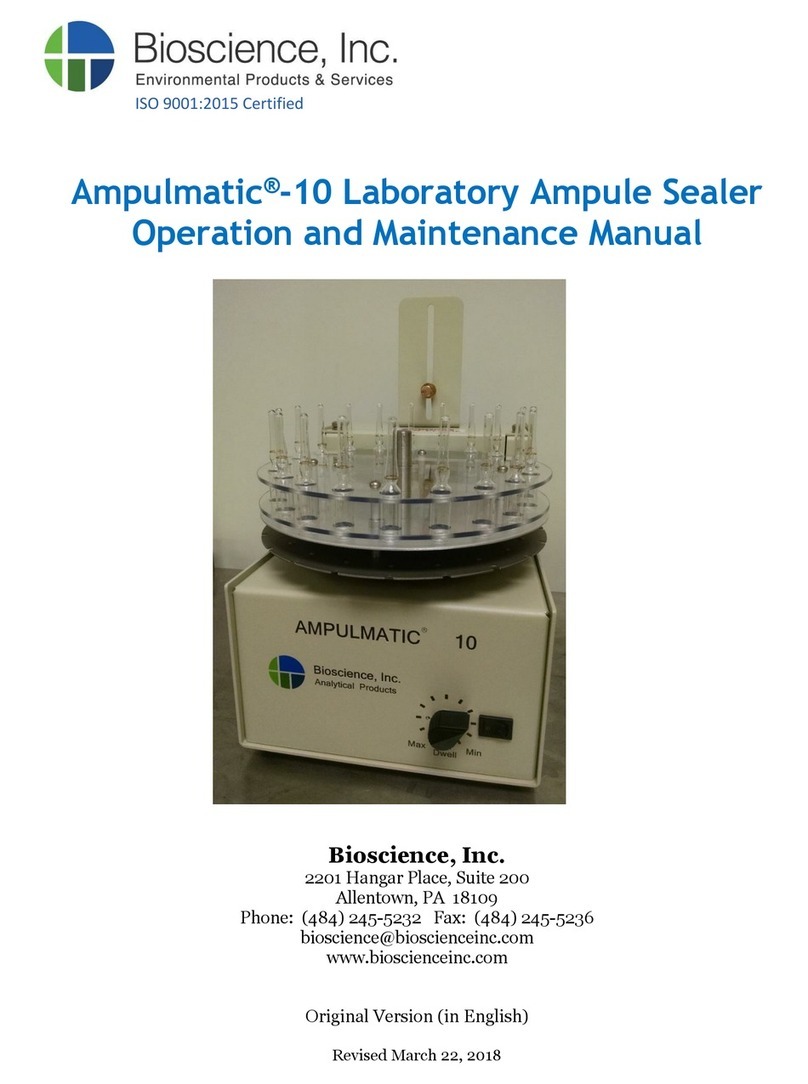

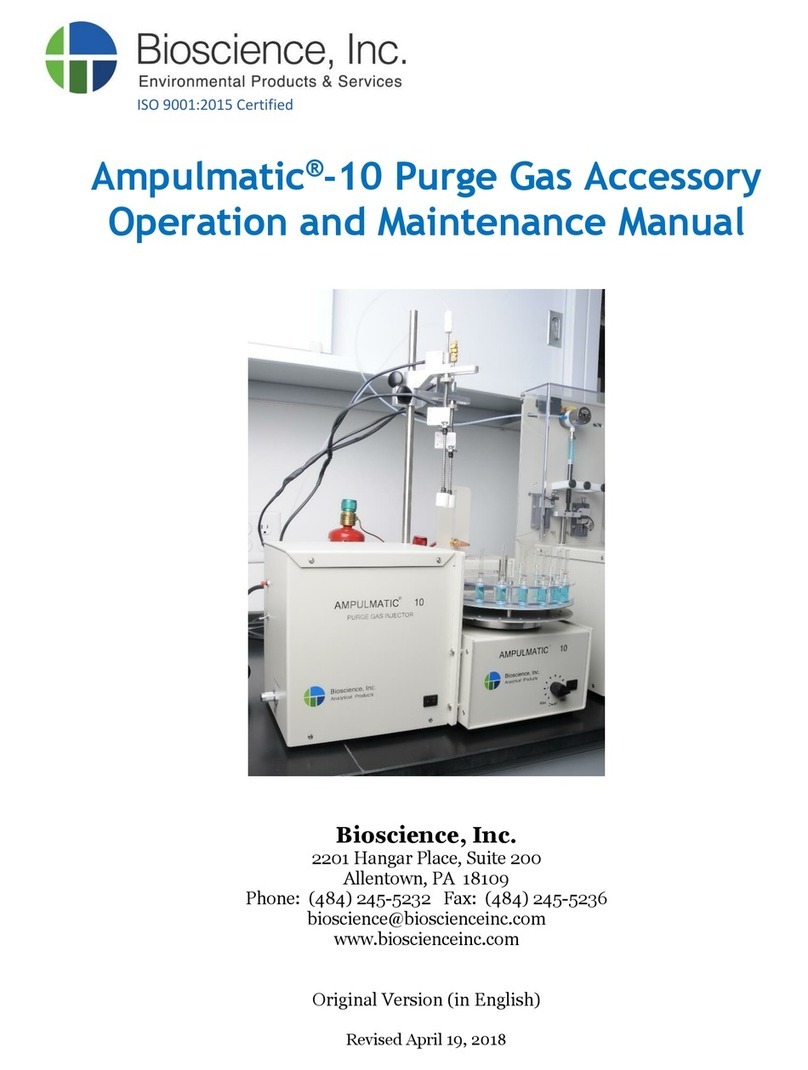

Bio-Science Ampulmatic-10 Purge Gas Injector User manual

ISO 9001:2015 Certified

Ampulmatic®-10 Liquid Filler Accessory

Operation and Maintenance Manual

Bioscience, Inc.

2201 Hangar Place, Suite 200

Allentown, PA 18109

Phone: (484) 245-5232 Fax: (484) 245-5236

bioscience@bioscienceinc.com

www.bioscienceinc.com

Original Version (in English)

Revised April 19, 2018

Contents

Section-Page

Title

1-1

Introduction

2-1

Statement of Warranty

3-1

Model Description

3-2

Ampulmatic-10 Liquid Filler Features

4-1

Unit Specifications

5-1

Setup

5-1

Initial Setup

5-2

Installing the Liquid Filler Syringe

5-4

Installing the Tubing

5-5

Calibrating the Filling Volume

5-6

Final Setup

5-7

Adjusting the Syringe Speed

6-1

Ampule Glass and Size

7-1

Maintenance

8-1

Troubleshooting Guide

9-1

Spare Parts List

Introduction

Thank you for choosing the Ampulmatic®-10 Liquid Filler accessory. Bioscience, Inc. has striven

to create the most reliable, easy-to-maintain and easy-to-use instrument available for bench scale

ampule filling and sealing. This equipment has been tested extensively in our labs and in the field

to ensure that the components and systems are reliable.

We have gone to extra lengths to be sure that should something become misaligned, require

adjustment or need to be replaced, it is easily accessed and addressed. The Ampulmatic-10 Liquid

Filler accessory has been designed with a good deal of flexibility to allow a sufficient range of

sealing volumes and liquid types.

We have had extensive experience dealing with the unique filling and sealing problems of our

customers and are proud to be the leader in bench-scale ampule filling and sealing. We will be

happy to work with you to furnish custom solutions to your specific filling and sealing problems

at your request.

For maximum value and ease of startup, please proceed as follows:

1. Inspect the carton and the unit for shipping damage. Notify the carrier immediately if

damage is found.

2. Use the "Accessory Check List" attached to this manual when unpacking the unit to verify

that the complete unit has been received. Do not discard packing materials until everything

has been accounted for.

3. Reference the Ampulmatic-10 Operation and Maintenance Manual and Ampulmatic-10

Purge Gas Accessory Operation and Maintenance Manual for setup instructions.

4. Carefully follow directions in the "Setup" section of this manual.

5. Follow the recommended preventive maintenance measures found in the “Maintenance”

section of this manual for long equipment life.

6. Keep this manual in a practical location for ready reference.

7. If you have any questions, please contact our Technical Service department at 484-245-

5232, 800-627-3069, or bioscience@bioscienceinc.com.

All Rights Reserved

The information contained in this manual is the exclusive property of Bioscience, Inc. and has been provided

solely to enable the users of the equipment described herein to operate and maintain such equipment. Any

other use of this information, or the reproduction or transmission of all or any portion of this manual, without

prior written consent of Bioscience, Inc. is expressly prohibited.

1-1

Statement of Warranty

The Ampulmatic®-10 Liquid Filler accessory is warranted against faulty workmanship or the use of

defective materials for a period of 365 days from the date of shipment. This warranty is the only

warranty made by Bioscience, Inc. (Manufacturer) and is in lieu of all other warranties, expressed

or implied, except as to title and can be amended only by a written instrument signed by the

Manufacturer. The Manufacturer provides no warranty to the Customer, either express or implied

nor for title. Manufacturer further disclaims any warranty of merchantability or fitness for a

particular purpose in connection with the customer’s purchase of units of any Product under this

agreement. The liability of the Manufacturer under this warranty is limited solely to replacing,

repairing, or issuing credit (at Manufacturer’s discretion) for any device which is returned by the

customer during the period provided for above, provided that (a) Manufacturer’s product is

returned properly packaged in the package made per specifications equal to or better than

Manufacturer’s original carton specifications, (b) Manufacturer is promptly notified in writing upon

discovery of such defects by customer, and customer obtains return authorization from

Manufacturer to ship the unit, (c) the defective unit is returned to Manufacturer, transportation

charges prepaid by customer, (d) warranty card, with date of receipt of product and signed by the

customer, is returned to the Manufacturer within 30 days of purchase, and (e) Manufacturer’s

examination of such unit shall disclose, to its good faith satisfaction, that such defects have not been

caused by misuse (including the filling and/or sealing of corrosive materials), neglect, improper

shipping or installation, repair, alteration, or accident. In no event shall Manufacturer be liable for

loss of profits, loss of use, or damages of any kind based upon a claim for breach of warranty.

All claims under this warranty will be made directly to Manufacturer. Faulty units are to be shipped

prepaid to the Manufacturer’s designated location. Manufacturer shall prepay transportation

charges when repaired units are returned and bill customer unless the units are found defective

under this warranty. Manufacturer shall pay return freight of units found defective under warranty.

Claims with the freight carrier for damages in shipment shall be made by the party of destination.

For your records, please record: Ampulmatic-10 Liquid Filler Serial No. _________________

Complete, Detach and Return Within 30 Days of Receipt

--------------------------------------------------------------------------------------------------------------------------------

User’s Name _________________________User’s Signature ____________________________

Title_______________________________Ship Date ________________________________

Company ___________________________ Receipt Date_______________________________

Address____________________________ Warranty Received at Bioscience_________________

____________________________ Have you set up your new Liquid Filler? ____________

Phone ____________ Fax _____________ Have you operated your Liquid Filler?_____________

Liquid Filler Serial No. _________________

Comments (Sales, Delivery, Manual, Instructions)

2-1

Model Description

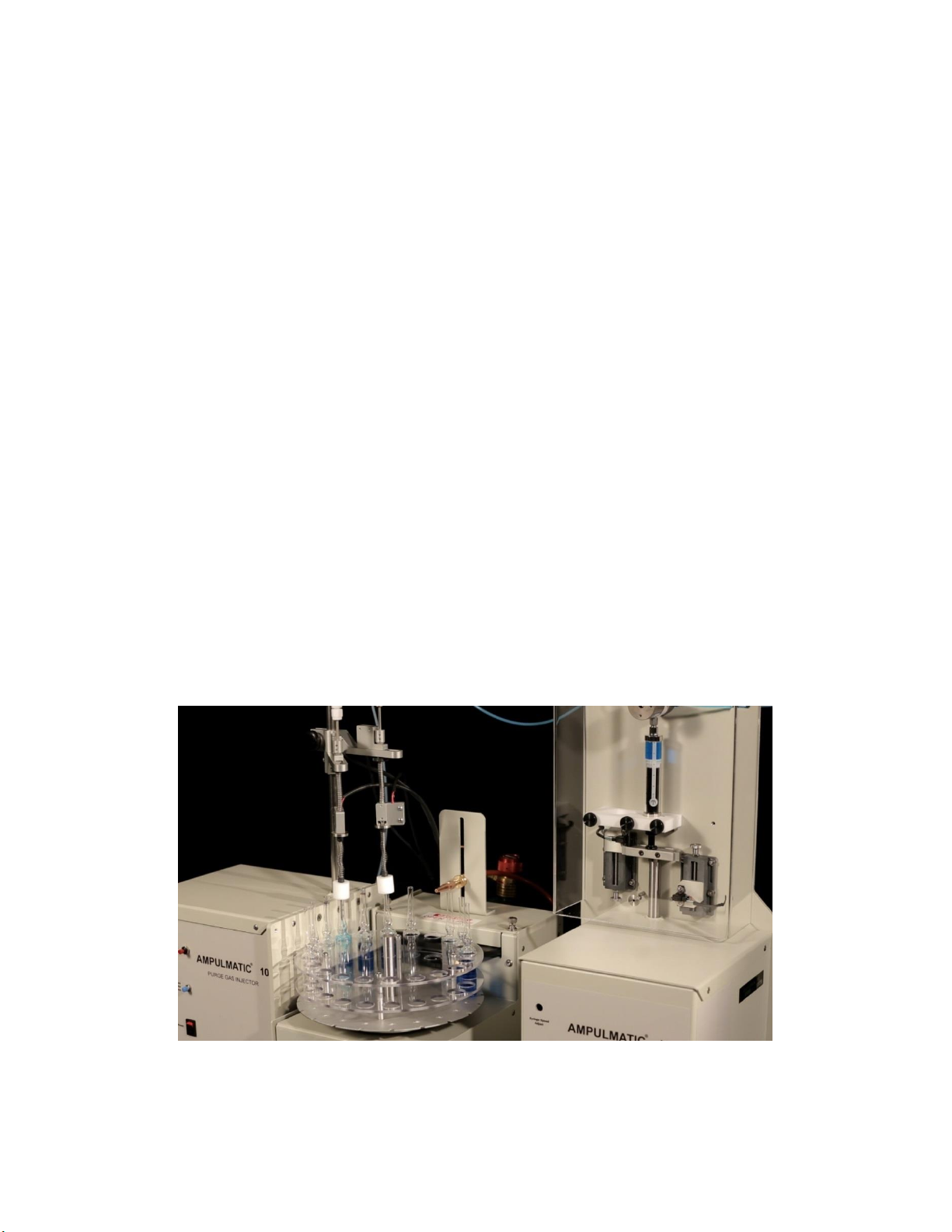

The Bioscience, Inc. Ampulmatic®-10 Liquid Filler accessory is designed to inject a precise

amount of liquid into an ampule in conjunction with the Purge Gas Injector accessory and the

Ampulmatic-10 base unit. The Purge Gas Injector accessory is used to move a plunger head into

each ampule prior to sealing, while the Liquid Filler accessory injects fluid through the plunger

head into each ampule. The Liquid Filler accessory is designed to inject volumes between <1ml

and 20ml into each ampule within the cycle time required to flame seal the ampule.

It was designed with a chemically-inert fluid path to accommodate the injection of a wide range

of chemicals. The Ampulmatic-10 ampule sealer and its accessories were designed to withstand

non-corrosive chemicals commonly found in lab environments. The cases are designed to protect

interior components from chemical leakage or spillage.

The Liquid Filler accessory can be easily added onto any Ampulmatic-10 base unit with the Purge

Gas Injector accessory.

3-1

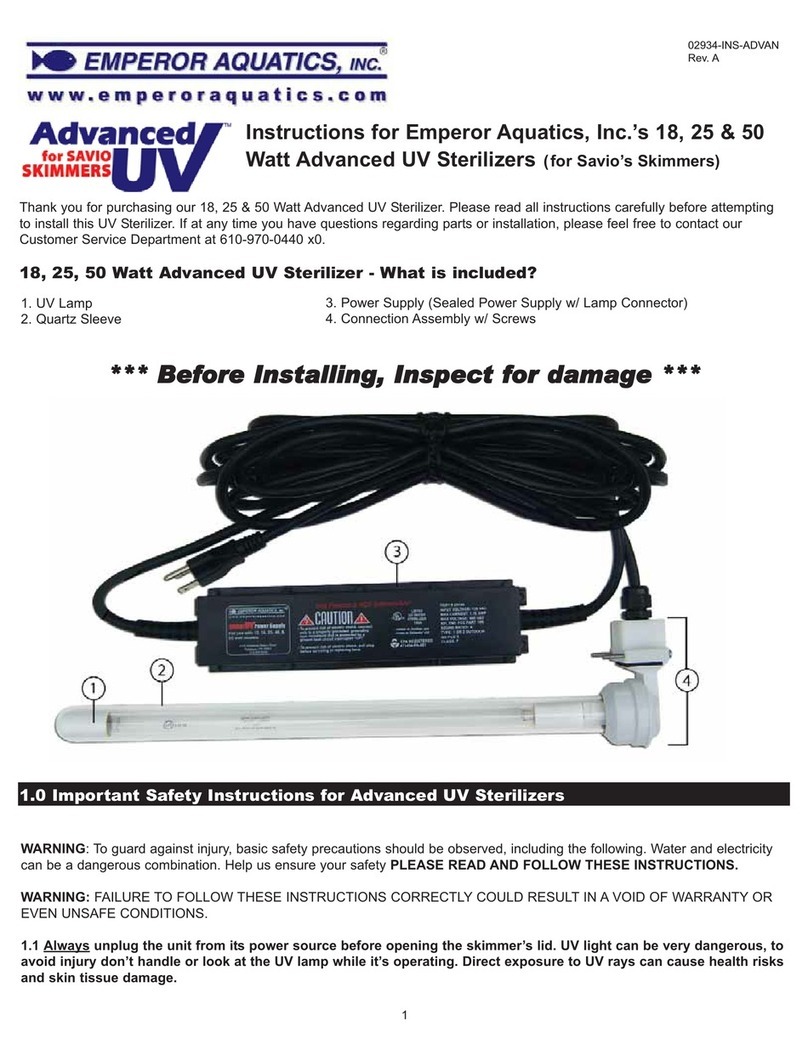

Ampulmatic-10

Ampule Sealer

Purge Gas Injector

Accessory

Liquid Filler

Accessory

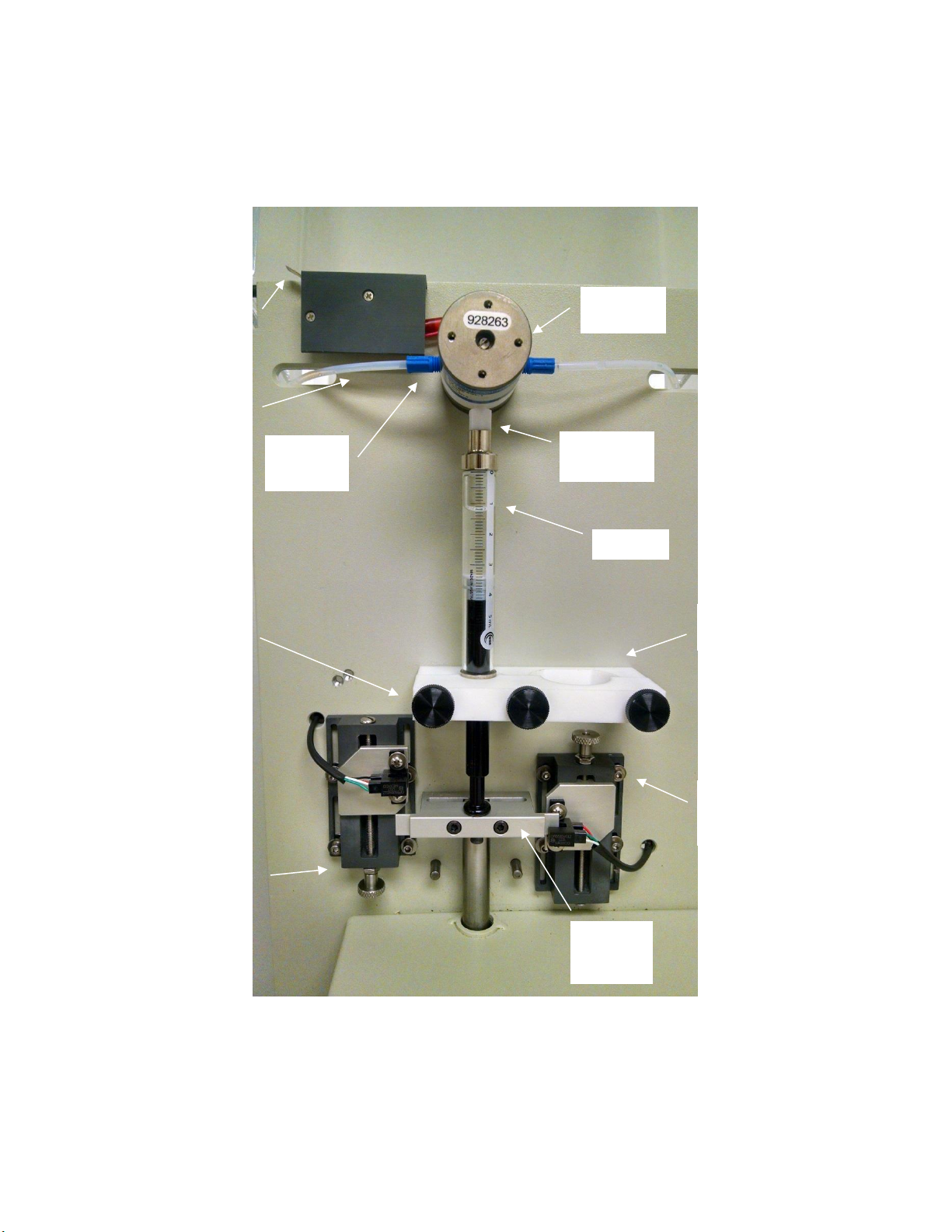

Ampulmatic-10 Liquid Filler Features

3-2

Syringe

Solenoid

Valve

Safety

Switch

Syringe

Clamps

Upper

Limit

Switch

Lower

Limit

Switch

Solenoid

Luer Lock

Black Knob

Fasteners

(3)

Switch

Trigger

Bracket

PTFE

Ferrules

PTFE

Tubing

Unit Specifications

Overall Dimensions

The overall dimensions of the Ampulmatic-10 Liquid Filler accessory are 8”W x 16”H x 8”D (20.3

cm W X 40.6 cm H X 20.3 cm D).

Shipping Weight

The shipping weight of the Ampulmatic-10 Liquid Filler accessory is approximately 27 lbs (12.25

kg).

Electrical Requirements

All electrical parts are UL listed/approved. The Ampulmatic-10 Liquid Filler operates internally

on 12 VDC. This voltage can be supplied by the power transformer furnished with your unit from

a power source of from 100 to 240 VAC (50-60 Hz).

Materials of Construction

Outside Body

Powder Coated Aluminum

Fluid Path

Borosilicate Glass, PTFE, 316ss

Note: Corrosive liquids must be tested in advance of filling and sealing for compatibility with the

materials of construction of the Ampulmatic-10 base unit and its accessories. Special materials

for corrosive resistant Ampulmatic-10 models are available by request.

CAUTION: Do not operate the Ampulmatic-10 ampule sealer with corrosive liquids

that are incompatible with the materials of construction of the unit.

Operating Conditions:

Acoustic Noise: <70db(A)

Atmospheric Pressure: 760-1080mBar

Storage Temperature: Between 5°C to 40°C

Operating Temperature: Between 5°C to 40°C

Altitude: Less than 2000m

Humidity Conditions: Between 30% to 90% (non-condensing)

Country of Origin

The Ampulmatic-10 Liquid Filler accessory is manufactured by Bioscience, Inc. in the USA.

4-1

Setup

Follow the instructions for setting up the Ampulmatic-10 base unit (Ampulmatic-10 Operation

and Maintenance Manual) and Purge Gas Injector accessory (Ampulmatic-10 Purge Gas

Accessory Operation and Maintenance Manual). The Purge Gas Injector accessory is required for

the use of the Liquid Filler accessory and must be completely set up before proceeding.

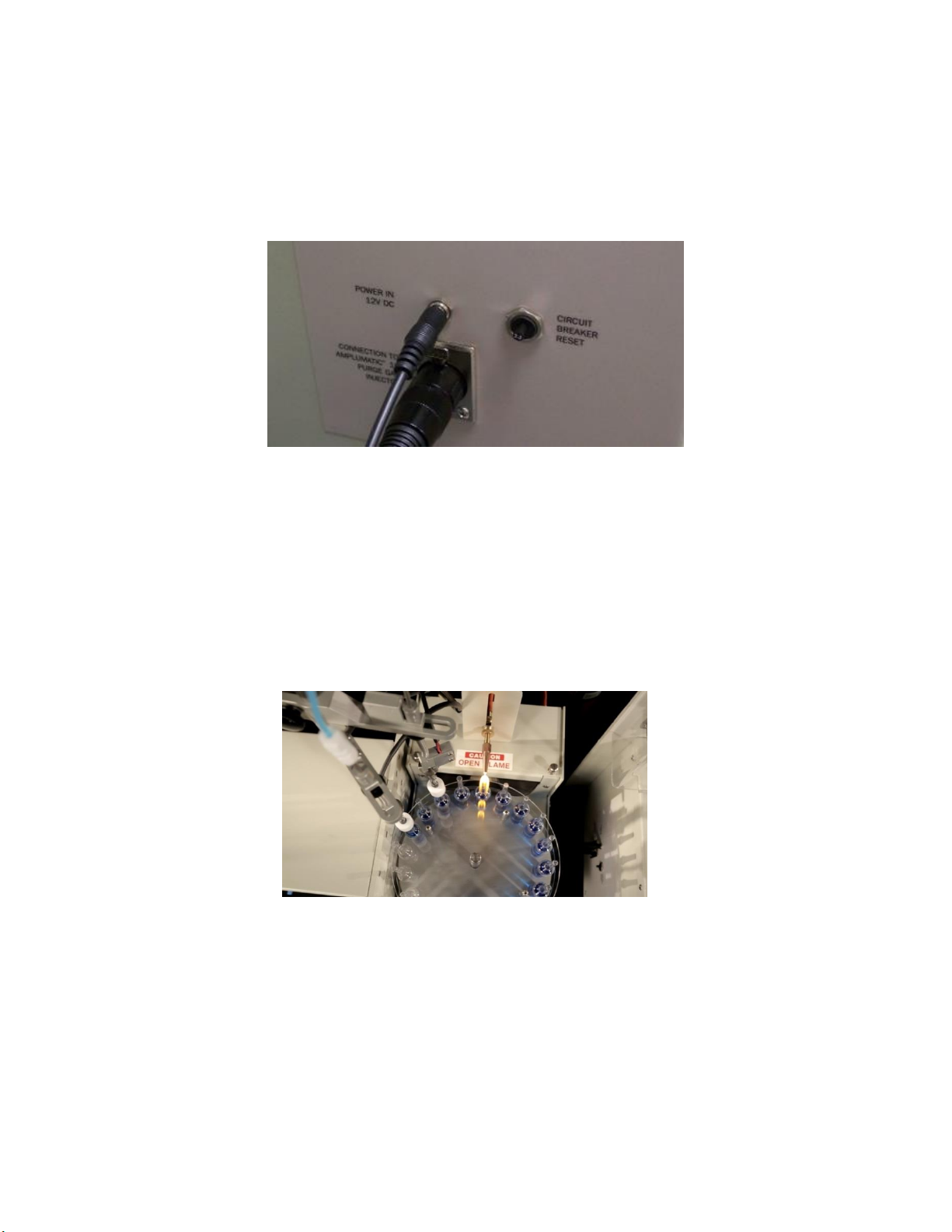

The Ampulmatic-10 ampule sealer and each accessory have separate power supplies. The switch

on the front of the Ampulmatic-10 module controls power to the turntable and ampule rotation.

This power switch does not control power to the purge gas injector accessory nor the liquid filler

accessory.

The switch on the front of the Liquid Filler accessory controls power to the Liquid Filler accessory

only. Do not turn this switch on until the Ampulmatic-10 base unit, Purge Gas Injector accessory,

and Liquid Filler accessory have been completely set up.

After the Ampulmatic-10 has been set up (gas supplies connected and the flame adjustments

made), and the Purge Gas Injector accessory has been completely set up, the Liquid Filler

accessory may be set up.

Reference the “Ampulmatic-10 Liquid Filler Features” located in Section 2-2 of this Manual

during the setup process.

CAUTION: Make sure the power cord is unplugged before opening the case for any

reason!

Note: Use appropriate Personal Protective Equipment (PPE) when operating the

Ampulmatic-10 System. Review the Safety Data Sheets of all chemicals being filling

and/or sealed with this equipment. Recommended PPE includes eye protection and

heat resistant gloves. See the Safety Accessory section of this manual for more

information.

Initial Setup

1. Place the Liquid Filler Injector Head onto the Purge Gas Injector Rod.

If using both a Liquid Filler Injector Head and a Purge Gas Injector Head, the Liquid Filler

Injector Head should be placed on the Rod first, under the Purge Gas Injector Head.

The Injector Heads will be fully aligned later in the setup process.

2. Verify that the Injector Head cables are hooked into the appropriately labeled ports on the

Purge Gas Injector accessory.

5-1

Installing the Liquid Filler Syringe

1. Choose an appropriate syringe size based on the liquid injection volume.

Syringe

Injection Volume

5 ml syringe (270 064)

<1 ml –4 ml

10 ml syringe (270 065)

2 ml –8 ml

25 ml syringe (270 066)

5 ml –20 ml

NOTE: 1ml and 2.5ml syringes may be special ordered for small volume injection.

Please contact Bioscience for more information.

CAUTION: Use syringes provided by Bioscience, Inc. only. Other syringes may not

be designed to fit in the unit.

2. Remove the front and rear white syringe clamps from the Liquid

Filler base plate by unscrewing the black knob fasteners.

3. Attach the syringe to the luer lock on the solenoid valve by twisting

the syringe clockwise onto the luer lock fitting. Do not over

tighten. Orient the syringe so that the flat edge of the metal end

of the syringe barrel is parallel to the base plate and the graduated

syringe readout can be read from the front. If the markings are not

oriented toward front, unscrew the syringe and rotate it counter-

clockwise ¾ turn and retighten.

4. Attach the front and rear syringe clamps to the base plate with the black knob fasteners.

The appropriate orientation of the syringe clamps will depend on whether you are using

the 5 ml, 10 ml, or 25 ml syringe (see next page). Tighten the black knob fasteners so that

the clamps grip the metal end of the syringe barrel. They should turn easily if properly

aligned. Do not force or threads may be damaged.

5-2

Syringe Clamp Positioning

5. Extend the syringe plunger so that it reaches the switch trigger bracket. Insert the provided

#6-32 screw through the bottom of the switch trigger bracket. Straight up and tighten

with an allen wrench to grip the plunger of the syringe.

5-3

5ml Syringe

10ml Syringe

20ml Syringe

Installing the Tubing

For smaller fill volumes, 1/8” outer diameter (OD) tubing is used for 5 and 10 mL syringes (shown

in the pictures below). This is preferred for more rapid startup (washing out previous solution or

solvent, elimination of air bubbles, and easier sealing of connections).

For larger fill volumes, ¼” OD tubing is used to ensure that filling can be done before the sealing

cycle is complete.

1. Attach PTFE tubing to the fitting on the right side of the solenoid valve using PTFE

ferrules. Route the tube through the right-hand slot on the base plate and place the free

end of the tube in the reservoir of fluid that is to be injected.

2. Attach PTFE tubing to the fitting on the left side of the solenoid valve using PTFE ferrules.

Route the tube through the left-hand slot on the base plate.

3. Attach the free end of the tube to the top of the

plunger tube, also using PTFE ferrules.

5-4

Calibrating the Filling Volume

Caution: Potential pinch hazard. Do not put fingers inside the safety shield during

operation.

1. Place an empty container under the Liquid Filler Injector Head to catch any fluid

dispensed during the setup and calibration process.

2. Connect the Liquid Filler accessory power supply. Turn on power to the Liquid Filler

accessory only.

Note: Unplug the connection between the Liquid Filler accessory and the

Purge Gas Injector accessory while calibrating the filling volume. The

solenoid will not engage if the cable is connected while the Purge Gas Injector

power is off. This is a safety feature.

3. Use the “Manually Pump Syringe” button on the Liquid Filler accessory to purge the fluid

path of air. Small air bubbles may remain in the syringe, but this will not affect the injected

volume. However, air bubbles entering the syringe with each stroke may indicate a leak

in the fluid path. If this occurs, consult the Troubleshooting Guide in this Manual.

NOTE: The safety shield must be in the down position for the Liquid Filler

accessory to operate. The unit must be manually restarted every time the

safety shield is raised and lowered. Turn the power switch off and on to

restart.

4. Use the upper and lower limit switch adjustment knobs to adjust the volume of fluid

injected. Note that the plunger in the syringe will not reach the very top of the syringe. Use

the middle of the range of the syringe to inject the amount desired.

For example, to inject 3ml of fluid, the

upper limit switch could be set so that

the plunger reaches a top of 1ml on the

syringe, and the lower limit switch

could be set so that the plunger

reaches a bottom of 4ml on the

syringe, giving a range of 3ml.

5. To check the lower and upper limits of

the syringe, push the “Manually Pump

Syringe” button on the side of the

Liquid Filler accessory. Hold the

button to read the upper limits. Use

the graduated syringe readout on the

front of the syringe to determine the

dispense volume.

6. Dispense fluid into a container to verify the amount dispensed before using in a production

environment. Note: One mL of water weighs one gram.

5-5

Final Setup

1. Connect the Liquid Filler accessory to the appropriate port on the Purge Gas Injector

accessory using the cable provided. The Purge Gas Injector accessory should also be

connected to the Ampulmatic-10 base unit.

2. If using both a Purge Gas Injector Head and a Liquid Filler Injector Head, verify that the

Liquid Filler Injector Head is placed on the Purge Gas Injector Rod first. Position the

Purge Gas Injector Head so that injection occurs at least 2 positions prior to flame sealing.

Position the Liquid Filler Injector Head 1 or 2 positions before the Purge Gas Injector

Head.

3. If using only the Liquid Filler Injector Head, position it so that injection occurs at least 2

positions prior to flame sealing.

NOTE: Refer to the Purge Gas Accessory Operation and Maintenance Manual for

adjustment of plunger heads.

4. Fill the carousel with empty ampules and check for correct operation. Visually inspect

ampules before use to discard any broken or distorted ampules. Defective ampules may

cause improper operation. This unit is designed to accept normal variance in glassware;

however, ampules should be of high quality and uniformity for best results.

5. The Liquid Filler accessory is now set up and ready to use. Turn power on to Ampulmatic-

10 base unit and Purge Gas Injector accessory. Liquid injection will occur automatically.

5-6

Adjusting the Syringe Speed

The “Syringe Speed Adjust” controls the speed of the syringe as it dispenses liquid. The syringe

must move fast enough to inject the liquid within the time it takes the Ampulmatic-10 base unit to

flame seal an ampule.

If necessary, a small flat-bladed screwdriver can be used to adjust the speed of the syringe by

inserting the screwdriver into the “Syringe Speed Adjust” hole and turning the potentiometer

clockwise to increase the speed or counterclockwise to reduce the speed.

Note: If the speed of the syringe is too fast, air bubbles may form when the syringe is pulled down.

In this case, turn the “Syringe Speed Adjust” counterclockwise to reduce the speed. The dwell

time on the base unit can be adjusted to slow the base unit down if necessary.

5-7

Ampule Glass and Size

The type of glass and size of ampules are important factors to consider in getting the best results

with your sealer. In general, the smaller the ampule and the weaker the glass, the more important

the positioning and adjustment of the filler heads. To get more consistent seals with volatile

substances carefully follow the directions in the main manual. Small ampules (< 2 ml) made of

soft glass (other than borosilicate) will require careful alignment of the accessory filler heads and

possible adjustment of the loading of the integrated filler head spring to avoid ampule breakage.

Soft glass is not recommended due to the rapid heating and cooling during flame sealing; seals

will tend to be brittle and crack easily especially when volatile substances are being sealed.

Standard carousels are designed for Wheaton gold band ampules or equivalent. Ampule samples

or specifications should be provided to Bioscience to confirm compatibility. Custom carousels are

available for non-standard ampule sizes.

6-1

Maintenance

The Ampulmatic-10 Liquid Filler accessory was designed to require a minimum amount of

maintenance. However, following the recommended maintenance procedures and intervals will

ensure that you obtain the highest level of reliability and fluid injection accuracy.

Daily (Before Use)

•Ensure liquid filler plunger head is positioned correctly above ampule for injection.

•Ensure fluid lines and syringe are free of air bubbles during injection.

•Calibrate and check injection volume.

Every 10,000 injection cycles or 25 hours of operation or 1 month, whichever

comes first

•Remove and inspect syringe

•Clean syringe and syringe plunger

•Check syringe and plunger for wear

Every 100,000 injection cycles or 250 hours of operation or 1 year, whichever

comes first

•Replace syringe and/or syringe plunger depending on wear

•Inspect safety shield switch

Every 1,000,000 injection cycles or 2,500 hours of operation or 10 years,

whichever comes first

•Replace relays on electronics board

•Inspect solenoid valve for wear

7-1

Troubleshooting Guide

NOTE: Due to interconnections between the Purge Gas Injector and Liquid Filler

accessories, make sure that the power to the Purge Gas Injector is on (or disconnect

the cable from the Liquid Filler to the Purge Gas Injector) when manually operating

the filler.

Ampulmatic-10 base unit does not advance after connecting Liquid Filler accessory.

OR

Ampulmatic-10 base unit advances, but plunger heads do not go down into ampules.

OR

Ampulmatic-10 base unit advances, plunger heads go down into ampules, but Liquid Filler

accessory does not pump syringe/inject liquid.

•Check to ensure cable is connected between Liquid Filler accessory and Purge Gas Injector

accessory.

•Check to make sure power is connected to Liquid Filler accessory and Liquid Filler

accessory is turned on.

•Check to make sure plunger head for liquid injection is connected to appropriate port on

Purge Gas Injector accessory.

•Check to make sure safety shield is down and safety switch is triggered on Liquid Filler

accessory.

•Check to make sure plunger for liquid injection is dropping down into ampule and that the

ampule detection switch is triggered.

•Ensure upper and lower limit switches are set far enough apart that both are not triggered

simultaneously.

•Adjust “Syringe Speed Adjust” clockwise to ensure that enough force is being applied to

move syringe.

Fluid line contains air bubbles.

•Check to make sure fluid input tube is tightly connected.

•Check to make sure fluid input connector is tightly connected to solenoid valve.

•Check to make sure luer lock is tightly connected to solenoid valve.

•Check to make sure syringe is tightly connected to the luer lock.

•Check to make sure fluid output tube is tightly connected.

•Check to make sure fluid output connector is tightly connected to solenoid valve.

•Check syringe integrity and replace syringe if necessary.

8-1

Inject several drops of water around each connection one at a time. If after several injection cycles

the bubbles disappear that would indicate a connection that is not airtight, the connection might

need to be resealed. If the connection is a threaded connection, try removing and replacing Teflon

tape on the threads.

Syringe clamps do not fit properly around syringe.

•Syringe clamps may need to be reoriented as they have different orientations based on

syringe size.

•Syringe needs to be turned so that flat part of metal barrel end is parallel to base plate.

Syringe pulls in air bubbles on downstroke.

•Adjust “Syringe Speed Adjust” counterclockwise to reduce syringe speed. See “Adjusting

Syringe Speed” in the “Setup” section of this manual.

•Check all fluid path connections for air leaks (see “Fluid line contains air bubbles”)

•Check syringe integrity and replace syringe if necessary.

Syringe does not inject full volume of fluid or travel fully between upper and lower limit

switches.

If syringe does not move quickly enough to complete injection within cycle time of Ampulmatic-

10 base unit, you can:

•Adjust dwell time on Ampulmatic-10 base unit to a longer period (turn the dwell dial

counterclockwise).

•Adjust “Syringe Speed Adjust” clockwise to move syringe faster.

Discoloration of metals and/or painted surfaces of the Liquid Filler.

Stop operation. Check compatibility of all filling solutions with the materials of construction of

the Liquid Filler before continuing. Contact Bioscience, Inc. for information on corrosion-

resistant replacement parts.

8-2

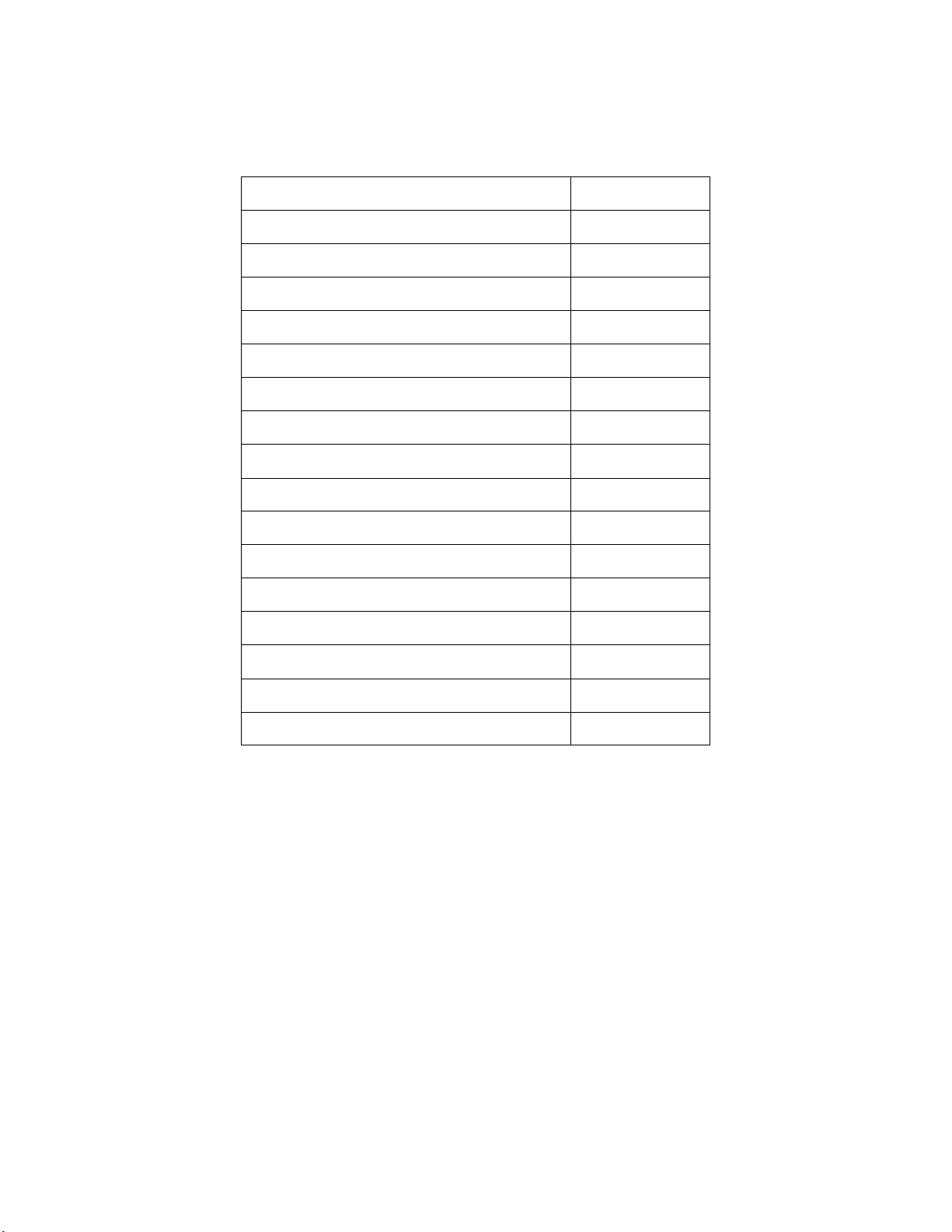

Spare Parts List

Part

PCN

Syringe, 5ml

270 064

Syringe, 10ml

270 065

Syringe, 25ml

270 066

Safety shield switch

270 073

Syringe clamp, rear

270 054

Syringe clamp, front

270 055

Syringe clamp screws

270 056

Solenoid Valve

270 067

Swagelok SS ¼-28 to ¼” OD fitting

270 080

Swagelok SS ¼” OD to 1/8” OD fitting

270 089

Swagelok ¼” OD Teflon ferrules

270 082

Swagelok 1/8” OD SS ferrules

270 081

¼-28 to syringe luer lock fitting, SS

270 077

¼-28 to 1/8” OD fitting

270 094

1/8” Teflon ferrules

270 095

Swagelok 1/8” coupling, SS

210 062

9-1

Other manuals for Ampulmatic-10 Purge Gas Injector

2

Table of contents

Other Bio-Science Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Izon

Izon AUTOMATIC FRACTION COLLECTOR V1 quick start guide

Scientific Industries

Scientific Industries MULTI VORTEX-GENIE SI-M236 operating instructions

Emperor Aquatics

Emperor Aquatics 02818 instructions

Varian

Varian 3900GC Assembly procedures

ABS

ABS ABT-FRP-04 owner's guide

Hanil

Hanil Ultra 5.0 operating manual