Bio-Science Ampulmatic-10 Purge Gas Injector User manual

ISO 9001:2015 Certified

Ampulmatic®-10 Laboratory Ampule Sealer

Operation and Maintenance Manual

Bioscience, Inc.

2201 Hangar Place, Suite 200

Allentown, PA 18109

Phone: (484) 245-5232 Fax: (484) 245-5236

bioscience@bioscienceinc.com

www.bioscienceinc.com

Original Version (in English)

Revised March 22, 2018

Contents

Section-Page

Title

1-1

Introduction

2-1

Model Description

2-2

Ampulmatic-10 Features –Front View

2-3

Ampulmatic-10 Features –Back View

3-1

Statement of Warranty

4-1

Unit Specifications

5-1

Where to Install Your Unit

6-1

Unpacking and Assembly

6-1

Setting Up Oxygen and Propane

6-1

Gas Pressures/Flow

6-2

Connecting to Compressed Gas Cylinders

6-3

Placing the Carousel on the Turntable

6-4

Placing the Torch Tip Assembly

6-4

Power Requirements

7-1

Operating Procedures

7-1

Lighting the Burner

7-1

Flame and Ampule Dwell Time Adjustment

7-2

Ampule Sealing Trouble Shooting

7-2

Turning off the Ampulmatic-10 Sealer

7-3

Sealing Volatile Substances

7-4

Sealing Corrosive Substances

7-4

Ampule Glass and Size

7-5

Sealing Thick Glass Ampules

7-5

Opening the Sealed Ampules

8-1

Maintenance

8-1

Preventative Maintenance Recommendations

8-1

Carousel Advance System

8-2

Ampule Spinning Drive Belt Replacement

8-2

Ampule Spinning Drive Belt Diagram

8-2

Carousel Advance Motor Speed Adjustment

9-1

Troubleshooting Guide

10-1

Replacement Parts List

11-1

Accessories List

11-1

Safety Accessories List

Introduction

Thank you for choosing the Ampulmatic®-10 Laboratory Ampule Sealer. Bioscience, Inc. has

striven to create the most reliable, easy-to-maintain and easy-to-use instrument available for

bench-scale filling and sealing of small batches of ampules. This equipment has been tested

extensively in our labs and in the field to ensure that the components and systems are reliable.

We have gone to extra lengths to ensure that should something become misaligned, require

adjustment or need to be replaced, it is easily accessed and addressed. Finally, the unit has been

designed with a good deal of flexibility to allow a sufficient range of sealing temperatures, dwell

times and motor speeds so that the Ampulmatic-10 ampule sealer can easily adapt to the sealing

demands of a variety of ampule types, sizes and sources worldwide. We have had extensive

experience dealing with the unique sealing problems of our customers over several decades and

are proud to be the leader in bench-scale ampule sealing. We will be happy to work with you to

furnish custom solutions to your specific filling and sealing problems at your request.

For maximum value and ease of startup, please proceed as follows:

1. Inspect the carton and the unit for shipping damage. Notify the carrier immediately if

damage is found.

2. Use the "Accessory Check List" attached to this manual when unpacking the unit to verify

that the complete unit has been received. Do not discard packing materials until everything

has been accounted for.

3. Read the “Where to Install Your Unit” section of the manual before deciding on an

appropriate location for the unit. You must consider the availability of power and other

equipment requirements as well as user convenience in operation.

4. Carefully follow directions in the "Unpacking and Assembly" section of the manual.

5. Insist that each operator be familiar with the "Operating Procedures" section of the manual.

6. Follow the recommended preventive maintenance measures found in the “Maintenance”

section of this manual for long equipment life. Avoid strong corrosives as they may damage

critical components of the system.

7. Keep this manual in a safe location for ready reference to the "Operating Procedures" and

"Maintenance" sections.

8. If you have any questions, please contact our Technical Service department at 484-245-

5232, 800-627-3069, or bioscience@bioscienceinc.com.

All Rights Reserved

The information contained in this manual is the exclusive property of Bioscience, Inc. and has been provided

solely to enable the users of the equipment described herein to operate and maintain such equipment. No

warranty for fitness for a particular purpose is provided. Any other use of this information, or the

reproduction or transmission of all or any portion of this manual, without prior written consent of Bioscience,

Inc. is expressly prohibited.

1-1

Model Description

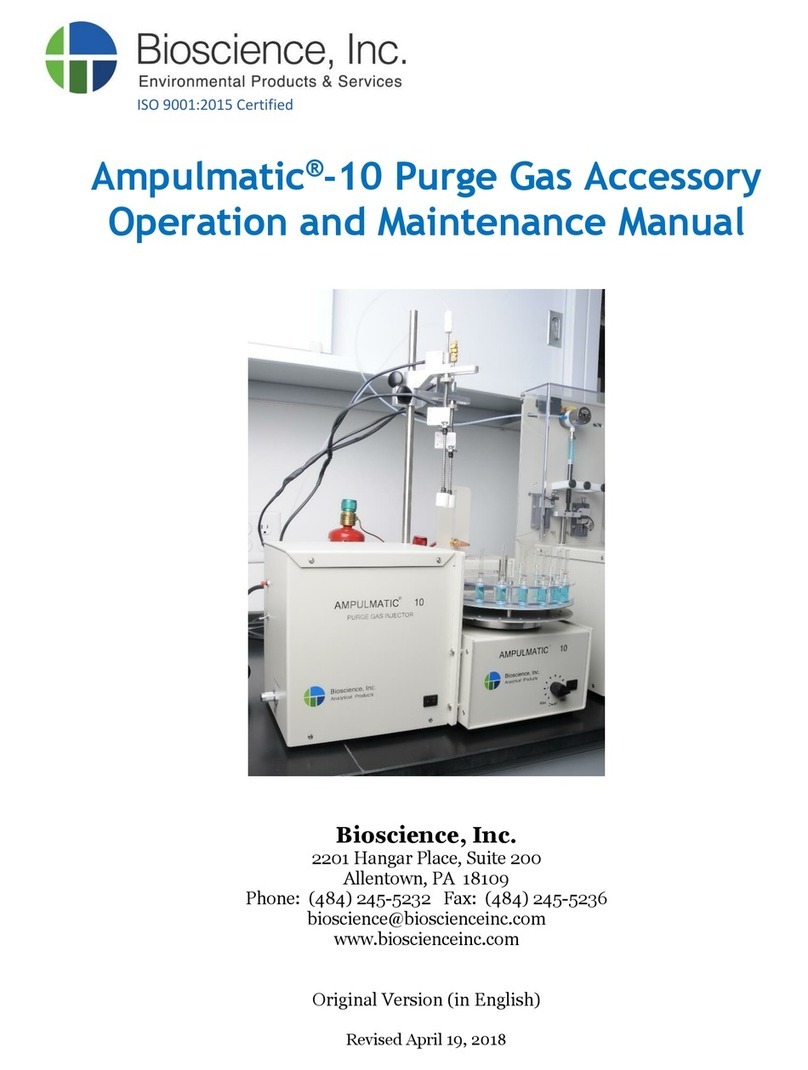

The Bioscience, Inc. Ampulmatic®-10 Ampule Sealer is an automated sealing device capable of

flame-sealing glass ampules in sizes ranging from 1 ml to 50 ml. It is designed to seal up to

approximately 900 ampules per hour in a laboratory setting. Each ampule in the carousel is

automatically indexed into position and a hemispherical seal is created as the ampule spins in front

of a propane and oxygen flame.

The design provides easy adjustments to ensure that an

excellent seal can be obtained under a variety of conditions.

Oxygen and fuel gas flow are metered by needle valves on the

rear of the unit to control flame size and temperature. The

dwell time of each ampule in front of the flame can be adjusted

by turning a knob on the front of the unit. The carousel

advance speed is also adjustable internally, if necessary. The

height of the sealing flame and distance from the ampule can

also be changed to accommodate different size ampules.

Note: While different sizes can be handled, ampules batch to batch must be consistent in height,

diameter, form, etc.

The Ampulmatic-10 Ampule Sealer was designed to withstand non-corrosive chemicals commonly

found in lab environments. The case is designed to protect interior components from chemical

leakage or spillage. The materials of construction include aluminum (case, carousel parts and

machined parts), stainless steel (machined parts and fasteners), brass (machined parts), copper

tubing and chemically-resistant polycarbonate (carousel). Corrosive liquids must be tested in

advance of filling and sealing for compatibility with the materials of construction of the

Ampulmatic-10 base unit and its accessories. Corrosion resistant replacement parts may be

available.

A variety of carousels are available to handle ampules of different sizes. They are designed to hold

up to 20 ampules (with the exception of the 50 ml carousel which

holds 10 ampules). As the carousel rotates, most users will add

filled ampules to the left side of the carousel and remove sealed

ampules from the right side of the carousel (after they have cooled

enough to handle or while wearing heat resistant gloves).

However, it is also possible to remove and replace entire carousels

for batch operations.

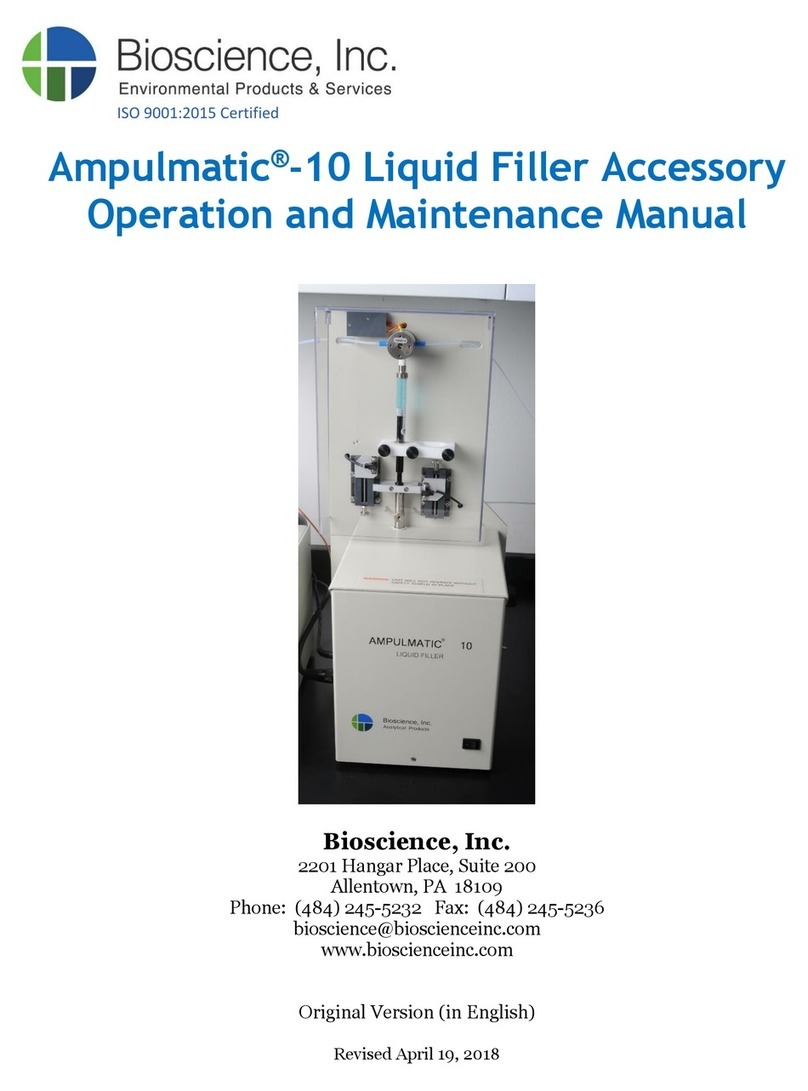

The Ampulmatic-10 sealer was also

designed to be expandable to

accommodate additional ampule filling

and inerting functionality. An add-on

port and mounting points are available

to allow plug-and-play devices, such as a

Purge Gas Injector and a Liquid Filler.

2-1

Ampumatic-10 Features –Front View

2-2

Power

Switch

Dwell Time

Adjustment

Turntable

Optical

Sensors

Ampule Spinning

Drive Belt

Carousel

Spindle

Torch Tip

Torch Tip

Bracket

Ampumatic-10 Features –Back View

2-3

Propane Tank

Valve Attachment

Torch

Height

Adjustment

Propane

Tank

Bracket

Oxygen

Inlet

Circuit

Breaker

Power

Inlet

Oxygen

Toggle

Valve

Oxygen

Needle

Valve

Propane

Needle

Valve

Statement of Warranty

The Ampulmatic®-10 bench-scale automatic ampule sealer and its accessories are warranted

against faulty workmanship or the use of defective materials for a period of 365 days from the date

of shipment. This warranty is the only warranty made by Bioscience, Inc. (Manufacturer) and is in

lieu of all other warranties, expressed or implied, except as to title and can be amended only by a

written instrument signed by the Manufacturer. The Manufacturer provides no warranty to the

Customer, either express or implied nor for title. Manufacturer further disclaims any warranty of

merchantability or fitness for a particular purpose in connection with the customer’s purchase of

units of any Product under this agreement. The liability of the Manufacturer under this warranty is

limited solely to replacing, repairing, or issuing credit (at Manufacturer’s discretion) for any device

which is returned by the customer during the period provided for above, provided that (a)

Manufacturer’s product is returned properly packaged in the package made per specifications equal

to or better than Manufacturer’s original carton specifications, (b) Manufacturer is promptly

notified in writing upon discovery of such defects by customer, and customer obtains return

authorization from Manufacturer to ship the unit, (c) the defective unit is returned to Manufacturer,

transportation charges prepaid by customer, (d) warranty card, with date of receipt of product and

signed by the customer, is returned to the Manufacturer within 30 days of purchase, and (e)

Manufacturer’s examination of such unit shall disclose, to its good faith satisfaction, that such

defects have not been caused by misuse (including the filling and/or sealing of corrosive materials),

neglect, improper shipping or installation, repair, alteration, or accident. In no event shall

Manufacturer be liable for loss of profits, loss of use, or damages of any kind based upon a claim for

breach of warranty.

All claims under this warranty will be made directly to Manufacturer. Faulty units are to be shipped

prepaid to the Manufacturer’s designated location. Manufacturer shall prepay transportation

charges when repaired units are returned and bill customer unless the units are found defective

under this warranty. Manufacturer shall pay return freight of units found defective under warranty.

Claims with the freight carrier for damages in shipment shall be made by the party of destination.

For your records, please record: Ampulmatic-10 Serial No. __________________________

Complete, Detach and Return Within 30 Days of Receipt

--------------------------------------------------------------------------------------------------------------------------------

User’s Name _________________________User’s Signature ____________________________

Title_______________________________Ship Date ________________________________

Company ___________________________ Receipt Date_______________________________

Address____________________________ Warranty Received at Bioscience_________________

____________________________ Have you set up your new Ampulmatic? ___________

Phone ____________ Fax _____________ Have you operated your Ampulmatic?_____________

Ampulmatic 10 Serial No. _______________ Carousel Rack Size__________________________

Comments (Sales, Delivery, Manual, Instructions)

3-1

Unit Specifications

Overall Dimensions

The overall dimensions of the Ampulmatic-10 Ampule Sealer are 8.5” W x 12” H x 17” D (21.6 cm W

x 30.5 cm H x 43.2 cm D).

Shipping Weight

The shipping weight of the Ampulmatic-10 Ampule Sealer base unit is approximately 21 lbs (9.53

kg).

Carousel Capacity

Carousel racks are available from Bioscience, Inc. in the following sizes and capacities. Refer to the

“Replacement Parts List” in this manual for part numbers. Custom carousels are also available by

request for other ampule sizes.

Ampule size

Number of

ampules

1 ml

20

2 ml

20

5 ml

20

10 ml

20

20 ml

20

50 ml

10

Electrical Requirements

All electrical parts are UL listed/approved. The Ampulmatic-10 base unit operates internally on 12

VDC. This voltage can be supplied by the power transformer furnished with your unit from a power

source of from 100 to 240 VAC (50-60 Hz). Power consumption of the base unit (not including add-

on modules) is less than 30 watts and the base unit has a resettable circuit breaker on the rear panel

which limits the internal current to 3 amps at 12 VDC.

Gas Requirements

The Ampulmatic-10 ampule sealer requires the blending of a propane, MAPP, or natural gas source

with oxygen in order to create a flame for sealing. See the “Unpacking and Assembly” section in this

manual for more information.

Operating Conditions:

Acoustic Noise: <70db(A)

Atmospheric Pressure: 760-1080mBar

Storage Temperature: Between 5°C to 40°C

Operating Temperature: Between 5°C to 40°C

Altitude: Less than 2000m

Humidity Conditions: Between 30% to 90% (non-condensing)

Country of Origin

The Ampulmatic-10 ampule sealer is manufactured by Bioscience, Inc. in the USA.

4-1

Materials of Construction

Outside Body

Powder Coated Aluminum

Carousel

Chemical-Resistant Polycarbonate and Anodized Aluminum

Burner Tip

Copper

Gas Tubing and Fittings

Copper, Brass, 316ss

Note: Corrosive liquids must be tested in advance of filling and sealing for compatibility with the

materials of construction of the Ampulmatic-10 base unit and its accessories. Special materials for

corrosion resistant Ampulmatic-10 models may be available for specific applications by request.

CAUTION: Do not operate the Ampulmatic-10 ampule sealer with corrosive liquids

that are incompatible with the materials of construction of the unit.

Durability

The Ampulmatic-10 Ampule Sealer is designed for light to medium duty applications in a

laboratory. Consult your Bioscience Technical Representative for recommendations should heavy

duty, large scale sealing be desired.

4-2

Where to Install Your Unit

The Ampulmatic-10 ampule sealer should be installed on a level and stable bench or table with easy

access to required electrical and gas supplies. It must be placed in an area with good ventilation due

to its use of flammable gases and the production of by-products from combustion. It is

recommended that the unit be placed in or directly in front of a fume hood. Due to the presence of

an open flame, the area around the Ampulmatic-10 sealer should be free of combustible materials.

Crimping or excessive bending of the gas tubing leading into the Ampulmatic-10 sealer may create

gas leaks or limit gas flow. Use the appropriate length of tubing for your installation. Use a power

source easily accessible to the unit to avoid stretching the power cord.

5-1

Unpacking and Assembly

The Ampulmatic-10 Sealer carton contains the Ampulmatic-10 base unit, the torch tip assembly,

and a stainless steel rod (carousel spindle), along with a spare parts pack and certain tools and any

purchased carousels. Please use the “Accessory Check List” in this manual when unpacking to verify

that the complete unit has been received.

1. Setting up Oxygen and Propane

The Ampulmatic-10 ampule sealer requires the blending of a propane, MAPP, or natural gas

source with oxygen in order to create a flame for sealing. These gases are generally available

and are plumbed into the instrument with 1/8” (0.32 cm) outside diameter (OD) copper or

plastic tubing. A regulator valve is provided for use with a conventional commercially

available tank as a source for propane or MAPP gas. However, other fuel gas sources, such

as larger tanks or plumbed natural gas, can also be used with suitable adapters. The oxygen

is plumbed into the instrument through the Swagelok®fitting accessible at the rear of the

instrument.

You will need a cylinder of commercial grade oxygen with a 2-stage regulator, a standard 14

ounce disposable bottle (3 inch [7.62 cm] diameter) of propane of the type available from

hardware or sporting goods stores and a convenient length of 1/8” (0.32 cm) OD tubing to

run from the oxygen tank to the Ampulmatic-10 unit. Small oxygen tanks are not

recommended. Connect the 1/8” OD tubing to your oxygen regulator and momentarily pass

oxygen through the tube to remove any dust particles. Connect the other end of this tube to

the oxygen bulkhead connector (a 1/8” Swagelok®compression fitting). Check to see that

the propane regulator valve is turned off, and then connect the propane bottle to the propane

regulator and install the bottle in the bracket on the rear of the unit. Check for gas leaks

with soap solution.

2. Gas Pressures/Flow

A pressure of 10-20 pounds per square inch (psi) for oxygen (and propane if using larger

bottles and regulator) is recommended. This allows for the best adjustment of the needle

valves for flow control.

Typical propane usage is 0.1-0.15 liters per minute (lpm) and typical oxygen usage is 0.6-

0.8 lpm. However, measured gas flow for different sized ampules is variable. Both propane

and oxygen flow should be increased as the ampule size increases. Torch tip position

adjustments (distance from the ampule during sealing) will also affect gas flow

requirements. Slight adjustment may also be required depending on the ampule contents

(e.g. solvents and whether solvents are chilled before sealing).

In the Purge Gas Injector accessory, purge gas flow will also depend on ampule size, liquid

volume and dwell time. At least 10 ampule headspace volumes are recommended in the

normal ~5 seconds of purging. Thus, for a 10mL actual volume (not nominal volume), purge

gas flow should be 10mL*10 volumes/5 seconds*60 seconds/min = 1,200 mL/min = 1.2

lpm.

Note: a 1mL nominal ampule contains ~2.5 mL total volume before sealing.

6-1

3. Connecting to Compressed Gas Cylinders

The gas inlets to the Ampulmatic-10 base unit are 1/8” compression fittings. To connect to

larger cylinders you will need to purchase a regulator and adapter for 1/8” OD tubing.

McMaster-Carr is a vendor that supplies a wide range of equipment and components and will

typically carry everything you need to get started. Bioscience doesn’t endorse a particular

vendor and you may be able to find equivalent or better equipment or components at a lower

cost. McMaster-Carr part numbers have been provided for reference only.

NOTE: If metric parts are required, contact Bioscience, Inc. for guidance.

Regulators

Single stage regulators, though less expensive, will show significant pressure changes as the

supply pressure decreases (as the tank empties). For best results, a two stage regulator is

recommended. The example regulators referenced below have “outlet” configurations such

as 9/16”-18 Right Hand (RH) or Left Hand (LH). To adapt the regulator to 1/8” OD tubing you

will need an adapter with ¼” NPT threads on one end and a 1/8” OD compression fitting on

the other. Note that the regulators for each gas type are different. Part specifications can be

found below.

Propane

The valve supplied with the Ampulmatic-10 ampule sealer screws onto small propane tanks

(generally 14-16 oz.). These are available from vendors ranging from home improvement

stores, camping suppliers, and general merchandisers such as Walmart, Sears, or K-mart.

The inlet to the Ampulmatic-10 base unit is a 1/8” compression fitting. To connect to larger

cylinders you will need to purchase a regulator and adapter for 1/8” OD tubing.

Large Propane Cylinder Connection Parts:

•Single-Stage Gas Regulator (McMaster-Carr #7897A66) or Two-Stage Gas Regulator

(McMaster-Carr #7897A18).

•Straight Adapter (McMaster-Carr #5272K291).

•Copper tubing (McMaster-Carr #5174K1) or Nylon tubing (McMaster-Carr

#8359K11).

Oxygen

The inlet to the Ampulmatic-10 base unit is a 1/8” compression fitting. To connect to larger

cylinders you will need to purchase a regulator, adapter, and 1/8” OD tubing. Use only large

oxygen cylinders for oxygen supply. Small oxygen cylinders are not recommended.

Large Oxygen Cylinder Connection Parts:

•Single-Stage Gas Regulator (McMaster-Carr #7897A61) or Two-Stage Gas Regulator

(McMaster-Carr #7897A3).

•Straight Adapter (McMaster-Carr #5272K291).

•Copper tubing (McMaster-Carr #5174K1) or Nylon tubing (McMaster-Carr

#8359K11).

6-2

Gas Regulator Specifications

Gas

Type

CGA

#

Connection

Type

For

Tank

Threads

Stage

Operating

Pressure

(psi)

Tank

Content

(psi)

McMaster-

Carr Item

#

Propane

510

Male

Standard

Duty

Female

Single

0-50

0-400

7897A66

Two

7897A18

Oxygen

540

Female

Standard

Duty

Male

Single

0-145

0-4,000

7897A61

Two

0-125

7897A3

Straight Adapter Specifications

Tubing

Type

OD

Wall

ID

Max psi

Bend

Radius

McMaster-

Carr Item

#

Copper Tubing

⅛”

0.03”

0.065”

3,000 @

100°F

-

5174K1

High Strength

Clear Nylon Tubing

⅛”

0.014”

0.096”

430 @ 75°F

1 ¼”

8359K11

4. Placing the Carousel on the Turntable

Place the carousel on the Ampulmatic-10 turntable by sliding the notched bottom of the

carousel across the carousel turntable so that the center hole aligns with the hole in the

turntable. Insert the carousel spindle through the hole in the carousel and push it down

through the carousel guide holes into the turntable, making certain that it is down as far as

it will go. The drive belt and drive wheels will fit between the top plates of the carousel. Be

careful not to dislodge the ampule spin belt while placing the carousel. If the

belt is dislodged, see the “Maintenance”section of this manual to restore the belt to

operating position. Correct placement of the spindle will leave about 1 inch (2.54 cm) of the

spindle showing above the top plate of the carousel. Plug in the power supply and turn on

the unit to advance the carousel into position. The carousel should then advance to the next

position automatically. The amount of time in front of the torch tip is controlled by the

“dwell” knob on the front. Turn the knob toward Minimum to decrease the dwell time and

toward Maximum to increase the dwell time.

CAUTION: Do not operate the Ampulmatic-10 ampule sealer without the

carousel and carousel spindle in place. Exposed belt drive may present a pinch

hazard when carousel is not in place.

6-3

Adapter Type

For Tube

OD

Pipe

Size

Pressure Rating

McMaster-

Carr Item #

For Tube

Wall

Thick.

Max. psi

@ 72°F

Tube-to-Male

Threaded Pipe

⅛”

¼”

0.035”

2,900

5272K291

5. Placing the Torch Tip Assembly

Loosely attach the torch tip assembly to the top of the unit with the two screws provided.

Both washers should be on top of the torch tip assembly plate. Attach the rubber tubing

from the torch tip to the hose barb fitting on the rear of the Ampulmatic-10. Next, place an

ampule into the carousel one or two positions before the torch tip (carousel rotates

clockwise). Turn on the unit and allow the ampule to index in front of the torch tip. Turn off

the power and adjust the height of the torch tip to about 3/16” (5 mm) below the top of the

ampule to be sealed.

Torch Tip Height

To adjust torch tip height, loosen the torch tip height adjust knurled nut, move the torch tip

to the desired height and re-tighten the nut.

Torch Tip Horizontal Position

If necessary, the horizontal alignment of the torch tip can be adjusted by loosening the two

screws holding the torch tip bracket to the top of the case. Reposition the bracket and torch

tip slightly and retighten the screws.

Torch Tip Distance from Ampule

To adjust the distance of the torch tip to the ampule, adjust the two knurled nuts located in

front and behind the torch bracket. We recommend 1/8” (3 mm) distance from the torch

tip to the ampule.

6. Power Requirements

The Ampulmatic-10 ampule sealer is supplied with a 3-prong grounded plug power cord

(US and selected countries) and an external transformer for your safety. If a power cord is

not supplied, a locally obtained power cord with IEC 320 connector should be used. The

required power source is 100 to 240 VAC (50-60 Hz). The base unit is designed to draw less

than 30 watts of power. Add-on modules such as the Purge Gas Injector and Liquid Filler

accessories will have a separate power source.

6-4

OPERATING PROCEDURES

Note: Use appropriate Personal Protective Equipment (PPE) when operating the

Ampulmatic-10 System. Review the Safety Data Sheets of all chemicals being filling

and/or sealed with this equipment. Recommended PPE includes eye protection and

heat resistant gloves. See the Safety Accessory section of this manual for more

information.

1. Lighting the Burner

Each Ampulmatic-10 ampule sealer is tested by Bioscience, Inc. before leaving the factory.

Factory gas flow settings should allow the flame to be ignited and (when oxygen is turned

on) an ampule to be sealed with minimal adjustment of gas flows. If multiple sizes of

ampules are to be sealed, however, adjustment may be necessary for each ampule size.

CAUTION: Do not light the burner until after the carousel is installed on the

turntable. Always turn the burner off before removing the carousel or use

flame resistant gloves while removing the carousel spindle to avoid burns.

1. Install carousel on turntable.

2. Verify that the toggle valve on the rear panel marked “oxygen on/off” is off (lever should

be parallel to back of case).

3. Open the oxygen tank valve and adjust the oxygen delivery pressure at the regulator to

about 20 psi.

4. Open the propane regulator valve at the bottle fully.

5. Ignite the flame, then adjust for a 2-1/2” (6.35 cm) flame, if necessary.

6. Turn on the oxygen flow by pulling the toggle switch slowly to a position perpendicular

to the case.

7. Place several ampules in the carousel and turn on the Ampumatic-1o power (switch on

front of unit). An ampule will advance to the position in front of the flame and seal

before advancing. Make small adjustments to the flame temperature or dwell time until

the seal is perfect.

If the ampule is not completely sealed, slowly increase the oxygen to the flame with the

oxygen adjust valve (counterclockwise) until the flame is intense blue and oxidizing with no

white or yellow area.

If the ampule has a bubble on top or the seal blows out, reduce oxygen flow (clockwise

rotation of the oxygen adjust valve).

The dwell time (the time the ampule is in front of the flame) can also be adjusted by rotating

the knob next to the power switch (counterclockwise increases dwell time). An increase in

dwell time can be used to correct an incomplete ampule seal and a decrease in dwell time

can reduce bubble formation or blow-out.

Once adjusted these settings can be maintained by following the turn-off procedure below.

The Ampulmatic-10 ampule sealer will then require little or no readjustment when restarted

for the same size ampules.

7-1

2. Flame and Ampule Dwell Time Adjustment

The Ampulmatic-10 ampule sealer was designed to provide flexibility in sealing ampules

ranging from <1 mL capacity to 50 mL capacity and made of various types of glass. As

shipped from the factory, the Ampulmatic-10 sealer is set to a relatively short dwell time in

order to seal more vials in a given time.

It is possible to shorten the dwell time by using a hotter flame (substituting MAPP gas for

propane will allow higher flame temperature). However, remember that as the dwell time

is reduced, small inconsistencies in ampules to be sealed (imperfect glass of the ampule, a

drop of liquid on the ampule neck, small dimensional variation, etc.) may lead to an

imperfect seal. Dwell time is adjustable from approximately 2 seconds to 14 seconds. As

ampule size increases, the amount of heat necessary to seal the ampule will increase.

Increased heat can be accomplished by increasing flame size (increase fuel and oxygen),

increasing temperature (increase oxygen) and/or increasing dwell time.

Once a good sealing flame is achieved for a particular ampule size, it may be most convenient

to adjust dwell time to accommodate another ampule size. Use the following table to

troubleshoot common sealing problems.

Ampule Sealing Trouble Shooting

Symptom

Possible Causes

Solutions

Seal is brittle, glass cracks

Flame is too hot

Reduce oxygen and increase dwell

time

Bubble forms on top of ampule

Flame too hot

Ampule dwell time too long

Reduce oxygen

Reduce ampule dwell time

Ampules not completely sealed

Flame too cold

Ampule dwell time too short

Increase oxygen

Increase ampule dwell time

Uneven seal

Turning belt dirty, ampule slipping

Wipe belt with alcohol

Pinhole through seal

Burner hitting too high on ampule

Flame too cold

Ampule dwell time too short

Lower burner height

Slightly increase oxygen

Increase ampule dwell time

Discoloration of the components

Corrosive liquids

Stop operation and consult with

Bioscience, Inc.

Ampules Breaking

If using accessories, misalignment

of purge or fill head.

Adjust purge or fill head position.

3. Turning Off the Ampulmatic-10 Sealer

1. Make sure no ampules are in front of flame.

2. Turn off the Ampumatic-1o base unit power (switch on front of unit).

3. Turn off the oxygen toggle valve on the rear panel marked “oxygen on/off” (lever

should be parallel to back of case).

CAUTION: Always turn the oxygen toggle valve to the “Off” position before

turning off the propane. The flame will change from blue to orange.

7-2

4. After the oxygen has been turned off, turn the propane off at the bottle with the propane

regulator valve. The flame will disappear in a few seconds, as quickly as the fuel in the

line has burned off.

CAUTION: The burner, spindle, and ampules may be hot. Protect skin from

heat damage before handling.

It is not necessary to remove the carousel but if so desired, wear heat-proof gloves or wait

until the spindle is thoroughly cooled, remove the spindle from the carousel, then carefully

remove the carousel. Keep the carousel parallel to the turntable to avoid dislodging the belt.

4. Sealing Volatile Substances

Many Ampulmatic-10 ampule sealer users seal ampules containing a variety of flammable

liquid solvents for gas chromatography standards and other applications. For the safe

handling of such flammable liquids use the following guidelines:

a. Flammable solvents may be chilled by immersion in cold baths of various types

prior to flame sealing (see table below).

b. The polycarbonate plates, used for the carousel of the Ampulmatic-10 sealer,should

not be immersed in a dry ice cold bath to avoid crazing and cracking of the

polycarbonate plastic. Ampules should be chilled separately, then inserted into the

carousel.

c. A shorter dwell time can be used to minimize the time required to advance and seal

the ampules, thus minimizing warm-up of the solvent.

d. An inert gas such as nitrogen or argon can be injected above the liquid (using the

optional Purge Gas Injector accessory) to prevent mixing of solvent vapor and

oxygen.

e. All procedure development should be done with the smallest volatile liquid volumes

possible and a safety shield should be used to protect users from possible explosion.

f. Ampules should be inspected prior to use to remove ampules with cracks or other

flaws that might cause breakage and spilling of the contents.

g. Make sure the Ampulmatic-10 sealer is set-up and adjusted correctly to handle the

ampule size being used. Make all adjustments with ampules containing non-

flammable solvent (e.g., water) to minimize warm-up of the solvent during

adjustment.

h. Clean solvent spills up as soon as they occur to avoid damage to the Ampulmatic-10

components.

7-3

Bath Components

Concentration of *

Temperature (°C)

Ice/water/NaCl*

Excess

-10 to -15

Ice/water/CaCl2*

Excess

-29

Dry ice*/ethanol or isopropanol

Excess

-72 to -78

Dry ice*/ethylene glycol

Excess

-15

5. Sealing Corrosive Substances ( e.g. acids)

Sealing corrosive materials poses special challenges for the Ampulmatic-10 ampule sealer.

For concentrated and volatile corrosives, additional steps may need to be taken to ensure a

consistent, reliable sealing operation. Corrosion resistant parts may be available by request.

Contact your Bioscience Technical Representative for more information.

6. Ampule Glass and Size

The type of glass and size of ampules are important factors to consider in getting the best

results with your sealer. Soft glass is not recommended due to the rapid heating and cooling

during flame sealing; seals will tend to be brittle and crack easily especially when volatile

substances are being sealed.

Standard carousels are designed for Wheaton gold band ampules or equivalent. The

Ampulmatic-10 Ampule Sealing System can be adapted to seal a variety of ampule designs

and sizes. However, non-standard sizes or designs should be submitted to Bioscience to

confirm suitability prior to purchase. Custom carousels may be available for non-standard

ampule sizes.

Ampulmatic®-10 Recommended Ampule Specifications

Wheaton Brand Ampule Specifications

Size

Diameter

(mm)

Height

(mm)

1ml

10.5

67

2ml

12

75

5ml

16.5

84

10ml

19

107

20ml

22.5

130

50ml

26

150

7-4

Ampulmatic Carousel Specifications

Rack

Size

Min Outside

Diameter

Max Outside

Diameter

Min Height

Max Height

In

cm

In

cm

In

cm

In

cm

1ml

0.356

0.89

0.418

1.05

2.63

6.68

4.75

12.06

2ml

0.418

1.06

0.480

1.22

2.94

7.47

5.00

12.70

5ml

0.621

1.57

0.683

1.73

2.75

6.98

5.00

12.70

10ml

0.715

1.81

0.777

1.97

3.25

8.26

5.50

13.97

20ml

0.840

2.13

0.902

2.29

3.25

8.26

5.50

13.97

50ml

1.121

2.84

1.183

3.00

3.25

8.26

7.25

18.42

Custom carousels may be available for other ampule sizes.

Please contact your Bioscience, Inc. representative for more information.

7. Sealing Thick Glass Ampules

A Dual Flame module is available for sealing thicker glass ampules. Contact your Bioscience

Technical Representative for more information.

8. Opening the Sealed Ampules

Sealed ampules are best opened by sliding an ampule breaker over the top of the ampule to

the color break or scored line and then breaking with a bending motion. A piece of flexible

or semi-flexible plastic tubing can be placed over the neck of the ampule if no ampule

breaker is available. Gloves are recommended to protect hands from broken glass and/or

possible contact with contents of the ampule.

7-5

Maintenance

Make no attempt to service or repair the Ampulmatic-10 ampule sealer while still under warranty

before consulting with Bioscience, Inc. After the warranty period, such consultation is still advised,

especially when the repair may be technically sophisticated or difficult. No equipment, however,

should be returned to the manufacturer without prior approval. Obtain a Return Authorization

(RA) Number from Bioscience, Inc. before returning the equipment. Mark the RA number on the

shipping label.

1. Preventive Maintenance Recommendations

The following preventive maintenance measures will help to ensure that the Ampulmatic-

10 Ampule Sealer continues to function properly and that there are no unintended

interruptions in service from the unit.

Note: Turn the power switch “off” and unplug the unit from its power source.

Disconnect all gas connections before attempting to clean any spills or to

perform maintenance, repairs or service.

•General cleaning of the outside cabinet is recommended after use. Use a mild

detergent and moist towel to wipe the outside surface of the Ampulmatic-10 base unit

and the carousel rack clean. Organic solvents other than alcohol are not

recommended, especially for the carousel polycarbonate plates.

•Regular cleaning of the Ampulmatic-10 belt is required to ensure proper rotation of

the ampule while in the sealing position. Use alcohol on a paper towel or cloth to clean

the belt, by gently pressing it against the belt while it is spinning.

•The ampule spinning drive belt should be replaced every 12 months or 1,000,000

ampules. The Ampulmatic-10 ampule sealer will seal about 100,000 ampules per

month if used continuously, 40 hours per week.

•Occasional checks for gas tubing leaks are recommended to ensure safe operating

conditions.

•Immediately clean all spills of solvents and corrosives. Neutralization of acids with

5% sodium bicarbonate and bases with 5% acetic acid are recommended.

•Any broken glass should be carefully removed with vacuum cleaner.

2. Carousel Advance System

The current design of the Ampulmatic-10 Ampule Sealer uses optical switches to position

the carousel. There are no mechanical parts to adjust or replace in the carousel advance

system.

8-1

Other manuals for Ampulmatic-10 Purge Gas Injector

2

Table of contents

Other Bio-Science Laboratory Equipment manuals