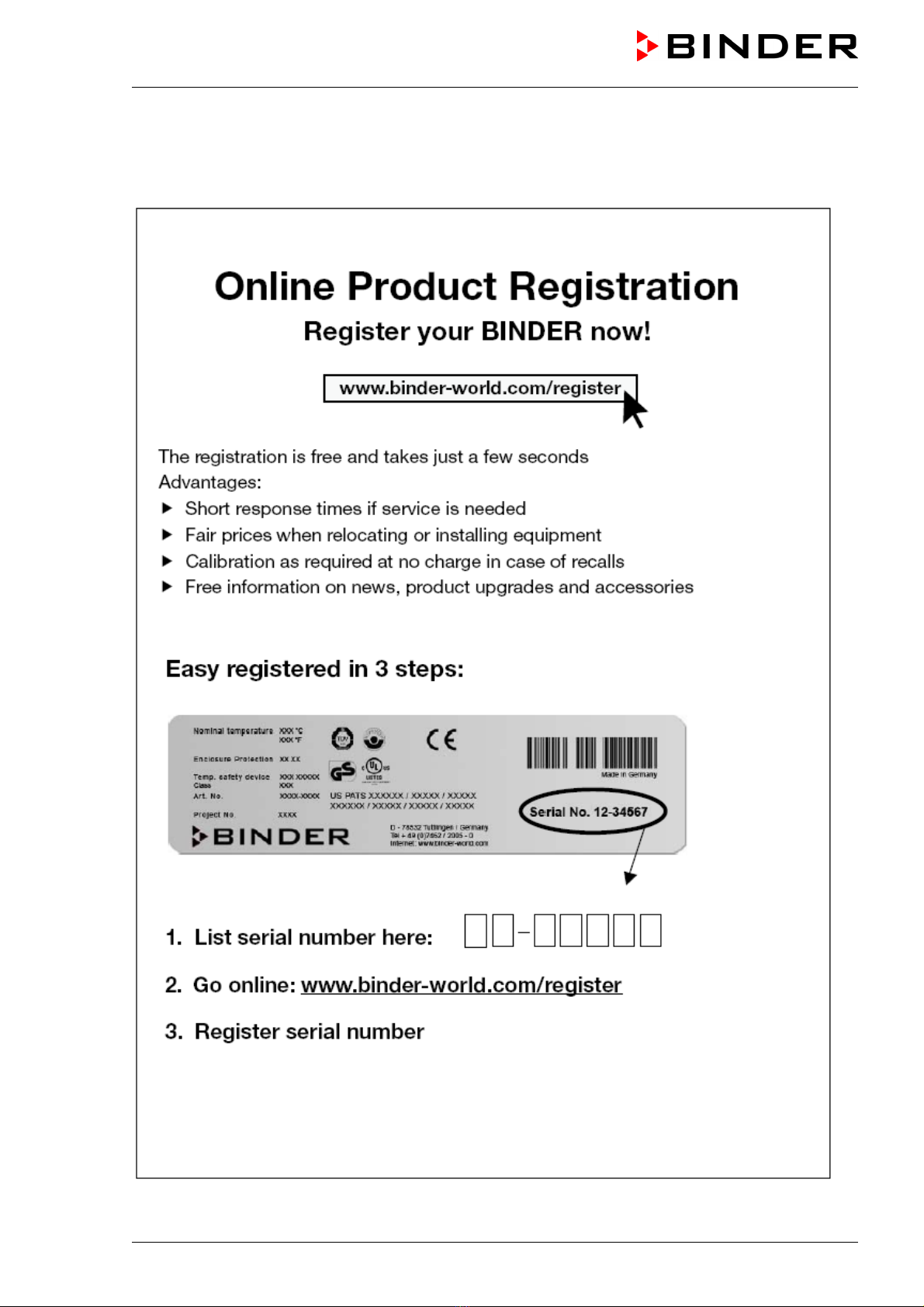

Product registration .......................................................................................................................................5

1. SAFETY..................................................................................................................8

1.1 Legal considerations ...........................................................................................................................8

1.2 Structure of the safety instructions......................................................................................................8

1.2.1 Signal word panel .....................................................................................................................8

1.2.2 Safety alert symbol ...................................................................................................................9

1.2.3 Pictograms................................................................................................................................9

1.2.4 Word message panel structure...............................................................................................10

1.3 Localization / position of safety labels on the unit.............................................................................10

1.4 Type plate .........................................................................................................................................11

1.5 General safety instructions on installing and operating the vacuum drying oven ............................12

1.6 Intended use .....................................................................................................................................14

2. DESCRIPTION OF THE EQUIPMENT.................................................................14

2.1 Overview of the equipment ...............................................................................................................15

2.2 VD 23 control panel...........................................................................................................................16

2.3 VD 53 / 115 control panel .................................................................................................................16

2.4 Connections at the rear of the unit....................................................................................................17

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION....................................................................................................18

3.1 Unpacking, and checking equipment and completeness of delivery................................................18

3.2 Guidelines for safe lifting and transportation ....................................................................................19

3.3 Storage..............................................................................................................................................19

3.4 Location of installation and ambient conditions ................................................................................19

4. INSTALLATION AND CONNECTIONS................................................................20

4.1 Vacuum expansion racks..................................................................................................................20

4.2 Electrical connection .........................................................................................................................21

4.3 Vacuum connection ..........................................................................................................................21

4.4 Inert gas connection..........................................................................................................................22

5. START UP............................................................................................................22

5.1 Settings at the RD3 program controller ............................................................................................22

5.2 General indications ...........................................................................................................................24

6. FIXED VALUE ENTRY MODE .............................................................................25

7. WEEK PROGRAM EDITOR.................................................................................26

7.1 Program table template for Week program Editor ............................................................................28

7.2 Programming example of the Week program editor.........................................................................29

7.2.1 Desired time function ..............................................................................................................29

7.2.2 Proceeding overview ..............................................................................................................29

7.2.3 Proceeding in detail ................................................................................................................30

8. PROGRAM EDITOR.............................................................................................35

8.1 Selecting between set-point ramp and set-point step.......................................................................35

8.1.1 Programming with setting “Ramp” (default setting) ................................................................35

8.1.2 Programming with setting “step”.............................................................................................37

8.1.3 General notes on programming temperature transitions........................................................38

8.2 Set-point entry for program operation...............................................................................................38

8.3 Program table template.....................................................................................................................41

8.4 Deleting a program section ...............................................................................................................42