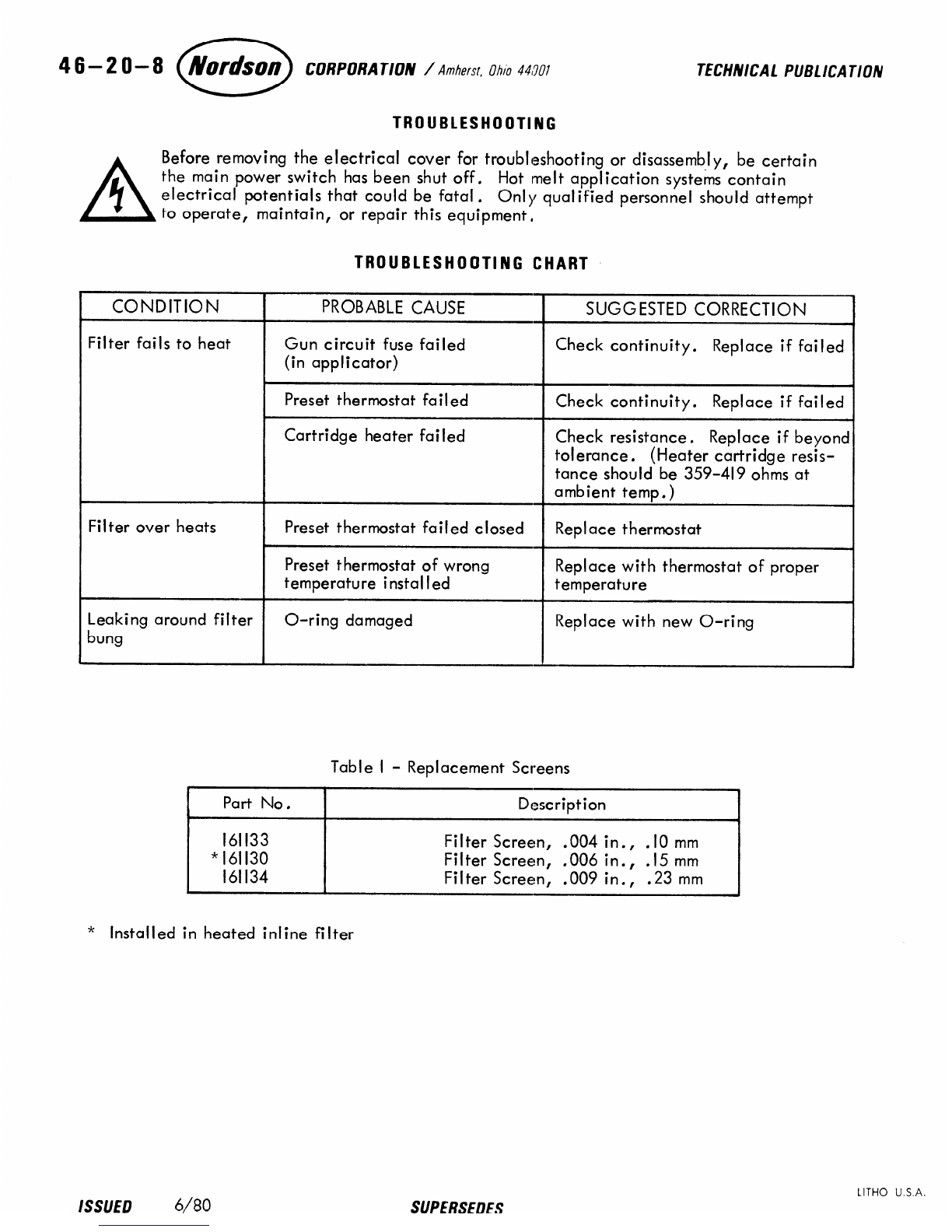

4 6 - 2 0 - 4 0Nordson CORPORATION / Amherst.Ohlo4~001 TECHNICAL PUBLICATION

Electrical Hot melt application systems contain electrical potentials that can be fatal. Only

qualified personnel should instal I, operate and maintain this equipment.

A preset thermostat of the correct setting for maintaining proper adhesive application tempera-

ture must be installed before applyins electrical current to the system. Preset thermostats are

available in settings from 120°F (49 C) to 450°F (232OC). (See Table 2, at the end of this

section.) A thermostat is included with eachdnline f’lter.

time the filter is ordered, a thermostat of 350 F (17 + Unless otherwise specified at the

supplied with each heated inline filter. C) will be installed at the factory and

Should a thermostat other then 35O’F be desired, it

must be noted at the time the order is placed. Order desired thermostat by correct part number

and description. Check to be sure the proper thermostat is installed in the filter before

connecting electrical power.

Single Inlet Guns

When installing the heated inline filter in an applicatiorl system using single inlet guns (e.g.,

H-20, standard AD-24) use the procedure specified below in steps 1 through 15. Refer to

Figure 4 for a wiring diagram.

1. Turn off applicator main power.

A2. Reduce input air pressure to the pump to zero and relieve system hvdraulic

+

0

&* pressure by triggering the guns.

3. Disconnect gun electrically and hydraulically from hose.

If the application system is at operating temperature, allow the aun to cool to

ambient. Wear safety gloves (P/N 902514) to avoid burns. -

4. Connect heated inline fiI ter to hose hydraulically.

5. Connect armored cordset attached to filter to the hose electrical connections.

The filter connects electrically to the hose exactly the same as the gun.

6. Remove the gun electrical cover and disconnect the armored cordset mechanically

and electrical I y* Discard this cordset.

7. Connect one end of the optional cordset shipped with the filter to the gun. This

cordset installs to the gun mechanically and electrically the sameas the cordset

just removed.

8. Reinstall the gun electrical cover.

9. Connect the gun hydraulically to the filter.

10. Remove the filter electrical cover and remove the “knock-out” from the cover.

11. Mechanically attach the other end of the cordset just installed on the gun to the

filter electrical cover through the “knock-out” hoie.

ISSUED 6/80 SUPERSEDES LITHO U.S.A.