IKA

®

-WERKE

1

Table of Contents

1 For your safety..................................................................................................4

1.1 General dangers .............................................................................................4

1.2 Definition.........................................................................................................4

1.3 Use as directed...............................................................................................4

1.4 Protective measures .......................................................................................5

1.4.1 Safety obligations on the part of the operator..........................................5

1.4.2 Specific safety information and symbols used.........................................6

1.4.3 General safety information ......................................................................7

1.4.4 Basic safety information during normal operation....................................8

1.4.5 Basic safety measures for maintenance and repairs...............................9

1.4.6 Working on electrical equipment ...........................................................11

1.4.7 Working on the barrier system...............................................................12

1.4.8 Observing environmental protection guidelines .....................................13

1.5 Remaining dangers.......................................................................................13

2 Description......................................................................................................14

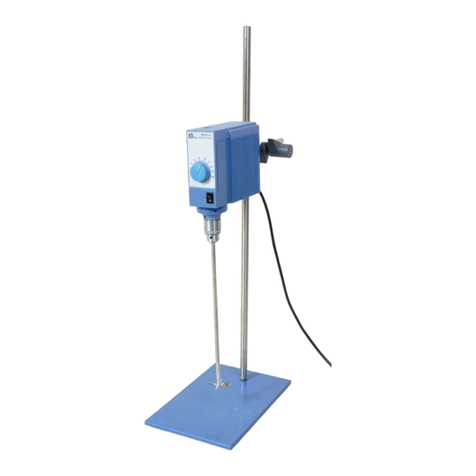

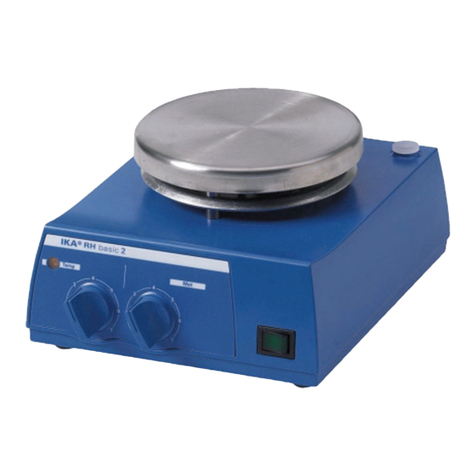

2.1 Construction of the ULTRA-TURRAX

.........................................................15

2.1.1 Sealing cartridge....................................................................................15

2.1.2 Mixing tools............................................................................................15

2.1.3 Drive ......................................................................................................15

2.1.4 Frame ....................................................................................................15

3 Specification sheet.........................................................................................16

3.1 Dimensions and weight:................................................................................18

4 Installation ......................................................................................................19

4.1 Securing the machine ...................................................................................19

4.2 Connecting product lines ..............................................................................19

4.3 Power supply ................................................................................................23

5 Operating mechanisms on the machine ......................................................24

6 Placing the ULTRA-TURRAX

in operation..................................................24

6.1 Connecting the machine ...............................................................................24

6.2 Short test ......................................................................................................24