EIJKELKAMP 08.02 SAND / KAOLIN BOX User manual

All it takes for environmental research

P.O. Box 4, 6987 ZG Giesbeek, T +31 313 88 02 00 Einfo@eijkelkamp.com

The Netherlands

F+31 313 88 02 99 Iwww.eijkelkamp.com M1.08.02.E

©

April 2016

Contents

1 Introduction .......................................................................................................................................................................2

2 Description of the Sand/Kaolin box............................................................................................................................3

3 Technical Specifications.................................................................................................................................................3

4 Assembling the Sand/kaolin box.................................................................................................................................5

4.1 Set up the sand/kaolin box ............................................................................................................................5

4.2 Check the set up values...................................................................................................................................6

4.3 Prepare the drainage system.........................................................................................................................8

4.4 Removal of air-bubbles...................................................................................................................................9

4.5 Laying the suction material............................................................................................................................12

5 Using the sand/kaolin box.............................................................................................................................................17

5.1 Prepare the samples.........................................................................................................................................17

5.2 Set Offset value..................................................................................................................................................20

5.3 Calculate set-point............................................................................................................................................21

5.4 Changing the set-point (suction to be applied to the samples)...........................................................22

6 Filling in as measurements are taken.........................................................................................................................25

7 Ending a measurement ...................................................................................................................................................26

8 Processing the results ....................................................................................................................................................28

9 Trouble shooting ..............................................................................................................................................................30

10 References and Literature...........................................................................................................................................31

11 Appendices.......................................................................................................................................................................32

08.02 SAND / KAOLIN BOX

OPERATING INSTRUCTIONS

2

1 Introduction

This sand/kaolin box (acc. to ISO 11274) can be used to apply a range of pressures from pF

2.0 (-100 hPa) to pF 2.7 (-500 hPa). Kaolin covered sand is used to convey the pressure

from the vacuum vessel and drainage system to the soil samples. If higher pF-values are

required, then the 08.03 Pressure Membrane Apparatus (pF 3.0 - pF 4.2) is required. When

lower pF values need to be applied to samples, then the 08.01 Sandbox should be used (pF

0 – pF 2).

Results of measurements taken with this instrument are points on the drying curves of the

relevant samples; associated with

decreasing

pressure. These pressure values are usually

standard water potential increments. The wetting curve, on the other hand, is determined

by graphing the water content against

increasing

pressure values. This curve is not

identical to the drying curve, because the water content does not respond

instantaneously to changes pressure (Hysteresis). PF-curves can be plotted - based on the

results of measurements taken with this instrument.

3

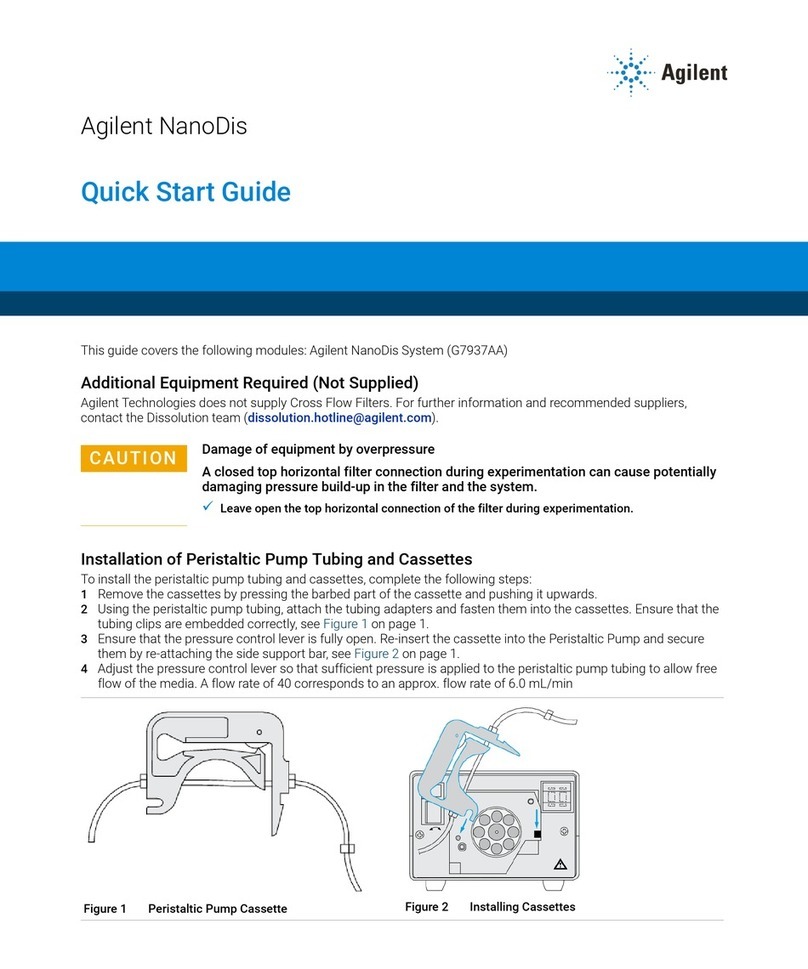

2Description of the sand / kaolin box

The sand/kaolin box (1) stands on four feet (2) and has a drainage system (4) inside it. This

box (1) is filled with very fine synthetic sand, which is covered by a layer of kaolin clay

(Kaolinite - also known as china clay). The lid (3) placed on the rilsaneted (specially

coated) box prevents evaporation. Nylon filter cloth is used to keep the kaolin layer clean.

The sample rings (13) are placed on top of this filter cloth, and are in contact with the

kaolin suction medium through it.

The pump (7) creates suction in the vacuum vessel (5) that is conveyed to the samples (13)

from the drainage system (4) through the sand and kaolin layers. An electronic regulator is

used to define the pressure level, while the pressure sensor, throttle valve (9) and sound-

absorber ensure that the pump creates the correct amount of suction. The pump can be

switched on using the pump button (12) while power can be switched on with the On/Off

button (11).

When tap A is switched to “supply” then water is transferred from the vacuum vessel (5) to

the box (1). If Tap A is switched to “Discharge”, with the appropriate Pump Settings, then

water will leave the box and install suction on the sand and kaolin layer. By opening tap B

the pressure in the vacuum vessel will equilibrate to the atmospheric pressure. Water is

released from the vacuum vessel by opening Tap C.

3Technical specifications

Item Specification

Soil sample rings

max. 40

Dimensions box

55.0 x 33.5 x 37.5 cm (l x w x h)

(excluding supply bottle and measuring device)

Operating range

100 – 500 hPa; 0.1 - 0.5 bar; pF 2.0 – 2.7

Vacuum system

Type: vacuum pump, vacuum tank and automatic suction

level control system

Contents

10 L

Accuracy

±10 hPa

Adaptor

220V to 24 V

4

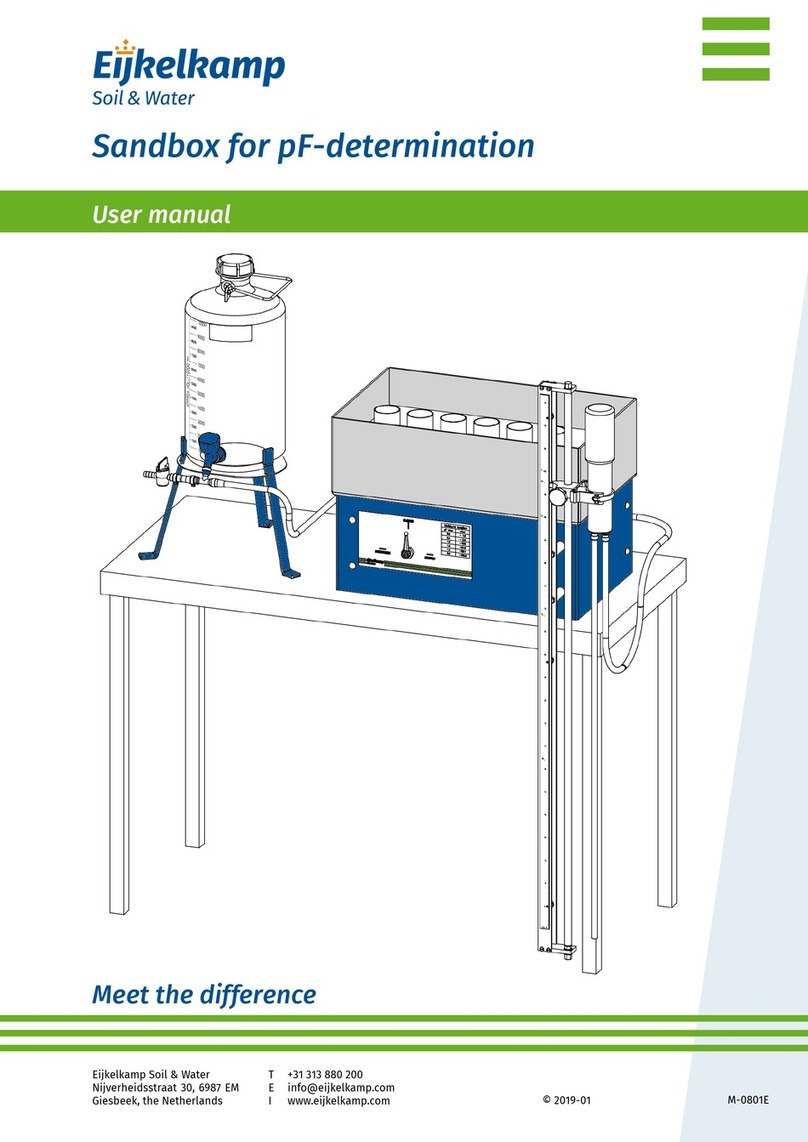

Figure 1: Assembled Sand/kaolin box with numbered

components

9. Throttle valve

10. Display

11. Power switch

12. Pump switch

13. Samples

1. Box

2. Box Stand

3. Lid

4. Drainage Pipe

5. Vacuum vessel

6. Vacuum vessel cap

7. Pump

8. Pressure sensor

Tap A

13

1

2

3

4

5

6

7

8

9

10

11

12

Tap D

Tap B

Tap C

Tap A

5

4 Assembling the sand / kaolin box

All of the tubes are connected and tested for leakage before delivery.

Take care not to break the tube connections while unpacking.

Check that the intended electrical supply has the correct voltage (230 V).

Construct the sandbox using the following instructions (Numbers refer to Figure 1):

4.1 Set up the sand / kaolin box:

4.1.1. Place the sand/kaolin box on a sturdy table,

with Tap A facing the front and turned to the

‘Closed’

position. (Fig 2)

4.1.2. Place the Vacuum Vessel (5) to the left of the

box, and plug it into an electrical supply (230

V).

4.1.3. Make sure that Taps A, B, C and D are all

closed.

Figure 2: Setup box with taps closed

A

B

C

6

4.2 Check the Setup Values

The Display (10 see figure 1 on page 4) facilitates access to a lot of extra

programming functions that should never be altered. Only adjust the settings

referred to in this manual.

4.2.1. Check that the pump is switched off (Figure1:

12) and then turn the power on (11).

4.2.2. The red L.E.D flashes to indicate that you are

in the first menu. The pump indicator.

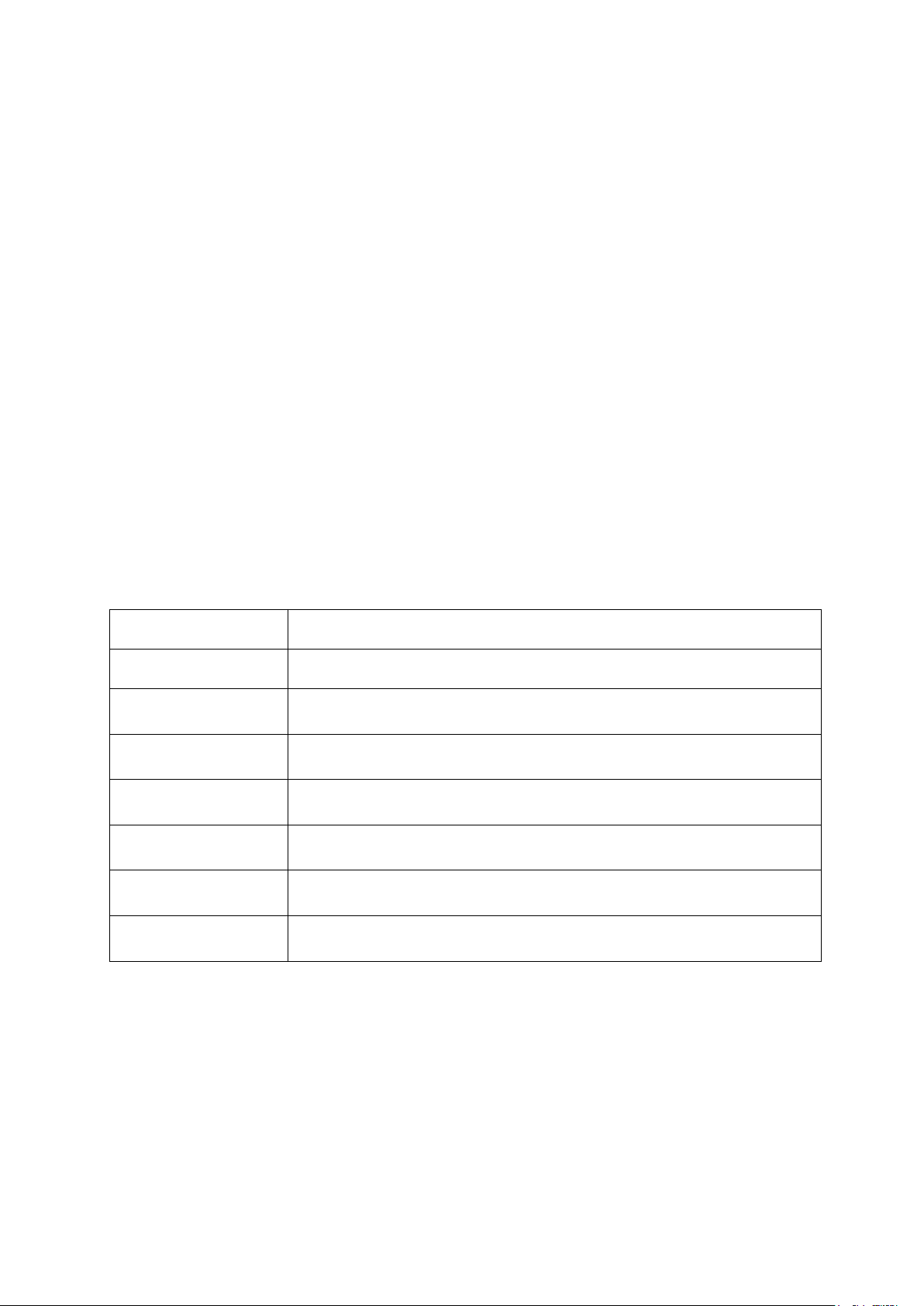

4.2.3. The First Menu has the three Parameters

listed in Table 1. The ‘default value’ displayed

is the current pressure in the Vacuum Vessel

(PrOC).

4.2.4. Hold the “Up-key” and “Down-key” down

simultaneously (for about 3 seconds) until

“FiLt” appears on the display. The yellow

L.E.D will be lighted to indicate that you are

in the Second Menu (See Table 2).

4.2.5. The first number displayed is the FiLt Setup

Value. Ensure that this is ‘0’ as seen in Table

2. If the FiLt Setup Value is not ‘0’, then use

the “Up key” or the “Down key” to correct it.

4.2.6. Press the “Scroll Key” twice to change

between Setup Names (E.g. ‘OFFS’ - See Table

2) and ensure that the Setup Values in Table 2

are installed.

Setup Name Setup Value Function

Input filter

time constant

value

Input offset

value

Enable access

to alarm value

Do Not Change Alarm value 1

Table 2: Second Menu

Parameter Meaning

Current Pressure

in the Vacuum

Vessel (12)

Alarm 1. Do not

change this

setting.

Pressure Set-

point

Table 1: First Menu

7

4.2.7. After all of the Setup Names have the First

Setup Values (Table 2) then use the “Scroll

Key” to return to the

‘FiLt’

Setup Name.

4.2.8. Push the “Up-key” and “Down-key”

simultaneously (for about 3 seconds) to exit

the second menu. The yellow L.E.D will

automatically turn off.

Note: Setup Values will be changed from the First Pump Settings (Table 2) for

removing the bubbles in the system, and in using the sand/kaolin box

(Chapter 5).

8

4.3 Prepare the Drainage System

The plastic drainage pipe (4) inside the box (1) must be covered with filter cloth. The

supplied filter cloth has two layers, and is 6 cm wide. The plastic drainage pipe needs top

be covered by 3 layers of cloth, so that sand wont block the holes in the pipe when suction

is applied, and the suction is diffused.

To apply the filter cloth to the pipe, the following steps should be followed:

4.3.1. Cut a 3.5m long section from the supplied roll

of filter cloth.

4.3.2. Cut down one side the filter cloth to make a

single 12cm wide layer.

4.3.3. To knot the cloth to the pipe, a 10cm long

section is cut into the each end of the strip to

form two ties. (Fig. 3).

4.3.4. Saturate the filter cloth in water (Fig. 4).

4.3.5. Tie the filter cloth to one end of the drainage

pipe - where it enters the inside of the box.

4.3.6. Coil the filter cloth around the drainage pipe

so that each consecutive winding covers two

thirds of the width of the previous one. This

will ensure that the entire pipe is covered by

three layers of filter cloth. (Fig. 5).

4.3.7. Fasten the cloth at the other end of the

pipe.(fig.6)

4.3.8. Cut off the extra cloth, and tie the end to one

end of the drainage pipe.

Figure 6: Complete Cloth Covering

Figure 5: First cloth layer

Figure 3: The 10 cm long ‘ties’

Figure 4: Saturate Cloth

12cm

4cm

Three

layers

cloth

Pipe Surface

9

4.4 Removal of air-bubbles

4.4.1. Boil 10 L of demineralised water, and leave it

to cool.

4.4.2. Open the Cap (6) of the Vacuum Vessel and Fill

the Vacuum Vessel up to the ‘Max’ line with

this water. (This maximum is visible on the

tube between Tap B and Tap C). (Fig.7)

You may add (0.01mg/l) copper sulphate to

reduce microbiological activity.

4.4.3. Turn Tap A, on the front of the box, to

‘Supply’

.

Allow water to flow from the Vacuum Vessel

(5) into the Box (1) until the Drainage Pipe (4)

is completely submerged in water.(fig 8)

Always ensure the water level in the Vacuum

Vessel (5) is higher than the water level in the

Box (1).When the water level in the Vacuum

Vessel becomes too low then add

demineralised water through the open Cap

(6).

Water must flow from the Vacuum Vessel (5)

into the Box (1) until the Drainage Pipe (4) is

submerged.

4.4.4. When there are no bubbles left in the supply

tube between the Vacuum Vessel and the Box

then turn Tap A to the

‘Closed’

position

.

4.4.5. Gently pour water directly into the box (1)

until it is half-full. (Fig.9 )

4.4.6. Open Tap D, at the back of the box, and allow

some water to run from the box (1) out of Tap

D into a beaker. (Fig 10)

Figure 9: Half-fill box with water

Figure 7 Fill the Vacuum Vessel with

DM water

TAP D

Figure 10 : TAP D at backside of the box

Figure 8: Turn tap A to

‘Supply’

10

4.4.7. When there are no air bubbles in the tube

between the Drainage Pipe (4) and Tap D then

close Tap D.

4.4.8. Tightly close the lid of the Vacuum Vessel (5).

(fig 11)

When using the pump there are some important considerations (See Caption 1).

Caption 1: Controlling the water level in the Vacuum Vessel.

The water level in the Vacuum Vessel (5) must be constantly monitored. This level

should never exceed the ‘max’ on the clear tube between Tap B and Tap C.

When the water level in the Vacuum Vessel becomes too high, then follow these steps:

a. Turn Tap A to the

“Closed”

position and switch

off the Pump (12).

b. Gently open the pressure release valve (Tap

B), to allow the air-pressure to equilibrate

with the atmosphere.(fig12)

c. Place a beaker under Tap C, and open it to

allow the excess water to drain out of the

Vacuum Vessel.(fig 13)

d. Close Tap C when the water level in the

Vacuum Vessel (see glass tube) has drained to

about 4cm below the rim of the box (1). Close

Tap B.

e. Turn the pump back on and wait for the

pressure in the Vacuum Vessel to return to the

relevant value before returning Tap A to

“Discharge”.

Suction must be created in the Vacuum Vessel (5) to remove air bubbles from the

discharge tube between it and the Box (1).

Figure 11: Tightly close the lid

Figure 12: Open the pressure release valve

Figure 13: Water drain out with open the Tap

11

4.4.9. Check that the Pump is switched off (12: see

fig.1 on page 4) and the tap A, B, C and D are

closed, then turn the Power on (11: see fig.1

on page 4). Fig.14 pump is off now.

4.4.10.The red L.E.D flashes to indicate that you are

in the First Menu.

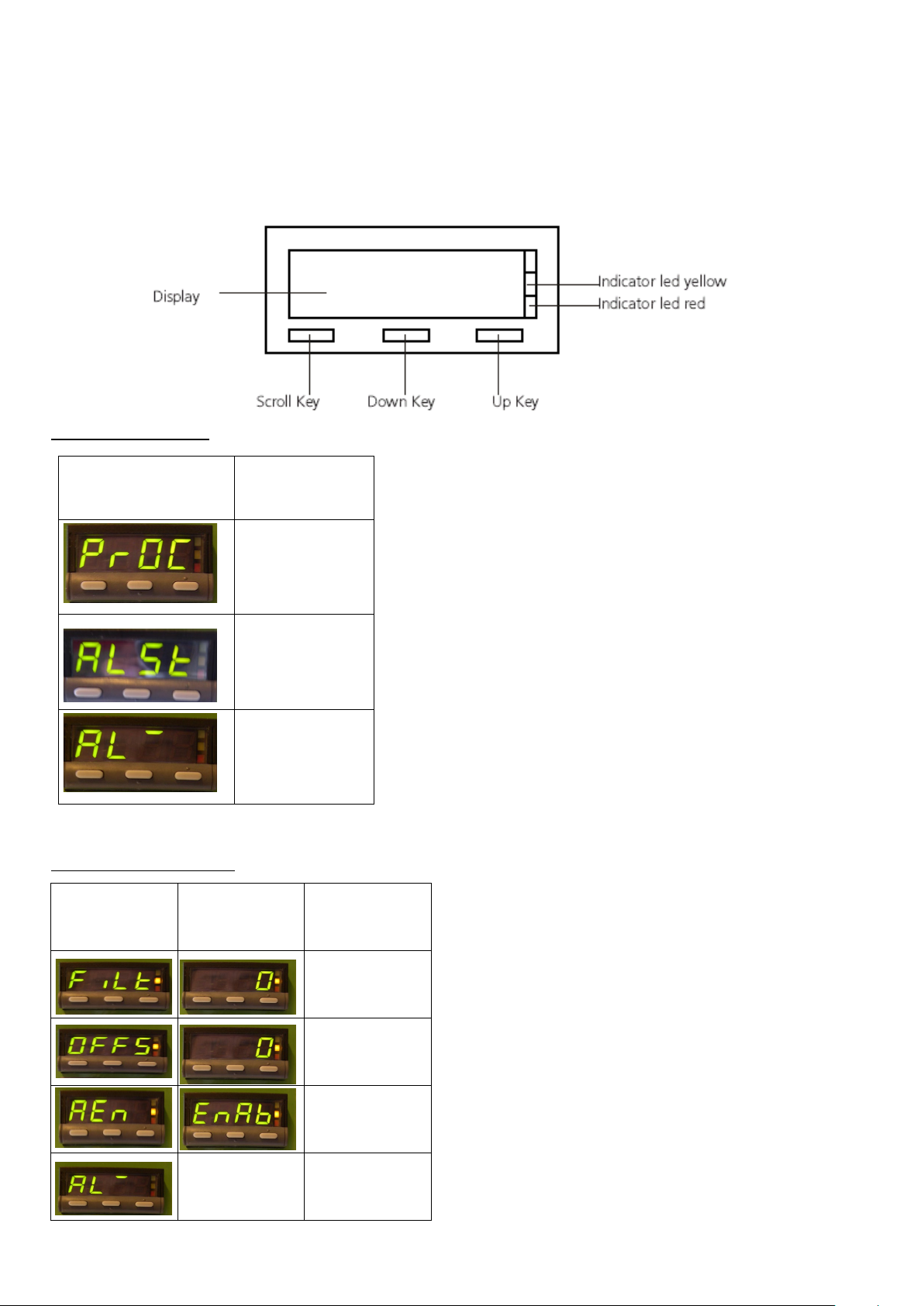

4.4.11. The First Menu has the three Parameters

listed in Table 1. The ‘default value’ displayed

is the current pressure in the Vacuum Vessel

(PrOC).

4.4.12.Press the “scroll key” twice (make contact

three distinct times less than 1.5 seconds

apart) until the ‘AL‘ Parameter is displayed.

4.4.13.Adjust the Set-point for the ‘AL‘ Parameter to

-100 hPa by pressing the “Down-key” or the

“Up-key”. (fig 15)

4.4.14.Press the “scroll key” twice so that the ‘PrOC’

name is displayed again.

4.4.15.Switch on the pump.

4.4.16.Switch Tap A to the position “Discharge”.

4.4.17. Some water will now be sucked into the

Vacuum Vessel (5). When there are no

bubbles between the Box (1) and the Vacuum

Vessel then turn the pump off.

Figure 15: Steps 4.411-4.413

Figure 14: Pump is off now

12

4.5 Laying the suction material

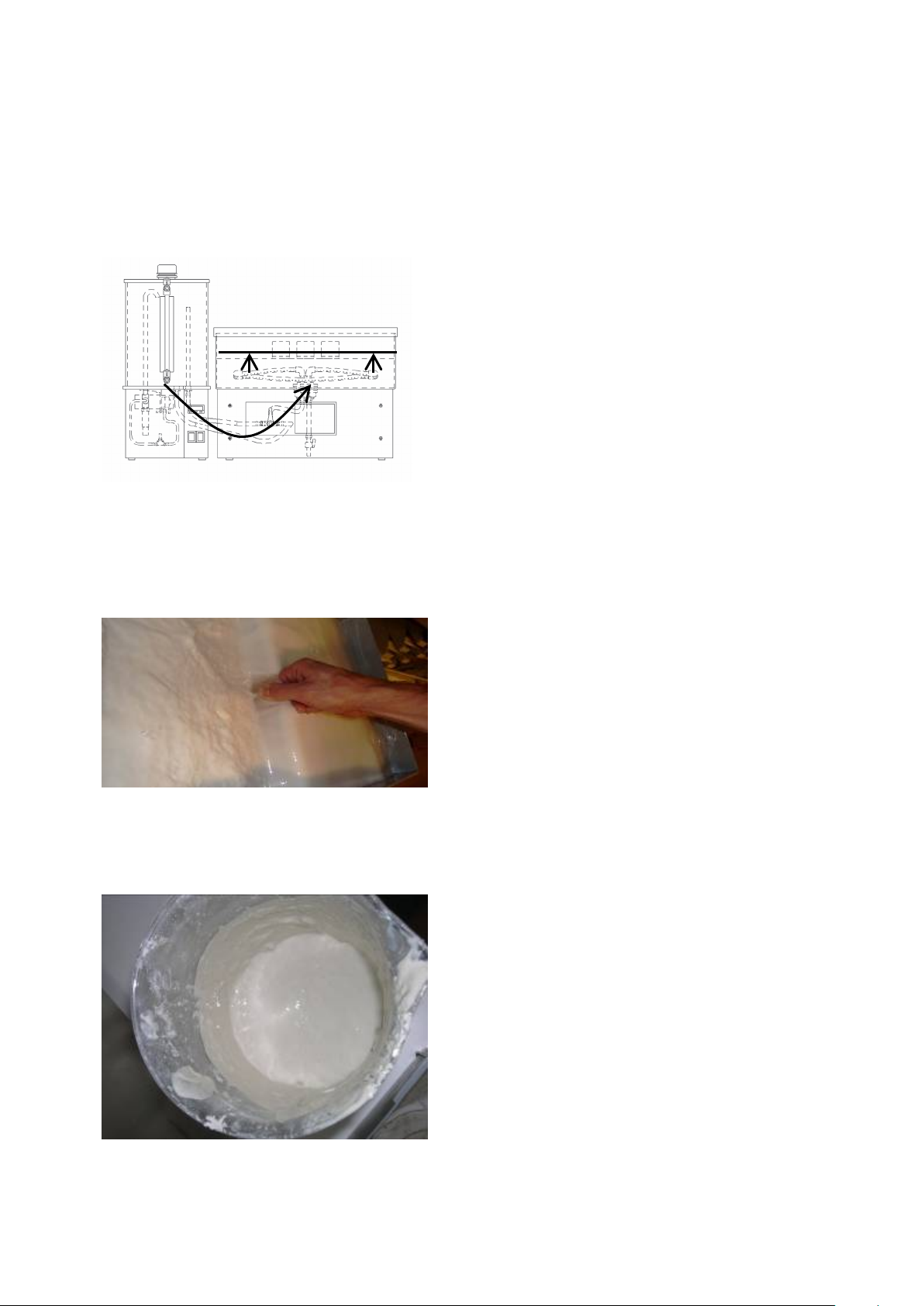

4.5.1 Saturate some synthetic sand with running

demineralised water and stir firmly to

remove air (Fig. 16).

There should be a high ratio of water to sand

so that it can be easily poured into the

box.(fig17) For the textural composition of the

sand see Table 3.

Table 3: Textural Composition of Sand

Particle size

diameter (mm)

Percentage

106

0

75

6.3

63

61.4

53

22.1

45

4.4

<45

5.8

Be careful to avoid damaging the drain system while stirring.

4.5.2 Slowly add the water-saturated sand to the

water in the sandbox (1) with a ladle while

stirring constantly to expel any entrapped

air.(fig 18)

The sand should be pressed against the side

walls of the sandbox, and into the corners, to

make sure that the sand does not contain air

pockets and a good seal between sand and

box is established.

4.5.3 When the water level in the Box (1) becomes

too high, then open Tap D – releasing the

excess water into a beaker.(fig 19)

Always retain a level of water in the box above the sand and the drainage system.

Figure 16: Saturate sand with water

Figure 17: A high ratio of water to sand

Figure 18: adding the water-saturate sand

Figure 19: Tap D open into bucket

13

4.5.4 Stop adding the saturated sand when the

sand level is 8 cm below the rim of the Box

(1).

Always ensure the water level in the Vacuum Vessel (12) is higher than the water

level in the Box (1).

4.5.5 Turn Tap A to the

‘Supply’

position, and open

Tap B. Water from the Vacuum Vessel (5) will

now flow through the drain into the sand and

remove final air residues.

The Vacuum Vessel Cap (13) must be open.

Keep 0.5cm of water above the surface level

of the sand.

4.5.6 Excess water (extra to the 0.5cm minimum

depth) can now be drained by opening Tap D.

(20)

These steps (4.5.5-4.5.6) must be done carefully: Any entrapped air cannot be

removed by this method after the Kaolin layer has been laid over the sand, because

the Kaolin and sand layers may become disengaged. The sand level must always

remain 0.5cm under water; otherwise air will be sucked into it.

4.5.7 Smoothen the surface of the sand with a

clean ruler, and leave it to settle for 1hr.(fig

21)

4.5.8 The Kaolin layer will now be added. Begin by

half-filling a large beaker with demineralised

water.

Be careful not to disturb the sand, or to mix the sand and kaolin layers.

4.5.9 Slowly add the kaolin powder to this beaker

while stirring the water.

4.5.10 Once the clay is completely saturated, spoon

it onto the surface of the sand using a large

ladle. Alternatively, pour it gently onto the

surface with the aid of a ruler. (fig 22)

4.5.11 The final Kaolin layer must be at least 1.5 cm

deep.

4.5.12 Allow the Kaolin to settle overnight – so that

there is a transparent layer of water above

the deposited clay.

Figure 21: Smooth sand with a clean ruler

Figure 22: Water-saturated Kaolin

clay

Saturated-sand

Flow

Flow

Flow

Figure 20 Water flow from vessel to box

14

When using the pump, the water level in the Vacuum Vessel must be checked

constantly (See Caption 1).

The pressure set-point for the Vacuum Vessel can now be set for flushing the sand /

kaolin suction medium.

4.5.13 Check that the pump is switched off (12), and

the taps A, B, C and D are closed.

4.5.14 Ensure that the lid of the Vacuum Vessel (5) is

tightly closed and the adaptor (230volt) is

connected to the power supply before

turning the Power On (11).

4.5.15The red L.E.D flashes to indicate that you are

in the First Menu.

4.5.16The First Menu has the three Parameters

listed in Table 1. The ‘default value’

displayed is the current pressure in the

Vacuum Vessel (PrOC).

4.5.17 Press the “Scroll Key” thrice (make contact

three distinct times less than 1.5 seconds

apart) until the ‘AL‘ Menu is displayed.(fig 23)

4.5.18 Adjust the Set-point within the ‘AL‘ Menu to

–500 hPa by pressing the “Up-key” or “Down-

key”.(fig 24)

4.5.19 Press the “scroll key” twice so that the ‘PrOC’

name is briefly displayed.

A 1 cm deep stratum of water must always remain above the kaolin layer.

Figure 23: Display from (PrOC).to ‘AL‘

Figure24: ‘AL‘ change to-500

15

The sand/kaolin suction medium will now be flushed for a few hours to remove the final

air-residues, and bond the sand and clay layers.

4.5.20 Press the kaolin clay firmly against the walls

of the box, especially in the corners, to

prevent air-leakage.(fig25)

4.5.21 Smooth the surface of the kaolin layer level

with a clean ruler.

4.5.22 Gently pour boiled, demineralised water on-

top of the kaolin layer with the aid of a ruler.

Fill the rest of the box (1) with this

water.(fig26)

4.5.23 Turn on the Pump (12) and set Tap A to

“Discharge”.

4.5.24 Let the water be sucked through the kaolin

and sand into the Vacuum Vessel for a 2

hours – always gently topping-up the water-

level in the box when it becomes less than

1cm deep.

Constantly monitor the water level in the Vacuum Vessel (on the clear tube

between Tap B and Tap C). This level should never exceed the ‘max’ line

(See Caption 1).

4.5.25 After there are no bubbles appearing in the

pipe between the Drainage Pipe (4) and the

Vacuum Vessel (5) then the suction medium is

air-free.

4.5.26 Continue flushing the air-free sand/kaolin

with the remaining water until there is a 1cm

deep layer of water above the kaolin

layer.(fig 27)

4.5.27 Set Tap A to the

“Closed”

position and turn

off the Pump (12). (About 2hrs are spent

flushing the suction medium).

Although not strictly necessary, it is recommended to cover the kaolin with one layer of

filter cloth to prevent it from becoming too dirty.

Figure 26: Gently add demineralised water

Figure 25 : Press the kaolin against the walls

Figure 27: Remaining water a 1 cm deep

16

4.5.28 Cut the filter cloth to the correct size by

tracing around the lid of the box (1).

4.5.29 Saturate the filter cloth with water in a

beaker, before placing it onto the surface of

the kaolin layer. (fig 28)

4.5.30 Remove any air bubbles between the filter

cloth and the kaolin by gently smoothing it

from the centre outwards.

The sand/kaolin box is ready to use. There must be no air-bubbles in the system

from this point onwards. Vibration may cause a leak between the sidewalls of the

sandbox and the suction medium.

Figure 28: cover the filter cloth on the top of the sand

17

5 Using the sand/kaolin box

The environment around the sand/kaolin box should be kept at a constant

temperature between measurements, since temperature changes affect water

viscosity and therefore water retention values.

5.1 Prepare the Samples

5.1.1. Uncap the core sample ring. If the sampled

soil volume is larger than the volume of the

core ring, carefully remove excess soil by

‘chipping’ it off with a sharp edged tool.

Prevent smearing the sample surface so as

not to affect the physical properties of the

soil. (fig29)

5.1.2. Fix a piece of nylon cloth to the bottom side (sharp

edged side) of the sample with an elastic-band, or an

O-ring.

If the soil volume is less than the volume of the ring, or if the sample has been

damaged during transport, the sample should not be used for analysis. Samples

with large projecting stones may also have to be discarded.

5.1.3. Ensure that a 1cm layer of water is covering

the surface of the kaolin in the box (1).

Never turn Tap A to the “Supply” position or the bond between the sand and kaolin

layers will be broken. If water needs to be added to the box, then do so with

demineralised water, and pour it gently onto the kaolin surface with the aid of a

ruler. 5.1.4. Mark the rings, and draw a diagram of the box,

so that the rings can be replaced in exactly

the sample place after removal. (fig30)

The samples now need to be saturated. Steps 5.1.5 to 5.1.8 can be followed, or

alternatively an excicator may be used.

5.1.5. Place the soil sample with the bottom side

down in the sand/kaolin box. Let the sample

adapt for 1 hour.(fig 31)

1.

2.

3.

4.

Figure 30: Mark samples

Figure 31: Allow samples to adapt for 1hr.

Figure 29: Chip off excess soil – don’t smear!

18

5.1.6. Gently pour demineralised water onto the

kaolin surface with the aid of a ruler.

Raising the water level to quickly may entrap air in the samples or damage the

soil structure.

5.1.7. Stop adding water when the water level is 1cm

below the top of the sample ring.(fig 32)

5.1.8. Place a lid on the basin (to prevent

evaporation) and allow the sample to

saturate for 2 or 3 days (sandy soils) or up to

1 or 2 weeks (clayey soils).

Take care not to leave sandy soils wetting for too long since slaking may occur.

5.1.9. Take the ring carefully out of the water

/excicator and wipe off any water drops

hanging underneath the sample before

weighing it. (accuracy of balance 0.01 g). This

weight (including ring, cloth and elastic) is

used to calculate water content at saturation,

pF 0.(fig 33)

5.1.10. Record this weight as ‘Weight A’ in ‘Chapter 6:

Table 9’ for Processing the Results.(fig 34)

Note any irregularities that occurred during saturation (e.g. swelling of clayey

soils, changes in soil structure, accidental loss of soil material).

If an excicator was used in place of Steps 5.1.6 to 5.1.9 then ensure that a 1cm layer of

water remains above the surface of the kaolin in the box (1).

Water content measurements at pF 0 are relatively inaccurate:

•It is difficult to transfer the saturated sample to a balance without changing water content,

especially with sandy samples.

•The middle of the soil sample is used as the reference level for zero pressure, but the free

water level (h = 0) is in fact 1 cm below the top of the sample ring. The moisture tension

thus ranges from +1 cm at the bottom of the sample, to -4 cm at the top of the sample.

Note that at decreasing pressures this difference due to sample size becomes less

important.

Figure 32: Stop adding the water now

Figure 34: Weigh the Samples

Figure 33 : Take the ring out of the water

19

5.1.11.Place each sample ring at its designated

position on the kaolin surface. Press the ring

slightly, to improve soil - kaolin contact.(fig

35)

5.1.12. Ensure that the Pump is switched off.

5.1.13. Check that the electrical supply is plugged in

and the power (11) is turned on.

5.1.14. Make sure that the cap of the Vacuum Vessel

is closed tightly (6).

5.1.15. Turn Tap A to the

“Closed”

position.

5.1.16. Ensure Tap B is open and check that the

display shows ‘0’. If this is not the case, then

follow the correction steps under the heading

‘5.2

Set Offset Value’.

Figure 35: Place the sample at the exact the

Figure 36: Ensure Tap B is open

20

5.2 Set Offset Value

This section details how the neutral point for the electronic vacuum regulator is corrected

during use. If you are in the First Menu with Tap B open, and the PrOC parameter value is

not zero, then the atmospheric pressure has changed.

To correct this, execute the following steps:

5.2.1. The red L.E.D flashes to indicate that you are

in the First Menu (See Table 4).

5.2.2. The First Menu has the three Parameters

listed in Table 4. The ‘default value’ displayed

is the current pressure in the Vacuum Vessel

(PrOC).

5.2.3. Hold the “Up-key” and “Down-key” down

simultaneously (for about 3 seconds) until

“FiLt” appears on the display. The yellow L.E.D

will be lighted to indicate that you are in the

Second Menu (See Table 5).

5.2.4. The first number displayed is the FiLt Setup

Value. Press the “Scroll Key” twice until the

‘OFFS’ Setup Name is displayed.

5.2.5. If the PrOC parameter value (Current pressure

in the Vacuum Vessel) was +5 hPa when Tap B

was open then the Setup Value for the “OFFS”

Setup Name must be set to “-5” to

compensate for this.

5.2.6. Use the “Up-key” and “Down-key” to alter the

Setup Value for the “OFFS” Setup Name to

correct for the change in atmospheric

pressure. (See Table 5)

5.2.7.Use the “Scroll Key” to return to the

‘FiLt’

Setup Name.

5.2.8.Push the “Up-key” and “Down-key”

simultaneously (for about 3 seconds) to exit

the second menu. The yellow L.E.D will

automatically turn off.

5.2.9. The display must now show “0” for the PrOC

parameter value.

Setup Name Setup Value Function

Input filter

time

constant

value

-5 Input offset

value

Enable

access to

alarm value

Do Not Change Alarm value 1

Table 5: Reset Offset Value

Parameter Meaning

Current

Pressure in

the Vacuum

Vessel (12)

Alarm 1. Do

not change

this setting.

Pressure Set-

point

Table 4: First Menu

Table of contents

Other EIJKELKAMP Laboratory Equipment manuals