3. Components

The Ocean Clear Filter unit includes the following components:

Filter Body, Lid, and gray Thread Ring.

Filter media according to model (see above)

Parts pack - Drain Valve with garden hose thread outlet, 3/4" and 1" Straight

and Elbow Hose Adapters, 5" piece of 3/4" ID. Vinyl Tubing, 2 Speedy Clamps,

Vent Plug for Lid, 1/4' pipe Plug,

Pressure gauge (for models 317, 325, 340 and 375)

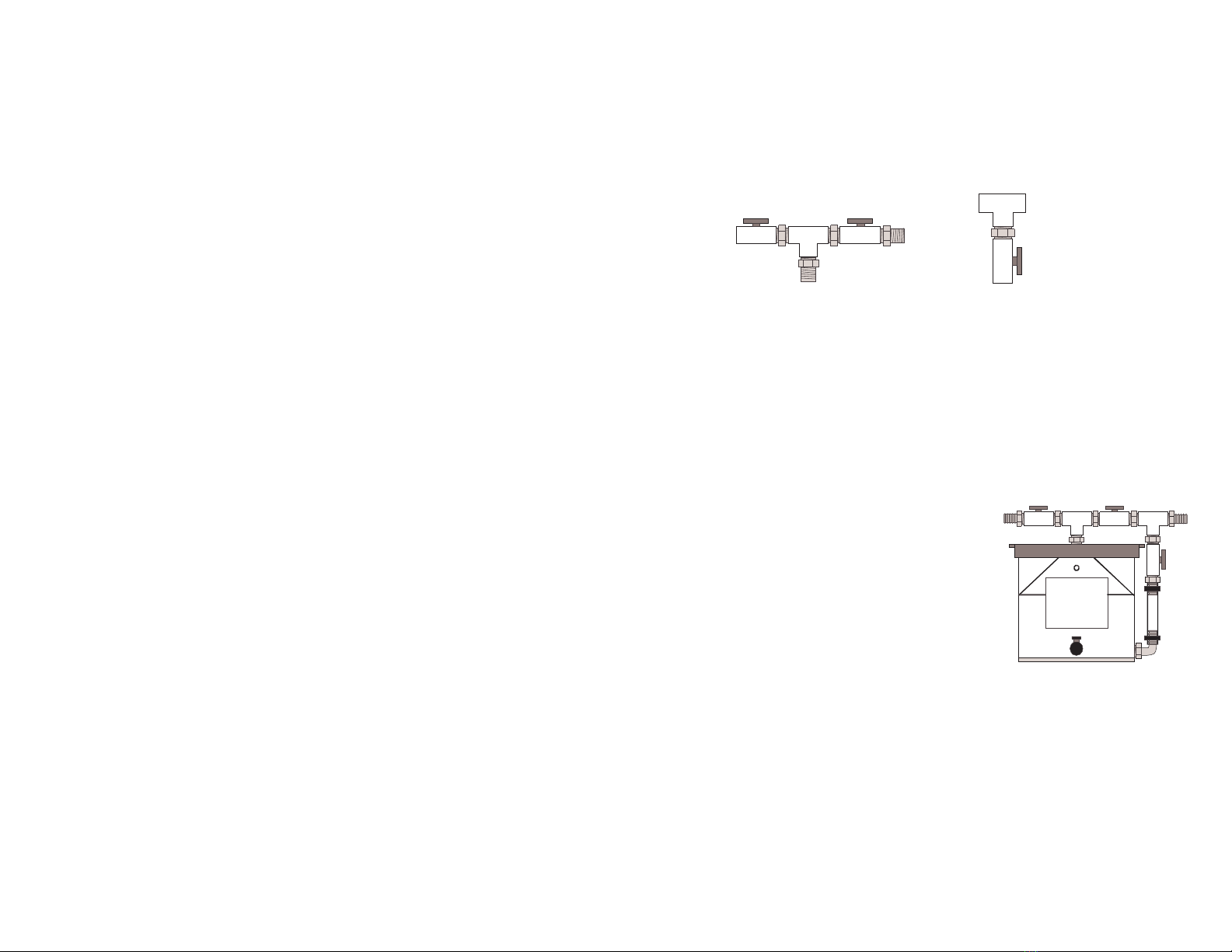

Model 354 - Valve system in two sections.

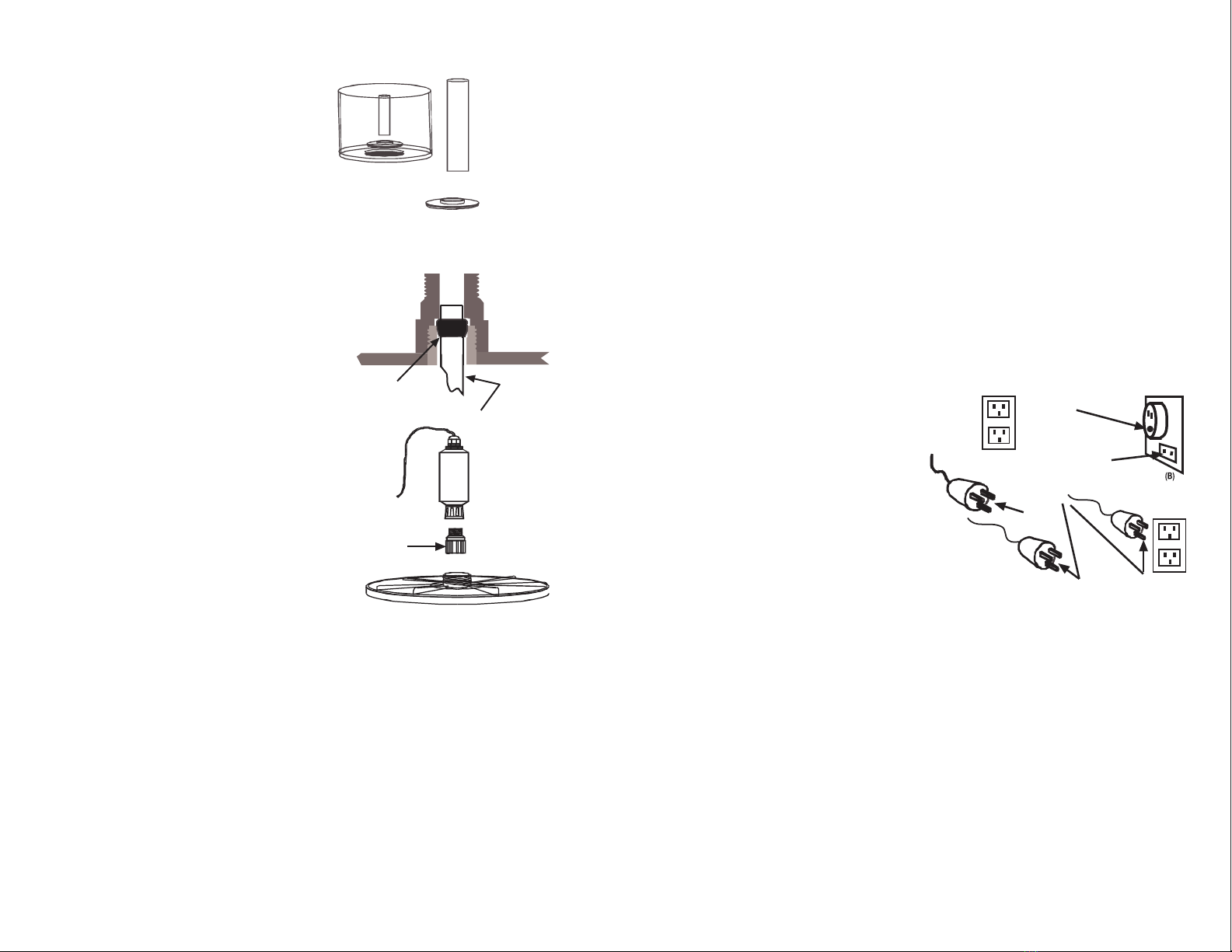

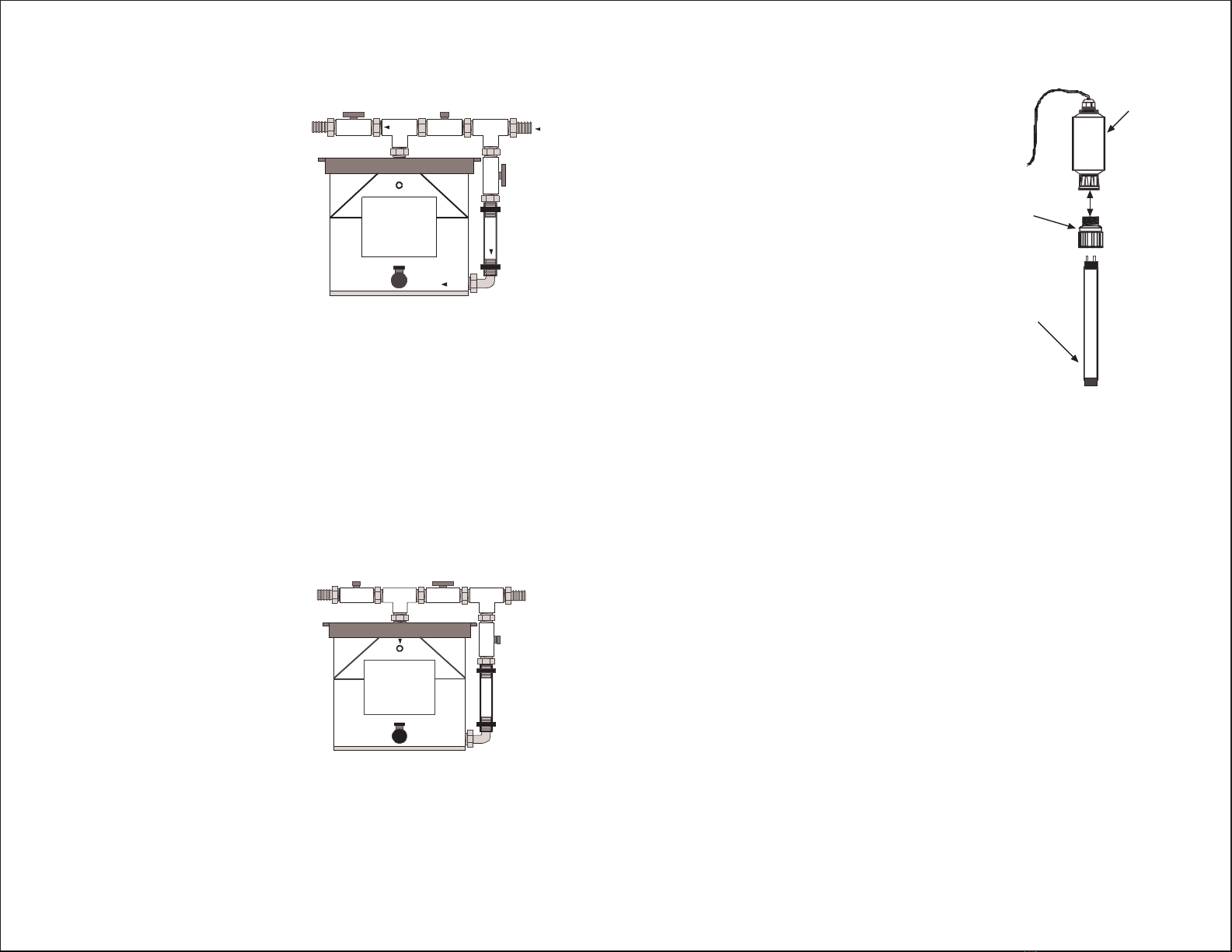

Model 375 & 380 UV Kit - Base Plate, Middle Pipe, Quartz sleeve, Transformer

& UV Lamp.

Instruction Manual & Product Registration Card.

The following additional equipment is required to operate and install the Ocean

Clear Filter: Roll of Teflon Tape; Flexible tubing; Water Pump.

4. Safety

IMPORTANT SAFETY INSTRUCTIONS (for Model 375 & 380)

WARNING - To guard against injury, observe the following safety precautions.

WARNING - UV radiation is harmful to the eyes and can be irritating to the skin.

Do not test the UV lamp outside of the filter body.

Note: UV radiation is not transmitted through the PVC lid and therefore viewing

the UV lamp through the lid is not harmful.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

DANGER - To avoid possible electric shock, special care should be taken since

water is employed in the use of aquarium equipment. For each of the following

situations, do not attempt repairs yourself; return the appliance to an authorized

service facility for service or discard the appliance. If the appliance falls into

water, DON'T reach for it! First unplug it and then retrieve it. If any electrical

components get wet, unplug the appliance immediately.

a. Do not operate any appliance if it has a damaged cord or plug, or if it is

malfunctioning or if it is dropped or damaged in any manner.

b. To avoid the possibility of the appliance plug or receptacle getting wet,

position aquarium stand and tank to one side of a wall mounted receptacle

to prevent water from dripping onto the receptacle or plug. A "drip loop"

shown in the figure, should be arranged by the user for each cord connecting

an aquarium appliance to a receptacle. The "drip loop" is that part of the

cord below the level of the receptacle, or the connector. Use an

extension cord if necessary,

to prevent water traveling

along the cord and coming

into contact with the receptacle.

If the plug or receptacle does get

wet, DON'T unplug the cord.

Disconnect the fuse or circuit

breaker that supplies

power to the appliance.

Then unplug the device and

examine for presence of water in the receptacle.

3

Aquarium

Drip Loop

Chemical and UV filtration media. Each filter configuration includes internal

channeling devices to ensure even flow throughout the filter bed. Based on

the size and bio-load of the system, optimal filtration may be achieved by

combining 2 or more Ocean Clear Filters connected in series. The Following is

a brief description of the various configurations currently available.

Model 317 Mechanical filter with triple density Polystrand Pads

Consists of 177 Sq. Ft of Polystrand Filter Pads in three gauges ranging from 100

micron at the water inlet, down to 50 micron before the outlet. The full flow

grid, set into the filter base ensures continued flow throughout the entire cross-

section of the filter material. This model includes a 30psi pressure gauge.

Model 318 Biofilter with Polystrand Filter Pads

Consists of 205 Sq. Ft of Polystrand Bio-media that has a continuously available

wetted surface area for nitrifying bacteria to colonize. It is advisable to install a

mechanical filter such as the Ocean Clear 317, 325 or 340 in front of the biofilter.

Model 319 Mechanical, Biological & Carbon Filter

Consists of 154 Sq. Ft of Polystrand Dual Function Filter Pads. The upper 100

micron Polystrand pads provide Mechanical filtration at the water inlet. The 50

micron Polystrand Bio-media around an Ocean Clear Carbon core provides

respectively biological and chemical filtration.

Model 320 Carbon Bio-Filter

Contains 7 lb. of Ocean Clear Carbon.

Model 325 Mechanical Filter with pleated Micron Cartridge and Carbon

Consists of a 25 micron spinbonded polyester filter cartridge to provide fine

mechanical filtration with a core of Ocean Clear Carbon. The 325 includes a

30psi pressure gauge. This filter must be used in combination with a Biofilter

such as the Ocean Clear 318.

Model 340 High Capacity Mechanical & Biological Filter

Consists of 40 Sq. Ft of 25 micron spinbonded polyester filter cartridge to

provide fine mechanical filtration with a core of 50 sq. Ft of Polystrand Bio-

media. The 340 includes a 30psi pressure gauge.

Model 354 Polybead Mechanical & Biological Filter

Contains 7lb. Of high density polyethylene spherical beads that provide superb

mechanical particulate filtration and supports the growth of nitrifying bacteria

for biological filtration.

Model 375 UV Sterilizer & Pleated Cartridge Filter

Consists of a 25 micron spinbonded polyester filter cartridge to provide polished

filtered water and an 18 watt UV sterilizer to kill harmful free floating bacteria

and algae.

Model 380 UV Sterilizer & Polystrand Filter

Consists of 154 Sq. Ft of Polystrand Dual Function Filter Pads providing Mechanical

filtration at the water inlet and an 18 watt UV Sterilizer to kill harmful free floating

bacteria and algae.

2