BIOLAN GREYWATER FILTER 70 Parts list manual

70573300

BIOLAN GREYWATER FILTER 70

Instructions for installation, use and maintenance EN

11/2012

Serial No.

Assembler Date of manufacture

Seller's stamp, signature and date of purchase

2

EN-1

EN

Contents

Component list EN-2

Component drawing EN-2

1. Overview EN-3

2. Planning and selecting the location EN-3

2.1Technicalspecications EN-3

2.2 To be located above the ground EN-3

2.3 Location inside a residential building EN-3

2.4Conductingwastewatertothelter EN-4

2.5 Discharge point for the wastewater EN-4

3. Installation EN-4

3.1 Connecting the inlet and outlet sewer pipes EN-4

3.2Puttingtheltermaterialinplace EN-4

3.3 Opening the air valves EN-4

4. Use and maintenance EN-4

4.1 Follow-up of the operation EN-5

4.2Changingtheltermaterial EN-5

4.3Storingthelteroverwinter EN-5

5. Possible malfunctions EN-5

6. Disposal of the product EN-5

Biolan accessories EN-6

About the guarantee EN-6

BIOLAN GREYWATER FILTER 70

Instructions for installation, use and maintenance

The Biolan Greywater Filter 70 is a purifying unit for washing waters of one family,

especially designed for weekend residences. Into the lter may be conducted wash-

ing waters and waters from sauna as well as dishwashing and laundry waters. The

Biolan Greywater Filter 70 shall be installed above the ground. The wastewater is

conducted directly into the lter either by gravity or by pumping. The lter's treat-

ment capacity is 500 litres per day, which in practice is sufcient for 1–5 persons.

EN-2

EN

Part name Number Material

1 body 17733010 PE + urethane insulation

2 service door 17733020 PE + urethane insulation

3lterbox 17715060 ABS plastic

4 disk valve body 18733080 PP

5 disk valve 18715060 PP

6connectingpipe250x75mm 28733110 PP

7 branch sleeve 75 / 75 mm 28733120 PP

8 inlet pipe end 18715250 PP

9connectingange 18715110 PP

10 lip seal 19733130 EPDM

11 plug 75 mm 18715130 PP

12 rubber pad 19733060 EPDM

In addition to the components illustrated in the component drawing, the Greywater Filter 70 also in-

cludes:

attachment screw for rubber pad 20010016 RST

door latch 20080008 RST

attachmentscrewforange 20010011 RST

doorseal15x10mm 19733160 EPDM cell rubber

llingplugforurethane,grey 18715240 PE

user manual Finnish/Swedish 27733280 Paper

usermanualin10languages(exportproductsonly) Paper

ltermaterial 70574100 Package PE

Spare parts sales: dealers and the Biolan online shop at www.biolan.

Component list

3

6

5

2

10

4

7

8

9

1

12

11

Component drawing

EN-3

EN

1. Overview

ThepuriermeetstherequirementsoftheStateCouncil'sde-

cree (209/2011) on treatment of domestic wastewater outside

the sewer systems of the waterworks.

Wastewater from a WC or dry toilet in the property must be con-

ducted into a closed tank or treated otherwise in a due manner.

Rain- or stormwater or drainage water from foundations must

notbe conductedinto thelter.If installedin accordancewith

theinstructions,thetreatmentcapacityofthelterisabout500

litres per day, which in practice meets the need of washing water

for1–5people.The treatment capacityofthe lter materialis

good for about 100 days, after which it needs to be replaced in

accordance with the maintenance instructions.

Theoperationofthelterisbasedonmechanicalandbiologi-

calltrationofwastewater.Thedirtinthewastewatersticksto

theorganicltermaterialinthelter.Themicro-organismsliving

onthe surface ofthe lter materialuse the impuritiesas their

nutrition.

TheGreywaterFilter70comprisestwopurierunits,a.k.a.mod-

ules. The incoming wastewater is divided into the modules by

meansofthebranchsleeve(part7)locatedbetweenthemod-

ules.Bothmodulescontainvelterboxesplacedoneontop

of the other. The wastewater is conducted into the uppermost

lterboxes.Insidethelter,thewastewaterowsbygravitation

fromonelterlayertotheotherthroughtheopeningsintheend

ofthebox.

In Finland, building a wastewater system or chang-

ingitalwaysrequiresabuildingoractionpermission

from the municipal building authority or a submission

of notication of action. The building permission is

applied by submitting a relevant plan.

2. Planning and selecting the

location

2.1Technicalspecications

• dimensions of one module: (width x height x depth) 600 x

700x1010mm

• two modules side by side: width about 135 cm

• pipe connectors for Ø 75 mm sewer pipes

• heightdifferenceofinletandoutletconnectors(heightoffall):

530 mm

• capacity: about 500 litres a day

• weightwithoutltermaterial:2xabout38kg

2.2 To be located above the ground

The Biolan Greywater Filter 70 shall be installed above the

ground.Placethelterinalocationwherewaterwillnotgather,

evenwhenthere is ooding.Theltercan be installedout of

doors without a cover. The unit is thermally insulated, which

means it tolerates slight frost. If the lter is used in winter, it

must, however, be equipped with the Biolan Heating Cable,

whichisavailableasanoption,ortheltermustbeplacedin

a space, where the temperature stays above zero at all times.

The space required for use and maintenance must be taken

into account when selecting the location. A free space, at least

one metre deep, must be provided in front of the unit for chang-

ingtheltermaterial.Asufcientspacemustalsobeprovided

at the sides and the rear of the unit to enable maintenance of

the outlet connector for the sewer and the adjustment of the air

valvesintherearwall.Toensurethesupplyof oxygentothe

micro-organisms,theairexchangevalvesmustnotbecovered

ortheairexchangemustbearrangedinsomeotherway.

2.3 Location inside a residential

building

Biolan Greywater Filters are primarily intended for installation

outofdoors.Ifyouareplanningtoinstallthelterindoorsorin

closeproximitytoaresidentialbuilding(forexample,underthe

terrace),thensomemaintenancespacewithitsownentrance

should be provided. This space must also be provided with a

oorwelloranearthenoorforpossiblemalfunctions.

Thereplacement airforthe lteris takenfrom theend ofthe

discharge pipe and the outlet air is conducted as sewer ventila-

tion to the roof of the building. To avoid odour problems, the air

valves of the unit must be kept closed. The outlet air can also

be conducted through the upper air valve in the rear wall of the

lterintoaseparateoutletairchannel.Iftheunitisinstalledin-

doors,theoutletairchannelshallbettedwithanaspiratorthat

maintainsaslightnegativepressureinsidethelter.

Whenever the Greywater Filter is located in a warm

spaceinaresidentialbuilding,orincloseproximity

to a residential building, the correct installation must

alwaysbeveriedwiththeexpertinchargeofplan-

ningtheHVACsystemforthebuilding.

EN-4

EN

2.4 Conducting wastewater to the

lter

Thewastewaterisconducteddirectlytothelteralternativelyby

gravity,byowdrainageorbyapumpwell.Toensureaneven

distribution, the inlet pipe should be provided with a straight

80cm-longpartbeforethebranchsleeve(part7),thatreduces

turbulenceoftheincomingwaterow.

If you intend to utilise existing septic tanks during pumping,

these should be in good condition and hermetically sealed. The

operationofthepumpmustbesequencedusingatimersothat

duringonesequencethepumpwillfeedatmaximum20litres

ofwastewatertothelter.Theintervalbetweenthesequences

must be at least 10 minutes. The Biolan Timer, the Submersible

Pump and the Pump Well are available as an option.

2.5 Discharge point for the

wastewater

Conduct the treated wastewater to a suitable discharge point,

forexample astone pocketor anopen ditch.When planning,

bear in mind that the discharge of wastewater should be unob-

structed even when the level of the surface water or groundwa-

ter is high. If you route the water to an open ditch, provide the

endofthepipewithaaporanettopreventrodentsorother

small animals from gaining access.

Toxic

Hazardousto

the environ-

ment

Corrosive

Inammable

Oxidizing

3. Installation

Placethelteronarmandevensurfacethatisnotsusceptible

tofrost,suchas,forexample,abedofgravelorcrushedstone

oracastconcreteslab.Theltermustbeinahorizontalposi-

tionbothlengthwiseandlaterallytoallowthewastewatertoow

smoothlyovertheentirecleaningareaoftheltermaterial.

3.1 Connecting the inlet and outlet

sewer pipes

Whileinstallinggravityowsewers, asufcient gradient(ofat

least1-1,5%)needstobeprovidedtoallowthewastewaterto

owwithoutobstructionfromthe seweroutletofthe houseall

the way to the discharge point. There are inlet and outlet con-

nectors for 75 mm sewer pipes on both sides of the modules.

The inlet connectors are located at the upper edge and the out-

let connectors at the lower edge. Join the inlet connectors of the

modules together using the connecting pipes (part 6) and the

branchsleeve(part7).Connectthesewerpipecomingfromthe

building to the branch sleeve that joins the modules together.

Thebranchsleevedividestheincomingwastewateroweven-

ly into both modules. To ensure an even distribution, the inlet

pipe can be provided with a straight 80cm-long part before the

branch sleeve, that reduces turbulence of the incoming water

ow.Theoutletconnectorsfortreatedwaterarelocatedatthe

loweredgeofthelter,oneithersideofthemodules.

The treated wastewater can be conducted to the discharge point

either separately from each module or by joining together the

outlet connectors of the modules using an intermediate pipe,

and conducting the water out through the outlet connector of

one of the modules. The outlet connectors of the modules can

also be joined together using a similar branch sleeve that was

used in the inlet pipe. The discharge point for treated wasterwa-

ter can then be located between the modules. The unused inlet

andoutletconnectorsshallbeclosedusingtheplugs(part11)

includedinthedelivery.Ifthelterwillbeusedinwinter,theinlet

sewer must be insulated. Whether also the outlet sewer needs

to be insulated, shall be considered case by case.

4. Use and maintenance

The unit must be used and maintained in accordance with the in-

structions, and its operation must be monitored regularly. Main-

tenance of the wastewater system also involves maintenance of

the pump well and the septic tanks, if provided.

Intotheltercanbeconductedwashingwatersandwatersfrom

saunaaswellasdishwashingandlaundrywaters.Theltertol-

erates a small amount of anti-bacterial or chlorine-based agents

that are commonly used for cleaning. Follow the dosing instruc-

tions issued by the manufacturer of the detergent.

Wastewater from a WC or a dry toilet, rain water or stormwater,

or drain water from foundations must not be conducted into the

lter. Toxic chemicals or substances that contain such chemi-

cals, which can kill the micro-organisms that clean the waste-

water, such as drain openers, paints, oils or solvents, must not

beconductedintothelter.Harmfulchemicalscanbeidentied

from the markings on their packaging:

3.2Puttingtheltermaterialinplace

The lter material is packed in plastic bags for transportation.

Remove the plastic bags. Rip the lter material loose and

spreaditevenlyacrosstheboxbytappingitgently.Finally,draw

theltermaterialabout5cmtotherearfromtheV-openingsin

thedischargeendofthebox.

Theltermaterialboxesareidentical,buttheirdirectionshould

be observed – in the uppermost box water ows towards the

rearwall,inthenextboxitowstowardstheservicedooretc.In

thelowermostboxwaterowstowardstherearwall,fromwhere

it falls along the shaped bottom into the discharge sewer.

3.3 Opening the air valves

Theoperation ofthelter isbased onactivityof themicro-or-

ganisms.Thesemicro-organismsneedoxygentosurvive,and

therefore, it is vital to provide the lter with sufcient air ex-

change.Therearetwoadjustablediskvalvesforairexchangein

the rear wall of the modules. Set both disk valves of the module

about 10–20 mm ajar for the summer. In winter keep the valves

onlyslightlyajar(about5–10mm).Ifyouhaverealisedtheair

exchange by means of sewer ventilation, keep the air valves

completelyclosedtoavoidodourproblems(seepoint2.3).

EN-5

EN

4.1 Follow-up of the operation

Checktheoperationofthelteratleasttwiceduringeveryoper-

atingseason.Awell-functioninglterdoesnotgiveoffastrong

smell,theltermaterialinitremainsmoistandtheexitingwater

isclearandodourlessanddoesnotcontainasignicantamount

of solid matter.

Check that

1. wastewaterisowingsmoothlyinbothmodulesthroughall

theopeningsofthebox

2. theltermaterialhasbeendrawntoadistanceofabout5

cmfromtheopeningsinthedischargeendofthebox

3. theairexchangevalvesareinthecorrectpositionandthe

airisowingwithoutobstruction

4. the visible connections of the sewers are in order

5. thepuriedwastewaterisowingfreelyoutofthelter

4.2Changingtheltermaterial

Normally,theltermaterialoftheltermustbereplacedevery

100 days of operation. Only material, specially intended for use

inthe Biolanlters, shallbe usedasltermaterial.Biolan Oy

does not guarantee the purication capacity of the unit if any

otherltermaterialisused.

1. Changetheltermaterialofallboxesatthesametime.

2. Open the service door of the lter and draw out the lter

materialboxeskeepingtheminalevelposition.

3. Emptytheltermaterialintothecompostoruseitascover

soil for ornamental plants.

4. Relltheboxeswithnewltermaterial.Riptheltermate-

riallooseandspreaditevenlyacrosstheboxbytappingit

gently.Finally,drawtheltermaterialabout5cmtotherear

fromtheV-openings.

5. Check the inlet and outlet connectors for wastewater and

clean them.

6. Returnthe boxeslledwith ltermaterialtothelter unit.

The lter material boxes are identical, but their direction

should be observed – in the uppermost box water ows

towardstherear wall,inthenextboxitows towardsthe

servicedooretc.Inthelowermostboxwaterowstowards

the rear wall, and from there it falls along the shaped bottom

into the discharge sewer.

7. Make sure that the unit is on a level both lengthwise and

laterally so that wastewater will be evenly divided into both

modulesandowssmoothlyfromonelterboxtotheother.

8. Closetheservicedoorsoftheltercarefully.

9. Write down the service measures that were taken.

4.3Storingthelteroverwinter

Leavetheltermaterialboxesinsidethelter.Freezingofthe

ltermaterialdoesnotdamagetheunit.Iftheltermaterialis

still frozen when the operation starts in spring, thaw it by pouring

warm,clearwaterthroughthelter.

5. Possible malfunctions

Theltermaterialboxremainslledwithwater

Theltermaterialboxshalldrainoffbetweenthetimesofop-

eration.Ifthisisnotthecase,theltermaterialmaybeclogged.

1. Makesurethattheltermaterialhasbeendrawntoadis-

tance of about 5 cm from the openings in the discharge end

ofthebox.Asnecessary,pushtheltermaterialslightlyto

the rear.

2. Checktheageoftheltermaterial.Inheavyandcontinu-

oususe,theltermaterialmaygetcloggedalreadyduring

therst100daysofoperation.Replacetheltermaterial,

if necessary.

Fliesinthelter

TheairopeningsoftheGreywaterFilterarettedwithynets

ofsmallmeshsize.Despitethenets,smalliesorgnatsmay

sometimesestablishthemselvesinthelter.Ifiesareinterfer-

ingwiththelter,youcandoawaywiththemusingapyrethrin-

based insecticide. Consult your local garden centre to select a

suitable product.

6. Disposal of the product

The raw materials used are presented in the component list (see

page4).Disposeofeachpartasprescribed.Alwaysfollowthe

regionalandcollecting-point-specicinstructions.

PE = polyethylene

to collection of energy waste or recycling of plastic

PP = polypropylene

to collection of energy waste or recycling of plastic

RST = stainless steel

to recycling of metal

Paper

to recycling of paper

EN-6

EN

Biolan Oy

P.O.Box2,FI-27501KAUTTUA

Tel. +358 2 5491 600

www.biolan.

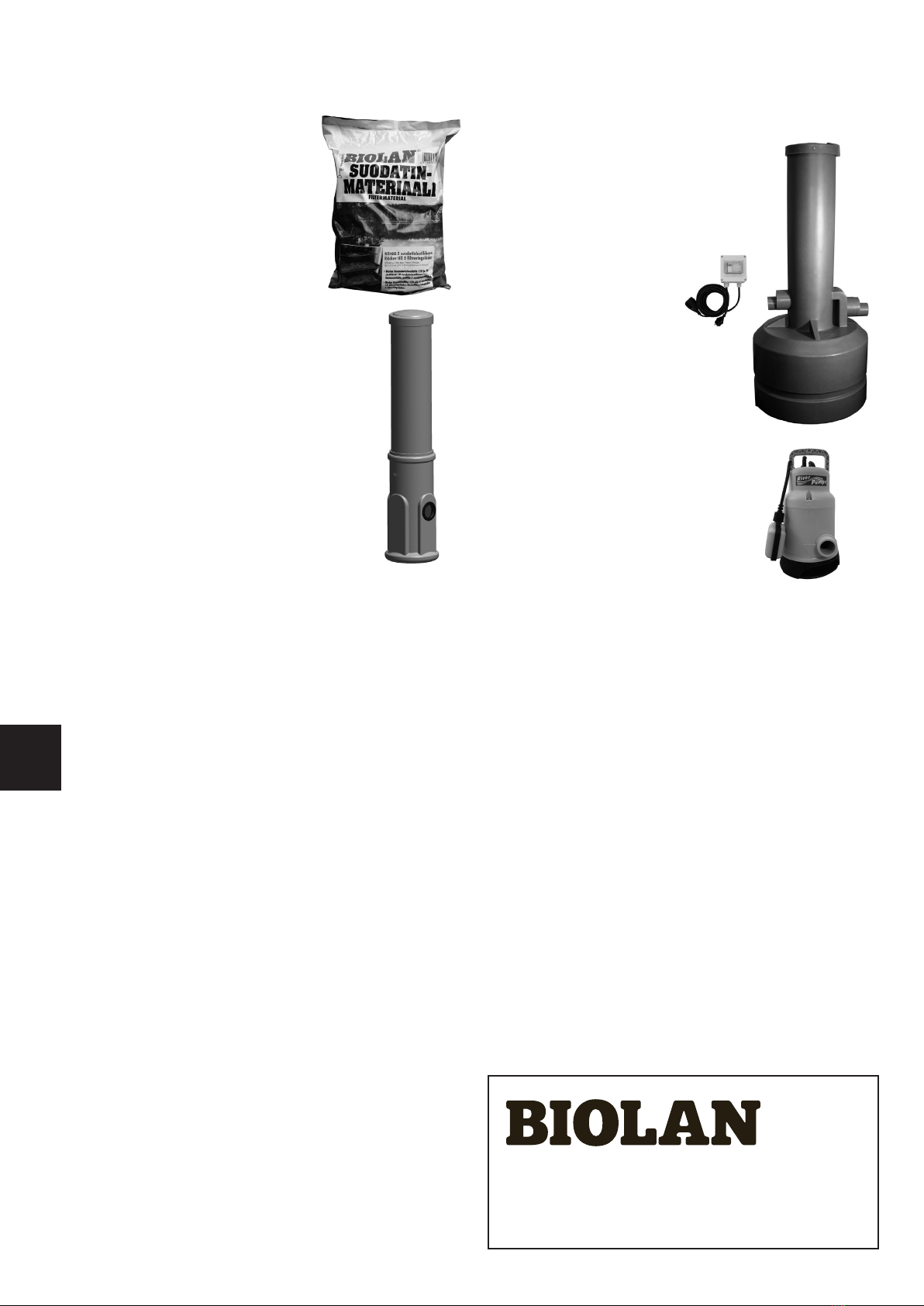

Biolan accessories

Availability varies from country to country. Consult your local dealer for details.

Biolan Filter Material

TheltermaterialfortheGreywaterFilter

ismadeofWarnstoraorCalliergonmoss

collected in connection with restoration of

lakes. The moss, which has grown under

conditions rich in nutrients, makes an ef-

cientandnaturalmaterialforpurication

of waste water.

Product no. 70574100,

HVACnumber3623604

Biolan Sampling Well

The Biolan Sampling Well is an accessory that

makes it easier to supervise the operation of the

wastewater treatment system, and enables reli-

able sampling of the wastewater. It is also suitable

for an underdrain well or a pump well.

Product no. 5713,

HVACcode3623605Biolan

Pumping Package

The Biolan Pumping Package is an acces-

soryforplaceswheregravityowdrainage

ofthewastewatertothelterisnotpossi-

ble. By means of the Timer the wastewa-

terisfedfromthePumpWelltothelter

in suitable doses. The Pumping Package

comprises three parts: Timer,

Submersible Pump and Pump

Well. The parts are also avail-

able separately.

Product no. 70577300,

HVACcode3623606

Comprises:

Timer 70577000,

HVACnumber3623608

Submersible pump 70577100,

HVACnumber3623609

Pump Well 70577200,

HVACnumber3623607

About the guarantee

TheBiolanGreywaterFilter70isguaranteedforveyears

1. The guarantee is valid from the date of purchase and cov-

ers possible defects in material and workmanship. The

guarantee does not cover any indirect damage.

2. Biolan Oy retains the right to decide about repairing or re-

placing damaged parts at its discretion.

3. Any damage resulting from careless or forcible handling of

the device, from failure to observe the operating instruc-

tions, or from normal wear, will not be covered by this guar-

antee.

4. Thebuyermustpresentadulylledoutguaranteecerti-

cate or a detailed purchase receipt when submitting claims

under the guarantee.

For matters related to the guarantee, please consult Biolan Oy

directly.

Table of contents

Other BIOLAN Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Interpet

Interpet CF mini Instruction manual and set up guide

Nordson

Nordson 104 477A Technical publication

Red Sea

Red Sea Ocean Clear 317 Installation & operation manual

filtreau

filtreau UVC manual

Monarch Water

Monarch Water SCALEOUT ADVANCE SA-15 install guide

YAMIT

YAMIT F-700TS HYDROCYCLON Installation & operation manual